Transcription

ISO 9001TransitionguideISO RevisionsMoving from ISO 9001:2008to ISO 9001:2015The new international standardfor quality management systems

ISO 9001 - Quality Management System - Transition GuideSuccessful businesses understand the value of an effective QualityManagement System that ensures the organization is focussed onmeeting customer requirements and ensuring that they are satisfiedwith the products and services that they receive from you.This guide has been designed to help you meet therequirements of the new international standard forQuality Management Systems (QMS)ISO 9001 :2015, which replaces the previousversion ISO 9001:2008. It specifies therequirements for establishing, implementing,maintaining and continually improving a QMS forany organization, regardless of type or size. Integrate with other management systemsSo why is it changing?NB. This transition guide is designed to be read inconjunction with the latest available version ofISO 9001—Quality Management Systems —Requirements with guidance for use. It does notcontain the complete content of the standard andshould not be regarded as a primary source ofreference in place of the published standard itself.All ISO management system standards are subjectto a regular review under the rules by which they arewritten. Following a substantial ISO user survey thecommittee decided that a review was appropriateand created the following objectives to maintain itsrelevance in today’s market place and in the future:2 Provide an integrated approach to organizationalmanagement Reflect the increasingly complex environments inwhich organizations operate Enhance an organization’s ability to satisfy it’scustomers

bsigroup.comWhy adopt a Quality ManagementSystem standard?Manage quality whatever the size of your business with a standard that’srecognized the world over and used by over one million organizations. Consistently meet customers’ expectationsThese are some of the benefits that our customers tell us they havereceived as a result of adopting and implementing a system thatmeets the requirements of ISO 9001. Differentiate your company and win more businessThe standard allows: Improve company performance (increasing efficiency and bottom You to become a more consistent competitor in your marketplaceWith ISO 9001 Quality Management you can;line)An ISO 9001 quality management system will help you to continuallymonitor and manage quality whether you run a single site operationor a global business. As the world’s most widely recognized qualitymanagement standard, it outlines ways to achieve, as well asbenchmark, consistent performance and service. Better quality management helps you meet customer needs More efficient ways of working will save time, money and resources Improved operational performance will cut errors and increaseprofits Motivate and engage staff with more efficient internal processes Win more high value customers with better customer service Broaden business opportunities by demonstrating compliance.Implementing ISO 9001ISO 9001 is part of a family of quality management related standards. You may find this sectionuseful for further reference in addition to ISO 9001:1 ISO 9000, Quality management systems - Fundamentals andvocabulary5 ISO 10004, Quality management - Customer satisfaction Guidelines for monitoring and measuring2 ISO 9004, Managing for the sustained success of an organization- A quality management approach6 ISO 10014, Quality management - Guidelines for realizingfinancial and economic benefits3 ISO 10001, Quality management - Customer satisfaction Guidelines for codes of conduct for organizations7 ISO 19011, Guidelines for auditing management systems4 ISO 10002, Quality management - Customer satisfaction Guidelines for complaints handling in organizations3

