Transcription

U . S. Department of CommerceNational Bureau of StandardsResearch Paper RP2086Volume 44, April 1950Part of the Journal of Research of the National Bureau of StandardsHeats of Combustion and Formation of Cellulose andNitrocellulose (Cellulose Nitrate)By Ralph S. Jessup and Edward 1. ProsenThis paper gives t he results of bomb calorimetric measurem ents of heats o f co mbu stionat 30 C of o ne sampl e of cellul ose and four samples of nitrocellulose fr om cotto n linters,and of one sample of cel lulose and four sampl es of nitrocellul ose from wo od pulp. Th eres ults have been combined with values for the heats of formation of carb on d ioxide a ndwate r to obtain values of heats of formation of t he celluloses a nd nitr oc e lllllo es . Emp iricaleq uations are given ex pressin g heat of comb ustion and h eat of formation of the nitrocel lulosesas fun ctio ns of nitroge n conte nt.1. IntroductionThe work described in thi s papcr was don e atth e request of th e N alion al Defense R esea rchCommitt ee, a nd the res ults were ori gin a lly r eported in their Armor a nd Ordnanc e Repo rt No.A- 285 (OSRD No. 3932).The data presen ted in tllis pa per differ fromtho se given in the above report in th e follow in grespects: (J ) the resul ts are now expressed interms of the absolu te joule in stead of t b e in te1"national joule as th e fundamental energy unit;(2) the res ul ts have been r edu ced to the basistha t all gases in volved in the r eac tion s di sc ussedare in the thermodynami c s tate of uni t fu gacityLot;\0.instead of the stale of l he r eal gases at atm os ph ericpress ure.II. MaterialsTh e materials whose h eat of combu slioll .h avebeen determined wer e miLcle avail abl e to th eNational Burea u of Stand ard s through a rran gements mad e by t il(' National Defense R esearchComm iL tee with th e Office of the Chief of Ordna ncc, IiVa l' D epar tmell t.Th e lots oJ eellulose from colto n lin te rs andwooel pulp wcre obLiLin ed from t he HerculesPowder Co. , Radford Ordnan ce Works, Radford,Va. For th e nitrocellulose, the manufacture!',mft tel'ial nitriLted , iLnd th e ni t rogen contents wereas follows:Source of cellulose)j" anufact urcr?\ itrogcll-----P ercentA 4801 SL Cotto n lin te rsA 4803S7 doEPA 1963 RRSL Wood pulpEPA 1964 HRS7 do403-74- 2 Cotton lin ters416-50 clo403- 74- L . \1iT ood p ul p416-49 doThe analyses for nitrogen wel'e made by theHercul es Powd er Co. The samples of celluloseand nitrocellulose were reg ular plant amples.B ecause of the urgent n eed for the datiL, and as theHeats of Combustion of Nitrocellulose13. 4212.6213. 3612.5312. 14II. 4912. 12I I. 7- -- - - - - - - - - - --jR ercLl les Powder Co., Hadforcl Ordnan ce \Y ork s, Hadford Va.}H"'"'''' P",d" Co.,Pad;" , N. J.h eats of combustion oJ the actual plant sampleswere desired, no atlemp t was miLde to purify thesamples further .38l

III. Preparation and Weighing of SamplesThe following procedure of preparation andweighing of the samples was followed. A batchof cellulose or nitrocellulose sufficiently large toserve for all the experiments on that sample wasplaced in a desiccator, which was evacuated untilthe material seemed dry and fluffy. Then portions about 10 percent larger than the amountneeded for an experiment, about 2 g, were roughlyweighed out and placed in separate beakers.These portions were then wetted with distilledwater and were compressed into tight pellets in apellet press. The pellets then contained approximately 20 to 30 percent of water. These pelletswere placed in separate weighing bottles havingground-glass necks and evacuated in a desiccatorfor about 3 to 8 hr. The bottles were thenplaced in an oven, kept at 100 C for 1 hr, cooledin a desiccator, stoppered