Transcription

1.HYDAC ACCUMULATOR TECHNOLOGYFLUID TECHNOLOGY EFFICIENCY THROUGH ENERGY MANAGEMENT.HYDAC Accumulator Technology canreflect on over 45 years' experience inresearch & development, design andproduction of Hydac accumulators.Bladder, piston, diaphragm and metalbellows accumulators from HYDACtogether form an unbeatable range and ascomponents or units, support hydraulicsystems in almost all sectors.The main applications of our accumulatorsare:zzEnergy storage,zzEmergency and safety functions,zzDamping of vibrations, fluctuations,pulsations (pulsation damper), shocks(shock absorber) and noise (silencer),zzSuction flow stabilisation,zzMedia separation,zzVolume and leakage oil adjustment,zzWeight equalization and alsozzEnergy recovery.Using accumulators improves theperformance of the whole system andspecifically this has the following benefits:zzImprovement in the functionszzIncrease in service lifezzReduction in operating and maintenancecostszzReduction in pulsations and noiseOn the one hand, this means greatersafety and comfort for operator andmachine.On the other hand, HYDAC accumulatorsenable efficient working in all applications.E 3.000.0/04.09Basic criteria, such as:zzDesign pressure,zzDesign temperature,zzFluid displacement volume,zzDischarge / Charging velocity,zzFluid,zzAcceptance specifications and alsozzMounting optionsare important parameters required forsizing the correct accumulator.In addition the knowledge developed byour accumulator specialists will help toselect the right type of accumulator. Thecomprehensive range of HYDACaccessories simplifies installation andmaintenance according to thespecification.22.QUALITYQuality, safety and reliability are paramountfor all HYDAC accumulator components.They comply with the current regulations(or standards) for pressure vessels in theindividual countries of installation.In taking delivery of a HYDAC HydraulicAccumulator therefore, the customer isassured of a high-quality accumulatorproduct which can be used in everycountry in the world, depending on thecertification.For more details, please turn to Section 4.All the processes involved, fromdevelopment, engineering and productionto approval and delivery are defined byHYDAC's certified management systemand the relevant international accreditationfor the manufacture of pressure vessels.In conjunction with the customer servicedepartment at HYDAC's headquarters,service is possible worldwide.HYDAC's worldwide distributor networkmeans that trained staff are close at handto help our customers.This ensures that HYDAC customers havethe support both before and after sale ofan experienced workforce.

Page1.HYDAC Accumulator Technology22.Quality23.Safety instructions44.Regulations55.Product overview5.1.Bladder accumulators5.1.1CataloguesectionPageE 3.0002StandardE 3.201175.1.2Low pressureE 3.202255.1.3High pressureE 3.203335.2.Piston accumulators5.2.1StandardE 3.301375.2.2Series SK280E 3.303495.3.Diaphragm accumulatorsE 3.100535.4.Metal bellows accumulatorE 3.304595.5.Hydraulic dampersE 3.701655.6.Special accumulators5.7.Accumulator stationsE 3.653855.8.Accumulator accessories5.8.1Hydraulic accumulators with back-up nitrogen bottlesE 3.553915.8.2Universal charging and testing unitE 3.501975.8.3Safety and shut-off blockE 3.5511075.8.4Safety equipment for accumulatorsE 3.5521295.8.5Supports for hydraulic accumulatorsE 3.5021355.8.6ACCUSET SBE 3.5031416.Industries and applications7.Website8.Sizing9.Note6–89 – 101011 – 1212E 3.000.0/04.09CONTENTS3

