Transcription

Cleanroom BasicsControlling the environment UF

What is a cleanroom?ISO 14644-1: 'A room in which the concentration of airborneparticles is controlled, and which is constructedand used in a manner to minimise theintroduction, generation, and retention ofparticles & microbes inside the room and inwhich other relevant parameters, e.g.temperature, humidity, and pressure, arecontrolled as necessary.' UF

Who’s being protected from What? UFCenter of Excellence for Regenerative Health Biotechnology

Protecting the ProductThe quality of biopharmaceuticalsdepends on the absence of contaminationfrom beginning to end of the productionprocess.Live influenza virusMany virus particlesReplicate in cellsExtensive Purification UFInfluenzaVaccine

Contamination Control Environmental Control––––AtmosphericMaterials and suppliesEntrance and exitCleaning and maintenance Personnel Control– Activity– Personal Hygiene– Gowning UF

How Clean? Cleanrooms are classified according to thedegree of cleanliness required of themanufacturing step. Upon receiving a classification, the room mustbe maintained to meet the specifications tyPressureNumber of air changes/hr.Flow rate (CFM) UF

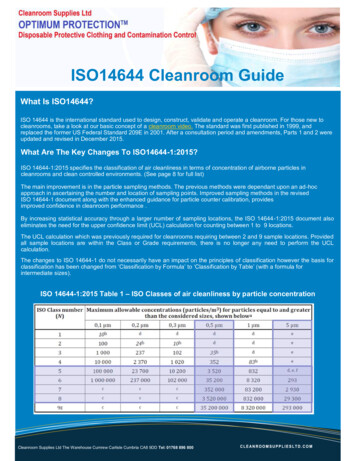

Classification of CleanroomsISO 16644-1 Air Cleanliness Classes for Cleanrooms and Clean ZonesISO Classification #SIEnglish (Former FED-STD-209E)ISO Class 3M 1,51ISO Class 4M 2,510ISO Class 5M 3,5100ISO Class 6M 4,51,000ISO Class 7M 5,510,000ISO Class 8M 6,5100,000*The required standard of cleanliness of a room is dependent on the taskperformed in it; the more susceptible the product is to contamination the better the UFstandard.

Sources of Contamination Facilities:– walls, floors, ceilings, paint, coatings, constructionmaterial (sheet rock, saw dust etc.), air conditioningdebris Equipment/Supplies:– Particles from friction and wear, lubricants &emissions, vibrations, brooms, mops, items broughtinto cleanroom, cleanroom debris People:– Skin flakes and oil, hair, spittle, cosmetics & perfume,clothing debris (lint, fibers, etc.) UF

Potential Contaminates Microorganisms– Viruses, bacteria, fungus Particles– Clothing fibers, equipment, paint UF

Controlling Contamination:Air Quality Filtration– Pre-filtered in air handling units– HEPA (High Efficiency Particulate Air) filtered prior toentering cleanroom. Removes 99.99% of particles(typically 0.3um).– Air is not recycled Temperature– Maintained to reduce microbial growth (viruses,spores, fungi, bacteria)EmployeeComfort Humidity– Effects static, and growth of microbes UFClass 10,000 Specifications: Temperature 72 /- 2.5oF, Humidy 45 /- 5%

Laminar FlowAir flows with uniform velocity in parallel layers, with nodisruption between the layers.HEPA Filtershttp://www.s2c2.co.uk/docs/Cleanroom Design Intro.html UFAir extracted throughvents low on walls.

