Transcription

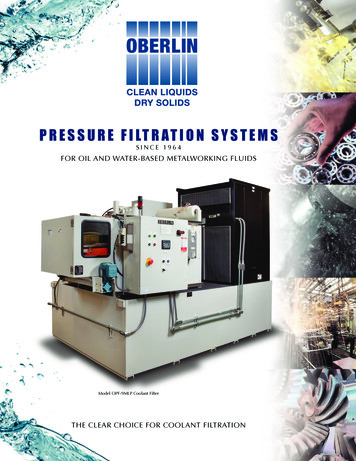

P R E S S U R E F I LT R A T I O N S Y S T E M SSINCE 1964FOR OIL AND WATER-BASED METALWORKING FLUIDSModel OPF-9MLP Coolant FilterTHE CLEAR CHOICE FOR COOLANT FILTRATION

O B E R L I N P R E S S U R E F I LT E R SPROVEN PERFORMERS FOR MOST METALLIC ANDNON-METALLIC GRINDING AND HONING APPLICATIONS Gear grinding Creep feed grinding Surface grinding Slot grinding Tungsten carbide grinding Honing Machining systems Piston ring grinding Bearings: race, track, ball and needle grinding ID, OD, centerless grinding Driveshaft, crankshaft, connecting rod grinding Non-metallic - countertops, fiberglass, phenolic resins,ceramics, powdered carbon grinding, sawing, sandingOBERLIN FILTERS ALLOW YOU TO PRODUCE BETTER RESULTS WHILE LOWERING YOUROPERATING COSTS.NEED:FEATURE:BENEFIT: Produce better grinding results High performance media and depthfiltration delivers 10 ppm solidsabove 10 microns Improved surface finish Less wheel loading/burn Better part size control Less heat build-up Reduce metalworking costs Virtually all particles 15 micronsremoved Filter cakes 80% by weight in typicalsteel grinding Less tool wear Less wheel dressing Minimal coolant loss in cake,less makeup coolant Extended coolant life Cut swarf disposal costs/increasereclamation revenues Automatic drying of filter cake withcompressed air Reduced landfill costs Easy reclamation Reduce medical costs and increaseproductive time Clean coolant Removal of fines cuts down ongrowth sites for bacteria and fungus Reduces dermatitis Decrease filtration costs High-pressure filtering Completely automatic operation Optional cleanable media Lengthens water-based coolant life5 to 10 times No labor needed to unload Less media usage2

O B E R L I N P R E S S U R E F I LT E R SBASIC CONCEPT: DIRT FILTERS DIRT. GOAL: ECONOMICAL FILTRATION.The idea is to pass liquids contaminated with solids through media, trapping the unwanted solids in, then on, the media. The goalfor the most economical filtration cost is to lengthen the filter’s cycle time. This maximizes the quantity of the unwanted solidsper area of media to reduce media costs. Long cycles mean the filtration process is working with fewer interruptions for mediachanges. This increases the capacity of a filter. Smaller filters cost less and take up less space than larger filters. As the unwantedsolids build up on the media, the flow of the liquid is impeded. Unless the liquid is highly pressurized, the flow of the liquidthrough the filter will drop quickly and not satisfy the flow capacity required.Oberlin Filters pressurize the liquid by pumping it into a chamber whose only outlet is through the unwanted solids on the media.The pressure is limited only by the size of the pump, not by atmospheric pressure. 30-40 psi is typical of an Oberlin Filter. This isabout three to four times more pressure than gravity or vacuum filters can develop. The time it takes to reach 10 psi is much lessthan the time to reach 30-35 psi in many applications. The graph below shows a typical relationship of filter pressure versus time.40CASTIRON*30FILTERPRESSURE(PSI)STEEL*20AREA OFOPTIMALFILTRATION101020304050607080TIME (MIN)* Actual cycle times will vary from application to application and even on the same coolant and machinedepending on the workpiece material, wheel, stock removal, particle size removed and amount of wheel dressing.EXTEND YOUR OIL OR WATER-BASEDCOOLANT SERVICE LIFE. OBERLIN’S THICKERCAKES TRAP FAR MORE GRINDING FINES. Filter cakes over 80% solids by weight in typical steel grinding. Lengthens water-based coolant life 5-10 times. High performance media and depth filtration typically delivers lessthan 10 ppm solids above 10 microns. Accepts most commercially available disposable media –low-cost/light weight or heavy/high-performance types. Optional, cleanable, semi-permanent belts availablefor certain applications. Discharges a dry cake with less coolant loss.3

