Transcription

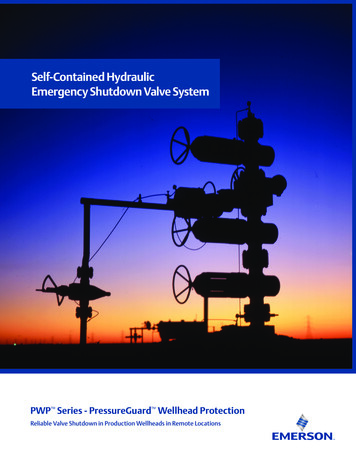

Self-Contained HydraulicEmergency Shutdown Valve SystemPWP Series - PressureGuard Wellhead ProtectionReliable Valve Shutdown in Production Wellheads in Remote Locations

Design/OperationBettis PWPTM series is a self-contained hydraulic emergency shutdown system. The PWP series is delivered as a complete solutionconsisting of an API 6A gate valve and bonnet, hydraulic spring return linear actuator, self-contained hydraulic module, andshutdown trigger accessories which can include pressure pilots, solenoid valves and a temperature-sensing fusible plug.The Bettis PWP system is designed to provide reliable valve shutdown in production wellheads in remote locations where automaticlocal valve ESD is required, but power source is not available and/or local supervision is minimal.Bettis PWP system is ideal for all applications requiring an emergency shutdown system including any emergency well shut-ins, suchas drill stem tests, well tests, flowbacks, and well cleanups.In the event requiring automatic ESD valve operation, a control component vents hydraulic fluid to the reservoir from the actuatorcylinder allowing the compressed spring to move the valve to its fail-safe position.Emergency Shutdown Functions Shutdown by high and/or low pressure sensing (Options)High and/or low pressure pilots, such as Pressurematic, are installed on the flow line to automatically trigger the valve shutdownin case of an emergency. The high and/or low pressure pilots initiate the valve shutdown when flow line pressure rises above/below a high/low-level threshold, as would occur if the flow line pressure were blocked, ruptured or leaking. Remote Shutdown by an ESD signal (Options)OptionalLockableCoverThe system can be remotely shut down by an ESD signal STET throughenergizing or de-energizing a solenoid valve integrated in the system. It willinitiate the valve shutdown when receiving ESD signal, providing remotecontrol capacity.LimitSwitchPressurePilotJunctionBox Fire protection with a hightemperature shutdown (Options)The system can integrate a fusible plug to initiate the valve shutdown duringa fire. Three standard temperature options are available; 184 F / 84 C,203 F/95 C and 255 F/124 C (others available upon request). Trigger by pressure drop rate (LineGuard )The system has an option to integrate the Bettis LineGuard, which monitorspressure drop rate. If pressure drops or increases outside of the configuredMajor Event set point for a certain period, LineGuard would initiate the valveshutdown. For more information, please check Bettis LineGuard brochure(www.bettis.com).Bettis PWP series emergency shutdown can be triggered by any one orcombination of the above.BenefitsFeatures Improved safety for personnel and equipment withestablished fail-safe well test conditions and duringemergenciesBettis PWP series is a turnkey system, ready for use.Quickly responds for immediate valve shutdownMetal to metal seal valve for reliability in harshenvironments, reducing environmental risksPrevents overpressure conditions on downstreamequipmentPermit automatic, remote, and/or manual closureCompliance with API 6A 20th Edition SelfContainedModuleSolenoidValveAPI 6AGate ValveHydraulic Spring-ReturnActuatorAll electric components are CSA Class I, Division I, GroupC&D certifiedOptional lockable coverOptional sun shieldHigh/low pilot shutdownRemote ESD signal shutdownPressure drop rate shutdown

