Transcription

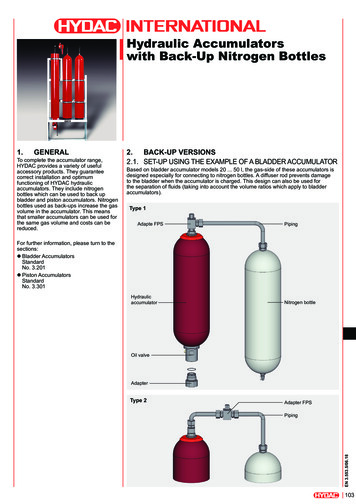

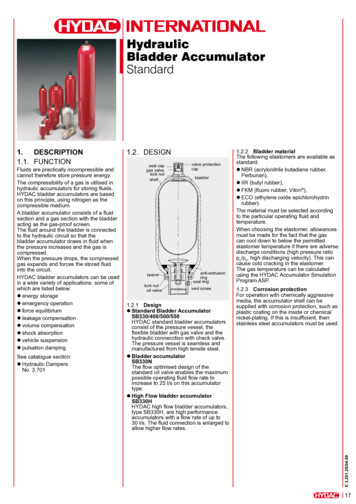

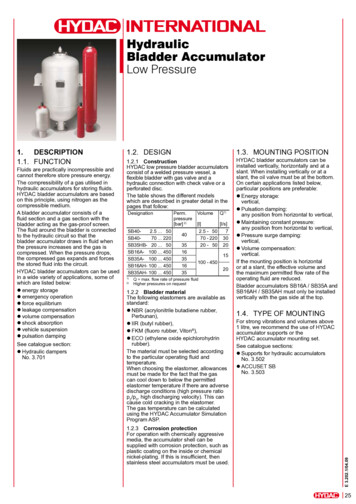

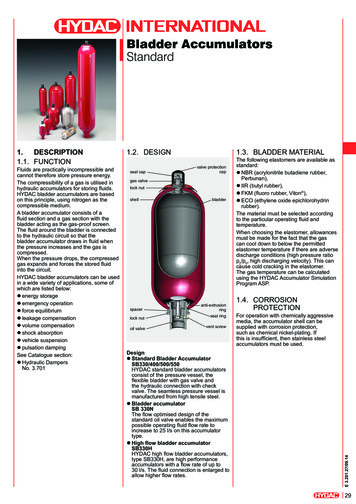

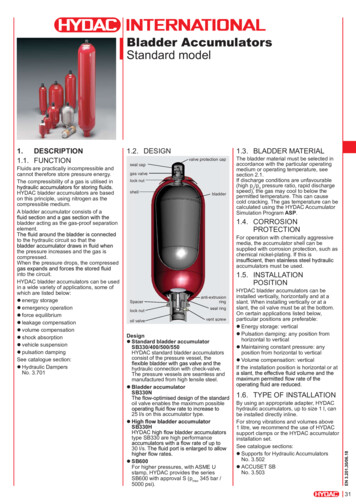

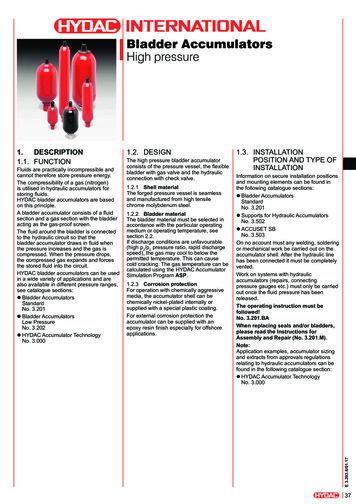

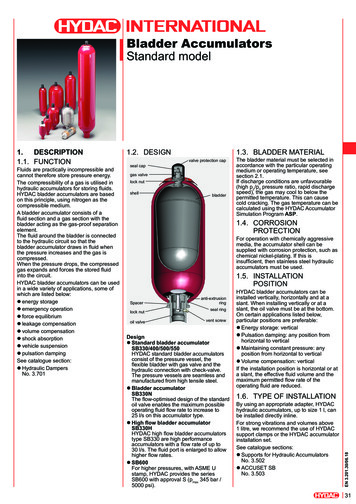

Bladder AccumulatorsStandard modelFluids are practically incompressible andcannot therefore store pressure energy.The compressibility of a gas is utilised inhydraulic accumulators for storing fluids.HYDAC bladder accumulators are basedon this principle, using nitrogen as thecompressible medium.A bladder accumulator consists of afluid section and a gas section with thebladder acting as the gas-proof separationelement.The fluid around the bladder is connectedto the hydraulic circuit so that thebladder accumulator draws in fluid whenthe pressure increases and the gas iscompressed.When the pressure drops, the compressedgas expands and forces the stored fluidinto the circuit.HYDAC bladder accumulators can be usedin a wide variety of applications, some ofwhich are listed below:zzenergy storagezzemergency operationzzforce equilibriumzzleakage compensationzzvolume compensationzzshock absorptionzzvehicle suspensionzzpulsation dampingSee catalogue section:zzHydraulic DampersNo. 3.7011.2. DESIGNseal cap1.3. BLADDER MATERIALvalve protection capgas valvelock nutshellbladderThe bladder material must be selected inaccordance with the particular operatingmedium or operating temperature, seesection 2.1.If discharge conditions are unfavourable(high p2/p0 pressure ratio, rapid dischargespeed), the gas may cool to below thepermitted temperature. This can causecold cracking. The gas temperature can becalculated using the HYDAC AccumulatorSimulation Program ASP.1.4. CORROSIONPROTECTIONFor operation with chemically aggressivemedia, the accumulator shell can besupplied with corrosion protection, such aschemical nickel-plating. If this isinsufficient, then stainless steel hydraulicaccumulators must be used.1.5. INSTALLATIONPOSITIONSpacerlock nutoil valveanti-extrusionringseal ringvent screwDesignzzStandard bladder accumulatorSB330/400/500/550HYDAC standard bladder accumulatorsconsist of the pressure vessel, theflexible bladder with gas valve and thehydraulic connection with check-valve.The pressure vessels are seamless andmanufactured from high tensile steel.zzBladder accumulatorSB330NThe flow-optimised design of the standardoil valve enables the maximum possibleoperating fluid flow rate to increase to25 l/s on this accumulator type.zzHigh flow bladder accumulatorSB330HHYDAC high flow bladder accumulatorstype SB330 are high performanceaccumulators with a flow rate of up to30 l/s. The fluid port is enlarged to allowhigher flow rates.zzSB600For higher pressures, with ASME Ustamp, HYDAC provides the seriesSB600 with approval S (pmax 345 bar /5000 psi).HYDAC bladder accumulators can beinstalled vertically, horizontally and at aslant. When installing vertically or at aslant, the oil valve must be at the bottom.On certain applications listed below,particular positions are preferable:zzEnergy storage: verticalzzPulsation damping: any position fromhorizontal to verticalzzMaintaining constant pressure: anyposition from horizontal to verticalzzVolume compensation: verticalIf the installation position is horizontal or ata slant, the effective fluid volume and themaximum permitted flow rate of theoperating fluid are reduced.1.6. TYPE OF INSTALLATIONBy using an appropriate adapter, HYDAChydraulic accumulators, up to size 1 l, canbe installed directly inline.For strong vibrations and volumes above1 litre, we recommend the use of HYDACsupport clamps or the HYDAC accumulatorinstallation set.See catalogue sections:zzSupports for Hydraulic AccumulatorsNo. 