Transcription

tiastar with PROFIBUS-DPCommunicationsTMMotor Control CentersAnswers for industry.

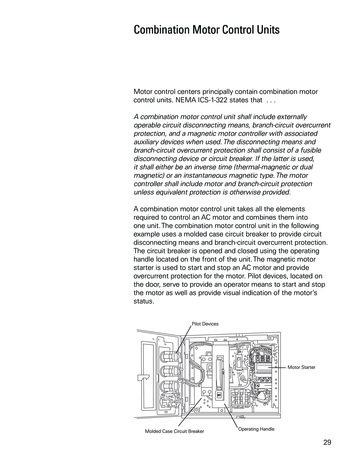

Process managementOperations anceStationPowerManagementEthernetControlPROFIBUS DP Protecting/monitoring Controlling/interlocking Data/communicationsSIMOCODE proSwitchboardTotally Integrated AutomationWhen the tiastar MCC is integrated into a PCS7 DCS or S7 PLC system, users can take advantageof quick commissioning and pre-configured displays for the information from several of the units.Motor Control CentersToday’s motor control centers havecome a long way since the first unitswere introduced back in 1937 to do littlemore than save floor space by placing thestarters in centralized cabinets. Modernprocesses and facilities now dictate thatmotor control centers additionally displaya high level of intelligence as well. Theymust deliver vital operating information;plus provide automation features, optimalcontrol, and critically fast communicationsto meet even the most demandingapplications. Ideally, too, the best-ofthe-best must also save installationtime and money.Introducing the Siemens tiastar MotorControl Center with PROFIBUS-DPcommunications. It does all the above andmore. Combining heavy-duty industrialconstruction and user friendly features,these intelligent units deliver detaileddiagnostics and control by communicatingwith the starter units via PLC/DCS. Thismeans the overload relays of the starters,linked to the PLCs, are now able todeliver detailed motor managementdata at speeds previously unheard of.PROFIBUS-DP, the backbone of the system,not only has the performance bandwidthto communicate the large packets ofdata that a process demands, but alsothe ability to meet the stringentspeed requirements.Gone are the days when a motor controlcenter obtained its data through hardwiredfeedback and controls. The tiastar MotorControl Center eliminates the hardwiringand thus the need for additional items liketransducers and analog input modules. Ofcourse, with elimination of the hardwiringrequirement, the commissioning time isreduced as well. That’s not all. Interfacingto the Siemens S7 and PCS7 systems overthe tiastar Motor Control Center’s fastcommunication bus, increases uptimethrough detailed status and informationfeedback from the driven process loads.Detailed DiagnosticsUtilizing the SIMOCODE Pro MotorManagement System, users now haveaccess to detailed feedback informationto continually monitor their process.In addition, detailed diagnostics andadvanced warning capability from thestarter units allow for predictivemaintenance of motors, thus avoidingunexpected downtime. With theSIMOCODE Pro V installed within thetiastar MCC, users now also haveaccess to power monitoring informationdirectly from each connected motor.

AS-InterfMaste acerTerminalBlockAS-iSlaveSIMOCODE ProRemoteI/0PROFIBUS-DPVFDPLCPROFIBUSTraditional Hard Wired Control in an MCCMany applications of MCCs involve connection of PLCsor I/O to combination motor control units and variousrelated devices for the purpose of feedback and controlof the system. Distributed I/O and conventional PLCwiring can involve the routing and connection ofhundreds of wires as shown in the illustration here,and yet provide only basic feedback and control foreach motor control unit. This traditional wiringmethod requires extensive time and cost forinstallation, terminations, and troubleshootingof individual wiring connections.PLCPROFIBUS-DPEnhanced Control and Feedback UsingPROFIBUS-DP CommunicationUsing PROFIBUS-DP communication within the motorcontrol center greatly simplifies traditional I/O wiring,while providing more detailed process information tothe PLC system. PROFIBUS-DP is an open protocol that isproven and in operation worldwide over a wide range ofapplications. Within the motor control center, PROFIBUSDP is connected directly to a motor management system,variable frequency drive, reduced voltage soft-start,circuit breaker, or power meter, and communicates largedata packages of information at high speed to the PLC.In addition, AS-Interface is an additional communicationsnetwork that can be used for bit level data transfer toremote I/O relays, and easily integrate into the upstreamPROFIBUS-DP network. The result is simplified wiring,more available information on the process, and reducedtime for troubleshooting.