API 6A Gate ValveBettis PWP series uses a field-provenAPI 6A reverse acting gate valve andbonnet from OMNI Valve, a reputablemanufacturer of surface safety valves foroil and natural gas wellheads, manifoldsor other critical service applications withoperating pressures from 2,000 to 15,000PSI. The reverse acting slab gate valvesare API 6A 20th Edition monogrammedequipment and are available in bore sizesranging from 1-13/16” through 7-1/16”.Studs and NutsBonnet Seal RingReverse Acting Slab GateValve BodySeat RingsBonnet SpecificationsSizeAPI 6A 1-13/16” to 7-1/16”Pressure RatingsAPI 6A 2,000 to 15,000 PSIAPI Material ClassAA, BB, CC, DD-0.5/1.5/NL, EE-0.5/1.5/NL, FF-0.5/1.5/NLAPI Production Specification LevelPSL-1, 2, 3API Temperature RatingL to X, -50 F to 350 F, -46 C to 177 CCast-body Gate Valve, Working Pressure 2000, 3000, & 5000 PSINon-NACE TrimsNACE TrimsAPI Mat’l urSourTrimStandardSS TrimFull SSStandardSS TrimSS TrimSS TrimFull SSFull SSFull SSCorrosiveNoAvail. API Temp L to ighlyHighlyL to XP to XL to XL to XL to XL to XP to XP to XP to XBodyASTM A487ASTM A487ASTM A217ASTM A487ASTM A487ASTM A487ASTM A487ASTM A217ASTM A217ASTM A217CL 4 60K Alloy CL 4 60K Alloy CA-15 75K SS CL 4 60K Alloy CL 4 60K Alloy CL 4 60K Alloy CL 4 60K Alloy CA-15 75K SS CA-15 75K SS CA-15 75K SSGateAISI 413075K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 413075K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedSeatsAISI 413075K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 413075K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedAISI 410 SS75K NitridedBonnet SealRingAISI 316 SSAISI 316 SSAISI 316 SSAISI 316 SSAISI 316 SSAISI 316 SSAISI 316 SSAISI 316 SSAISI 316 SSAISI 316 SSStudsASTM A193GR B7ASTM A193GR B7ASTM A193GR B7ASTM A193GR B7M orASTM A320GR L7MASTM A193GR B7M orASTM A320GR L7MASTM A193GR B7M orASTM A320GR L7MASTM A193GR B7M orASTM A320GR L7MASTM A193GR B7M orASTM A320GR L7MASTM A193GR B7M orASTM A320GR L7MASTM A193GR B7M orASTM A320GR L7MNutsASTM A194GR 2HASTM A194GR 2HASTM A194GR 2HASTM A194GR 2HMASTM A194GR 2HMASTM A194GR 2HMASTM A194GR 2HMASTM A194GR 2HMASTM A194GR 2HMASTM A194GR 2HMForged-body Gate Valve, Working Pressure 10,000 and 15,000 PSINon-NACE TrimsNACE TrimsAPI Mat’l urSourTrimStandardSS TrimFull SSStandardSS TrimSS TrimSS TrimFull SSFull SSFull erateHighlyHighlyHighlyAvail. API TempL to YL to YP to YL to YL to YL to YL to YP to YP to YP to Y

Hydraulic Spring-Return ActuatorThe piston type, hydraulic spring return actuatoroperates the fail safe surface safety valve. It isideally suited for wellhead emergency shutdownapplications, flow lines, header valves andgathering lines - any application requiring failclose. The actuator is compact, easy to maintainand has been proven as a reliable product inthe harshest of environments and operatingconditions, onshore or offshore.Upper ShaftUpper Shaft SealAssemblyPistonBenefits and Features Easily replaceable nonmetallic seals andother partsCorrosion protection with internal andexternal coated housing and stainless steelor coated internal componentsOptional limit switch to provide valveposition signalMaximum working pressure up to 3000 PSIAPI material class: AA/BB/CCAPI temperature rating: (-20 F to 180 F /-29 C to 82 C)CylinderSpringOperating StemPacking RetainerStem SealAssemblyAPI 6A Valve BonnetBonnet VentFittingLimit Switch AssemblyHousingSight GlassSwitch TargetGO SwitchPosition SensorsActuatorUpper ShaftLimit Switch AssemblyFeatures Carbon steel housingLocal position indicatorElectrically-monitored valvepositionGO Switch 73 Series(SPDT) Single Pole DoubleThrow, Form C4amp/120VAC, 3amp/24VDCLimit switch enclosure material 316 stainless steelCSA Class 1 Division 1 Group A-D

