Transcription

When You Need Humidity!HumidificationLoad CalculationManualEngineeringManualIncludes What is Humidity, Affects ofRelative Humidity, CalculatingRelative Humidity, Requirements toCalculate Humidifier Load, and LoadCalculations2553856-A 08 SEP 2010

Thank you for choosing Nortec.Proprietary NoticeThis document and the information disclosed herein are proprietary data of WALTER MEIER LTD. Neither thisdocument nor the information contained herein shall be reproduced used, or disclosed to others without thewritten authorization of WALTER MEIER LTD., except to the extent required for installation or maintenance ofrecipient’s equipment. All references to the Nortec name should be taken as referring to WALTER MEIER LTD.Liability NoticeNortec does not accept any liability for installations of humidity equipment installed by unqualified personnel orthe use of parts/components/equipment that are not authorized or approved by Nortec.Copyright NoticeCopyright 2009, WALTER MEIER LTD. All rights reserved.

Contents56What is HumidityEffects of Relative Humidity6Static Electricity7Moisture Stability8Health and Comfort1012Calculating Relative HumidityRequirements to Calculate Humidification Load12Design Conditions – Selecting an RH Setpoint16Outdoor Air Conditions22Load Calculations22Natural Ventilation23Mixed Air System23Makeup or Exhaust Air System

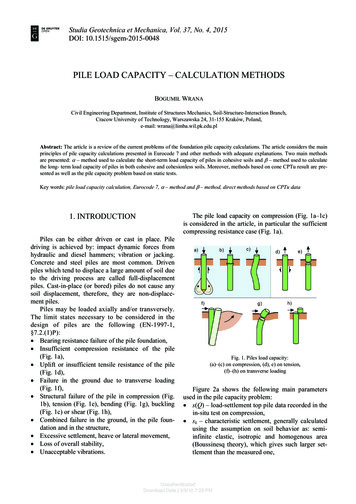

What is HumidityIf a closed container is partially filled with water, then some of the water molecules in the liquidwill leave the surface of the water and become vapor. Once some water molecules are presentas vapor they will also re-enter the liquid. After some time at constant temperature equilibriumwill be reached where the same number of molecules are leaving and entering the liquid. AtWaterVapor Equilibrium68 ºF ( 20ºC)100% RHWater vapor content0.00108 lb/cu.ft(0.0173 kg/cu.m)Waterthis equilibrium point the relative humidity of the water vapor is 100%.Figure 1: Water Vapour EquilibriumRelative humidity (RH) is the percentage of water vapour present in the air relative to theamount that would be present in the equilibrium state.The equilibrium point is temperature dependent. At higher temperatures the equilibrium occurswith more water vapor. If the container above was heated to 86ºF (30ºC) the water and watervapor would no longer be in equilibrium. The relative humidity of the vapor right after increasingthe temperature would be 57%. This means that immediately after heating there are 57% asmany water vapor molecules as would be present in the equilibrium state.WaterVaporHeat to86ºF(30ºC )WaterVapor WaterWaterEquilibrium68ºF ( 20ºC)RH 100%0.00108 lb/cu.ft(0.0173 kg/cu.m)Not in Equilibrium86ºF ( 30ºC)RH 57%0.00108 lb/cu.ft(0.0173 kg/cu.m)Given timeandsufficientwaterWaterVapor WaterEquilibrium86ºF ( 30ºC)RH 100%0.00190 lb/cu.ft(0.0303 kg/cu.m)Figure 2: Relative Humidity after HeatingIt is the above process that causes dry air in buildings. As cold incoming air is heated, itsrelative humidity value drops. Therefore moisture must be added to attain an acceptable levelof humidity within the building.Load Calculations - on page 22 outlines how to calculate the amount of moisture that must beadded to maintain a constant relative humidity.5 Humidification Load Calculation

