Transcription

ANSI/ASME B40.1HIGHLIGHTS of ANSI/ASME B40.1I NSTAL L ATION:GAUGE SHOULD BE INSTALLED BY TIGHTENING THE PRESSURE CONNECTION USING THEWRENCH FLATS PROVIDED. FAILURE TO DO SO MAY RESULT IN LOSS OF ACCURACYAND/OR MECHANICAL DAMAGEOP E R ATING PRESSURE:THE OPERATING PRESSURE SHOULD OCCUR IN THE MIDDLE HALF (25%-75%), OF THEFULL SCALE PRESSURE OF THE GAUGE SELECTED. THE OPERATING PRESSURE SHOULDBE HALF OF THE FULL PRESSURE OF THE GAUGEOV E R P RESSURE F A IL URE:WHEN VALVES OPEN OR CLOSE, SHORT DURATION PRESSURE IMPULSES MAY BE MANYTIMES THE NORMAL OPERATING PRESSURE AND MAY NOT BE INDICATED BY THE GAUGE.THE RESULT COULD BE IMMEDIATE FAILURE OR LOSS OF ACCURACY. OPERATING PRESSURE SHOULD NEVER EXCEED 75% OF FULL SCALE.V I BRATION F AIL URE:VIBRATION OR HIGH CYCLIC LOADING WILL CAUSE GRADUAL LOSS OF ACCURACY ANDFAILURE OF THE POINTER. IT MAY ALSO CAUSE CRACKS IN THE ELEMENT OR JOINTSWHICH COULD RESULT IN A FAILURE SIMILAR TO AN EXPLOSIVE FAILURE. PRESSURESNUBBERS AND GLYCERINE FILLED GAUGES ARE RECOMMENDED IN THESE APPLICATIIONS.WA RNING:MISUSE OF PRODUCT MAY CAUSE EXPLOSION AND PERSONAL INJURY. READ ANSI-B40.1AND APPARATUS INSTALLATION/OPERATION MANUALS BEFORE USING.2%3%3%3%ANSI GRADE BG784%4%ANSI GRADE C

How To OrderGAUGE ORDER NUMBER MATRIX25SSG10152025354045 1”1 - 1 /2 ”2”2 - 1 /2 ”3 - 1 /2 ”4”4 - 1 /2 ”02-0 B ac k1 B ott om1 1/8” NPT2 1/4” NPT4 1/2” NPT( only available in4” & 4.5” DialDiameter )PAD SA D SG D SSG SP M LSS SSA D DP G P LASTIC C ASE A C RYLIC LENS DRYSTEEL C AS E AC RYLIC LENS D RYSTEEL C AS E G LASS LENS DRYSTA IN LESS STEEL CASE G LY CERINE FILLEDSTEEL CAS E PA N EL MOUNT DRYL IQU ID FILLED A LL STAINLESS S TEELA LL STA IN LESS S TEEL ACRY LIC LENS D RYDRY PROC ESS G AU GE (FILLABLE)1.5KV C 15 30 60 100 200 300 400 500 600 1K 1.5K 2K 3K 5K 6K 10K 15K 30 H G- 030 H G- 0- 300-150-300-600-10 00-20 00-30 00-40 00-50 00-60 00-10 000-15 000-20 000-30 000-50 000-60 000-10 0000-15 000G79

Dry Gauges Center-BackMountBottomMountFeatures:Utility Gauges for Commercial and IndustrialMarketsBlack Steel Case with Chrome BezelCopper Alloy InternalsAvailable with Stainless Steel CaseCertificate of Accuracy, NIST Traceable C/FTemperature Range -50 F to 160 FADimensionsCFa c eS ize1”1-1/2”2”2-1/2”3-1/2”4-1/2”A (CBM Only)B (LM Only)CDn/a.64/16mm (n/a).99/25mm (n/a)1 / 8 ” NP T1.54/ 39m m2.26 /57mm.93/24mm1.64/42mm1 / 8 ” o r 1 / 4” NP T1.90/ 48m m2.83 /72mm1.03/26mm (1.06/27mm)2.07/53mm1 / 4 ” NP T1.97/ 50m m3.31 /84mm1.17/30mm (1.13/29mm)2.50/63mm1 / 4 ” NP T2.02/ 51m m4.49/114mm1.22/31mm (1.12/28mm)3.49/89mm (3.53/90 m m )1 / 4 ” o r 1 / 2” NP T2.18/ 55m m5.80/147mm1.31/33mm (1.12/29mm)4.50/114mm (4.79/12 2 m m )Connection1 / 8 ” NP T31254G80DC B M Center B ac k MountLM Lower MountBBill of sPointerCopper AlloyBlack, SteelChrome Plated SteelPlasticBlack, Aluminum