Control SystemThe PWP PressureGuard self-contained hydraulic control systems are supplied with a basic manifolded control system thatprovides one-way local control using the handpump. In addition to its reliability, it provides quick and simple maintenance.HandpumpPressure GaugesPressure RegulatorManual Reset ValveLP AccumulatorHydraulic Fluid Level IndicatorHydraulic Fluid ReservoirBenefits and Features Less tubing reduces complexity and leak pathsEach component is easily identified and quickly isolated for preventative maintenance or testingLockable weatherproof cover for the manifold assembly (optional)Zero hydraulic fluid leakageAn accumulator to prevent cyclic transfer due to temperature changeInstrument tubing of 316 stainless steel with Swagelok fittingsBasic Control st of Components51024282High PressureLow PressureReservoir 13.14.16.20.23.24.27.28.OperatorWellhead ESD ValveHandpumpFilterCheck ValveGauge, LP 2.5”Gauge, HP 2.5”Relief Valve, HPPressure RegulatorRelief Valve, LPPressure Pilots (optional)Selector Valve (optional)Solenoid Valve N.C. (optional)Reset ValveReservoirAccumulatorIsolation Test Valve (optional)

PressurematicBettis PressurematicTM is a pressure pilot used to monitorpipeline or process pressure. It is suitable for use in highand/or low pressure shutdown applications utilizing a pneumaticor hydraulic signal. Set points are determined by piston size,spring rate and adjustments to the trip mechanism. A springloaded piston converts pressure into motion, activating a pilotvalve when a pre-determined set point is reached.Pilot ValveSupply PortSignal PortExhaust PortBenefits and Features Field adjustable high and/or low pressure set pointsStandard automatic reset on pilot valve, manual reset asan optionStandard 2 MNPT threaded process connectionTemperature limits:Process –50 F to 392 F (–46 to 200 C)Ambient –50 F to 212 F (–46 to 100 C)Input is pipeline or process pressureOutput is pneumatic or hydraulic signal, responding tohigh and/or low pressure conditionsRepeatability is 2% of set point (or 5 PSI if greater)High set points (increasing) up to 6000 PSILow set points (decreasing) down to 20 PSINo brass or bronze componentsNACE trim available for corrosive applicationsElectroless nickel plated process piston with TFE seal; nodiaphragm to ruptureAluminum housing with sealed coverNitrile seals standard, Viton seals optional for higher temperaturesHousingHex BodyPiston(Internal)Pressurematic Model DesignationProductNameResetType**Series20002000 seriesAR:P:PressurematicAuto reset22002200 seriesMR:Manual reset24002400 seriesPAR2000Body Material Code1234C:CS body1L:2A350 body,3Low temp NACE4N:SS body, NACE1234Example ModelCLow Set Point High Set 00-3220400-44001550-60001650-41003*NOTE: The difference between high set point and low set point must be fall in the span.For example, if the low set point is 200 psi, high set point is 1500 psi. The difference between high and set point is 1300.The model suitable for this are PAR2000C4 or PAR2400C2.**2000 and 2200 series are the most common models and have shorter lead time.Span*(PSIG)

PWP Performance DataValveSizeWorkingPressureStandard closingtime (no load)Sec. (Estimated)Closing time with hydraulicquick exhaust (no load)Sec. (Estimated)2 1/16"200010 to 162 9/16"200010 to 16Weight (Estimated)lbkgHandpumpstrokes(Estimated)3 to 4283128144 to 5370168163 1/8"200010 to 165 to 6388176204 1/16"200015 to 186 to 8750340445 1/8"200019 to 227 to 1013696211157 1/16"200026 to 3010 to 1415607081482 1/16"300010 to 163 to 4327148142 9/16"300010 to 164 to 5405184163 1/8"300010 to 165 to 6456207204 1/16"300010 to 166 to 8827375445 1/8"300019 to 227 to 1014536591157 1/16"300026 to 3010 to 1416327401482 1/16"500010 to 163 to 4327148142 9/16"500011 to 164 to 5562255283 1/8"500013 to 185 to 6644292354 1/16"500013 to 186 to 8864392445 1/8"500019 to 227 to 1015186891157 1/16"500026 to 3010 to 1418258281481 13/16"1000011 to 162 to 3541245212 1/16"1000011 to 163 to 4576261232 9/16"1000011 to 164 to 5672305273 1/16"1000012 to 145 to 61116506704 1/16"1000015 to 186 to 81447656881 13/16"150008 to 92 to 3933423442 1/16"1500010 to 123 to 4958435472 9/16"1500010 to 124 to 51112504583 1/16"1500012 to 145 to 61461663744 1/16"1500018 to 226 to 82173986215

