Transcription

S urface T reatmentsBituthene System 4000Surface ConditionerBituthene Primer WP-3000Use Apply Bituthene System 4000Bituthene System 4000 Surface Surface Conditioner to clean, dry, frost-free surfaces at aConditioner is used to condicoverage rate of 300 ft2/galtion all structural concrete,(7.4 m2/L).masonry or wood surfaces onwhich Bituthene System 4000 Surface Conditioner should notWaterproofing Membranebe applied so heavily that itwill be applied.puddles or runs.Safety, Storage and Handling Back roll over all applied areas.Information Allow Bituthene System 4000Surface Conditioner to dry one Bituthene System 4000hour or until substrate returnsSurface Conditioner isto its original color.nonflammable. Bituthene System 4000 Bituthene System 4000Surface Conditioner is clearSurface Conditioner has awhen dry and may be slightlyfreezing point of 14 F (-10 C)tacky. In general, conditioningas packaged.should be limited to what can Read product label and thebe covered within 24 hours.Material Safety Data Sheet Do not prime polyethylenebefore use.surfaces. Stable up to 5 freeze-thaw Before Surface Conditionercycles.dries, tools should be cleanedApplicationwith water. Bituthene System 4000 Surface After surface conditioner dries,Conditioner is ready to usetools should be cleaned withand can be applied by spraymineral spirits. Mineral spiritsor roller.is a combustible liquid which For best results, use a pumpshould be used only intype air sprayer with fan tipaccordance with manufacturer’snozzle, like the Bituthenerecommendations.System 4000 Surface Do not use solvents to cleanConditioner Sprayer, to applyhands or skin.the surface conditioner. Do not dilute with water orsolvent.UseBituthene Primer WP-3000 isused to prime all structuralconcrete, masonry or woodsurfaces on which Bituthenemembranes will be applied.154 In general, priming should belimited to what can be coveredwithin 24 hours. Do not prime polyethylenesurfaces. B efore primer dries, toolsSafety, Storage and Handling should be cleaned with water. A fter primer dries, tools shouldInstructionsbe cleaned with mineral spirits. B ituthene Primer WP-3000 isMineral spirits is a combustiblenonflammable.liquid which should be used Store product in temperaturesonly in accordance withabove freezing 32 F (0 C).manufacturer’s safety R ead product label and therecommendations.Material Safety Data Sheet Do not use solvents to cleanbefore use.hands or skin.Application B ituthene Primer WP-3000 ispackaged ready to use. Do not dilute with water orsolvent. For best results, use a pumptype air sprayer with fan tipnozzle, like the BitutheneSystem 4000 SurfaceConditioner Sprayer, to applythe primer. A pply Bituthene PrimerWP-3000 to clean, dry, frostfree surfaces at a coveragerate of 500-600 ft2/gal(12-15 m2/L). P rimer should not be appliedso heavily that it puddles or runs. Back roll over all applied areas. A llow primer to dry one hour oruntil concrete returns to originalcolor.155

S urface T reatmentsBituthene Primer B2 LVCUseBituthene Primer B2 LVC isused to prime “green” concrete, damp concrete, masonryor wood surfaces on whichBituthene waterproofingmembranes will be applied.Safety, Storage and HandlingInformation Bituthene Primer B2 LVCvapors are flammable. Read product label andMaterial Safety Data Sheetbefore use.Application Bituthene Primer B2 LVC maybe applied by roller or brush.Use a heavy nap roller made ofnatural material, such aslamb’s wool. Apply it to clean dirt-free, frostfree surfaces at a coverage rateof 325-425 ft2/gal (8-10.5 m2/L). Do not apply to frozenconcrete or to areas withstanding or visible water. Do not use during wetweather.156 Allow Bituthene Primer B2 LVCto dry one hour or until tackfree. Deep puddles of primer shouldbe avoided as this will lengthendrying time. Back roll over all applied areas. Avoid pouring primer directlyonto a horizontal substrate. In general, priming shouldbe limited to an area that canbe covered with Bituthenewater-proofing membranewithin 24 hours. Although it may be used ongreen concrete and dampsurfaces, moisture maybecome trapped under theBituthene waterproofingmembrane. Therefore, coverthe membrane as soon aspossible to minimize blistering. If blistering occurs, allowmembrane to cool and re-rollwith heavy roller. Blisters over 4 in. (100 mm)in diameter should be cut andpatched. Do not prime polyethylenesurfaces. C lean tools with mineral spiritsat the end of each day. Mineralspirits is a combustible liquidand should be used only inaccordance with themanufacturer’s safetyrecommendations. Do not use solvents to cleanhands or skin.157