Effects of Relative HumidityThe reasons for humidifying dry air vary from one building to another and from one geographicarea to another, however there are three fundamental reasons. These are: Static ElectricityPoor Moisture StabilityHealth and ComfortStatic ElectricityStatic electricity is a condition caused by stationary charges of electricity and is a major problemin most unhumidified areas. Since static electricity is caused by friction, particularly when theelements in friction are dry, the problem increases proportionately with the speed of productionmachinery. Without sufficient humidification, high-speed machinery might well defeat its ownpurpose. Reduced efficiency is frequently the result of static electricity.In the printing industry presses must self-feed paper evenly, one sheet at a time at very highspeeds. When the static electricity causes sheets of paper to stick together, the paper bunches,the feeding becomes uneven, and eventually the paper jams the presses.In the textile industry static electricity causes the yarns to adhere to each other, the shuttlesmiss threads and improper weaving patterns result.In offices, static electricity can disrupt operations and increase operating costs. In manyphotocopiers, sheets of paper stick together and jam the machine, wasting time and paper.Severely jammed equipment may even require service calls.In computer rooms and data processing areas, the lack of humidity results in static electricitythat causes problems such as circuit board failure, dust buildup on heads, and storage tapebreakage.Static electricity can also be dangerous. Sparks caused by static are extremely hazardous inlocations such as hospital operating rooms where flammable gases are present. Many flashfires – even explosions - are caused by static electricity.Controlling Static Electricity - Maintaining relative humidity above 35% is one importantmeasure that can be taken to reduce static electricity.Controling Static ElectrictyOne of the easiest and most common methods of minimizing static electricity is to increase therelative humidity level. Electrostatic charges do not dissipate through moist air, but through amoisture film that is absorbed on the charged surfaces. This moisture film decreases thesurface resistance and causes static charges to be drained.This effect is most pronounced at RH above 30-35% and it also corresponds with a decrease inozone production (a by-product of electrostatic discharge). Static electricity is a problem thatshould be of primary concern to any manufacturing plant interested in running efficiently andaccurately.Humidification Load Calculation 6

Moisture StabilityWhen air is heated the relative humidity will decrease. When this occurs the rate at which watermolecules leave objects containing water or the rate at which water evaporates is increased. Allhygroscopic or fibrous materials either lose of gain moisture in direct relation to the relativehumidity of the surrounding airMoisture stability is the ability of a material to maintain a level of moisture content despitefluctuations in the humidity of the environment. Many materials give off, or take on moisturerapidly which can result in serious damage to the material or the process in which it may beinvolved. The drying out of a material can result in product deterioration, while conversely, a drymaterial can also suffer damaging side effects of moisture regain. In many cases, productdeterioration is directly related to the lack of moisture stabilityTable 1 gives the hygroscopic regain of some common hygroscopic materials. Hygroscopicregain is defined as the amount of water a completely dry material will absorb from the air. It isexpressed as a percent of the dry weight. (For example the weight of completely dry timber willincrease by 9.3% if it is stored at an RH of 50%)Table 1: Hygroscopic Regain of Some Common MaterialsRelative Humidity - %Industry and/or MaterialBakingCrackersFlourWhite BreadLeather - Sole Oak, TannedPrintingPaper – Comm. Ledger – 75% Rag1% AshPaper M.F. Newsprint – 24% AshPaper White Bond Rag – 1% AshPaper Writing – 3% AshTextileCotton – AbsorbentCotton – American-clothCotton – Sea Isle-rovingHemp – Manila and SisalJute – Average GradeLinen – Dried Spun – YarnRayon – Celulose – Acetate – FibreRayon – Cupramonium – Average SkeinRayon – Viscose NitrocelSilk – Raw Chevennes-SkeinWool – Australian-Marino-SkeinTobacco - CigaretteWoodTimber – AverageGlue – HideMiscellaneousCharcoal-Steam ActivatedGelatinSilica E: Moisture content expressed in per cent of dry weight of the substance at various relative humidities – Temperature 75 F (22ºC)7 Humidification Load Calculation