3.502zzACCUSET SBNo. 3.503EN 3.201.30/06.181.DESCRIPTION1.1. FUNCTION31

2.SPECIFICATIONS2.1. EXPLANATIONS, NOTES2.1.1 Operating pressuresee tables in section 3. (PED)May differ from nominal pressure for othertest certificates.2.1.2 Permitted operating temperatureof the hydraulic accumulator-10 C . 80 Cstandard design, others on request2.1.3 Nominal volumesee tables in section 3.2.1.5 Effective volumeVolume of fluid which is available betweenthe operating pressures p2 and p1.2.1.6 Max. flow rate of the operatingfluidIn order to achieve the max. flow rategiven in the tables, the accumulator mustbe installed vertically. It must be noted thata residual fluid volume of approx. 10 % ofthe effective gas volume remains in theaccumulator.The maximum fluid flow rate wasdetermined under specific conditions andis not applicable in all operating conditions.2.1.4 Effective gas volumesee tables in section 3.Based on nominal dimensions, this differsslightly from the nominal volume and mustbe used when calculating the effective fluidvolume.MaterialsMaterialcode 1)Temperature rangeNBR2-15 C . 80 C5-50 C . 50 C9-30 C . 80 CECOEthylene oxide 3epichlorohydrinrubber-30 C . 120 CzzMineral oil (HL, HLP)zzFlame-resistant fluids from thegroup HFBzzSynthetic esters (HEES)zzWaterzzSea waterIIRButyl rubber4-50 C . 100 CzzOperating fluids of type HFD-RzzFlame-resistant fluids from thegroup HFCzzWaterFKMFluorine rubber 6-10 C . 150 CzzMineral oil (HL, HLP)zzHydraulic fluids from the groupHFD,zzSynthetic esters (HEES)zzFuelszzAromatic hydrocarbonszzInorganic acids1)EN 3.201.30/06.182)322.1.7 Working temperature andoperating mediumThe permitted working temperature of abladder accumulator is dependent on theapplication limits of the metal materialsand the bladder. Outside this temperaturerange, special materials must be used. Theoperating medium must also be taken intoaccount.The following table displays a selectionof elastomer materials including max.temperature range and a rough overviewof resistant and non-resistant fluids. Pleasecontact us for help in selecting a suitableelastomer.Acrylonitrilebutadienerubbersee section 2.2. Model code, material code, accumulator bladderothers on requestOverview of the fluids 2)Resistant tozzMineral oil (HL, HLP)zzFlame-retardant fluids from thegroups HFA, HFB, HFCzzSynthetic esters (HEES)zzWaterzzSea waterNot resistant tozzAromatic hydrocarbonszzChlorinated hydrocarbons(HFD-S)zzAmines and ketoneszzOperating fluids from the groupHFD-RzzFuelszzAromatic hydrocarbonszzChlorinated hydrocarbons(HFD-S)zzAmines and ketoneszzOperating fluids from the groupHFD-RzzFlame-resistant fluids from thegroups HFA and HFCzzFuelszzMineral oils and mineral greaseszzSynthetic esters (HEES)zzAliphatic, chlorinated andaromatic hydrocarbonszzFuelszzAmines and ketoneszzAmmoniazzSkydrol and HyJet IVzzSteam