3.SAFETY INSTRUCTIONSE 3.000.0/04.09Hydraulic accumulators are pressurevessels as defined in the PressureEquipment Directive 97/23/EC.They are closed vessels which aredesigned and built to store pressurizedfluids. Hydraulic accumulators are chargedwith nitrogen which is separated from thefluid section by a piston, bladder ordiaphragm. Hydraulic accumulators arespecifically designed to store and thendischarge pressurized fluids.The regulations for commissioning andoperating hydraulic accumulators whichare in force at the place of installationmust be observed. The plant operatoris exclusively responsible for ensuringcompliance with these regulations.Relevant instructions are provided in theoperating manuals for our products.As regards production and placing onthe market, HYDAC has carried out acomprehensive risk assessment.4Similarly the manufacturer of productswith hydraulic accumulators must proceedaccordingly (see Pressure EquipmentDirective 97/23/EC) and the followingprinciples must be adhered to and in thisorder of priority:zzRemoval or reduction of risks, insofar asthis is reasonably possible,zzApplication of appropriate protectivemeasures against risks which cannot beeliminated;zzIf required, training of the users onthe residual risks and instructionson appropriate special measures forreducing the risks during installation and/or operation.For safe handling and operation, theoperator must draw up a risk assessmentfor the installation site, particularly incombination with other components andrisks.The resulting measures must beimplemented accordingly.In the case of fundamental risks affectinghydraulic accumulators, e.g.zzExcessive pressure andzzIncrease in temperature(in the event of fire)we already have the relevant productsavailable.On no account must any welding, solderingor mechanical work be carried out on theaccumulator shell. After the hydraulic linehas been connected it must be completelyvented. Work on systems with hydraulicdampers (repairs, connecting pressuregauges etc) must only be carried out oncethe pressure and the fluid have beenreleased.3.1. RISK OF EXCESSIVEPRESSUREProducts:Safety and shut-off block for the fluid sidein various sizes and versions.See catalogue section:zzSafety and Shut-off Block SAF/DSVNo. 3.551Gas safety valve and gas safety block forthe gas sideBursting discs for gas and fluid sidessee catalogue section:zzSafety equipment forhydraulic accumulatorsNo. 3.5523.2. RISK OF RISE INTEMPERATUREProducts:Safety and shut-off block with solenoidoperated valve (open when de-energised)in conjunction with temperature monitoring.See catalogue section:zzSafety and Shut-off Block SAF/DSVNo. 3.551 or on requestTemperature fusessee catalogue section:zzSafety equipmentfor hydraulic accumulatorsNo. 3.552

PRESSUREEQUIPMENT DIRECTIVEREGULATIONSOn 29 November 1999 the Directive97/23/EC (Pressure Equipment Directive)came into force and has been operativesince 29 May 2002. This Directive appliesto the design, manufacture, conformityassessment and placing on the market ofpressure equipment and assemblies witha maximum permitted pressure of over0.5 bar. It guarantees the free movementof goods within the European Community.EU member states must not prohibit,restrict or obstruct the placing on themarket and the commissioning of pressureequipment on account of pressure-relatedhazards, if the equipment complieswith the requirements of the pressureequipment directive and has the CE mark,and is subject to a conformity assessment.Hydraulic accumulators with a capacity ofV 1 litre, a maximum permitted pressurePS 1000 bar and a pressure capacityPS V 50 bar l for gases of fluid group2 (non-hazardous fluids) are subject toArticle 3, Paragraph 3 of the EuropeanPressure Equipment Directive and do notreceive the CE mark.Inspection of the equipment andinstallation, operational safety and repeattesting are controlled as before by nationallaws.The equipment relating to safety isdescribed in AD2000, ISO 4126 andEN 14359.The repeat testing intervals are stipulatedin the new German industrial safetyregulations.4.1. OVERSEASPressure accumulators which are installedoverseas (outside the EU), are suppliedwith the relevant test certificates requiredin the country of installation.The country of installation must be statedat the time of ordering.HYDAC pressure vessels can be suppliedwith virtually any test certificate. In some ofthese the permitted operating pressure candiffer from the nominal pressure.Depending on the authority, the differentmaterial requirements must be observed.The following table contains the codesused in the model code for differentcountries of installation.4.2. Certificate code S(U STAMP)HYDAC Technology GmbH has hadauthorization since 1985 to use theCode Symbol "U STAMP" on pressurevessels which have been manufactured inconformity with the ASME specificationsand to market these using the "NB"symbol, in the jurisdiction (area ofapplication) of “The National Board ofBoiler and Pressure Vessel Inspectors“.4.3. Certificate code P(KHK certificate)For the Japanese market, HYDACTechnology GmbH has had approval asa "Self Inspecting Manufacturer" sincethe year 2000. Consequently, HYDACis authorized to manufacture and testpressure vessels for the Japanese marketand to import them into Japan.4.4. Certificate code A9(MANUFACTURERLICENSING CHINA)Since 1998 HYDAC Technology GmbHhas had approval from the Chineseauthority "SELO" as a manufacturer ofpressure vessels and valves. HYDAC istherefore authorized to import bladder,piston and diaphragm accumulators, andsafety valves, into the Chinese nadaSwitzerlandCosta RicaCzech RepublicAlgeriaEcuadorEgyptHungaryHong yaMalaysiaMexicoNorwayNew ZealandPakistanPeruPolandPuerto iaKorea (Republic)PhilippinesRussiaSaudi rkeyUnited StatesNigeriaYugoslavia(Serbia/Montenegro)South AfricaAKZ(Certificatecode)F 1)U 3)U 3)U 3)U 3)EA12S1 2)UE 3)UU 3)U 3)UU 3)A9U 3)U 3)UU 3)U 3)PU 3)U 3)U 3)U 3)U 3)U 3)TU 3)U 3)UE 3)U 3)U 3)A9U 3)U 3)U 3)UU 3)U 3)A6U 3)UUU 3)UU 3)U 3)USU 3)UU 3)approval required in the individual territoriesapproval required in the individual provincesalternative certificates possibleE 3.000.0/04.094.5