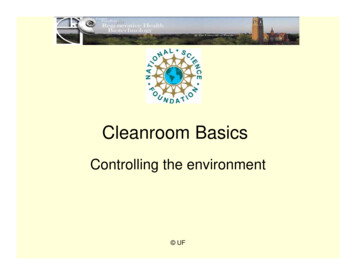

ISO 9001 - Quality Management System - Transition GuideComparing the latest version ofISO 9001 with ISO 9001:2008ISO 9001:2015 will be based on Annex SL – the new high levelstructure (HLS) that brings a common framework to all ISOmanagement systems. This helps to keep consistency, align differentmanagement system standards, offer matching sub-clauses againstthe top-level structure and apply common language across allstandards.With the new standard structure in place, organizations will find iteasier to incorporate their quality management system into the corebusiness processes and get more involvement from seniormanagement.Based on Annex SL, Fig. 1 shows how the clauses of the new highlevel structure could also be applied to the Plan-Do-Check-Act cycle.The PDCA cycle can be applied to all processes and to the qualitymanagement system as a whole.4Figure 1ACT5. Leadership10. Improvement4. Context of theorganization9. PerformanceevaluationPLAN6. Planning7. SupportCHECKDO8. OperationNew/updated conceptCommentContext of the organizationConsider the combination of internal and external factors and conditions that can have aneffect on an organization’s approach to its products, services and investments and interestedpartiesIssuesIssues can be internal or external, positive or negative and include conditions that eitheraffect or are affected by the organizationInterested partiesCan be a person or organization that can affect, be affected by, or perceive themselves to beaffected by a decision or activity. Examples include suppliers, customers or competitors.LeadershipRequirements specific to top management who are defined as a person or group of peoplewho directs and controls an organization at the highest levelRisk associated with threatsand opportunitiesRefined planning process replaces preventive action.and is defined as the ‘effect ofuncertainty on an expected resultCommunicationThere are explicit and more detailed requirements for both internal and externalcommunicationsDocumented informationReplaces documents and recordsPerformance evaluationThe measurement of quality performance and the effectiveness of the QMS, covering themethods for monitoring, measurement, analysis and evaluation, as applicable, to ensure validresultsNonconformity and correctiveactionMore detailed evaluation of both the nonconformities themselves and corrective actionsrequiredManagement ReviewMore detailed requirements relating to inputs and outputs of the review

bsigroup.comThis is a new clause that establishes the context for the QMS. Firstly,the organization will need to determine external and internal issuesthat are relevant to its purpose, i.e. what are the relevant issues, bothinside and out, that have an impact on what the organization does, orthat would affect its ability to achieve the intended outcome(s) of itsmanagement system.It should be noted that the term ‘issue’ covers not only problemswhich would have been the subject of preventive action in previousstandards, but also important topics for the management system toaddress, such as any market assurance and governance goals thatthe organization might set.The final requirement in clause 4 is to establish, implement, maintainand continually improve the QMS in accordance with therequirements the standard.This clause places requirements on ‘top management’ which is theperson or group of people who directs and controls the organizationat the highest level. The purpose of these requirements is todemonstrate leadership and commitment by leading from the top.Top management now have greater involvement in the managementsystem and must ensure that the requirements of it are integratedinto the organization’s processes and that the policy and objectivesare compatible with the strategic direction of the organization. In thesame context, they need to have a grasp of the organization’sinternal strengths and weaknesses and how these could impact onthe ability to deliver their products or services. This will strengthenthe concept of business process management including the neednow to allocate specific responsibilities for processes, anddemonstrate an understanding of the key risks associated with eachFinally, the clause places requirements on top management to assignQMS relevant responsibilities and authorities. but must remainaccountable for the effectiveness of the QMS.Clause 6: PlanningThis clause works with Clauses 4.1 and 4.2 to complete the new wayof dealing with preventive actions. The first part of this clauseconcerns risk assessment whilst the second part is concerned withrisk treatment. The organization will need to plan actions to addressboth risks and opportunities, how to integrate and implement theactions into its management system processes and evaluate theeffectiveness of these actions.Act - incorporateimprovementsas necessaryInputsPlan the process extent of planningdepends on riskDo - carry out theprocessOutputsCheck - monitor/ measureprocess performanceInteraction with other processesClause 5: Leadershipprocess and the approach taken to manage, reduce or transfer therisk.Interaction with other processesClause 4: Context of the organization5