Glycerin Filled GaugesFeatures:Center-BackMount BottomMountGlycerin Filled for added Durability andVibrationStainless Steel Case and BezelCopper Alloy InternalsCertificate of Accuracy, NIST Traceable C/FTemperature Range 30 F to 160 FADC B M Center B ac k MountLM Lower MountBCDimensionsFac eS ize1-1/2”2”2-1/2”4”ConnectionA (CBM Only)B (LM Only)CD1 / 8” NP T1.74/ 44m m2.28/58mm1.02/26mm (1.00/25mm)1.85/47mm1 / 8 ” o r 1/ 4” NP T2.08/ 53m m2.95/75mm1.18/30mm (1.20/31mm)2.28/58mm2.80/71mm4.29/109mm1 / 4” NP T2.28/ 58m m3.55/90mm1.34/34mm (1.40/36mm)1 / 4 ” o r 1/ 2” NP T3.15/ 80m m5 .21/132mm1.16/29mm (1.75/45mm)Bill of sPointerCopper AlloyStainless SteelStainless SteelPolycarbonateBlack, Aluminum32154G81

Panel Mount GaugesFeatures: Utility Gauges for Commercial and IndustrialMarketsChrome Plated Steel Case and BezelCopper Alloy InternalsCertificate of Accuracy, NIST Traceable C/FTemperature Range -50 F to 160 FACase O/DBCDimensionsSizeConnectionABCCase O/D1-1/2”2”2-1/2”3-1/2”1 / 8 ” NP T1.61/ 41m m1.84 /47mm1.03/26mm1.61/41mm1 / 8 ” o r 1/ 4” NP T1.84/ 47m m2.31 /59mm1.18/30mm2.04/52mm1 / 4 ” NP T1.87/ 48m m2.68 /68mm1.12/28mm2.44/62mm1 / 4 ” NP T2.02/ 51m m3.98/101mm1.23/31mm3.59/91mmBill of BezelLensPointerCopper AlloyChrome Plated SteelChrome Plated SteelPlasticBlack, Aluminum

DPG Process GaugesFeatures: CSolid Front Blow-Out Back Safety CaseField Liquid Fill-able316 Stainless Steel InternalsCertificate of Accuracy, NIST Traceable C/FTemperature Dry -30 F to 160 FTemperature Glycerine Filled 30 F to 160 FBDA120 FGE0.243 holeson 5.39” ”5.085 .8 43 .4 41 .1 0-2 .5 44 .2 71/ 2”Bottom4-1/2”5.075 .9 13 .0 30 .9 11 .3 82 .5 61 .3 81/ 4”21Bill of erStainless SteelPhenolic CasePolycarbonateBlack, Aluminum34G83

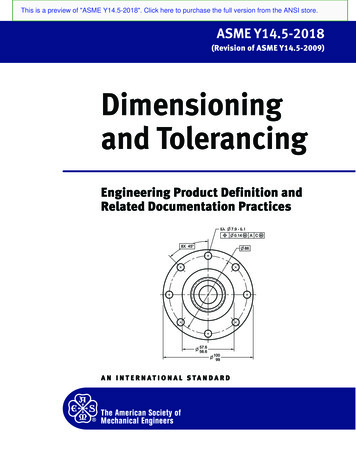

ansi/asme b40.1 g78 ansi grade b ansi grade c 2% 3% 3% 3% 4% 4%. gauge order number matrix ssg 25 0 2 - 1.5k pad sad sgd ssg spm lss ssad dpg 10 1” 15 1-1/2” 20 2” 25 2-1/2” 35 3-1/2” 40 4” 45 4-1/2” 0 back 1 bottom 1 1/8” npt 2 1/4” npt 4 1/2” npt (only available in 4” & 4.5” dial diameter) v c 15 30 60 100 200 300 400 500 600 1k 1.5k 2k 3k 5k .