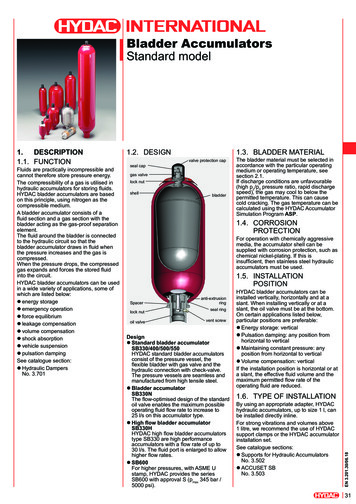

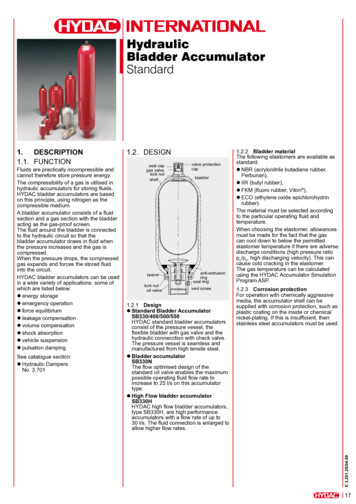

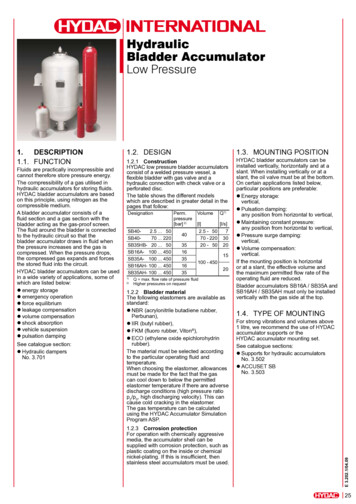

5.PRODUCT OVERVIEW5.1. BLADDERACCUMULATORS5.1.1 StandardNominal volumes:0.5 . 200 lMax. operating pressure:330 . 550 barBenefits of HYDAC bladder accumulators:zzHigh discharge speeds,zzNo differential pressure between fluidand gas sides,zzCompact, maintenance-free,zzHigh charging and dischargefrequencies.5.1.2 Low pressureNominal volumes:2.5 . 450 lMax. operating pressure:up to 40 bar5.1.3 High pressureNominal volumes:1 . 54 lMax. operating pressure:5.0 . 1000 bar5.2. PISTONACCUMULATORS5.2.1 StandardNominal volumes:0.2 . 1200 lMax. operating pressure:210 . 350 bar(higher pressures on request)5.2.2 Series SK280Nominal volumes:0.16 . 5 lMax. operating pressure:280 barBenefits of HYDAC piston accumulators:zzMinimal pressure differential betweenthe fluid and gas sides,zzLarge usable volume,zzVariable mounting position,zzMonitoring of the piston position possibleusing various systems,zzParticularly suitable for back-upconfigurations,zzHigh flow rates possible,zzNo sudden discharge of gas when sealsare worn.5.3. DIAPHRAGMACCUMULATORSE 3.000.0/04.095.3.1 Diaphragm accumulatorsWeld typeNominal volumes:0.075 . 4 lMax. operating pressure:50 . 330 bar6Screw typeNominal volumes:0.1 . 4 lMax. operating pressure:210 . 750 barBenefits of HYDAC diaphragmaccumulators:zzDesign optimized for function andweight,zzChoice of mounting positions,zzNo differential pressure between fluidand gas sides,zzLow-maintenance and long service life.

