Transcription

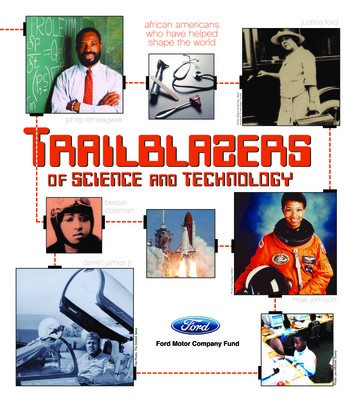

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]Menominee Range Historical FoundationMuseum and the Chamber of Commerce.Acknowledgements go to Mid-PeninsulaLibrary Cooperative for contributing thepaper and printing, to Frank Marsden,printer, to Renee Augustine for manuscriptpreparation, to Margaret Johnson, to theDickinson County Festival of the Arts forpromotion of the tour, to Tulio Chiesa andJap Colantonio for their oral histories, toLodal and Les Brisson, John Pipp andMike Woller and also Larry Swartout, RonDelo and Alan Enciso.INTRODUCTIONThis booklet primarily covers the period1920-1925 which, because of the buildingof the Ford Plant, was a time of greatexcitement and expansion for thecommunity. The growth of the area istouched upon from the organization of theVillage of Kingsford in 1923 until it beingmade a city in 1947.The tour sites concern buildings whichplayed an integral role in Ford’s story andare located in the Ford Plant area and arealso scattered across the cities of Kingsfordand Iron Mountain. None of the sites areopen for inspection. The museum, libraryand Festival Committee request that peopleon the tour do not intrude upon the propertyof the present owners.The primary research sources for thisbooklet were The Daily Tribune-Gazetteand The Iron Mountain News. A completebibliography of Ford articles contained inthese newspapers from 1920-1925 isavailable at the Dickinson County Libraryand the Menominee Range HistoricalFoundation Museum. For a much more indepth treatment of the Ford story in IronMountain, the reader is urged to consultthese articles.The Dickinson CountyLibrary has all early Iron Mountainnewspapers on microfilm and two microfilmreaders for patron use. Also many of thesesame articles are in the vertical file in theLocal History and Genealogy Room of thelibrary.The museum archives containmany sources and photographs of theperiod as well. The photographs includedin this tour guide are courtesy of themuseum.These booklets will be available not onlyon the tour date, July 16, but alsothroughout the summer at the DickinsonCounty Library and its branches, theWilliam J. Cummings, ManagerMenominee Range Historical FoundationMuseumDavid Curtis, LibrarianDickinson County Library1983(Maps of the Ford Plant area and the toursites are contained on both sides of theback cover.)FORD COMES TO IRONMOUNTAIN: THE BIRTH OFKINGSFORDLong before 1920, the great iron oremining boom had ended in Michigan’sUpper Peninsula.Extensive miningoperations were still being carried on bymajor mining concerns, but many smallermines had been closed. The era of pinelogging on a massive scale had endedalmost two decades earlier, as thelumbermen following the pine to the WestCoast. The economic future of the UpperPeninsula was uncertain at best.In 1920, the population of the areawhich now comprises Kingsford was aneven 40, consisting mainly of ironminers who worked in the Iron Mountain1