ISO 9001 - Quality Management System - Transition GuideClause 7: SupportClause 10: ImprovementThis clause begins with a requirement that organizations shalldetermine and provide the necessary resources to establish,implement, maintain and continually improve the QMS. Simplyexpressed, this is a very powerful requirement covering all QMSresource needs. The clause continues with requirements forcompetence, awareness and communication.Due to the new way of handling preventive actions, there are nopreventive action requirements in this clause. However, there aresome new corrective action requirements. The first is to react tononconformities and take action, as applicable, to control andcorrect the nonconformity and deal with the consequences. Thesecond is to determine whether similar nonconformities exist, orcould potentially occur.Finally, there are the requirements for ‘documented information’. Thisis a new term, which replaces the references in the 2008 standardto ‘documents’ and ‘records’.The requirement for continual improvement has been extended tocover the suitability and adequacy of the QMS as well as itseffectiveness, but it no longer specifies how an organization achievesthis.Clause 8: OperationThis clause deals with the execution of the plans and processes thatenable the organization to meet customer requirements and designproducts and services. It includes much of what was previously referredto in Clause 7 of the 2008 version.The change has brought some changes to the terminology used asshown in the table below:Major differences in terminology between ISO 9001:2008 andISO 9001:2015Clause 9: Performance evaluationISO 9001:2008ISO 9001:2015Performance evaluation covers many of the areas previously featured inClause 8 of the 2008 version.ProductsProducts and servicesExclusionsNot used (see Annex 4 for clarification ofapplicabilityRequirements for monitoring, measurement, analysis and evaluation arecovered and you will need to consider what needs to be measured, methodsemployed, when data should be analyzed and reported on and at whatintervals.Internal audits must also be conducted at planned intervals withmanagement reviews taking place to review the organization’s managementsystem and ensure its continuing suitability, adequacy and effectiveness.6Documentation, records Documentated informationWork environmentEnvironment for the operation of processesPurchased productExternally provided products and servicesSupplierExternal provider

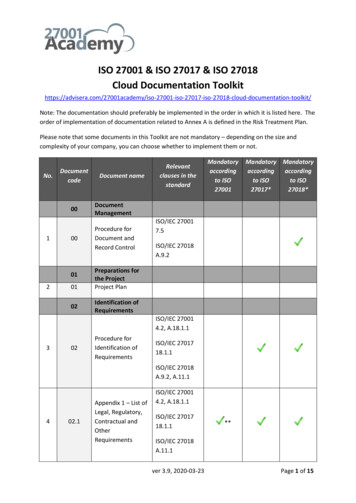

bsigroup.comDocumented informationAs part of the alignment with other management system standards acommon clause on ‘Documented Information’ has been adopted. Theterms “documented procedure” and “record” have both been replacedthroughout the requirements text by “documented information”.Where ISO 9001:2008 would have referred to documentedprocedures (e.g. to define, control or support a process) this is nowexpressed as a requirement to maintain documented information.Where ISO 9001:2008 would have referred to records this is nowexpressed as a requirement to retain documented information.Requirements to maintain documented information are detailedthroughout the standard and some examples are given. Please readthe standard carefully particularly 7.5.4.3Scope of the QMS8.4Control of externally provided products and services4.4QMS and its processes8.5.1Production and service provision5.2QMS policy8.5.2Identification and traceability6.2QMS objectives8.5.6Control of changes7.1.5Monitoring and measuring resources8.7Control of non conforming processes7.2Evidence of competence7.5Documented information determined by theorganization as being necessary for the effectiveness ofthe QMS9.1Control of monitoring, measurement, analysis andevaluation9.2Evidence of the audit programme(s) and the audit results9.3Evidence of the results of management reviews8.1Operational planning and control8.2Determination of requirements for products andservices10.1Evidence of the nature of the nonconformities and anysubsequent actions taken10.3Evidence of continual improvement8.3.5Design and developmentMapping tableThe table below is a clause by clause comparison between the requirements of the proposed 2015 version and the current 2008 standard.ISO DIS 9001ISO 9001:20084Context of the organization1.0Scope4.1Understanding the organization and its context1.1General4.2Understanding the needs and expectations ofinterested parties1.1General4.3 Determining the scope of the quality management system1.2 Application4.2.2 Quality manual4.4 Quality management system and its processes44.1Quality management systemGeneral requirements5Leadership5Management responsibility5.1Leadership and commitment5.1Management commitment5.1.1 Leadership and commitment for the quality managementsystem5.1Management commitment5.1.2 Customer focus5.2Customer focusContinued 7