with their ground-glassstoppers, and weighed against a tare (an emptyweighing bo ttle of the same size). They wereagain placed in the oven at 100 C for intervals of7f hr until constant weight (within about 0.1 mg)was obtained. This was usually reached withinabout 2 hI' in the oven at 100 C. About 10percent of water, an amount that was found toproduce the best conditions for burning the samplesin the bomb, was added to the pellets, and thepellets were transferred from the weighing bottlesto the platinum crucible in which they were to bebumed. The weighing bottles, together h anyparticles of sample left in them, were put m theoven at 100 C for 1 hr and reweighed against thetare. From these weighings the weight of drysample was obtained.All weights were corrected to the vacuum basisusing the factor 1.00080, obtained by assuming avalue of 1.25 g/ml for the density of dry celluloseand nitrocellulose.IV. Apparatus and Method for Measurements of Heats of CombustionMeasurements of heats of combustion were madeby burning weighed samples of the material inoxygen in a constant-volume bomb that was partof a calorimetric system described elsewhere[1, 2, 3).1 The bomb was made of a corrosionresistant alloy (illium) and had a capacity of1 Figures in brackets indicate the literature references at the end of thispaper.3880.380 liter. Two types of experiments were made.In one of these a measured quantity of energywas supplied to the calorimetric system, and theresulting rise in temperature was observed. Inthe other type of experiment a weighed sample ofcellulose, or nitrocellulose, was burned in thebomb, the resulting rise in temperature was observed, and the mass of carbon dioxide formed wasdetermined. The first type of experiment givesthe energy equivalent (effective heat capacity)of the calorimetric system, and when the energyequivalent is known, the temperature rise in thesecond type of experiment is a measure of theheat produced by combustion [4, 5]. For eachexperiment the mass of the dry sample of materialburned, the mass of carbon dioxide formed incombustion in the bomb, and the mass of carbondioxide formed in subsequent oxidation of gaseousproducts of incomplete combustion were determined. The mass of carbon dioxide formed byoxidation of the products of combustion wasusually 0.01 or 0.02 percent of the mass formedin combustion in the bomb. Correction for incomplete combustion was made on the assumptionthat the only product of the incomplete combustionwas carbon monoxide. The details of the methodsused have been described elsewhere [3, 6] .In connection with the correction for the heatof formation of nitric acid in the bomb, the question arose as to whether some nitrous acid mightalso be formed, especially when the nitrocelluloseswere burned in the bomb . To answer this question tests for nitrous acid were made by W. S.Clabaugh 2 o'n the washings from the bomb aftereach of four combustions, two of benzoic acidand two of nitrocellulose. The air initially inthe bomb was flushed out with oxygen beforeburning th e two samples of nitrocellulose andbefore burning one of the samples of benzoic acidbut was not flushed out in the case of the secondsample of benzoic acid. The amount of nitricacid formed in the second combustion of benzoicacid was, therefore, several times that formed inthe first. The amount of nitrous acid found didnot exceed 0.5 percent of the total acid formedin any of these experiments. The error int.:'oduced into the results of heat of combustlOnmeasurements by assuming all the acid to benitric acid is entirely negligible.2Chemistry Division of the National Bureau of Standards.JoW'nal of Research