S urface T reatmentsBituthene Deck Prep Surface TreatmentUseBituthene Deck Prep is ideallysuited as a: Leveling agent for roughconcrete decks for new andrehab construction Non-structural repair materialfor defects in concrete decksfor new and rehab construction Temporary waterproofing layer Primer layer for Bituthenewaterproofing membranesSafety, Storage and HandlingInformation Read product label andMaterial Safety Data Sheetbefore use.Compatibility Bituthene Deck Prep is completely compatible with all otherBituthene products and withexisting asphalt or coal tarbased waterproofing materials. It is also compatible with curedsilicone and polyurethane sealants. It is not compatible withcreosote, pentachlorophenol,linseed oil or polysulfide-basedsealants.158Application Substrate surfaces must becompletely dry and free fromdirt, grease, oil, dust or otherdebris. Bituthene Deck Prep may beapplied at temperatures of25 F (-4 C) or above. For applications below 40 F(5 C), store in a warm placeprior to use for best results. Do not apply if wet weatheris expected within 4 hours ofapplication. Add the entire contents of thePart B container to Part A andmix for 3 to 5 minutes untiluniform. A low speed (150 rpm)mechanical mixer with flat parallel blades is required. Once mixed, Bituthene DeckPrep should be poured directlyonto the deck and spread witha squeegee or a trowel. Apply Bituthene Deck Prepwithin one hour after mixing. Bituthene Deck Prep should beapplied in sufficient thicknessto smooth all rough areas andfill all voids. A pply material in thicknessesnot to exceed 1/2 in. (13 mm)per coat. Bituthene Deck Prepwill adhere to dry, unprimedconcrete. The product will support lightfoot traffic after an overnightcure. For interior applications,it may remain tacky even afterfully cured. Apply Bituthene waterproofingmembranes directly to curedBituthene Deck Prep. Nopriming or conditioning isnecessary. C lean tools and equipmentwith mineral spirits beforethe product has cured.Mineral spirits is a combustibleliquid and should be usedonly in accordance with themanufacturer’s safetyrecommendations. Do not use solvents to cleanhands or skin.159

Grace Construction ProductsGRACE ICE & WATER SHIELDSelf-adhered roofing underlayment Product DescriptionGrace Ice & Water Shield is a premier membranecomposed of two waterproofing materials—anaggressive rubberized asphalt adhesive backed bya layer of high density cross laminated polyethylene. The rubberized asphalt surface is backed witha foldless release paper that protects its adhesivequality. During application, the release paper iseasily removed, allowing the rubberized asphalt tobond tightly to the roof deck. In addition, embedded in the membrane is a split release on demandfeature called Ripcord .The full width membrane is supplied in threeroll sizes. See the Product Data chart for productinformation.Membrane strips are also available in 75 ft (22.9 m)long rolls at widths of 6 in. (150 mm), 9 in.(225 mm), 12 in. (300 mm) and 18 in. (450 mm).Features & BenefitsEasy to handle and apply—The self-adhesivemembrane bonds firmly to the roof deck withoutheat or special adhesives.Ripcord is a unique and patented feature thatmakes Grace Ice & Water Shield easier to applyby giving the applicator a split release on demand.Faster application of the membrane in the straightaways, as well as ease of membrane positioning indetailed areas (valleys, around dormers, etc.), arejust some of the benefits.Foldless release paper—The foldless releasepaper provides multiple performance enhancements: fewer edge catches, 180 pull-back, ease ofmembrane cutting (single cuts) and membranepositioning, quicker “one-man installs” resultingin an easier, more productive release.Seals around nails—The rubberized asphalt layerin Grace Ice & Water Shield seals around roofingnails, resisting leakage caused by water back-upbehind ice dams, or from wind-driven rain.Dual barrier protection—Rubberized asphaltand polyethylene are combined to form two waterproofing barriers providing maximum protection.Membrane will not crack, dry out or rot—Grace Ice & Water Shield resists attacks fromfungus and bacteria; maintains its integrity forlong lasting protection.Protects under all standard sloped roofcoverings—Grace Ice & Water Shield protectsunder slate, tile, cedar shakes or metal, as well asunder conventional asphalt shingles.Slip resistant surface—Grace Ice & Water Shieldhas a slip resistant embossed surface to maximizetraction and safety for applicators.Proven track record—Grace Ice & Water Shieldis the name brand in roofing underlayments with a30-year track record of protecting roofs from icedams and wind-driven rain.Reroofable—Unlike granular surfacedmembranes, Grace Ice & Water Shield will notadhere to the underside of the exposed roof covering. In retrofit applications, Grace Ice & WaterShield can be applied over the old Grace underlayment (except over Grace Basik , Grace Tri-Flex and Grace Tri-Flex Xtreme ) making re-roofingeasier, less costly (since there is no need forremoving the existing underlayment), moredurable and environmentally friendly (as thestructural deck remains intact avoiding the needto purchase additional wood decking).Grace technical support—Grace Ice & WaterShield is backed by a team of local technicalsupport personnel that help ensure every application goes smoothly.

