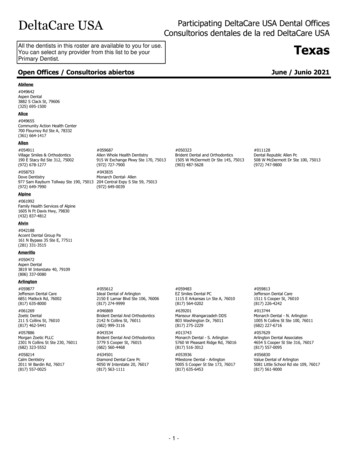

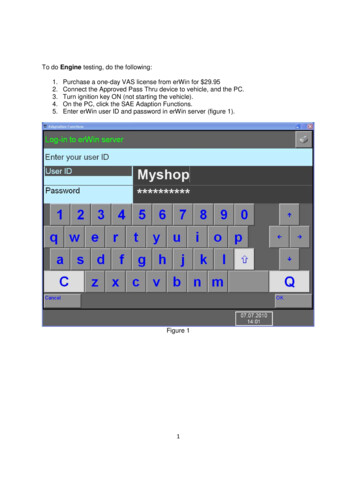

Transcription

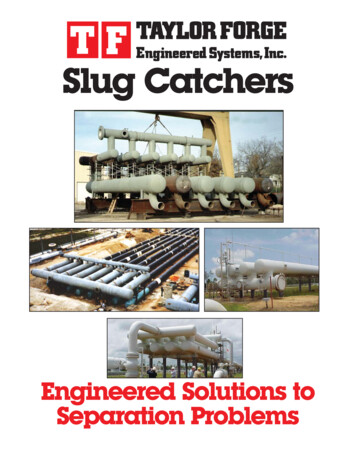

Slug CatchersEngineered Solutions toSeparation Problems

SeparationProducts fromTaylor ForgeTaylor Forge EngineeredSystems has been aleading manufacturer ofliquid separation equipment for the pipelineindustry for over fortyyears. We design andmanufacture all types ofvessels, components,sub-assemblies andcomplete systems forliquid separation andstorage. Our extensiveexperience in componentmanufacturing andknowledge of field construction has helped usdesign products thatminimize costs andinstallation time.Each liquid separationsystem has its ownunique characteristicsand must be examinedon a case-by-case basis.This bulletin concentrates on the separationand storage of largevolume liquids fromnatural gas. We do,however, furnish all sizesof systems.Horizontal Separator Vessel Can give small particleseparation (10 microns)where there is more liquidand lower gas flow. Useful as three phaseseparator. Becomes expensive andheavy when large sizesare required. Good separation up to5 - 700 bbls. slug size.Vertical Separator Vessel Useful where small particleseparation (10 microns) isrequired and gas flow islarge in relation to liquidslug size. Equipment is expensiveand heavy when large sizesare required. Good separation -- usefulup to 5 - 700 bbls.slug size.Pipe Fitting Type Slug Catcher Very economical wheresmall liquid slugs are tobe caught. Particle separation ispoor and relativelyunpredictable. Catches slugs up to150 - 200 bbls.This type of separation equipmenttypically has an impingement plateto knock out bulk liquids and a vertical column to form a gravity typeseparator, but it usually has insufficient area to effectively removesmall particles. Normally, it is justused to catch the slugs of liquid andhold them. For economic reasons,these slug catchers are usuallydesigned as pipe and fittings, ratherthan as pressure vessels.The pipe fitting type slug catcherprovides good slug separation andslug storage volume at a reasonablecost. Small particle separation ispoor, but it improves at low flowrates. A slug catcher of this type canbe used to protect a centrifugal typeseparator and the combination willgive separation and slug storagecapacity.