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]iron mines and had purchased a forty ortwo for farming in their spare time.There were no settled communities, nostores and no businesses of any kind.Twenty per cent of the land was cleared;eighty per cent was wild.A year earlier, Henry Ford contactedEdward G. Kingsford by telephone, askingKingsford to accompany him on a campingtrip to discuss the reserves of iron andlumber in the Upper Peninsula. Ford hadbeen considering these reserves as earlyas 1912, as he was interested in acquiringraw materials for his factories. Kingsford,the husband of Ford’s cousin, MinnieFlaherty, had been a timber cruiser in hisearlier years, and at the time was a realestate agent and Ford dealer in IronMountain.The Ford Motor Company had beenplanning to locate a plant in the UpperPeninsula for some time, wanting tomanufacture the wooden parts of Fordautomobiles near the source of the rawmaterials and ship them directly to largebranch assembly plants throughout thecountry.This would relieve thetransportationandmanufacturingcongestion in Detroit, where about98,000,000 feet of lumber were shippedannually to be made into car parts forshipment to these branch assembly plants.By 1919, Ford was ready to move. Heinformed Kingsford that he wanted to buy alarge tract of land for the purpose ofsecuring timber, mining iron ore andbuilding a community. Kingsford found313,447 acres which had recently beenpurchased by the Michigan Iron andLumber Company from the estate ofThomas A. Brassey, an English noblemanand capitalist, who had bought the lands inthe western portion of the Upper Peninsulafrom John M. Longyear more than thirtyfive years earlier.Ford ultimately became the owner of400,000 acres of iron and timberlands inthecountiesofAlger,Baraga,Dickinson, Houghton, Iron, Marquetteand Menominee, of which 350,000 werecomposed of hardwood forests.Imagine the hopeful excitementgenerated throughout the peninsulawhen plans for the construction of asawmill and body plant by the FordMotor Company were announced earlyin July, 1920.IronMountain’sfirstformalannouncement of these plans waspublished in the July 7 edition of The DailyTribune-Gazette, where an article on pagethree noted that Henry Ford, his son Edseland C.W. Avery, general manager of theFord Motor Company, had been in the cityfor a few hours that morning looking over aprospective site for the location of a factoryto build Model T bodies and a big sawmill.A number of Iron Mountain citizenshad worked on behalf of the Ford MotorCompany to secure options on about900 acres of land south and west of thecity limits extending to the MenomineeRiver, according to an article appearing inthe July 8 edition of The Iron MountainPress. The article also stated that theaverage price paid for this land was lessthan 100 per acre.The 160-acre farm south of CrystalLake belonging to Joseph Mongrain wasconsiderednecessaryforthecompletion of the tract desired by theFord Motor Company, and was the centerof considerable community controversy andconcern for nearly two weeks.While many rumors were circulatedabout the controversy, the following detailsare taken from a letter from JosephMongrain published in the July 9 edition ofThe Daily Tribune-Gazette.Mongrainstated that Wilbur Thompson and M.J.Fox had attempted to secure an option on2

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]his property which he refused because hishome was not for sale. He then stated thatwhen Henry Ford asked him if he wouldsell at his own fair price, Mongrain toldAvery, Ford’s agent, he would sell for 75,000. Avery offered Mongrain 32,000,which Mongrain flatly refused. Thompsonasked him if he would accept 50,000,which Mongrain also refused, and then, thatsame evening, Thompson returned withFox, and offered him 32,000, stating thatwas the limit they could offer.WhenMongrain refused that offer, they offeredhim 40,000, again stating this was theirlimit, an offer Mongrain again rejected.Mongrain also denied a rumor which hadbeen printed in the previous issue of TheDaily Tribune-Gazette that he had agreedto the price of 45,000.That same Friday, July 9, a meetingwas called in the city council rooms at 1:30in the afternoon when a committeecomposed of Dr. J.A. Crowell, G.P.Fugere, W.A. Henze, John Daprato andW.G. Monroe was formed.Thursday evening J.A. Payant, G.P.Fugere, W.A. Henze, Peter Brouillire andDick Trepanier had visited with Mongrainand talked with him about the sale of hisproperty.Mongrain, according to thisgroup, agreed to do the “square thing,” butwoulddobusinesswithFord’srepresentatives directly, and no one else.The committee was to meet again at7:30 Friday evening, after having conferredwith the Ford representatives and Mongrainduring the afternoon.This committee began solicitingfunds in the community in an attempt toraise 30,000, the figure they thoughtwould be required to add to the Fordoffer to purchase the Mongrain farm. Bynoon on July 12, about 8,000 had beenraised, and the committee had only beguncanvassing the city that morning. Althoughthe rumor that Ford had decided to locatehis plant in Republic was circulating,solicitations were continued since Ford hadnot informed the committee of such adecision.Another rumor was thatMenominee had not only offered the FordMotor Company free land upon which conconstruct their factory, but had also offeredthe company a 20,000 bonus for settlingthere.By noon the following day [July 13],Tuesday, 15,000 had been collected. Thecommittee felt encouraged by the fact thatthe Ford Motor Company had notifiedpersons who had been given options ontheir property to come and get their money.This seemed to leave little doubt that IronMountain was to be the site selected by theFord Motor Company.Iron Mountain supposedly wasrecommended by Ford’s engineers andofficials as the logical place for theplant. Advantages included the large,relatively level tract of land near theMenominee River which was also apotential power source, plus a favorablegeographic location.On Wednesday, July 14, a telegramfrom the Ford Motor Company wasreceived stating the company would notstand for Iron Mountain’s raising 30,000to swing the deal in regard to theMongrain farm.The telegram furtherstated that the Ford Motor Company wasthen considering Republic as a possiblelocation for the plant, according to thearticle in The Daily Tribune-Gazette. It wasalso reported in this article that JosephMongrain had gone to Marquette onMonday or Tuesday, and then he had leftMarquette for Detroit upon having beenrequested to do so, the implication beingthat this request was made by the FordMotor Company.Up to the time thetelegram was received, the committee hadcollected 20,000.3