2.1.9 Limits for gas pre-chargepressurep0 0.9 p1with a permitted pressure ratio of:p2 : p0 4 : 1p2 max. operating pressurep0 pre-charge pressure2.1.10 Certificate codesCountryEU member statesAustraliaBelarusCanadaChinaHong KongIcelandJapanKorea (Republic)New ZealandNorwayRussiaSouth AfricaSwitzerlandTurkeyUkraineUSACertificatecode (AKZ)UF 1)A6S1 1)A9A9UPA11TUA6S2UUA10S2.1.11 Gas-side connectionstandard modelSeriesSB330 /SB400SB500 /SB600SB550Volume[l] 1 50 5010 . 50Gas valve type5/8-18UNF7/8-14UNFM50x1.5 / 7/8-14UNFM50x1.5 / 7/8-14UNF1 . 5 7/8-14UNFother pressure ranges on request registration required in the individual territories orprovincesothers on request1)On no account must any welding, solderingor mechanical work be carried out on theaccumulator shell. After the hydraulic linehas been connected it must be completelyvented.Work on systems with hydraulicaccumulators (repairs, connectingpressure gauges etc.) must only be carriedout once the pressure and the fluid havebeen released.The operating instruction must beobserved!No. 3.201.BANotice:Application examples, accumulator sizing,instructions and extracts from approvalsand transport regulations relating tohydraulic accumulators can be found in thefollowing catalogue section:zzHYDAC Accumulator TechnologyNo. 3.000EN 3.201.30/06.182.1.8 Gas chargingHydraulic accumulators must only becharged with nitrogen.Never use other gases.Risk of explosion!In principle, only use nitrogen of at leastClass 4.0 (filtration 3 μm).If other gases are to be used, pleasecontact us for advice.33

2.2. MODEL CODEEN 3.201.30/06.18Not all combinations are possible. Order example.For further information, please contact HYDAC.34SB330 (H) – 32 A 1 / 112 U – 330 A 050SeriesType codeno details standardH high flowN flow-optimised valve, fluid sideA shock absorberP pulsation damper 3)B bladder top-removableE bladder with foam fillingDA bladder integrity system, industry model(others on request)L light weightCombinations must be agreed with HYDAC.Nominal volume [l]Fluid connectionA standard connection, thread with internal seal faceF flange connectionC valve mounting with screws on undersideE sealing surfaces on front interface(e.g. on thread M50x1.5 - valve)G male threadS special connection, to customer specificationGas side1 standard design (see section 2.1.11)2 back-up version 4)3 gas valve 7/8-14UNF with M8 internal thread4 gas valve 7/8-14UNF with gas valve connection 5/8-18UNF5 gas valve M50x1.5 in accumulators smaller than 50 l6 7/8-14UNF gas valve7 M28x1.5 gas valve8 M16x1.5 gas valve(with M14x1.5 bore in gas valve)9 special gas valve, to customer specificationMaterial codedependent on operating mediumstandard model 112 for mineral oilsothers on requestFluid connection1 carbon steel2 high tensile steel3 stainless steel 2)6 low temperature steelAccumulator shell0 plastic coated (internally)1 carbon steel2 chemically nickel-plated (internal coating)4 stainless steel 2)6 low temperature steelAccumulator bladder 1)2 NBR 5)3 ECO4 IIR5 NBR 5)6 FKM7 other9 NBR 5)Certification codeU European Pressure Equipment Directive (PED)Permitted operating pressure [bar]Connection, fluid sideThread, codes for fluid connections: A, C, E, GA thread to ISO 228 (BSP)B thread to DIN13 or ISO 965/1 (metric)C thread to ANSI B1.1 (UN.-2B seal SAE J 514)D thread to ANSI B1.20.1 (NPT)S special thread, to customer specificationFlange, codes for fluid connection: FA EN 1092-1 welding neck flangeB flange ASME B16.5C SAE flange 3000 psiD SAE flange 6000 psiS special flange, to customer specificationPre-charge pressure p0 [bar]) at 20 C, must be stated clearly, if required!when ordering a replacement bladder, state diameter of the smaller shell portdependent on type and pressure rangesee catalogue section Hydraulic Dampers, No. 3.7014)see catalogue section Hydraulic accumulators with back-up nitrogen bottles, No. 3.5535)observe temperate ranges, see section 2.1.1)2)3)3.DIMENSIONS ANDSPARE PARTS3.1. DIMENSIONSadapter,see section 4.2.