V. Calibration of CalorimeterThe energy equivalen t of the calorimeter forthe temperature interval 28.5 to 30 C wasdetermined by burning NBS Standard Sample39f of b enzoic acid in the bomb, usin g th e value26433.8 absolute joules per gram mass (weight invacuum), r ecently obtained in this laboratory[3 , 9, 10], for the heat of combustion of thismaterial under the conditions of the standardbomb process at 25 C. Appropriate correctionswere made to take account of differences betweenthe actual and standard bomb processes. Theresults of these calibration experiments are asfollows: Series I , five exp eriments, energy equivalent 13862 .6 2.1 (standard d eviation of m ean )joules per d eg C; Series II, six exp eriments, cnergyequival ent ] 3833.9 1.2 (sdm) joules per d eg C.These values of energy equivalen t are for th ecalorimeter containing the same mass of wateras in th e experiments on th e ni trocelluloses, andwith the bomb contalning 1 g of water and oxygenund er a pressure of 30 atm at 30 C. In them casuxemen ts on the nitroeelluloses th e valuesused for th e energy equivalent differed from th emean values given above by two small corrections, one for the h eat capacity of the charge ofnitro cellulose and one for the h eat capacity ofthe oxygen in the bomb in excess of that r equiredto fill it to 30 atm at 30 C.The mean valu e of the en ergy equivalent obtained in Series I was used in calcula tin g theresults of m easurem ents on the samples of nitrocellulose mad e from cotton linters and con taining11.49 p ercent and 12.]4 percent of nitrogen .After the m easurem ents on these samples werecompleted, the insulation of the firing elec trodein the bomb failed , and the n ecessary repairsinvolved some change in the heat capacity of thebomb. The calorimeter was therefore reealibra ted with the repaired bomb. The calibrationexperiments of the second series were made underthe same conditions as those of the first, exceptthat the calorimeter contained a smaller amountof water in the second series. Th e m ean valueof energy equivalent obtained in Series II wasused in calculating the results of all m easurem entsof heat of combustion, except tho se on th e twosamples of nitrocellulose just m ention ed.Heats of Combustion of NitrocelluloseVI. Calorimetric Experiments on Celluloseand Nitrocellulose1. Measureme nts of Heat of W e ttingSince th e samples were wet when ignited in th ebomb , the observed h eat produ ced by combustionof each sample was lower than thaL for th e drysample by an amount equal to th e heat of weLLingof the dry sample with t h e amount of water addedto it. In order to obtain data for correeLing th eobserved heats of combusLion for t his effect,m easurements were mad e of the h eats of wettingof the various materials.The method used was similar to that describedby Katz [7]. Samples of 2 to 5 g of each celluloseand nitro cellulose were placed in weighed glasstubes of about 12-mm inside diameter, one endof which was drawn down to a fine capillary andscaled . The samples were th en dried in vacuum(residu al pressure less th an 10- 4 mm of m ercury)until no water could be detected with the McLeodgage after th e vacuum pump had been shut off forseveral hours. Dry air was then admitted Lo thevacuum space, and the tubes wer e removed, corkedimmediately, and weighed.To determine the h eat of complete wetting, atube containing dry material was immersed in thewater of a calorimeter with the sealed end downand the open end proj ecting 2 or 3 cm above thetop of th e calorimeter jacket. The top of thesample of material in the tube was 6 cm or moreb elow the surface of the water in the calorimeter.The temperature of the water in th e calorimeterwas slightly lower than that of the jacket, so thatthere was no h eat transfer by evaporation of