Hygroscopic Regain – is defined as the amount of water a completely dry material willabsorb from the air. . Any hygroscopic product that is purchased and sold by weightmust have a carefully controlled environment.Products such as vegetable, cut flowers, fruit and many grocery items cannot be brought backto original quality once they have lost their moisture. By installing an efficient humidificationsystem this costly loss of products can be avoided. Many food processors humidify their plantand storage areas and are able to store fruits and vegetables for months without any loss ofproduct quality or weigh.For any product that requires a certain percentage of moisture to maintain its quality, loss ofthat moisture reduces its valve. Some products can be brought back to their original conditionby returning the moisture to them. However, among those that cannot reabsorb moisture toregain their lost quality are fruit and vegetable products, paintings and art objects.Deterioration caused by loss of moisture is also a problem for treasures such as antiques, rarebooks, and works of art, all of which are susceptible to damage caused by moisture loss. Itcauses antiques, paintings, paper and book bindings to crack, warp and deteriorate.Fortunately, most libraries and museums are well aware of the need for controlled humidity toprotect their collections. They know that proper humidity control is a very inexpensive preventivemeasure that will avoid costly and often impossible restorations.A specific moisture content in materials is essential to the quality of products produced by awide range of manufacturers of hygroscopic or fibrous materials. Wood, paper and textiles areexamples of materials particularly affected by changes in content. If these materials have acorrect moisture content when they arrive at a plant, and if they are used immediately, they willrespond properly to the manufacturing process. But problems can be anticipated if thematerials are stored in a dry atmosphere.Paper provides a good example of the effects of dry air and the lack of moisture stability. Whenit is stored under dry atmospheric conditions, moisture from the outer layers and edges of thestacks escapes into the air. The moisture loss is much more rapid from the outer edges thanfrom the center of the stacks. The result is not only curled stock, but also uneven moisturecontent, which creates printing and processing problems.If moisture stability in the surrounding atmosphere is the answer to a manufacturing operation,then complete humidification of the plant and storage areas is an absolute necessity.Humidification is the best and least expensive way of maintaining moisture stability. If the airsurrounding the material is maintained at a proper and constant relative humidity level, so thatno moisture is emitted or absorbed by the materials, then the products will remain stable inboth moisture content and dimension.Ideally, humidification equipment should be installed in raw material storage areas,manufacturing facilities, and finished goods’ storage rooms, for full control of the productmoisture content.Health and ComfortDuring the heating season, inside air dries to the point where the humidity is substantially loweror comparable to that of the Sahara Desert. The effect on people is to dry out nasal and throatmembranes. For employees this means more susceptibility to colds and virus infections. Thesubsequent increased absenteeism proves costly for any employers. Another aspect of comfortHumidification Load Calculation 8

is the fact that humidity in the air makes a room feel warmer, so there will be fewer requests tohave the thermostat turned up.Most employers provide air conditioning for employee comfort and productivity during the hotdays of summer. Adding humidification for full winter comfort and productivity is just asimportant as air conditioning in the summer months. In fact, it is one of the most importantfunctions of the complete air conditioning or “total comfort” system.Decrease in bar width indicates decrease in effectOptimum sAllergic Rhinitisand ient dataabove 50% rh0102030405060Percent Relative Humidity7080901Figure 3: Optimum Humidity Range for Human Comfort and HealthThe advantage of conditioning the interior space of a building to increase productivity andreduce the downtime of machinery has been documented many times. Unfortunately it isusually equipment, such as computers and communications systems, that is placed in separateclimate controlled rooms, while the majority of employees have temperature control only.Temperature control must be combined with humidity control to maintain proper comfortparameters in an office environment. More than 75% of all I.A.Q. problems start with a comfortcomplaint. If this is not rectified, the employees will continue to complain and become lessproductive.Temperature control alone does not take into account the physiological aspects of theemployees. As demonstrated in Figure 3, indoor RH variations above and below the 40-60%range have a dramatic effect on the comfort and well being of employees. Humidity conditionsabove this range are usually controlled easily by the normal dehumidification process of the airconditioning system. However, as the cold, dry weather of winter approaches or in arid climates,the indoor RH can easily drop well below the recommended 40% parameter. It is not uncommon9 Humidification Load Calculation