NBR, carbon steelNominal 301602002)Eff. 57676467[mm] [mm] ISO 22833.5 96G 3/4115G 3/456123 G 1115G 1 1/456123 G 13.74126556170G 1 G1G 1 1/4G 1 1/46767674550509.3582101G210070G 2 1/2125906101015253017183133343841G21007015G210070G 2 1/2G21251009070G210070G 2 1/2125100907011075G210070G 2 1/212590G210070G 2 1/2125100907011075G210070G 2 1/21259070G2100G 2 1/2G 2 1/2G 2 1/2G 2 1/2G 2 1/2G 2 mm]505067[mm] [l/s] [kg]32443247456105010114561467Q 1) Weight23469517.518.456ØD Jmax. 28137167160200234283345403Q max. flow rate of the operating fluid under optimum conditionsslimline version, for confined installation spacesEN 330SB330SB330Max. operating pressureCertificate code Certificate code(AKZ) U(AKZ) S[bar] Part no.[bar] Part no.400 3047163 ––330 3047162 ––550 3110531 ––330 3047165 ––550 3068916 ––330 3047166 ––400 3017905 ––550 3090654 ––330 3047168 ––330 3047170 ––3047172 262 3141237330 3156632 ––3079081 ––400 3107393 ––500 3130252 ––––345 3322653047173 ––330 ––––––400 –––3047174 262 3117153330 3162982 ––3092659 ––400 3115007 ––500 3118156 ––––345 3322663047175 ––330 ––––––3047176 262 3117154330 3220899 ––3059515 ––400 3125141 290 –500 3760577 ––––345 3322673047177 262 362904330 3185604 ––3089605 ––400 3114662 ––500 3130253 ––––345 332268330 3341217 ––330 –––330 3098489 ––330 –––330 –––330 –––35

3.2. SPARE PARTSSB330/400/500/550/600SB330H / SB330NDescriptionItemBladder assembly 1)consisting of:Bladder2Gas valve insert*3Lock nut4Seal cap5Protective cap6O-ring7Seal kitconsisting of:O-ring7Washer15O-ring16Vent screw19Support ring23O-ring27Repair kit 1)consisting of:Bladder assembly (see above)Seal kit (see above)Oil valve assemblyconsisting of:Valve9-13Anti-extrusion ring*14Washer15O-ring16Spacer17Lock nut18Vent screw19Support ring23* available separately1)when ordering, please state diameter of the smallershell portAccumulator shell (item 1) and company label (item 8)not available as a spare partVent screw (item 19) for NBR/carbon steel:seal ring (item 20) includedAdapter (item 25) incl. O-ring (item 27)available as an accessory, section 4.Detail “X”SB330/400 – 0.5 . 6 lSB330 – 10 l slimline versionSB330/400NBR, carbon steelstandard gas 21120972127255 123127313320138431847693461300Seal 200Oil valve Anti-extru- Gas valveassembly sion ring insert3536063536093536213102043 r kit2128169 2)21062612106200210620421062082112

See catalogue section: z Hydraulic Dampers No. 3.701 1.2. DESIGN seal cap lock nut shell gas valve valve protection cap bladder Spacer anti-extrusion ring seal ring lock nut oil valve vent screw Design z Standard bladder accumulator SB330/400/500/550 HYDAC standard bladder accumulators consist of the pressure vessel, the flexible bladder with gas valve and the hydraulic connection with check .