Why Laminar Flow? Non-turbulent air flow, reduces thepossibility of contamination caused by themovement of particles “Scrubs” the room with air flowing fromceiling to floor UF

Air Change“The solution is dilution” Air Change– A volume of air equivalent to the room volumethat enters and exits a room.For example: 60 air changes an hour meansthat a volume of air equivalent to the roompasses through the room each minute.*FDA guidelines only specify a minimum of 20air changes per hour. The number of airchanges required to meet specification isdetermined for each individual cleanroom. UF

Cleanroom Architecture Elimination of spaces and crevasses thattrap particles:– Recessed lighting and vents– “Coved” floor– Covered light switches– Specialized furniture (wheels, low particleemitting, stainless steel)– Epoxy paint on walls and floors UF

CLEANROOM ARCHITECTURE Maintained at apositive air pressure– Indicated by pressuregauge or indicatorCenter of Excellence for Regenerative Health Biotechnology UF– Forces air to travel onlyOUT of the cleanroom,preventing dirty outside airfrom coming in.

Nested ZonesSterileFiltrationNote: Productoutflow notshown UF

CLEANROOM ARCHITECTURE Interlocking door system– Door to “dirtier” area mustbe closed before door to“clean” area can beopened.– Personnel must come inand out of the cleanroomthrough the gowningroom. buffer zone.– An open, non-air lockeddoor can add billions ofparticles per cubic ft UF

HUMANS IN CLEANROOMS(The biggest source of contamination)PEOPLE ACTIVITYPARTICLES/MINUTE (0.3 microns andlarger)Motionless (Standing or Seated)100,000Walking about 2 mph5,000,000Walking about 3.5 mph7,000,000Walking about 5 mph10,000,000Horseplay100,000,000 s/Cleaning%20the%20Cleanroom.htm

Must “Gown-In” prior to enteringcleanroom UF

Minimum Gowning RequirementsHair CoverISO Class8ISO Class7ISO Class6ISO Class5xxxxxxxHoodBeard CoverxFace MaskFrockxxxxxxxxxxxxxxxxxxCoverallShoe CoversBootsxISO Class4x UF

cleanroomClassroomTackyMatInterlockingDoorClean sideBenchDirty sideGowning room UFSterile HoodClass 100Sterile HoodClass 100Entering the Cleanroom

General Cleanroom Regulations No personal items such as jewelry, keys,watches, matches, lighters and cigarettes No eating, smoking or gum chewing No cosmetics such as lipstick, eye shadow,eyebrow pencil, mascara, eye liner, false eyelashes, fingernail polish, hair spray, mousse, orthe heavy use of aerosols, after shaves andperfumes. Approved skin lotions are sometimes allowed toreduce skin flaking. UF

Actions Prohibited inCleanrooms Fast motions such as running, walking fast orhorseplay. Sitting or leaning on equipment or worksurfaces. Writing on equipment or garments. Removal of items from beneath the cleanroomgarments. Wearing torn or soiled garments. Allowing hands to touch anything other thanproduct-related work UF

Minimizing particles Only approved cleanroom paper. Only approved ball point pens for writing Use of paper or fabric towels areprohibited-Two surfaces rubbing generates billions ofparticles per cubic ft.-Equipment should be specialized forcleanroom use (brushless centrifuges) UF

Cleaning the Cleanroom Cleaning is the essential element ofcontamination control.– Disinfectants filtered– Mops/Buckets autoclaved– Disinfectants rotated every two weeks– Only cleanroom approved wipers allowed– Clean top to bottom, cleanest area to dirtiest UF

Clean? When can the cleanroom be cleaned?– Need to work around production schedule How frequently does it need to becleaned?– Depends on use What is clean and how is it measured? UF

This material is based upon work supportedby the National Science Foundation underGrant No. 0438229.Any opinions, findings, and conclusions orrecommendations expressed in thismaterial are those of the author(s) and donot necessarily reflect the views of theNational Science Foundation. UF

ISO 16644-1 Air Cleanliness Classes for Cleanrooms and Clean Zones ISO Classification # SI English (Former FED-STD-209E) ISO Class 3 M 1,5 1 ISO Class 4 M 2,5 10 ISO Class 5 M 3,5 100 ISO Class 6 M 4,5 1,000 ISO Class 7 M 5,5 10,000 ISO Class 8 M 6,5 100,000 *The required standard of cleanliness of a room is dependent on the taskFile Size: 391KBPage Count: 27