Harp Type Separator/Slug Catcher Economical way to catch large slugs(thousands of barrels). Gives predictable particle separation in the50 micron and up sizes. Predictable separation up to tens ofthousands of barrels slug size. Ships in pieces for field assembly withline pipe. When slug size is large enough to justify thelogistics of field assembly, and B31.8 typeconstruction is allowed, the harp typeseparator/slug catcher will beconsiderably cheaper than vessels.The Taylor Forge Engineered Systems harp type separator/slug catcher is a versatile device for catching slugsand separating liquid and solid particles from pipelinegas. It is built from high strength material and in its largersizes can offer cost and delivery savings over vesseltype slug catchers.The units can be furnished completely engineered including the pig trap, separator/slug catcher, foundationand instrumentation The separator/slug catcher can beburied below ground or placed on piers above ground asconditions require. Controls can be integrated into theexisting systems. The system can be split in two halvesfor redundant operation and/or sequential construction.Effective level controls are normally installed, including avent line from a level column near the liquid manifold tothe gas out manifold. With proper interconnections andthe addition of interface controls, the sludge manifoldcan be used to effectively separate water from hydrocarbon liquids. If liquid particles smaller than 50microns are to be removed from the gas stream, separator elements can be added to the dry gas manifold ordownstream of the slug catcher.Depending on various conditions or the particular application, the basic design configuration may be easilymodified. The use of multiple slopes and/or elbowsallow the slug catcher to be filled to a higher level withoutdanger of re-entrainment and carryover of liquid. Theuse of reducers and/or a two-level arrangement allowsthe separation and storage tubes to be different sizes foreconomy and more efficient operation. The two-levelarrangementalso shortens theinstallation and allows thebulkof the liquid to be diverted from the gas stream priorto the separation of the smaller particles.The separator/slug catcher consists of several modules— distribution header, separation chambers, dry gasrisers, storage harps, and liquids and sludge manifolds.The distribution manifold takes the incoming gas/liquid stream, slows it down, and splits it into severalsmaller streams to allow uniform flow into the separationchambers.In the separation chambers, the majority of the gasliquid separation is accomplished. The required length,size and number of these chambers is a combinedfunction of gas flow, gas chemistry and other knownconditions.The primary functionof the dry gas risers is to deliver drygas back into the system. As some secondary separation occurs here, their sizing is important.The storage harps hold the liquids at line pressure andthe number and length of these harps is determined bythe storage requirements, i.e., slug size — 2 phase andresidence time — 3 phase. Secondary separation alsooccurs here.The liquid and sludge manifolds provide separation ofthe water, oil and debris. The oil and water are thenremoved from the storage end for further processing (oil)or reinjection (water). The debris is cleaned out on an asneeded basis. When the liquid build-up in the lines isheavy and lines are long, many barrels’ of liquid cancollect. When pigging lines, this liquid arrives at theslugging rate and must be stored at pressure or flashedand disposed. Inoffshore applications and cold climates,thousands of barrels of storage may be required.

Taylor Forge Pipe TypeSeparator/Slug CatcherOffers a Number ofBenefits and Advantages! Predictable Efficiency -- Usingworst-case design, our system is ableto perform separation when a vesselseparator cannot. "Carryover" -- is prevented becauseour system is designed for worst caseand unexpected slugs are handledalong with the uninterrupted gas flow. Ease of Installation -- Our TF separator/slug catcher system is shipped toyou in prefitted modules. The fieldcontractor only makes circumferentialbutt welds to fit the system together. Full Onstream Operation -- Our slugcatchers are on-line while pigging ordumping and can be automated to anydegree you wish. Short Lead Time -- We reduce thetime required from purchase order tooperation. Our delivery is normallyless than one-third the time to get alarge vessel-type separator. Planned Phase Addition -- Our designs allow your company to add morecapacity as gas supply increases, withminimum lead time, minimal expenseand no shut-down. Cost Effective -- We offer cost savings up to 50% over conventional largeOD vessel and pipe collection programs. Particular savings are realizedwhen ANSI B31.8 design is used. Large Volume Storage -- The largevolume storage is accomplished by themost economical way known -- in-linepipe or storage pipes. Sludge Manifolds -- The sludge manifold can be cleaned with on-linemaintenance while unit is in operation. Single Source Responsibility -- Wecan supply all structural, process andmechanical engineering for yourseparation installation.StoraDry Gas RisersSeparationChambersTwo Phase InSTANDARD ARRANGEMENTBETTER FLOW - FRONT ENDFILL HIGHER

age HarpsLiquid &SludgeManifoldDetail of distribution headerDry Gas OutDistribution ManifoldSubsea Slug CatcherDesigned to solve the problems associatedwith underwater production, the Subsea SlugCatcher is a compact and modular unit, suitable for installation on the sea floor. TheSubsea Slug Catcher, built into its own structure, can be dropped into place with a single lift.Our patented Pig Bypassing Device directsliquid slugs and gas through the slug catcherwhile allowing the pig to bypass the slug catcher.This mechanism eliminates the need for diversto launch and receive pigs around the slugcatcher.Typical Installation ofPig Bypassing Device at Slug CatcherSHORTER - SEPARATE SEPARATORFILL HIGHERSHOP FIT REQUIREDLIQUID DIVERTED SOONERSHORTER - SEPARATE SEPARATORFILL HIGHERSHOP FIT REQUIRED