waterfrom the calorimeter and condensation on thejacket. After sufficien t time h ad elapsed for th eattainment of a steady state, a series of readingsof calorimeter temperature and corresponding timewas made. The fine capillary at th e bottom ofthe glass t ube was then broken by pressing itagainst the bottom of the ca,lorimeter vessel, permitting water to rise in the tube and wet th e material contained therein. R eadings of time andtempera ture were continued for about 10 minafter th e rate of temperat ure change had becomecon stant. Similar measurem ents wer e made onsamples to which small kliown amounts of waterhad been added after drying and weighing.389

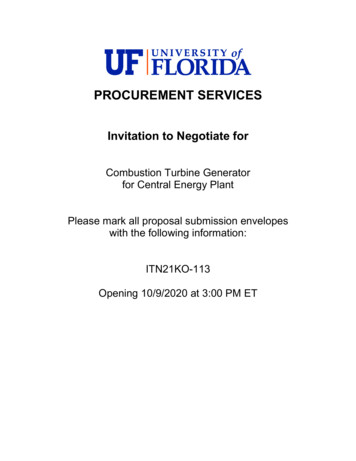

The results of the measurements of heat. ofwetting of the completely dry materials are givenin table 1, together with valu es calculated for th enitrocelluloses from the empiri cal eq uation:(2 93.20 - 67lj, (0.115;;;'.1;;;' 0.135) ,where Q is heat of wett ing in joules per gram , and.1 is the mass fraction of nitrogen in th e sample.TARLEl.17alues fu r heats of wetting oJ samples of drycellulose and n i trocelluloseHeat of wcitin gSource of celluloseObserved1\itroge n 1 - - - - - ; - - - - 1 m inuscalcuconte ntlatedo bserved : ;r-------------- - - - - - - ------CoLton lintcrsD o\,"ood pulpDoCotton linter3D oDoD oDoWood pulpDoDoDoD oPercent0. 00. 00. 00. 00It. 49II. 4912. 1412. 6213. 4211. 74J I. 7412.1212.5313.36jfg47.745. 959.358.616.516.611. 78.53.814. 913. iJ I. 28. i3. ,Ijig16. 116. 1It. 78. 53. 214. 414. 4II. 99. 13. 6j ig 0. 4 . .)0.0 .flof th e gaseous reactan ts and products is in itsth ermodyn amic standard state of unit fugacityat 30 O. The correctio n for h eat of wettingwas made on th e basis of th e observed value forh eat of wetting of th e dry material, alld th e datarepresented by th e dash ed curve of figure l.In column 4 of table 2 are given valu es of th eratio of carbon di oxid e formed in combu stion inthe bomb and in oxidation of produ cts of incomplete com bus lion to tb a t calculated from th emasses of dry sa,m pIes, based on th e assump tionth at t h ey were pure cellulose or nitrocelluloserepresented by the form ula C6Hl 0- X0 5( 0 2) X' Iffis the m ass fraction of ni trogen in the sample andm th e m ass of sample bllrned, then the calculatedm ass of carbon dioxide was taken as (l.62859- 5.23177f )m. The values of atomic weights usedill this and oth er calc ul ations connected with thisr eport a re 0 16 .000 ,0 12 .01 0, H l.0080 , andN 14.008.3. Further results derivable from experimentaldata .5-. i-. 7- .4-.2The resul ts of mel:l.SLlremen ts on samplrs co ntaining small amounts of water are shown graphically in fi gu re 1, where th e abscissa is the mass ofwater pel' gram of dry material, and th e ordinateis the diffrrence between the h ea ts of wetting ofth e dry and wet materials expressed as a fractionof the h eat of wetting of the dry material. Thesolid curve in figure 1 represents data calcula tedfrom Katz 's [7] equ ation for cellulose. Th edashed curve is drawn th rough the poin ts representing th e experim ental d ata obtained in thisinvestigation .It will b e seell from table 2 that the averagovalu es of the r at io (car bon dioxide formed: carbondioxide calculated ) are less than unity by amountsranging from 0.4 to 0.9 percent, indicating th atth e samples probably con tain ed at least th e corresponding amounts of impurity. If it is assumed1.0().r;:,00 .8iIIw 0 .6ozw'"two/- 6f-- f.