Transcription

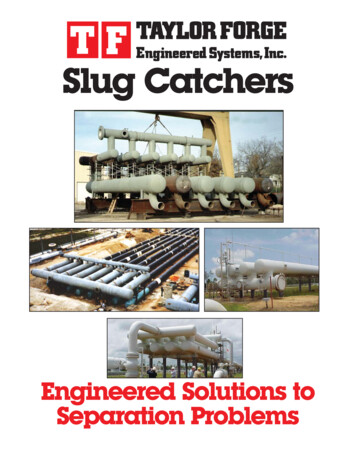

Engineered Solutions Our Core ProductsStarting with a collaborative, consultative approach, we work tounderstand the unique needs of a project in order to deliver thebest solution.Our Value Added ProcessFor All ProductsConcept Consulting on Code & Design Factors Weight & Space Optimization Conceptual Designs Preliminary / Budgetary Pricing Delivery Timeline Designer / Customer CollaborationSlug CatchersWe efficiently design 2-phase or 3-phase separation ahead ofyour processing facility. The proper design of this critical pieceof equipment will ensure the consistent and efficient operation ofthe facility. By designing for pigging and transient slugs to arriveat the full gas flow rate, you are assured of meeting current andfuture processed needs.FEED Finalize & Optimize the Sizing, Design, Budgets & TimingDesign Designed Using Extruded Connections Savingboth Space & Cost Detailed Design Phase CFD Analysis for Flow/Pressure 3D Modeling & Flow Analysis Process Guarantee & Performance Guarantee Mechanical Design, Pipe Stress, Foundation Loads(early in the process for civil/owner planning)Pipe Type Slug CatchersManufacturing Minimize Field Construction Cost with Prefab Components Minimize Field Welding Quality Controlled In-house Fitting Mfg Optimize Shipping Configuration 100% X-Rayed WeldsVessel Type Slug CatchersEPC / Install Supervised Final Completion forAssured Performance Guarantee TFES Owned Project Lifecycle Continued QC thru CommissioningFatigue analysis model.Vortex Tube Bundle CFD test model.Pipe Type Slug CatcherAlso called “Harp Type” or “Finger Type”. Very flexible designwith almost unlimited capacity potential. Units have been installedover 4 BSCFD of gas flow and over 50,000 bbls (8,000 cu m)of liquid storage. Plot space limitations can be optimized.Turnkey scope including installation is available.Vessels are the economical choice up to approximately 1000 bbls(165 cu m) of liquid storage. They are typically installed withoutprocess internals in slugging applications. Vessels canbe designed to ASME Sec VIII Div 1 or 2.Vortex Cluster CFD test model.Slug Catcher test model.

VortexTubeScrubberVortex Technology SeparationBy utilizing our unique Vortex Technology separation elements, veryhigh separation efficiency can be achieved (down to 1 micron particles).Using this technology can result in vessel size and weight reductionsup to 30%. It can also be retrofitted into existing separators wheregas flows need to be increased or operating pressures have dropped.Heat Exchanger BundlePipe Type Slug Catcher with Vortex Tube Scrubber.By listening to the specific needs of our client, our designteam provided them with a customized solution to theirgas/liquid handling and storage challenges.Extruded Outlets & HeadersThe engineered Extruded Outlet provides superiorstrength by moving the weld away from the highlystressed area and eliminates fatigue cracking fromcyclic or thermal loads. The advantages also includeflexible configuration of all sizes to maximize costsavings in welding, field fabrication, material usage,and space and weight savings.Extruded OutletShell & Tube Heat ExchangersOur 53,000 sq. ft. state-of-the-art fabrication facility focuses on processand heat transfer packages. Our dedicated In-House Thermal Designand Engineering team will design to the latest requirements includingHTRI, TEMA “R”, “C”, and “B”, as well as, API 660 standards. Our heatexchangers, condensers, reboilers, and evaporators will be fabricated tothe highest level of quality standards for our customers peace of mind.Extrusion Process