O B E R L I N P R E S S U R E F I LT E R SHOW THE FILTER WORKS1. FILTERING CYCLE:First the pneumatic airbag holds the filter upperchamber against the lower chamber. Platenseals on the perimeter of the chambers createa liquid-tight seal completely around the filtermedia or cleanable belt. Solids-bearing liquid ispumped into the upper chamber. Pump pressureforces the liquid through the filter media orcleanable belt. The filtered liquid is collected inthe lower chamber and drains out. Solids are heldback by the filter media or cleanable belt.Cleanable BeltPaperless System2. DRYING CYCLE:When the filter pressure reaches 30-40 psi (orhigher in some applications), pressurized air orgas is fed into the upper chamber. This forcesthe liquid through the filtered solids and mediaor cleanable belt. After the solids are dried,determined by the back pressure and timeelapsed, the chamber is lifted.Cleanable BeltPaperless System3. DISCHARGE CYCLE:The solids are automatically discharged using adisposable media reroller or an endless cleanablebelt conveyor. The solids are discharged into ahopper. After discharging, the upper chamberautomatically descends and a new filtrationcycle starts.Cleanable BeltPaperless System4

O B E R L I N C O M P L ET E C O O L A N T S Y S T E M SDESIGNED TO MEET YOUR SPECIFIC REQUIREMENTSHIGH PERFORMANCE CENTRAL SYSTEMHigh-Performance Filtration for Grinding ApplicationsWhen your need is for 100% filtration, an Oberlin highperformance stand-alone system will provide you with a continualflow of the highest quality clean coolant. Installing an Oberlinhigh-performance pressure filter is your assurance that yourmachine tools always receive clean coolant and never need to stopfor filter cycling.Cake Dry ValvePlant AirFilter MediaFeed RollMachineToolDry CakeDischargeFilterFeed PumpClean SupplyPump(s)Rerolled Spent llectionHopperDirty TankClean TankSLIPSTREAM SYSTEMPolishing Systems for a Wide Range of Grinding orMachining ApplicationsHow a high-flow slipstream system works: used coolant is pumpedout of an existing tank to the filter. From there, the clean coolantflows back to the tank. There is minimal disruption to the existingsystem. The bulk of the solids are typically discharged with theexisting dragout/conveyor.Inlet ValveMachineToolDirty FluidReturn Line(s)How a high-performance system works: used coolant flows bygravity or is pumped into the dirty compartment. From there, theused coolant is pumped into the filter where it gravity flows out ofthe filter into the clean compartment. Excess flow from the cleancompartment overflows to the dirty tank where it is refiltered.When the filter pauses to dry and discharge, the dirty tank acts asa buffer and stores coolant. When the filter comes back on linein 1.5 - 2 minutes, the dirty fluid level is lowered and the cleancompartment returns to full.Clean FluidTo MachinesCake DryValveDirty FluidReturnFor general machining applications requiring a high-flowcapability, an Oberlin slipstream pressure filter will provide youwith high-removal efficiency of fine, non-settling solids. With only10-20% slipstreams, significant reductions in solids levels havebeen achieved.Dirty Fluid InletSingle/Multiple Machine ToolsFilterFeedPumpCleanSupplyPump(s)Filter MediaFeed RollInletValvePlant AirDry Cake DischargeRerolled Spent MediaOBERLINPRESSUREFIL TERSolids Collection HopperExisting Filter SystemClean Pump Wellor Clean TankAncillary System Components Chillers Automatic Coolant Makeup Level Controls Tamp Oil Removal Systems Sump Tank Systems All components specially engineeredto your requirements.5