-//II0.4II0.22 . Results of Measurements of Heats ofCombustionThe results of th e measurements of heats ofcombustion at 30 0 ar c summari zed in table 2.The observed values of - t:. UB , th e h eat of combustion under th e condit ions of th e bomb process,were corrected for h eat of wetting, and redu ced ,in accordan ce with th e procedure outlin ed b y""'IVashburn [8], to th e correspondin g values of- t:. U , the decrease in internal energy accompanyI ng t he comb us tion reaction when each390ooFIG URE0.10.20 .30.40.5g WATER / g DRY MATERIAL0 .60 .71. R esults oJ m easurements of heat of wetting fo rsamples containi ng small amounts of water.Ab scissa. grams of water PCI' gram of dr y material. Ordinate, difIerc ncebe tween hea ts of we tting of dr y and w ot materials expressed as a fraction o fthe heat of wett ing of the dry material. Solid curve, K at z's data on cellulosc .Dotted cur ve d rawn to represent data obtained in present work . 6 , Cellulose from cotton linters; 0 , nitrocellulose from wood pulp , 11.74 percentnitrogen; D , nitroce llulose from wood pulp, 12. L2 pe rcent nitrogen ; () , nitrocellulose from cotton linters, 1l.49 percen t nitrogen; . , ni t rocellulose fromcotto n li nters, 12.14 percent nitroge n.Journal of Research

T AB L E:Source of cellulose it l'ogc ncontent2.Experimental data on the heats oj combustion'Nu mberOf ex peri-mentsH iid f [ .I;l g dt H eat of com bu stion based onca lculat d- ;,.u.co,jigjig17320.917343. I17352. 6 2.3bI7:385. 9. 18. 910680. 81069:3.811. 4912.1412. 6213.42'. 99577. 994 12b.99489.99407 0.0001 3 O. 00025 0.00014 0. 0001910667.910277. 310013.69538.8' 10667.610272.710005. :39526. 6 3. 1 2. 6 3. 1 1. 9104 28.71.0406. I10393. 010:357. I10428.810401. 4b10385.5103·13.9 2. 42.'1:3.:J2.3I l. 7412. 1212.5313.36. 99338.99238.99 162.99079 O. 00059 0.000 19 0.000 15 0.0002310506.310279. 210029. 29540. I10504. I10273.910021. 99527.7 i.610421;.41041 5. 51039·1. 010357.910·124.210'110.010386.510:IH . 6 2. 22.21.92. I0.00. 00Cotton linters . . .Do .Do . . . . .Do . . .Wooel pulp . .D o.Do ------- -- -- --------Do . , .c- u - ClUBC. 99576 0. 00020b. 99590 O. 00076PercentCotton linters . .Wood pulp . .b- LiU ----- -- - - - - - - - - - - - - -ILHeat of co mb ustion based.onthe mass of sample burned} ll I SS Of carbon dIOx id eca r bon dio x ide'1'ho val ues (ollowing th e s ign in this table arc th e standard d eviations of the1(ean of three exper ime nts.M:ea n of t wo cxpcri lllCJlts.that all tli e impurity in th e "amples \\·as il1 'l'tm atel'i al t hat did not enter into the combu sti onreaction in ti ll y way, then the values gj\·en int a ble 2 base d on th e mass of ca rbon dioxid e formedsho uld be the heats of combu s ti on of pure cellul oseand pure nitro cellulose. Under this ass umpt ion .h o\\·ev('r , the vallles of t il e nitroge n contents mu stb e adj Li sted, clu e to th e fact th at the n i trog-en co ntent of a nitrocellu lose containing jnert impurjt 'is higher than th at reported for the impul"(, sample.If w(' let R be th(' ratio (c arbon dioxid e form ed : carbon dioxid e calculated) (sec table 2), } br themass fr action of n itroge n as r r port ed (sec table 2),and i gr am be the amollnt of impurity P('L' (I -i)gram of C 6H 10-X0 5(N02)X, then it ca n be shownthat1-i R 3.2125}(1 - R) .The con eded value,./' , of the m ass fraction ofnitrogen in the ni trocellulose isjig 2. 8 2.6 2. 2jig CO,10700. 4 2. Ut\10720. :1 I . 4m CEL l1.t ion at 30 C as a func tion of tho cOL'l'ected n itrogenconten t. The following eq uat ions, whicb werederived by th e m ethod of least squares, represe ntthe heats of combustion pel' g ram of ni t roce llulosewithin abo u t 0.03 percent. For nitro cellulosefrom cot ton linters:M-I -4 1 69 .; 2 l4069.1'caljg (0.11 5 j' 0.13 5).