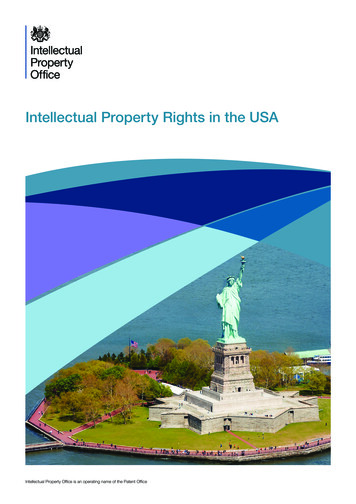

We Can Offer Complete Process and MechanicalResponsibility Based on Total Project Management VALUE ANALYSISWhat type of separatorslug catcher is right foryour application?Long term plan for fieldDesign codesEquipment type andarrangementType of materialType of construction PROCESS DESIGNGas Conditions2 or 3 phaseConstituent analysisSlug ForecastingLine profileTemperaturePerformanceSeparation EfficiencyMicron sizeMinimize carryoverMaterial Balance DiagramPiping and InstrumentDiagramVent SystemLiquid Removal MECHANICAL DESIGN MANUFACTURING/FABRICATIONMaterialsHigh yield -- Y-52to Y-70Carbon steelLow temp. with charpy'sHIC resistantIn-House TestingCharpy V-notchTensilesHardness -Brinell, RockwellWeld bendRollingFive rollsHot or coldMax. 7-1/2" thickWeldingASME IXAPI 1104Closed Die FormedExtrusionControlled wallthickness and radiusDimensional flexibilityHeat TreatingNormalizeQuench and temperStress relieveDesign CodeANSI B31.8ANSI B31.3ASME CodeBS5500Non-Destructive TestingAll in-house testingRadiographyUltrasonicMagnetic particleDye penetrantPiping Flexibility AnalysisIncluding all thermal andmechanicalstressesAnchoring systemPigging systemAbove and below gradeFabricationLargest piecesshippable tominimize fieldfabricationPre-Fit and Match-MarkSpecial CoatingsAbove groundBelow ground

MATERIALSMANAGEMENTProject coordination anduniformityWorldwide sourcingcapabilitiesDomestic sourcing asrequiredMaterial delivery timingLinepipeInstrumentsElectrical CIVIL DESIGNOptimize Site LocationOptimize Site UtilizationSingle levelMulti-levelFacility Expansion or GrassRoots FacilitySite PeculiaritiesWater tableWeatherSeaside or mountains CONSTRUCTIONMANAGEMENTLand SurveySoil SamplingField Weld ProceduresQualify & Train FieldWeldersNDT ServicesConstruction SequencingOn-Site Surveillance START-UP ANDTRAINING SERVICESStart-Up System includingValve SequencingEstablish Operating CyclesVerify AIRECompany NameAddressPerson to ContactPositionDatePressureDesignTemperature DesignOperatingOperatingGasS.G.CompositionFlow RateLiquidsPhone No.DesignS.G.CompositionFlow RateDesignWaterFlow RateDesignEstimated Liquid Slugging Rate DesignDesired Hold Up (bbls. or time) DesignSpecial Conditions and Site Limitations:Instrumentation and controls:Project timing:InitialInitialInitialInitialInitial

Pressure Vessels (Steam Drum)Extruded Outlets (Air Grid Hub and Arm)Trap with Patented Closure (Skid Mounted for Export)High Yield and NuclearTees and CapsSlug Catcher (Offshore Facility Utilizing Headers)12,000 psi Y-70/Y-80 Scraper Trap SkidHigh Yield and NuclearReducers and ElbowsTraditionally Dependable208 N. Iron StreetPaola, Kansas 66071Telephone: (913) 294-5331Telex; 62192610FAX: (913) 294-5337

rator/slug catcher is aversatile device for catching slugs and separating liquid and solid particles from pipeline gas.It isbuilt fromhighstrengthmaterialandinits larger sizes can offer cost and delivery savings over vessel type slug catchers. The units can be furnished completely engineered in-cluding the pig trap, separator/slug catcher, foundationFile Size: 982KBPage Count: 8