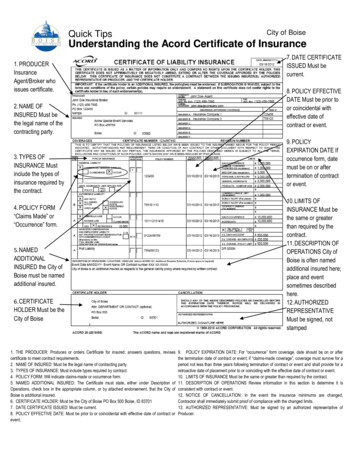

Guidelines for UseGrace Ice & Water Shield is used as an underlayment forsloped roofs to resist water penetration due to water back-upbehind ice dams or wind-driven rain. Grace Ice & WaterShield also offers leak protection in trouble prone spots likevalleys, skylights, protrusions and other flashing areas.Ice DamsGrace Ice & Water Shield should be used in conjunctionwith roof designs that minimize ice dam formation. In coldclimates, it is particularly important to provide proper insulation and ventilation to reduce the size of ice dams and toavoid interior condensation. Cathedral ceilings must includeventilation between rafters to allow for air flow to a ridgevent. Well ventilated cold roof designs are particularlyimportant in alpine regions to reduce the size of ice damswhich could contribute to structural damage.Several variables will influence the height of ice dams andthe membrane coverage required.1. Climate—The annual snow fall will affect the amount ofmembrane needed.2. Slope—On a low slope, ice dams will extend fartherinward from the roof edge.3. Overhang—A wide overhang will require moremembrane to reach the appropriate point on the roof.4. Insulation and ventilation—A very well insulatedbuilding with a cold, well ventilated attic will havesmaller ice dams.5. Valleys—Any valleys formed by projections such asdormers or roof direction changes are likely to trap moresnow and cause larger ice dams.6. Exposure—A northern exposure or shaded areas willgenerally contribute to larger ice dams. While gutters maymake it easier for an ice dam to start, large dams canoccur on roofs with no gutters.Removing snow from a roof edge or installing heat cablesmay not prevent ice dam formation, but may shift thelocation of the ice dam. Under certain conditions, a damcan form at the edge of the remaining snow.Local building codes should be consulted for specificrequirements.Use Grace Ice & Water Shield on all of thesecritical areasLow Slope AreaRake EdgeConfinedRake nged WindowsSillCornersExteriorDoorsGrace Ice & Water Shield Grace Tri-Flex Sill PlateGrace Vycor Plus & Vycor Pro Grace Vycor Deck Protector Ledger BoardDeck JoistsInstallation ProcedureSurface PreparationInstall Grace Ice & Water Shield directly on a clean, dry,continuous structural deck. Some suitable deck materialsinclude plywood, wood composition, wood plank, metal,concrete, or gypsum sheathing. Remove dust, dirt, loosenails, and old roofing materials. Protrusions from the deckarea must be removed. Decks shall have no voids, damaged,or unsupported areas. Wood planks should be closely buttedtogether. Repair deck areas before installing the membrane.Prime concrete, masonry surfaces and DensGlass Gold with Perm-A-Barrier WB Primer. Prime wood compositionand gypsum sheathing with Perm-A-Barrier WB Primer ifadhesion is found to be marginal (refer to Technical Letter12, Use on Oriented Strand Board (OSB) Roof Sheathing).Apply Perm-A-Barrier WB Primer at a rate of 250–350 ft2/gal(6–8 m2/L). Priming is not required for other suitablesurfaces provided that they are clean and dry.Membrane InstallationApply Grace Ice & Water Shield in fair weather when theair, roof deck, and membrane are at temperatures of 40 F(5 C) or higher. Apply roof covering material at temperatures of 40 F (5 C) or higher.Cut the membrane into 10–15 ft (3–5 m) lengths and rerollloosely. Peel back 1–2 ft (300–600 mm) of release liner,align the membrane, and continue to peel the release linerfrom the membrane. Press the membrane in place withheavy hand pressure. Side laps must be a minimum of 3.5 in.(90 mm) and end laps a minimum of 6 in. (150 mm). Forvalley and ridge application, peel the release liner, center thesheet over the valley or ridge, drape, and press it in place.Work from the center of the valley or ridge outward in eachdirection and start at the low point and work up the roof.Alternatively, starting with a full roll of membrane, unroll a3–6 ft (1–2 m) piece of membrane leaving the release linerin place. Align the membrane and roll in the intended direction of membrane application. Carefully cut the release lineron top of the roll in the cross direction being careful not tocut the membrane. Peel back about 6 in. (150 mm) of therelease liner in the opposite direction of the intendedmembrane application exposing the black adhesive. Holdthe release liner with one hand and pull the roll along thedeck with the release liner, leaving the applied membranebehind. Use the other hand to apply pressure on the top ofthe roll. Stop frequently to press the membrane in place withheavy hand pressure. When finished with the roll go back tothe beginning, reroll and pull the remaining release paperfrom the material, finishing the installation.For successive membrane courses, align the edge of therelease liner with the dashed line provided on the surface ofthe membrane to achieve the 3.5 in. (90 mm) side lap.Consistent with good roofing practice, install the membranesuch that all laps shed water. Always work from the lowpoint to the high point of the roof. Apply the membrane invalleys before the membrane is applied to the eaves.Following placement along the eaves, continue applicationof the membrane up the roof. The membrane may beinstalled either vertically or horizontally.Use smooth shank, electro-plated galvanized nails forfastening shingles to get the best seal. Hand nailing generally provides a better seal than power-activated nailing.If nailing of the membrane is necessary on steep slopesduring hot or extreme cold weather, backnail and cover thenails by overlapping with the next sheet.