O B E R L I N P R E S S U R E F I LT E R SAVAILABLE IN A WIDE RANGE OF SIZES AND FLOWSEnglish & Metric SpecificationsModelFiltering Area (Sq. Ft.)Footprint (in.) L x W x HTank (Nominal) L x W x HCapacity (gpm)Water Base*Capacity (gpm)200SSu Oil**OPF-2MLP263 x 47 x 56108 x 72 x 369550OPF-2MDOPF-4MLP2493 x 57 x 6668 x 53 x 56108 x 72 x 36129 x 84 x 36951005060OPF-4MDOPF-6MLP4696 x 62 x 6677 x 60 x 56129 x 84 x 36165 x 108 x 4816024080100OPF-7MDOPF-9MLP79107 x 71 x 6893 x 60 x 56190 x 108 x 48190 x 108 x 48280240115150OPF-12MLPOPF-12MD1212112 x 62 x 56110 x 87 x 81190 x 108 x 48190 x 108 x 84240480200200OPF-18MDOPF-21MLP1821134 x 94 x 81131 x 71 x 64240 x 130 x 84190 x 108 x 84720440300325OPF-24MDOPF-36MD2436148 x 94 x 81191 x 94 x 87276 x 120 x 84360 x 130 x 849601440400600OPF-50MD50174 x 129 x 91Application Dependent2000835Filtering Area (Sq. Meters)Footprint (m) L x W x HTank (Nominal) L x W x HCapacity (lpm)Water Base*Capacity (lpm)200SSu Oil**OPF-2MLP0.21.6 x 1.2 x 1.42.7 x 1.8 x 0.9350180OPF-2MDOPF-4MLP0.20.42.4 x 1.4 x 1.71.7 x 1.3 x 1.42.7 x 1.8 x 0.93.3 x 2.1 x 0.9350370180220OPF-4MDOPF-6MLP0.40.62.4 x 1.6 x 1.72.0 x 1.5 x 1.43.3 x 2.1 x 0.94.2 x 2.7 x 1.2600900300370OPF-7MDOPF-9MLP0.70.82.7 x 1.8 x 1.72.4 x 1.5 x 1.44.8 x 2.7 x 1.24.8 x 2.7 x 1.21050900430560OPF-12MLPOPF-12MD1.11.12.8 x 1.6 x 1.42.8 x 2.2 x 2.14.8 x 2.7 x 1.24.8 x 2.7 x 2.19001810750750OPF-18MDOPF-21MLP1.723.4 x 2.4 x 2.13.3 x 1.8 x 1.66.1 x 3.3 x 2.14.8 x 2.7 x 2.12720166011301230OPF-24MDOPF-36MD2.23.33.8 x 2.4 x 2.14.9 x 2.4 x 2.27.0 x 3.0 x 2.19.1 x 3.3 x 2.13630545015102270OPF-50MD4.64.4 x 3.3 x 2.3Application Dependent75703160Model* Nominal rate for steel OD grinding with 60 grit wheel. Consult factory for more precise estimates. ** Nominal rate for gear grinding, decrease for higher viscosity, increase for lower viscosity oil.UTILITY REQUIREMENTSELECTRICAL: All voltages Supported Including 120, 230,400, 460 VAC and 24 VDC 50 Hz and 60 Hz 5-Amp Base PowerPRESSURE LIMITS: 45 PSIG Standard 3.1 bar StandardOBERLIN FILTERMEDIA & PARTS6AIR:DESIGN STANDARDS: 4-6 SCFM/ft2 for 1-2 Minute Duration/Cycle NFPA (Oberlin Standard), UL, CSA, IEC,CE, Automotive 80-100 PSIG IEC, CE, Automotive 70-110 m3/hour/m2 for 1-2 minutesDuration/CycleCAPACITY: Up to 3 ft3 Solids/hr/ft2 of Filter AreaThe Oberlin Filter Media Department prides itself on providing only quality, 1st tierfiltration grade filter paper at competitive prices for all sizes of Oberlin Filter models. Inaddition we also carry an extensive line of various gravity & vacuum filter paper as well.Oberlin Filter Company stocks a large assortment of common items, along withproprietary parts for all models of Oberlin Filtration systems. Our experienced OberlinSales team is committed to making the ordering process as easy and accurate as possible.