to find relative humidities in the 10-15% range in most offices during this period. This low RHcreates comfort, productivity, and absenteeism problems costing immeasurable dollars toemployers worldwide. Studies conducted by Dr. George Green of the University of Saskatchewanindicates that increasing the indoor RH from 20 to 30% will reduce absenteeism by 15%. This,along with the productivity increase that can be gained from additional comfort result in a realeconomic benefit from general office humidification.Calculating Relative HumidityIf initial temperature and relative humidity are known then Table 2 and Table 3 can be used tocalculate the relative humidity after heating, cooling, or adding steam. The following twoexamples use Table 3 and SI units to show the method used for calculating the RH after heatingor after adding steam.Example 1: RH After Heating - What is the RH if air at 5ºC and 80% RH is heated to 30ºC?1 Obtain moisture content of air at 5ºC and 100% RH from Table 3.A 0.00680 kg/cu.m2 Multiply by starting RH to get the actual moisture content of the air.B 0.00680 x 80%/100% 0.00544 kg/cu.m3 Obtain moisture air at 30ºC and 100% RH from Table 3.C 0.0303 kg/cu.m4 Divide actual moisture content by moisture content at 100% RHD B / C 0.00544 / 0.0303 x 100% 18%RH After HeatingExample 2: RH after Adding Steam - What is RH if 10 kg of steam is added to 1,000 cu.m of theheated air in example 1?1 Multiply B (the actual moisture content) by the volume to get mass of water in the air.E B x 1000 cu.m 0.00544 kg/cu.m x 1000 cu.m 5.44 kg2 Add the amount of steam being added to the total mass of water.F E 10 kg 5.44 kg 10 kg 15.44 kg3 Divide by the volume of air to kg/cu.mG F / 1000 cu.m 15.44 kg /1,000 cu.m 0.0154 kg/cu.m4 Divide by moisture content at 100 % RHH G / C 0.0154 / 0.0303 x 100% 51%RH After Adding steamGrains/cu.ft – A common unit used for measuring water vapor in air is grains / cubic foot. Thisdocument uses pounds/cubic foot and kilograms/cubic meter to simplify calculating humidifier outputwhich is generally expressed in pounds per hour or kilograms per hour.1 pound water 7,000 grains.Humidification Load Calculation 10

Table 2: Water Content of Air at 100% RH (IP units) Flb/cu.ft Flb/cu.ft Flb/cu.ft Flb/cu.ft 910.005590.006340.007190.00812Table 3: Water Content of Air at 100% RH (SI units) Ckg/cu.m Ckg/cu.m Ckg/cu.m Ckg/cu.m 820.19011 Humidification Load Calculation

Requirements to Calculate Humidification LoadThe humidification load calculation assumes that the humidity and temperature in the spacebeing humidified are at the design conditions. Therefore the moisture that must be added isthe amount required to bring incoming air to the design condition. Figure 4 shows a schematicof a typical air conditioning system generated by Nortec’s HELP software. The figure alsoshows the 3 factors that must be known to calculate humidification load.Design Conditions – Temperature and RH that must be maintained in the humidified space.Outdoor Air Conditions (Incoming Air) – Temperature and RH of the outdoor air.Incoming Air Volume - The volume of outdoor air that flows into the space being humidified.H.E.L.P. SoftwareThe easiest way to calculate the humidification load for any application is to use Nortec’sHumidifier Engineering and Load-sizing Program (H.E.L.P.). The software can be downloadedfrom www.humidity.com. The software guides you through the different factors and designconsiderations affecting humidifier selection and provides an easy means for examining theeffect of changing conditions.1323Figure 4: Help Software System SchematicDesign Conditions – Selecting an RH SetpointThe optimum humidity setpoint depends on the reasons that a space is being humidified. Someof the most common reasons are outlined in Effects of Relative Humidity starting on page 6.The “ASHRAE Handbook – HVAC Applications” recommends specific design relative humiditylevels for specific applications. Table 4 provides recommendations for temperature andhumidity ranges for various purposes as taken from the ASHRAE Handbook and can be used forthe purpose of load calculations.Humidification Load Calculation 12