ISO 9001 - Quality Management System - Transition GuideMapping table – continuedISO DIS 9001ISO 9001:20085.25.3Quality policyQuality policy5.3 Organizational roles, responsibilities and authorities5.5.15.5.2Responsibility and authorityManagement representative65.4.2Quality management system planning6.1 Actions to address risks and opportunities5.4.28.5.3Quality management system planningPreventive action6.2Quality objectives and planning to achieve them5.4.1Quality objectives6.3Planning of changes5.4.2Quality management system planning7Support6Resource management7.1Resources6Resource management7.1.1General6.1Provision of resources7.1.2 People6.1Provision of resources7.1.3 Infrastructure6.3Infrastructure7.1.4 Environment for the operation of processes6.4Work environment7.1.5 Monitoring and measuring resources7.6Control of monitoring and measuring equipment7.1.6 Organizational knowledgeNew7.2 Competence6.2.16.2.2GeneralCompetence, training and awareness7.3Awareness6.2.2Competence, training and awareness7.4Communication5.5.3Internal communication7.5Documented information4.2Documentation requirements7.5.1 General4.2.1General7.5.2 Creating and updating4.2.34.2.4Control of documentsControl of records7.5.3 Control of documented Information4.2.34.2.4Control of documentsControl of records8Operation7Product realization8.1Operational planning and control7.1Planning of product realization8.2Determination of requirements for products and services7.2Customer-related processes7.2.3Customer communicationPlanning for the quality management system8.2.1 Customer communicationContinued 8

bsigroup.comMapping table – continuedISO DIS 9001ISO 9001:20088.2.2 Determination of requirements related to products andservices7.2.1Determination of requirements related to the product8.2.3 Review of requirements related to the products and services7.2.2Review of requirements related to the product8.37.3Design and developmentDesign and development of products and services8.3.1 GeneralNew8.3.2 Design and development planning7.3.1Design and development planning8.3.3 Design and development Inputs7.3.2Design and development inputs8.3.4 Design and development controls7.3.47.3.57.3.6Design and development reviewDesign and development verificationDesign and development validation8.3.5 Design and development outputs7.3.3Design and development outputs8.3.6 Design and development changes7.3.7Control of design and development changes8.47.4.1Purchasing process8.4.1 General7.4.1Purchasing process8.4.2 Type and extent of control of external provision7.4.17.4.3Purchasing processVerification of purchased product8.4.3 Information for external providers7.4.2Purchasing information8.57.5Production and service provision8.5.1 Control of production and service provision7.5.1Control of production and service provision8.5.2 Identification and traceability7.5.3Identification and traceability8.5.3 Property belonging to customers or external providers7.5.4Customer property8.5.4 Preservation7.5.5Preservation of product8.5.5 Post-delivery activities7.5.1Control of production and service provision8.5.6 Control of changes7.3.7Control of design and development changes8.6 Release of products and services8.2.47.4.3Monitoring and measurement of processesVerification of purchased product8.7Control of nonconforming process outputs, productsand services8.3Control of nonconforming product9Performance evaluationNew9.1Monitoring, measurement, analysis and evaluation8Measurement, analysis and improvement9.1.1 General8.1General9.1.2 Customer satisfaction8.2.1Customer satisfactionControl of externally provided products and servicesProduction and service provisionContinued 9

ISO 9001 - Quality Management System - Transition GuideMapping table – continuedISO DIS 9001ISO 9001:20089.1.3 Analysis and evaluation8.4Analysis of data9.2Internal audit8.2.2Internal audit9.3Management review5.6Management ontinual improvement10.2 Nonconformity and corrective action8.38.5.2Control of nonconforming productCorrective action10.3 Continual Improvement8.5.1Continual improvementTransition guidanceISO 9001:2015 Transition Timeline2015September 2015publication20162017Your transition journey2018September 2015 start of three yearstransition period to September 2018Transition is an opportunity – What do youneed to do?1. Take a completely fresh look at the QMS2. Attend a one–day transition course to understandthe differences3. Highlight the key changes as opportunity forimprovements4. Make changes to your documentation to reflect newstructure (as necessary)5. Implement new requirements on leadership, risk andcontext of organization6. Review effectiveness of current control setBSI has identified a step-by-step journey to help you through thetransition and realize the benefits of ISO 9001:2015. We havemapped out a framework which guides you through the options andsupport available from BSI to ensure you have the knowledge andinformation you require.Buy a copy of the Final Draft International Standard (FDIS) and/orInternational Standard on publication. This will help you becomefamiliar with the new requirements, terminology and layoutVisit the BSI website to access the most up-to-date support andtransition material available at bsigroup.com/isorevisions includingwhitepapers which can help you understand the changesLook at the wide range of BSI transition training courses available tomake sure you fully understand the changes including introductionand implementing courses as well as specific deep-dive modulesdesigned to help you understand core ISO Standard requirementsDownload our Implementation Toolkit developed to help youunderstand, implement and communicate the ISO 9001 revisionchanges throughout your organization7. Assume every control may have changed8. Carry out an impact assessment10Consider further services to help implement the changes. BSI has afull range of services available including GAP assessments, Entropysoftware to help you manage your systems and transitionassessments for organizations keen to transition quick and gain earlyadopter advantage