WHY OBERLIN Experience: Oberlin Filter Company has been designing and manufacturing High Quality Pressure FiltrationSystems for over 50 years for all types of Metalworking Applications Quality and Integrity: Oberlin Filter is a family owned company that truly understands reputation meanseverything and is guided by the simple principle : Make Filters that Really Work Pressure Filtration Authority: Oberlin Filter Company only manufactures Pressure Filtration Systems and we makethem better than anyone else. Others may offer pressure filters as an option, but they do not have the experienceof Oberlin in applying and making them work Dedication to Service: Our Knowledge & Experience allows Oberlin to provide World-Class Service/Support forour customers in the field Global Presence: Oberlin Filter Company has additional facilities located in England and Germany to provideglobal support. Each facility provides equipment, service and support along with filter paper/partsWHY OBERLIN PRESSURE FILTRATION Cleanest Liquid: Highest Differential Pressure of 30 PSI (4X Greater than Vacuum Filters Operate At)and True 4-Sided Sealing allows optimal filtration providing the cleanest liquid for your process Dry Solids: Dry solids minimize or eliminate disposal and fluid makeup costs Reliability & Maximum Machine Up-Time: The Oberlin Filter has very few moving partswith a simple heavy duty design. Filter is located above the Tank which eliminatesneed to drain Tank allowing easier maintenance Modular Design: Oberlin Filtration Systems are completely Modular allowing thesystem to fit into tight or irregular shaped spaces to help maximize floor space Versatility: The Oberlin Pressure Filter can handle high volumes of coarse solidsor low volumes of very small solids Economical and Environmentally Friendly: Clean Liquids / Dry Solids REDUCE AMOUNT of MATERIAL to LANDFILL MINIMIZE / ELIMINATEFILTER PAPER USAGE and REDUCE VOLUME of SOLIDS REDUCE CHEMICAL CONSUMPTION EXTEND LIFE of COOLANT and TOOLING MAXIMIZE EFFICIENCY with CENTRAL SYSTEM FILTRATION while using MINIMAL FLOOR SPACE DRY CAKE AUTOMATICALLY DISCHARGED from FILTER LESS REJECT PARTS REDUCED MACHINE WEAR MINIMIZE COOLANT CARRY-OUTTHE LAST FILTER YOU WILL EVER NEED TO BUY BECAUSE OBERLIN PRESSURE FILTERS WORK !!!!!!OBERLIN PRESSURE FILTERS FOR ALL YOUR FILTRATION NEEDSLOW SOLIDS – POLISHING:- Phosphate System- Plating Baths- Cooling Towers- Alkaline/Caustic Cleaner Baths- UF/RO Prefiltration- Clarifier Overflows- Metal Working Fluids and CoolantsHIGH SOLIDS/HIGH TEMPERATURE/HIGH CORROSION:- Crystallizers- Wet Scrubbers- Reactor Separations/Cleanouts- Radioactive ProcessingBACKWASH SEPARATIONS FROMTUBULAR/PRESSURE LEAFS:- Brewery- Winery- Chlor-Alkali- Juice Processing- ChemicalBATCH PROCESSING:- Specialty Chemical Separations- Sludge Dewatering- Clarifier Underflows- Pelletizer Water- Colloidal Solutions7

O B E R L I N F I LT E R C O M PA N YOFFERS COMPLETELY INTEGRATED SERVICESOberlin Filter Company’s modern, newlyexpanded offices and manufacturing facilityare conveniently located on ten acresin Waukesha, Wisconsin (a Milwaukeesuburb). Our completely integratedoperation includes lab, design andengineering, prototyping, manufacturingwith total quality control, startup andtesting. We also offer continuing technicalsupport for media selection and ourindustry-wide database allows us to ensurethat you are getting optimal results for yourfiltration. The plant warehouses a largeinventory of components and disposablemedia to support all Oberlin Pressure Filtersalong with other brands.L A B O R AT O R YWe offer free lab testing for processevaluation and equipment sizing.Small samples can be analyzed fordewatering rate, filtrate quality andcake dryness. Upon test completion,a report summarizing the results isissued. Pilot filters are available for fieldtesting. Laboratory support is alwaysavailable to our existing clients forprocess improvements.ENGINEERINGOur engineering group works closelywith our customers to develop systemspecifications and to insure all systemsmeet those specifications. All phasesof design and manufacturing aredocumented as part of our qualityprogram. A manual is provided witheach filter complete with drawing,parts list, sequence of operationsand maintenance.SERVICEAs part of our commitment toquality, our service department wasestablished for after-sale customersupport. Our service and engineeringstaff are available 24 hours a day toanswer technical questions, assist introubleshooting and to ship out spareparts. Qualified field service personnelare available for on site start-ups andmaintenance work anytime, anywhere.Agent manufacturier pour l'Est du Canada:418-564-3996English OperationsOberlin Filter LtdUnited KingdomPhone: 44 (0) 1325 317900Fax: 44 (0) 1325 nfilter.comCorporate HeadquartersOberlin Filter Company827 Silvernail RoadPewaukee, WI 53072-5588Phone: 262 547-4900Fax:262 547-0683Email: man OperationsOberlin Filter GmbHPhone:49 (0) 2403/5043-0Fax:49 (0) erlin-filter.de

OPF-21MLP 2 3.3 x 1.8 x 1.6 4.8 x 2.7 x 2.1 1660 1230. OBERLIN PRESSURE FILTERS FOR ALL YOUR FILTRATION NEEDS Pressure Filtration Authority: Oberlin Filter Company only manufactures Pressure Filtration Systems and we make .