For More Information on Design Conditions see: Nortec Form #00-124A – When You Need Humidity The ASHRAE HVAC Applications Handbook. Humidifiers section in the ASHRAE HVAC Systems and Equipment HandbookTable 4: Design Indoor Conditions for Various Places, Products, and ProcessesProduct and/or ProcessAbrasives ManufacturingBowling AlleysBilliard RoomsBreadFlour and Powdered Product StorageFermentation (Bread Dough)Retarding of DoughsFinal ProofCounterflow CoolingBrewingBrewing Hop Storage Yeast Culture RoomYeast Culture RoomCandyChocolate Pan Supply AirEnrober RoomChocolate Cooling Tunnel Supply AirHand DippersMolded Goods CoolingChocolate Packing Room and Finished Stock StorageCenters Tempering RoomMarshmallow Setting RoomGrained Marshmallow (deposited in starch) DryingGum (deposited in starch) DryingSanded Gum DryingGum Finished Stock StorageSugar Pan Supply Air (engrossing)Polishing Pan Supply AirPan RoomsNonpareil Pan Supply AirHard Candy Cooling Tunnel Supply AirHard Candy PackingHand Candy StorageCaramel RoomsCeramicsRefractoryMolding RoomClay StorageDecalcomania Production and Decorating roomCereal PackagingCheese CuringCheddarSwissBlueBrickLimburgerCamembert13 Humidification Load CalculationTemperature F C782573 – 7523 – 2473 – 7523 – 24RH %5050 – 5540 – 5070 – 808032 – 4095 – 1207521 – 27270–435 – 492460758585 – 9080 – 8529 – 32--2–0--50 – 608055 – 6280 – 8540 – 456240 – 456575 – 8075 – 78110125 – 15010050 – 6585 – 10570 – 8075 – 80100 – 12060 – 7070 – 7550 – 7070 – 8013 – 1727 – 294–7174–71824 – 2724 – 264352 – 663810 – 1829 – 4121 – 2724 – 2738 – 4916 – 2121 – 2410 – 2121 – 2745 – 5525 – 3070 – 854570 – 855030 – 3540 – 454015 – 2525 – 406520 – 3040 – 5030 – 352040 – 5535 – 404040110 – 1508060 – 8075 – 8075 – 8043 – 662716 – 2724 – 2724 – 2750 – 9060 – 7035 – 654845 – 5045 – 556048 – 5060 – 6560 – 6553 – 597 – 13169 – 1016 – 1816 – 1812 – 1585 – 9080 – 8595909590

Table 4: Design Indoor Conditions for Various Places, Products, and Processes (Continued)Product and/or ProcessClean Rooms – Computer RoomsComputer RoomClean Room – GeneralClean Room – CriticalComfort Air ConditionersDistillingGrain StorageGeneral ManufacturingAgingElectrical ProductsCoil and Transformer WindingX-ray Tube AssemblyInstruments Manufacture and LaboratoryThermostat and Humidistat Assembly and CalibrationClose Tolerance AssemblyMeter Assembly and TestFuse and Cutout Assembly, Capacitor Winding and Paper StorageConductor Wrapping with YarnLightning Arrestor AssemblyThermal Circuit Breaker AssemblyRunner HoppingProcessing Selenium and Copper Oxide PlatesFruit StorageApplesApricotsGrapefruits (California)Grapefruits (Florida)Grapes (Eastern)Grapes (Western)LemonsOranges (California)Oranges (Florida)Peaches and NectarinesPlumsSpecialty Citrus FruitFur ingHospitalsOperating, Cystoscopic and Fracture RoomsPatient RoomsIntensive Care UnitAdministrative and Service AreasLeatherDryingStorage, Winter Room TemperatureLenses (Optical)FusingGrindingLibraries and MuseumsNormal Reading and Viewing RoomsRare Manuscript Storage VaultsArt Storage AreasTemperature F CRH %70 – 8070 – 7471.5 – 72.575 – 8021 – 2721 – 2322 – 22.524 – 2740 – 6040 – 6043 – 4750 – 60600 – 7565 – 721616 – 2418 – 2235 – 4045 – 6050 – 154050 – 5550 – 5540 – 4560 – 635065 – 7020 – 4030 – 6030 – 5030 – 4030 – 4031 – 3258 – 605031 – 3230 – 3158 – 6040 – 4432 – 343130 – 3238 – 4040 – 50-1– 4-1 – 014 – 1610-1 – 0-114 – 164–70–1-1-1 – 03–44 – 109090 – 9585 – 9085 – 908590 – 9586 – 8885 – 9085 – 909090 – 9590 – 9555 – 6577687274742520222323336353475868 – 76757570 – 8020 – 24242421 – 275040 – 504030 – 5070 – 12050 – 6021 – 4910 – 167540 – 6075802727458070 – 7470 – 7265 – 7221 – 2321 – 2217 – 2240 – 504550Humidification Load Calculation 14