bsigroup.comISO RevisionsTransition training from BSIWhatever the specific requirement, BSI has designed a series oftraining courses that can meet your needs. It’s worth noting that allcourses have been designed by experts in their fields who have beendirectly involved in the development of the standards.Our experienced tutors can help you get to grips with the mattersthat concern you and your organization directly, whether deliveredin-house or as part of an open course where other delegates canshare their experience.The transition courses include:ISO 9001:2015 Auditor/Lead Auditor Transition2 day classroom based training course Learn how to audit the key changes to ISO 9001:2015 Combines the one day Transition course, with a supplementaryday of ISO 9001:2015 auditing activities Ideal for existing internal and lead auditors who need to convert toISO 9001:2015ISO 9001:2015 Deep DiveISO 9001:2015 Transition2 day classroom based training course1 day classroom based training course Gain a deeper insight into these important ISO 9001:2015 Learn about the new ISO high level structure and the differencesbetween ISO 9001:2008 and ISO 9001:2015 Essential for anyone involved with an ISO 9001:2015 transition,from managers to implementers and auditorsISO 9001:2015 Implementing Changes2 day classroom based training course Discover how to apply the key changes to ISO 9001:2015 andformulate a transition action plan Combines the one day Transition course with an additional day ofimplementation activitiesconcepts: Process Approach, Risk-based Thinking, Control ofExternal Provision and Leadership Auditing Valuable for anyone involved with an ISO 9001:2015 transition,including managers to implementers and auditorsISO 9001:2015 Senior Management Briefing2 hour face-to-face session Understand the purpose of ISO 9001:2015 and the leadershipresponsibilities outlined in the standard Important for top management of organizations transitioning toISO 9001:2015 Recommended for those responsible for transitioning an existingsystem to ISO 9001:201511

ISO RevisionsAdditional resourcesThere are a variety of materials which can be accessed on line atwww.bsigroup.com/iso-9001 and consists of:NEW: ISO 9001 Whitepaper - Understanding the changesWith the key changes in the proposed standard for 2015 based onthe Draft International Standard, published in May 2014, thisWhitepaper looks at those changes in detail, the timeline and whatyou can do now to prepare.NEW: ISO 9001 Frequently Asked QuestionsHere we aim to address those initial questions that you may have asyour begin your journey towards the revised standard.ISO 9001:2015 Revision WebinarLearn more about the new ISO 9001 revision and how the changeswill affect your business.ISO 9001 Whitepaper - The history and future of ISO 9001With a revision for 2015 underway, this whitepaper looks at thehistory of the standard, how it has developed over the years and thechanges companies can expect to see in ISO 9001:2015.ISO 9001 Whitepaper: Managing risk in Quality ManagementThis whitepaper explains the background to the revision, how risk isbeing incorporated into the revised standard and the benefits forISO 9001 clients.PLUS: Old-to-new ISO 9001 Mapping Guide Old-to-new ISO 9001 Transition Guide Self-assessment checklists for the new ISO 9001 Your Transition Journey to the new ISO 9001:2015We know ISO 9001;BSI shaped the original standard.BSI. Shaped the original BS 5750 which was the original standard Has the most highly trained and knowledgeable assessors Offers the widest range of support solutions in the market place Is the number one certification body in the UK, USA and Korea Looks after more than 70,000 global clients BSI Group 2014BSI/UK/554/SC/1214/en/BLD Has an unrivalled international reputation for excellencebsigroup.com

Comparing the latest version of ISO 9001 with ISO 9001:2008 ISO 9001:2015 will be based on Annex SL - the new high level structure (HLS) that brings a common framework to all ISO management systems. This helps to keep consistency, align different management system standards, offer matching sub-clauses against