5.4. METAL BELLOWSACCUMULATORS5.4.1 Metal bellows accumulatorfor heavy diesel enginesNominal volume:3.8 lMax. operating pressure:50 barSeries: SM50P-.Other models on requestBenefits of the HYDAC metal Media resistance over a wide range oftemperatures5.5. HYDRAULIC DAMPERS5.5.1 DampersNominal volumes:0.075 . 450 lMax. operating pressure:10 . 1000 bar5.5.2 SILENCERMax. operating pressure:330 barBenefits of the HYDAC hydraulic damper:zzReduces pressure pulsations,zzImproves the suction performance ofdisplacement pumps,zzPrevents pipe breaks and damage tovalves,zzProtects measuring equipment and itsfunction in the system,zzReduces noise level in hydraulicsystems,zzReduces maintenance and servicingcosts andzzExtends service life of the system.5.6. SPECIALACCUMULATORS5.6.1 Low weighthydraulic accumulatorsOver 80% reduction in weightcompared to equivalentcarbon steel accumulators.5.6.2 Spring accumulatorsare fitted with a spring.The energy is produced from the springforce, instead of gas.Further information on request.HYDAC supplies fully assembled pistonaccumulator stations which are ready foroperation, complete with all the necessaryvalve controls, ball valves and safetyequipmentzzas an individual accumulator unit orzzin a back-up model withnitrogen bottles toincrease the effectivevolume.E 3.000.0/04.095.7. ACCUMULATORSTATIONS7

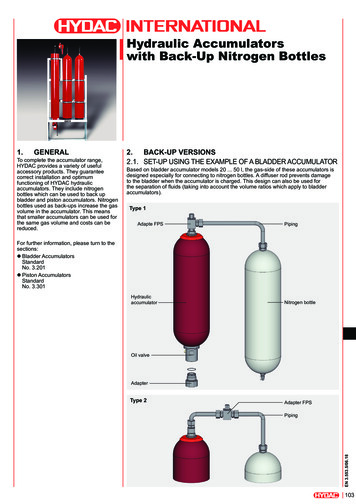

5.8. ACCUMULATORACCESSORIES5.8.1 Hydraulic accumulators withback-up nitrogen bottlesHYDAC also offers nitrogen bottles whichcan be used to back up bladder and pistonaccumulators. Nitrogen bottles used asback-ups increase the gas volume in theaccumulator.Using HYDAC nitrogen bottles providesthe following benefits:zzCost-effective expansion of theaccumulator volume and as a resultzzSmaller accumulators for the same gasvolume.5.8.2 Universal charging and testingunit FPU-1Charging hose, pressure gauge andpressure reducer for HYDAC and othermakes of accumulator, up to 300 bar.5.8.3 Safety and shut-off blockSAF/DSVNominal sizes:10 . 50Max. operating pressure:400 bar (DSV 350 bar)Pressure relief valve:Nominal size DN 125.8.4 Safety equipmentzzGas safety valve GSV6zzTemperature fusezzBursting disczzGas safety blockas safety equipment forHYDAC accumulator products.Approval according to Pressure EquipmentDirective PED and CE mark.5.8.5 Supports forhydraulic accumulatorsAccumulator sets, clamps and consolesfor efficient mounting of hydraulicaccumulators.E 3.000.0/04.095.8.5 ACCUSET

CONTENTS Page Catalogue section Page 1. HYDAC ACCUMULATOR TECHNOLOGY 2 E 3.000 2 2. QUALITY 2 3. SAFETY INSTRUCTIONS 4 4. REGULATIONS 5 5. PRODUCT OvERvIEw 6 – 8 5.1. BlADDer ACCumulATors 5.1.1 Standard E 3.201 17 5.1.2 Low pressure E 3.202 25 5.1.3 High pressure E 3.203 33 5.2. PisTon ACCumulATors 5.2.1 Standard E 3.301 37 5.2.2 Series SK280 E 3.303 49 5.3.