(1)For nitrocellulose from wood pulp :Ml - -1186.3 6 1420Ql' cal/g (0.115 } ' 0.1 35),(2)where}' is th e correc ted frac tion of nitl'ogen in thenitrocellulose.T ABLE3.Derived data Jor cellulose and nitrocelluloseCorrectedSource of cellu lose-Clu nitrogenat 30 C-tl ]f I- Cllf,conte ntat 30 C at 30 CPercentcatlgcatlgcallunitrocel- nilrocel- nitroceltutoselulo8elulo8e------}, L.I -'/,CoLton linte rsTh e derived values for the h eats of combustionand formation of cellulose and nitrocellulose, together with the corrected nitrogen contents, aregiven in table 3. Tbe propel' values for the heatsof formation of gaseous carbon dioxide and liquidwater at 30 C were t aken from refcrence [19).It was found that the data on the h eats of combustion of the nitrocellulose could be representedby lineal' equations exprcssing the heat of combusHeats of Combustion of NitrocelluloseWood pulp .------Cotton lill ters .Do .1)0 . .D o.----\\"ood pul p .Do .D o.Do . .1\.i/uCO,10700. 4 2. 9 10720.3 4. 'I41 65.04172. 841 65. 041 72. 81421. 01413.2I L 5212.1812.6613. 4610428. 810401. 410385. 51034.3. 9 2. I 2. 4 3. 3 2. 32557. 02464.02398. 72284. 72.)48.32454.82389. I2274. 5689. 5647.9617.0567. 011 . i910424. 210410.010386.510344. 6 2. 2 2.2 1. 9 2. I252 1. 02466.92407.32289.225 12. I2457.82397.82279. 1671. 2646.362!. 5569.40.00. 0012. 1812.5913. 43Standard de dation of the mean.391

20(;(;(;-10'""if)w 0---a:g l: 0'-'0- ----'V-10'"()z -200 ()()5 -30w()'"()()'"0. ",0 -40 -50II12131415NITROGEN CONTENT. %2. Devi ations of values of heat of combustion( - - H ) derived from results of various observers fromeq 3 of the present work.FIG U REO. Present work, nitrocellulose from cotton linters (300 C); presentwork. nitrocellulose from wood pulp (30 0 C); \1, Sarrau a nd Vieille (150 C)[ll];R ast [12] ; Muraour [13]; (), Prettre (20 0 C) [14]; A , Kozo Tomioka[15]; . Scbmidt a nd B eck er [16]; 0, Milus (250 C) [17]; /';. Taylor andnall (17 0 C) [18]. ,If we consider all the nitrocelluloses together, thefollowing equation represents the data withinabout 0.05 percent :tlH - 4176.70 14126j'caljg (0.115 j' 0.135).(3)Similar equations can be derived expressing tlHPat 30 C as functions of nitrogen content. Thusthe following equation, based on the data on allthe nitrocelluloses, represents the values given intable 3 on the nitrocelluloses within about 1.3caljg:tlH j - 5896.88 26178j' caljg (0.115 j' 0.135).(4)The data on the nitro cell uloses are plotted infigure 2. The abcissa is the nitrogen content ofthe nitrocellulose, while the ordinate is the deviaTABLE4.MaterialVII. Results of Previous MeasurementsM easurem ents of h eats of combustion or h eats ofexplosion of nitrocelluloses have been reported bySarrau and Vieille [11], Kast [12], Muraour [13],Prettre [14], Tomioka [15], Schmidt and Becker[16], Milus [17], and Taylor and Hall [18]. Infigure 2 the results of various investigators arecompared. The values of - !1H attributed toprevious investigators were derived as follows:3 I t is of interest to compare tbe data on cellulose and nitrocellulose witbsimilar data on etbanol and ethyl nitrate. Tbe differen ces between tbe beatsof formation of cellulose and nitrocellulose range from 24.4 to 25.0 kcal pernitrate gro up. Tbe corresponding difference between the heats of formationof liquid ethanol and liquid ethyl nitrate (referen ce [19], tables 23-29and 2.1-45 (1948» is 22.1 kcal. Combination o[ the latter value w itban accurate value for tbe heat of [ormation of cellulose would, tbere[ore, b ave y ielded values [or the heats o[ formation of d initrocellulose and trini·trocellulose in error by about 5 and 7.5 kcal per monomer unit. res pectivel y.H eats of combustion and formation of cellulose, dini trocellulose, and trinitrocellulose- 6 (J at 30 CSource of ccll uloseIcallg{cotton lintersCellulose .Wood pulp .rill"'mW" .Dinitroeellulose. . Wood pulp . .Cotton linters.Trinitrocellulose .Wood pulp . .392tion from the heat of