Table 4: Design Indoor Conditions for Various Places, Products, and Processes (Continued)Product and/or ProcessMatchesManufactureDryingStorageMeat and FishBeef (Fresh)Beef, Fish, Lamb and Pork (Frozen)Fish (Fresh)Lamb and Pork (Fresh)MushroomsSweating-out PeriodSpawn AddedGrowing PeriodStorageOil Paints: Paint SprayingPharmaceuticalsManufactured Powder Storage and Packaging AreaMilling Room, Table Compressing and CoatingEffervescent Tablets and PowdersHypodermic TabletsColloidsCough DropsGlandular ProductsAmpoule ManufacturingGelatin Capsules and StorageMicroanalysisBiological Manufacturing and Liver ExtractsSerumsAnimal RoomsPlasticsManufacturing Areas ThermosettingMolding CompoundsPlywoodHot Pressing (Resin)Cold PressingPrintingPlatemakingLithographic Press RoomLetterpress and Web Offset Press Rooms and Paper StoragePaper Storage (Multicolor Sheet Feed Lithography)Temperature F CRH %72 – 7470 – 7560 – 6222 – 2321 – 2416 – 1750605032 –34-10 – 033 – 3532 – 340–1-23 – -181–30–188 – 9290 – 9590 – 9585 – 90120 – 14060 – 7548 – 6032 – 3560 – 9049 – 6016 – 249 – 160–216 – 32–Nearly Sat.8080 – 858075757575708076757676767675 – 8024242424212724242424242424 – 273535203030 – 50405 – 1035 – 5035503550508075 – 802724 – 2735 – 3045 – 65909032326015 – 2575 – 8076 – 8076 – 8076 – 8024 – 2724 – 2724 – 2724 – 2745 Max43 – 47505 – 8 (higherthan press Room)Raw Material StorageNuts (insect)Nuts (rancidity)EggsChocolate (flats)ButterDates, Figs, etc.Corn SyrupLiquid SugarRubber Dipped GoodsCementingDipping Surgical ArticlesStorage Prior to ManufactureLaboratory (ASTM Standard)Tea Packaging15 Humidification Load Calculation4534 – 3830652040 – 4590 – 10075 – 8071–3-118-74–732 – 3824 – 2765 – 7565 – 7585 – 905065 – 75–30 – 408075 – 9060 – 7573.4652724 – 3216 – 24231825 – 3025 – 3040 – 505065

Table 4: Design Indoor Conditions for Various Places, Products, and Processes (Continued)Product and/or ProcessTextilesOpening and Picking CottonOpening and Picking Man-MadeCarding CottonCarding WoolCarding Man-MadeSilver and Ribbon Lapping CottonSilver and Ribbon Lapping Man-MadeCombing CottonCombing WoolCombing Man-MadeDrawing Cotton and WoolDrawing Man-MadeRoving CottonRoving Man-MadeSpinning CottonSpinning WoolSpinning Man-MadeWinding and Spooling CottonWinding and Spooling WoolWinding and Spooling Man-MadeTwisting CottonTwisting Man-MadeWarping CottonWarping WoolWarping Man-MadeKnitting CottonKnitting Man-MadeWeaving CottonWeaving WoolWeaving Man-MadeTobaccoCigar and Cigarette MakingSofteningStemming and StrippingFiller Tobacco Casing and ConditioningFiller Tobacco Storage and PreparationWrapper Tobacco Storage and ConditioningTemperature F CRH %75 – 8070 – 7575 – 8075 – 8070 – 7575 – 8070 – 7575 – 8075 – 8070 – 7575 – 8070 – 7575 – 8070 – 7575 – 8075 – 8070 – 7575 – 8075 – 8070 – 7575 – 8070 – 7575 – 8075 – 8070 – 75767675 – 8075 – 8070 – 7524 – 2721 – 2424 – 2724 – 2721 – 2424 – 2721 – 2424 – 2724 – 2721 – 2424 – 2721 – 2424 – 2721 – 2424 – 2724 – 2721 – 2424 – 2724 – 2721 – 2424 – 2721 – 2424 – 2724 – 2721 – 24242424 – 2724 – 2721 – 2455 – 7050 – 5550 – 5560 – 7050 – 6055 – 6055 – 6555 – 6565 – 7555 – 6550 – 6050 – 6050 – 6050 – 6035 – 6050 – 5550 – 6555 – 6555 – 6060 – 6550 – 6550 – 6555 – 7050 – 6550 – 6560 – 6550 – 6070 – 8550 – 6060 – 7070 – 759075 – 8575787521 – 243224 – 2924262455 – 6585 – 8870 – 75757075Outdoor Air ConditionsThe outdoor air conditions vary with geographic location and the time of year. For the purposeof calculating the humidification load the worst case condition is generally used. Table 6:Weather Data – Canada and Table 5: Weather Data - United States provide temperature and RHvalues for many US and Canadian cities taken from monthly weather data compiled by ASHRAE.The temperature value used is the 99% heating dry bulb temperature for the coldest month ofthe year. The relative humidity value is the average relative humidity of the driest month of theyear.To obtain the outdoor conditions find the city (or nearest city) where the humidification isrequired and read the RH and Temp values from the columns with the heading “LoadCalculation”. Example; The outdoor air conditions that would be used for a humidification loadcalculation in the city of Calgary Alberta are 42% RH and -20ºF (-29ºC).Humidification Load Calculation 16