Extend the membrane on the roof deck above the highestexpected level of water back-up from ice dams and abovethe highest expected level of snow and ice on the wallsheathing on vertical side walls (dormers) and vertical frontwalls for ice dam protection. Consider a double layer ofmembrane in critical areas, such as along the eaves or invalleys and in climates where severe ice dams are anticipated. Apply the membrane to the entire roof deck forwind-driven rain protection. Apply a new layer of Grace Ice& Water Shield directly over the old Grace underlayment inretrofit applications following the standard membraneapplication procedure.Precautions & Limitations Slippery when wet or covered by frost. Consistent with good roofing practice, always wear fallprotection when working on a roof deck. Release liners are slippery. Remove from work areaimmediately after membrane application. Do not leave permanently exposed to sunlight.Cover within 30 days. Place metal drip edges or wood starter shingles over themembrane. Do not fold over the roof edge unless the edge isprotected by a drip edge, gutter or other flashing material. Do not install on the chamfered edges of wood plank. Do not install directly on old roof coverings. Certain product applications are prohibited in hot desertareas in the southwestern United States. Check with yourGrace Construction Products representative. Check with the manufacturer of the metal roofing systemfor any special requirements when used under metalroofing. Do not install directly under roof coverings especially sensitive to corrosion, such as zinc, withoutproviding proper ventilation. Do not install under copper, Cor-Ten , or zinc metalroofing in high altitudes. These roofs can reach extremelyhigh temperatures due to the low reflectivity, high absorption, and high conductivity of the metals. Use Grace Ultrafor these roof types. Check with your Grace ConstructionProducts representative.Ice DamsWind-Driven Rain Provide proper roof insulation and ventilation to helpreduce ice dams and to minimize condensation. Grace Ice& Water Shield is an air and vapor barrier. Repair holes, fishmouths, tears, and damage to membranewith a round patch of membrane extending past thedamaged area 6 in. (150 mm) in all directions. If fastenersare removed leaving holes in the membrane, they must bepatched. The membrane may not self-seal open fastenerpenetrations. Do not install fasteners through the membrane overunsupported areas of the structural deck, such as over thejoints between adjacent structural panels. Due to its slight asphaltic odor, do not apply where themembrane is exposed to interior living space. Refer toproduct literature for more complete information. Not compatible with EPDM or TPO; use Grace Ultra fortie-ins (refer to Technical Letter 5, Chemical Compatibility). Not compatible with polysulfides, flexible PVC, or highconcentrations of resin (pitch). For more information,refer to Technical Letter 5.Code ComplianceGrace Ice & Water Shield meets the following standards: Underwriters Laboratories Inc. Class A fire classificationunder fiber-glass shingles and Class C under organic feltshingles (per ASTM E108/UL 790) Underwriters Laboratories Inc. Classified SheathingMaterial Fire Resistance Classification with RoofDesigns: P225, P227, P230, P237, P259, P508, P510,P512, P514, P701, P711, P717, P722, P723, P732, P734,P736, P742, P803, P814, P818, P824 International Code Council Evaluation Services (ICC-ES)Report No. ESR-1677 Miami-Dade County Product Control Approved. ReportNo. 09-0107.08 City of Los Angeles RR 25330 Florida State Approval Report No. FL289-R3 U.S. Department of Housing and Urban Development(HUD) Materials Release No. 1068gWater from meltingsnow over the heatedportion of the houseruns down the roof.It freezes at the coldeave and an ice dambegins to formpreventing drainage.As the ice dam grows,water is trappedbehind it and backsup under the shingles.Eventually it reachesthe roof deck andleaks through, damaging the interior of thestructure.Grace Ice & WaterShield resists thisleakage because ofthe seal around thefasteners, ability tomake watertight laps,and the membrane’sbond to the deck.Sloped roofs are notwaterproof. Theyprotect structures byshedding rain water.Storm-driven windscan cause sloped roofcoverings to lift. Raincan then be easilydriven under the roofcovering directly to theunprotected roof deckwhere it causes leaksand damage to theinterior of the structure.Grace Ice & WaterShield appliedbeneath the slopedroof covering helpsprevent wind-drivenrain from entering thestructure.