combustion tlH'L given byeq 3. The dotted lines represent eq 1 and 2.Although there were significant differencesbetween the heats of combustion of cellulose fromcotton linters and from wood pulp , 0.18 p ercent,and between the nitrocelluloses from cotton lintersand from wood pulp, maximum 0.1 p ercent, itis felt that this probably does not indicate a realdifference in the heats of combustion of pure cellulose or of nitrocellulose from cotton linters or woodpulp . Rather, the differences are an indicationthat the impurities in the materials made somecontribution to the heat of combustion.It will be noted that the nitrogen contents of thenitrocelluloses investigated are all intermediatebetween the nitrogen contents of dinitrocellulose,f' 0.1111 , and trinitrocellulose, j' 0.1414. Thevalues for the heats of combustion and formationof dinitrocellulose and tri. itrocellulose,3 calculatedby substitution of j' 0.1111 andj' 0.1414 intoeq 1 and 2, and the corresponding eq uations forh eat of formation, are given in table 4 along withthe values for the celluloses.4165. 04172.82614.42616.92190. 22188.7kcal/monomer- M'I at30 unitcallg675. 2179.52178.1CI kcal/monomerunit675.3676. 6657.1657.7647.6647.2-t Jf 7 at 30 0 Ccal/g1421. 9.2180.4179.7155.7156. 1Journal of Research

lWhere sufficient data were given, the reportedvalues of heat of combustion or h eat of explosionwere corrected to the basis of the energy unitsused in the present work, and for the ·W ashburneff ect [8], and, where n ecessary, wer c reduced to aconstant pressure basis. The resulting values werethen combined with values for h eats of formation[19] of the products of the combustion 01' explosionreaction to obtain th e values of - t::,I-1 . Thevarious values were not reduced to a commontemperature, because no data on the h eat capacities of nitroeclluloses have been found. Thedifferences b etween the results of different observers are so large that the reduction of the r esultsto a common temperature would not improve theagreem ent to a significant extent.VIII. References[1] H . C. Dick inson , Bul. BS 11, 189 (19 L4) S230.[2] R . S. Je ss up and C. B. G reen, J . Research NBS 13,496 (1934) RP721 .[3] R . S. Jess up, J . Research NBS 29, 247 (1942) RP1499.Heats of Combustion of Nitrocellulose[4] F. D. Rossini, Chem . R ev. 18, 233 (1936).[5] F. D. Rossini and W . E. Deming, J . Wa sil. Acad. Sci.29, 416 (1939) .[6] R. S. J ess up, J . R esear ch NBS 21, 475 (1938) RP1l40 .[7] J . R . Katz, Proc. R oy. Soc. Amste rdam 13 II, 958 (1911).[8] E. W. Washburn , BS J . R esearch 10, 525 (1933)RP546.[9] R . S. J ess up, J. R esearch NBS 36, 421 (1946) RPI71l.[10] NBS Circula r C475, p. 22 (1949) .[11] San'au and Vieille, Com p t. rend . 93 , 269 (J 88 1) .[12] H . Kast, Spre ng- und ;t;i.ind sto ffe p. 71 (1921 ) . Datat aken from refere nce [15].[13] Muraour, Data ta ke n fr om refe rence [15].[14] M. Prettre, Mem. P ou dres 24, 223 (1931) .[15] K Tomioka, J . Cellulose In t ., T okyo 8, 88 (1932).[16] A. Schmidt and F . Becker, Z. ges. Schi ess-u . Sprengstoffw. 28, 280 (1933) .[17] P . R. Milu s, Ind . E ng. Chem. 29, 492 (1937) .[18] J . Taylor and C. R. L . H all , J . Ph ys. C he m. 51 , 593(1937) .[19] Selected va lues of che mical t hermodynamic properties,Nat ional Bureau of Standa rd s, ·Washin gto n, D . C.,Series I , Vol ume I , T ables 8- 1 (1947) and 23- 2(1948).W ASHINGTON, D ecember 14, 1949.393

mined. The mass of carbon dioxide formed by oxidation of the products of combustion was usually 0.01 or 0.02 percent of the mass formed in combustion in the bomb. Correction for in complete combustion was made on the assumption that the only product of the incomplete combustion was carbon monoxide. The details of the methods