Motor Control CenterSiemens magnetic tripcircuit breakersDoor mounted, operator panelfor SIMOCODE ProPROFIBUS-DPCommunications connectedto each intelligent deviceMM4 variable frequencydrive with PROFIBUS-DPcommunication port

AS-Interface slimline moduleFVNR starter installed withSIMOCODE Pro V3RW40 and 3RW44 reducedvoltage electronic soft startersDoor mounted keypad for MM4variable frequency drivesHigher PerformanceDue to the inherent design of the PROFIBUS-DPnetwork, communication speeds are much fasterthan other fieldbus networks on the market, andallow for larger data packets to be communicatedbetween each started unit and the upstreamcontrol processor. In addition, redundant systemscan be implemented by connecting the tiastarMCC to redundant S7-400 PLC systems availablefrom Siemens.FlexibilityThe tiastar MCC allows the flexibility to configureindividual units to communicate bit level data orlarge bandwidth data packets. Whether the needis for low level communications, or full diagnosticand logic capabilities, Siemens tiastar MCC has asolution for the application. Utilizing AS-InterfaceSlimline Modules in a starter bucket allows for bitlevel feedback and control between the starter andthe PLC, such as ON/OFF status, trip status, breakerstatus, and ON/OFF control. When higher leveldiagnostics and feedback are required, the modulardesign of the SIMOCODE Pro can allow a user tocustomize the information available at the PLC/DCS.

PAC3200 Power MeterWL Circuit BreakersAS-Interface Slimline ModulesGreater FunctionalityThe tiastar MCC with PROFIBUS-DP Communications can allow for automated control of a large variety of differentunit types, including FVNR, FVR, 2-speed, reduced voltage soft starts, variable frequency drives, and power monitoring.In addition, the SIMOCODE Pro Motor Management System has expanded control, I/O, and diagnostic capability tosimplify a wide range of motor control applications.Siemens tiastar Motor Control Centersare packed with components andfeatures to offer optimal motor control,communications, monitoring, protection,and automation interfacing. The WL CircuitBreakers offer integrated communicationsover PROFIBUS to provide real-time dataon breaker status and power utilization.Detailed power monitoring is availablewith PROFIBUS-DP communications viathe PAC3200 Power Meter. Typically, thisis installed at the incoming power supplyto the tiastar Motor Control Center. Itsmonitoring information capabilities canbe extended to the overall MCC line-up viatransmitted data over the PLC/DS network.Bit level communication requirementsbetween the PLC/DCS and starter unitscan be provided by placing AS-InterfaceSlimline I/O module in individual MCCunits to reduce inter-connection wiring tothe PLC. The modules communicate overan AS-Interface network to an AS-Interfacemaster. The information is sent directlyto the connected PLC via the high-levelPROFIBUS-DP network.Central to any motor control center,of course, are its starters. The SIRIUS 3RW44 reduced voltage electronicsoft starters are now available intiastar Motor Control Centers insizes ranging from fractional to 800HP.They can be easily integrated to thePROFIBUS-DP network via an optionalcommunications interface. These unitscan be parameterized, controlled, anddiagnosed remotely by the connectionto the PROFIBUS-DP network.

SIRIUS 3RW44 Reduced Voltage StartersMM4 and 6SE70 Variable Frequency DrivesSpace savings are realized, too, when thesame housing that encloses the starterscan also house the electronic motor drivesthat are typically integral to a processor operation. The tiastar Motor ControlCenters accommodate this need forSiemens full line of MM4 and 6SE70variable frequency drives. Available upthrough 250HP for constant torque loads,the variable frequency drives can bereadily interfaced with PROFIBUS-DPallowing the user to get the status of thesystem, as well as control speed and otherprocess parameters.Automation interfacing for tiastar MotorControl Center units is easily accomplishedby linking either SIMOCODE Pro C orSIMOCODE Pro V modular motormanagement systems to the high-levelSIMOCODE Pro C and SIMOCODE Pro Vautomation system by means of PROFIBUS-DP.Designed for constant speed motors, thesemodular units implement all the motorprotection and control functions, determineoperational, diagnostic and statistical data,plus organize communications data betweenthe automation system and the motor feeder.In addition, SIMOCODE Pro V has powermonitoring functionality (Amperes, Voltage,Power Factor (cos phi), Active Power) thatcan be coordinated with the control logic forloss of load tripping.

Siemens provides these solutions through our 400,000employees to millions of customers and hundreds ofthousands of suppliers and partners in more than 190countries. That means you are selecting a long term partner,who can deliver globally and has the market position andtradition of innovation to provide best in class solutions.“The tiastar Smart MCCs, communicationsvia PROFIBUS, and our experience withSiemens automation technology haveeliminated plant downtime and savedlabor and material costs in excess of 150,000 annually.”Thomas Roe,Maintenance SupervisorArizona Chemical(a division of International Paper)Siemens Industry, Inc.Industry Automation Division3333 Old Milton ParkwayAlpharetta, GA ens.com/mccSubject to change without prior notice.Order No.: CCBR-SMCC2-1009All rights reserved. Printed in USA. 2009 Siemens Industry, Inc.The information provided in this brochure contains merelygeneral descriptions or characteristics of performancewhich in case of actual use do not always apply as describedor which may change as a result of further developmentof the products. An obligation to provide the respectivecharacteristics shall only exist if expressly agreed in theterms of contract.All product designations may be trademarks or productnames of Siemens AG or supplier companies whose use bythird parties for their own purposes could violate the rightsof the owners.

Gone are the days when a motor control center obtained its data through hardwired feedback and controls. The tiastar Motor Control Center eliminates the hardwiring and thus the need for additional items like transducers and analog input modules. Of course, with elimination of the hardwiring requirement, the commissioning time is reduced as well.