Product DataRoll lengthRoll widthRoll sizePackagingRoll weightRolls per palletPerformance Properties75 ft (22.9 m)36 in. (914 mm)225 ft2 (20.9 m2)Corrugated cartons61.4 lbs (27.9 kg)35PropertyColorThickness, membraneTensile strength, membraneElongation, membraneLow temperature flexibilityAdhesion to plywoodPermeance (max)Material weight installed (max)66.6 ft (20.2 m)36 in (914 mm)200 ft2 (18.6 m2)Corrugated cartons55 lbs (24.9 kg)35ValueGray-black40 mil (1.02 mm)250 psi (1720 kN/m2)250%Unaffected @ -20 F (-29 C)3.0 lbs/in. width (525 N/m)0.05 Perms (2.9 ng/m2s Pa)0.3 lb/ft2 (1.3 kg/m2)36 ft (11.0 m)36 in. (914 mm)108 ft2 (10.4 m2)Corrugated cartons33.6 lbs (15.3 kg)25Test MethodASTM D3767 method AASTM D412 (Die C modified)ASTM D412 (Die C modified)ASTM D1970ASTM D903ASTM E96ASTM r technical assistance call toll free at 866-333-3SBM (3726)Grace Ice & Water Shield, Grace Tri-Flex, Basik, Perm-A-Barrier, Vycor, Vycor Deck Protector and Ripcord areregistered trademarks of W. R. Grace & Co.–Conn.Cor-Ten is a registered trademark assigned to USX Corporation.DensGlass Gold is a registered trademark of Georgia-Pacific Corporation.We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate andis offered for the users’ consideration, investigation and verification, but we do not warrant the results to be obtained.Please read all statements, recommendations or suggestions in conjunction with our conditions of sale, which apply toall goods supplied by us. No statement, recommendation or suggestion is intended for any use which would infringe anypatent or copyright. W. R. Grace & Co.–Conn., 62 Whittemore Avenue, Cambridge, MA 02140.In Canada, Grace Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.This product may be covered by patents or patents pending.GIWS-060VPrinted in U.S.A.11/12Copyright 2012. W. R. Grace & Co.–Conn.FA/PDF