StateTable 5: Weather Data - United States51%15 (-10)Mobile52%24 (-5)Anchorage49%-11 (-24)Fairbanks38%-38 (-39)Little Rock53%15 (-10)Bakersfield22%31 (-1)Fresno22%30 (-1)Los Angeles59%37 (3)Sacramento28%30 (-1)San Diego56%41 (5)San Francisco58%33 (1)Denver34%-3 (-19)Grand Junction19%-2 (-19)Pueblo28%-5 (-21)CTBridgeport54%9 (-13)Wilmington50%6 (-14)Washington49%13 (-11)Jacksonville48%26 (-3)Miami54%47 (8)Atlanta49%14 (-10)Augusta45%18 (-8)Savannah46%23 (-5)Honolulu51%61 (16)Boise22%1 (-17)Lewiston25%5 (-15)Chicago54%-5 (-21)Peoria56%-4 (-20)Springfield54%-1 (-18)Fort Wayne54%-1 (-19)Indianapolis56%0 (-18)South bend54%-1 (-18)Des Moines55%-5 (-20)Sioux city52%-7 (-22)IAINILIDHIGAFLCOCAARAKALBirminghamDELoad CalculationRH Temp F (C)DCCityEconimizer Calculation - Temperature F (C) and Relative Humidity in %JFMAMJJASOND15 (-10) 21 (-6) 24 (-4) 40 (4) 48 (9) 56 (13) 62 (17) 62 (17) 52 (11) 41 (5) 25 (-4) 20 (-7)61%55%52%51%55%56%60%59%59%54%57%60%24 (-5) 29 (-2) 38 (3) 47 (8) 56 (13) 62 (17) 69 (20) 68 (20) 57 (14) 46 (8) 38 (3) 28 (-2)61%56%55%52%54%55%60%61%59%53%57%61%-11 (-24) -5 (-21) -1 (-18) 14 (-10) 30 (-1) 42 (6) 47 (8) 42 (6) 32 (0) 14 (-10) -1 (-18) -8 (-22)72%67%57%53%49%56%62%64%63%66%73%76%-38 (-39) -34 (-37) -23 (-31) 0 (-18) 21 (-6) 42 (6) 46 (8) 39 (4) 22 (-6) -2 (-19) -24 (-31) -36 (-38)69%63%53%46%38%43%50%54%55%67%73%71%15 (-10) 16 (-9) 29 (-2) 41 (5) 52 (11) 59 (15) 65 (18) 63 (17) 52 (11) 42 (6) 31 (0) 18 (-8)61%59%56%56%58%55%56%56%58%53%58%

Humidification Load Calculation Manual Engineering Manual Includes What is Humidity, Affects of Relative Humidity, Calculating Relative Humidity, Requirements to