Scraper TrapsScraper traps, or pig launchers and receivers, havebeen fabricated from 6” line size up to 60” andpressures up to 15,000 psi. With the applicationof extruded outlet connections, a safe, low stressfabricated assembly provides peace of mind toowners and extended operational life. Quick openingclosures of any style or manufacture can be included.Modularization of an entire pigging package canalso be provided.Pressure VesselsPressureVesselsTaylor Forge has supplied pressure vessels into manydifferent applications for over 70 years. With ASMEU, U2, S and National Board R certifications, we havebeen an experienced and influential leader in energyand industrial markets.Scraper trap extruded outlet connections.We also specialize in high pressure gas storage vesselsfor the Aerospace Industry. We have the resourcesto provide large storage volumes in a relatively smalldiameter with a heavy wall configuration, saving spaceand maintenance.High Strength Material TechnologyOver the years Taylor Forge has been an innovator inthe development of advanced grade forging materialsfor use in critical, high pressure applications requiringhigh strength, excellent toughness, good weldability,and sour service compliance aimed at maximizingvalue for our customers.70 years of pressure vessel design and installation experience.30mm ESW Overlay in 10” pipe.Harp Type 9000 Barrel 12-Finger Slug CatcherAftercooler Manifold

Engineered ValueWe tailor our custom layout and fabrication to suit theexact needs of your application. Taylor Forge is dedicatedto engineering value into every project we touch. High Quality Designs lead to High Quality ProductsIt all starts with collaboration, planning, design detailsand implementation at the highest engineered level. Industry Recognized Process GuaranteesBecause of our designs and deliveries, we are theindustry recognized leader. Metallurgical ExcellenceOur expertise in metallurgy and welding has beencrafted and engineered for over 100 years. Welding Technology is our ScienceThe most advanced welding experts in our field.We perform R&D, certified testing, and havequalified over 1,000 welding procedures. Fluid Dynamic Flow Analysis and Structural DesignWe invest in the best software and personnel tounderstand, test and provide design excellence.

Engineered Products LineExtruded Outlets & HeadersSlug Catchers Harp / Finger / Pipe type Vessel type 2 & 3 phase separation Single and multiple outlet headers (run size 12” andlarger, outlet size 2” and larger) Flow tees Meter header assembliesFabricated Assemblies Scraper traps, launchers/receivers (utilizing extrudedoutlets or fabricated from pipe and fittings) Pulsation bottles (extruded per DOT/B31.8 orASME stamped) Slug catcher assemblies (modularized shipments orfield assembled manifolds) Drip assemblies Valve settings After-cooler manifold assemblies Pipeline and station piping components Extruded headers per MSS-SP-75Vortex Technology Separation Vortex separators Vortex scrubbersMiscellaneous Offerings/MaterialsShell & Tube Heat Exchangers HTRI thermal ratings RCS mechanical design TEMA design and construction Certifications: ASME U, S and National Board R 6” to 120” diameter shells Weld overlay (316L/625) Pulsation bottle OffshoreTrap withHighPatentHighYieldClosureYield& Nuclear& si psiY-70/Y-80Y-70/Y-80High Yield & Nuclear Tees,PressureVesselsridt) FacilityHubFacility& dCaps,Caps,forReducersExport)Reducers& Elbows& rapSkidSkidCaps, Reducers & Elbows Certifications: ASME U, S and National Board R Vortex separators Vortex scrubbers Slug catchersOurOurCertificationsCertificationsOur Certifications High pressure gas storage Partial material list: Carbon steel High strength low alloy Stainless steel Duplex and super duplex12,000 psi Y-70/Y-80 1-1/4ScraperTrapCr,Skid2-1/4 Cr, 9 Cr Nickel alloysOurcommitmentcommitmentto toqualityqualityandandcontinuedcontinuedOur commitmentimprovementimprovementto hasqualityhas and continued improvement hasureOurequipmentfabricator,resultedresultedin ps:certificationfor the following stamps:nsas,providinghighqualityCommitment to c.andNPT.VIIINPT.U,U2and4, Sec. III - NA and NPT.riety of industriesincludingIn additionto oilour ASME and National Board ertified.hasapproval.alsoapproval.received ISO 9001 certification approval.uclear,aerospaceanddefense.TaylorForge- Paola,KSisTaylorISOcertification9001, Taylor Forge takes pride in itshorough mechanical design andes.World Headquarters:208 N. Iron StreetPaola, KS 66071(913) 294-5331www.tfes.comPlease contact our engineers today: ters:208208N. N.IronIronStreetStreetWorld Headquarters:208 N. Iron Street

Slug Catcher (Offshore Facility Utilizing Headers) High Yield & Nuclear Tees, Caps, Reducers & Elbows 12,000 psi Y-70/Y-80 Scraper Trap Skid Taylor Forge is a global pressure equipment fabricator, headquartered in Eastern Kansas, providing high quality engineered products to a