Grace Waterproofing ProductsHydroduct 660 Drainage Compositefor Horizontal ApplicationsTechnical Letter 19 Hydroduct 660 was developed to eliminatethe problem of choosing which drainagecomposite to use in projects with more thanone type of overburden. Hydroduct 660Drainage Composite is recommended for allhorizontal applications.Hydroduct 660 Drainage Compositecombines the best attributes of Grace’s previous drainage composites. The high impact,creep resistant drainage core has a compressive strength of 21,000 lbs/ft2 (1,000 kN/m2)and a drainage flow rate through the core of16 gal/min./ft (200 L/min./m). High strength,nonwoven filter fabric is uniquely designed toprovide enhanced permittivity with superiorresistance to damage on the job site. In addition it incorporates a backing film on the flatside of the core to protect sheet and fluidapplied waterproofing systems.Hydroduct 660 Drainage Composite serves asboth a drainage course and protection forBituthene and Procor waterproofingmembranes. As protection for these waterproofing membranes, drainage compositesshould be placed immediately following theinstallation of waterproofing membrane.In high wind or areas of heavy constructiontraffic it may be necessary to secure thedrainage composite to the waterproofingmembrane with Hydroduct Tape or temporaryballast. Overburdens should be installed assoon as possible to prevent construction tradedamage.Insulated DecksIn insulated designs, drainage compositeshould be placed directly on waterproofingmembrane and under insulation. While insulation manufacturers may recommendplacement of insulation as close as possible tothe structure, it is equally important and gooddesign practice to provide drainage at thewaterproofing membrane level. (ReferenceASTM C 898 “Guide for use of High SolidsContent, Cold Liquid Applied ElastomericWaterproofing Membrane with SeparateWearing Course” and ASTM C 981 “Guidefor Design of Built-Up Bituminous MembraneWaterproofing Systems for Building Decks”.)www.graceconstruction.comFor technical assistance call toll free at 866-333-3SBM (3726)Hydroduct and Bituthene are registered trademarks of W. R. Grace & Co.–Conn.Procor is a U.S. registered trademark of W. R. Grace & Co.–Conn., and is used in Canada under license from PROCOR LIMITED.We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for the users’consideration, investigation and verification, but we do not warrant the results to be obtained. Please read all statements, recommendations orsuggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation or suggestion isintended for any use which would infringe any patent or copyright. W. R. Grace & Co.–Conn., 62 Whittemore Avenue, Cambridge, MA 02140.In Canada, Grace Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.This product may be covered by patents or patents pending.WP-019Printed in U.S.A.4/08Copyright 2008. W. R. Grace & Co.–Conn.FA/pdf

Grace Construction ProductsShelf LifeTechnical Letter 5The shelf life of Grace Vycor Self-AdheredFlashings (Grace Vycor Plus, Grace VycorV40, Grace Vycor Aluminum, Grace VycorPRO and Grace Vycor Deck Protector ) ishighly dependent on storage conditions. Ingeneral, these products should be stored intheir original, unopened packaging at ambienttemperatures between 40–90 F (5–32 C)under dry conditions and protected fromexposure to direct sunlight.Grace Vycor Self-Adhered Flashings shouldbe used within one year from the date ofmanufacture.www.graceconstruction.comFor technical assistance call toll free at 866-333-3SBM (3726)Vycor and Vycor Deck Protector are trademarks, registered in the United States and/or other countries, of W. R. Grace &Co.-Conn. This trademark list has been compiled using available published information as of the publication date of thisbrochure and may not accurately reflect current trademark ownership or status.Grace Construction Products is a business segment of W. R. Grace & Co.-Conn. Copyright 2014 W. R. Grace& Co.-Conn. All rights reserved.We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and isoffered for the users’ consideration, investigation and verification, but we do not warrant the results to be obtained. Pleaseread all statements, recommendations or suggestions in conjunction with our conditions of sale, which apply to all goodssupplied by us. No statement, recommendation or suggestion is intended for any use which would infringe any patent orcopyright. W. R. Grace & Co.–Conn., 62 Whittemore Avenue, Cambridge, MA 02140.In Canada, Grace Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.This product may be covered by patents or patents pending.TP-065FPrinted in U.S.A.08/14Copyright 2014. W. R. Grace & Co.–Conn.GCS/PDF

Grace Ice & Water Shield is used as an underlayment for sloped roofs to resist water penetration due to water back-up behind ice dams or wind-driven rain. Grace Ice & Water Shield also offers leak protection in trouble prone spots like valleys, skylights, protrusions and other flashing areas. Ice Dams Grace Ice & Water Shield should be used in .