Product DimensionsTop ViewSide ViewValveSizeWorkingPressureABCDEin.in.in.in.2 1/16"200011.64.84.84.52 9/16"200013.15.65.63 1/8"200014.16.97.14 1/16"200017.18.6Front 4.022.24.024.022.24.021.024.022.24.05 022.24.07 .022.24.02 .24.02 .24.03 24.04 22.24.05 07 .02 .24.02 .24.03 .24.04 22.24.05 07 .01 022.24.02 22.24.02 22.24.03 04 .01 02 2 03 04 .0*NOTE: Dimension includes maximum control options

PWP Series Model DesignationProductPWP2105API 6A Gate ValveRJE0PU21R2Control Functions (optional)D1F1LGQSOrientation0 Valve Bore Size11: 1-13/16”21: 2-1/16”29: 2-9/16”31: 3-1/8” or 3-1/16”41: 4-1/16”51: 5-1/8”71: 7-1/16” Valve Working Pressure (PSI)02: 2000 03: 300005: 5000 10: 1000015: 15000 ConnectionRJ: RTJ Flange TrimsAA: AA trimCC: CC trimE0: EE-0.5 trimEN: EE-NL trimF1: FF-1.5 trimBB: BB trimDN: DD NL trimE1: EE-1.5 trimF0: FF-0.5 trimFN: FF-NL trim Valve Temperature ClassesL: -50 to 180 FN: -50 to 140 FP: -20 to 180 FR: Room TemperatureS: 0 to 140 FT: 0 to 180 FU: 0 to 250 FV: 35 to 250 FX: 0 to 350 FY: 0 to 650 F PSL Level1: PSL 1 2: PSL 23: PSL 3 PR Level1: PR 12: PR 2 High and/or low pressure to shutdownR1: Remote mounting, Single settingR2: Remote mounting, Dual settingT1: Integral to operator, Single settingT2: Integral to operator, Dual setting Electric signal to shutdownD1: De-Energize to close 12VDCD2: De-Energize to close 24VDCD3: De-Energize to close 120VACE1: Energize to close 12VDCE2: Energize to close 24VDCE3: Energize to close 120VAC High temperature to shutdown /Fire Protection / Fusible PlugF1: 184 FF2: 203 FF3: 255 F Pressure Drop to shutdownLG: LineGuard Other Control OptionsLA: Limit switch assemblyQS: Quick closing speedA2: Additional AccumulatorLC: Lockable aluminum cover Orientation0: Horizontal pipeline, Vertical valve stem1: Vertical pipeline, Horizontal valve stem2: Horizontal pipeline, Horizontal valve stem3: Other

World Area Configuration Centers (WACC) offer sales support, service,inventory and commissioning to our global customers. Choose the WACCor sales office nearest you:NORTH & SOUTH AMERICAMIDDLE EAST & AFRICA19200 Northwest FreewayHouston TX 77065USAT 1 281 477 4100P. O. Box 17033Jebel Ali Free ZoneDubaiT 971 4 811 8100Av. Hollingsworth325 Iporanga SorocabaSP 18087-105BrazilT 55 15 3413 8888P. O. Box 10305Jubail 31961Saudi ArabiaT 966 3 340 8650ASIA PACIFICNo. 9 Gul Road#01-02 Singapore 629361T 65 6777 8211No. 1 Lai Yuan RoadWuqing Development AreaTianjin 301700P. R. ChinaT 86 22 8212 330024 Angus CrescentLongmeadow Business Estate EastP.O. Box 6908 Greenstone1616 Modderfontein Extension 5South AfricaT 27 11 451 3700EUROPEHolland Fasor 6Székesfehérvár 8000HungaryT 36 22 53 09 50Strada Biffi 16529017 Fiorenzuola d’Arda (PC)ItalyT 39 0523 944 411 2019 Emerson. All rights reserved.For complete list of sales and manufacturing sites, please s or contact us atinfo.actuationtechnologies@emerson.comThe Emerson logo is a trademark and service mark of Emerson Electric Co.Bettis is a mark of the Emerson family of companies. All other marks are property oftheir respective owners.www.emerson.com/bettisBRO-02-03-0063-EN Rev D 07-19

High Pressure Low Pressure Process Reservoir Return Electrical Suction 1. Operator 2. Wellhead ESD Valve 3. Handpump 4. Filter 5. Check Valve 6. Gauge, LP 2.5" 9. Gauge, HP 2.5" 10. Relief Valve, HP 12. Pressure Regulator 13. Relief Valve, LP 14. Pressure Pilots (optional) 16. Selector Valve (optional) 20. Solenoid Valve N.C. (optional) 23 .