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]By Saturday, July 17, engineers forthe Ford Motor Company were workingon land purchased by the companywhere the body plant and sawmill wereto be erected. This site was to be west ofthe City of Iron Mountain. According to TheDaily Tribune-Gazette, since Friday anumber of lots and some property had beensold in the city.In a lengthy article under the headline“Facts About the Ford Plant for IronMountain” in the Monday, July 19, editionof The Daily Tribune-Gazette, informationgathered from a personal interview withEdwardG.Kingsford,Ford’srepresentative in Iron Mountain, clarifiedsome of the misinformation and rumorsrampant in the city and the peninsula.At that time Kingsford stated Mongrainhad agreed to what seemed to be asatisfactory sale price, but whether or notthe Ford Motor Company would accept itremained to be seen because the companyhad a very desirable site west of the city,almost directly west of the Pollard farmnear the Pine Grove Country Club.Kingsford noted that this land had beenstaked out, and that the Mongrain land wasalso being staked out to see which bestfitted the current plans for the factory site.The following day [July 20] Kingsfordreported that satisfactory arrangementshad been made between the Ford MotorCompany and Joseph Mongrain inregard to his land, but the selling pricewas not made public. By Thursday, July22, the final site for the location of thebody plant and sawmill had beendecided, and that site was the south partof the Mongrain farm.The beginning of the erection of sawmilland powerhouse only awaited the firstshipmentofcementandsteel.Construction started on July 29, 1920,and Ford hired the first employees. TheFord building period extended from 1920 to1925. To conduct sawmill, body plant andlogging operations, Ford organized theMichigan Iron, Land and LumberCompany with himself as president andKingsford as vice-president. By August 2,1920, Kingsford had received 1,000 ormore applications for work at the Fordplant. At the end of the first year, 3,000men were working on construction alone.On January 27, 1922, the first night shiftin the history of the plant began work atthe sawmill. In March of the same year,the first car parts were manufactured andshipped to Detroit.The coming of Ford caused business toincrease in all parts of the community.There was a boom in real estate andinflated prices for home purchases andrental property. Lots, streets and alleyswere constructed and much Iron Mountainproperty was being torn up to make way fornew construction. There were few homesfor incoming Ford employees to purchase.Where homes were built, convenienceswere lacking. Kingsford Heights and theFord Addition had private water systemsand Breitung had no water system at all.There were no sewers.The only way to deal with theseproblems was for the area to organize intoa village. The petition to organize was filedwith the county commissioners on May 24,1923, and was approved by the voters onDecember 29. A bond issue was approvedearly in 1924 for the construction of awater system.The system was putthrough in the summer of the same yearwhen extensive street improvements werealso made. The bond issue for the sewagesystem passed in 1925.The employment at the Ford plantreached a peak of 8,000 in the latter partof 1925. Plant growth was at its greatestbetween 1922 and 1925. From 1927 on,the plant decreased in activity. Part ofthe reason for this involved switching to4

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]Model A and V-8 cars from the Model Tand the corresponding use of fewer andfewer wooden parts. In 1928, the plantwas partially closed for the conversionof new machinery for the production ofModel A’s and employment was at astandstill. There was a slow-down again in1938 and 1939.The production ofstation wagons began in 1940 and washalted in 1942 when the plant wasconverted for the production of WorldWar II gliders. The first glider wascompleted in December, 1942.In 1945, Henry Ford retired and hisgrandson took control of the company.Because the Upper Peninsula plant was notproving to be profitable, Ford began theprocess of closing down the unit. Thechemical plant was sold to the KingsfordChemical Company in 1951. The bodyplant was closed in 1951, and Ford lefttown. Over 1,800 employees had to lookfor new jobs.As preparations were being developedfor the closing of the Ford plant, steps werebeing taken to make Kingsford a city. Thepetition to become a city was approvedby the voters on March 10, 1947. The citycharter was approved on August 7, 1947.Janesville, Wisconsin, helped lay the track.By August 26, 1920, a mile or more of theroad had been built. By September 9, allgrading work was completed and workmenbegan laying rails the following day.Many of the original rails are still inexistence on the former Ford property.SAWMILLConstruction of the first of the Fordbuildings, the sawmill, was completed overthe course of one year. It was planned tobe three times as large as the Von PlatenFox Mill in Iron Mountain. The machineryfor mixing concrete arrived July 24, 1920,and the cement arrived two days later whenconstruction began. By August 19, thefoundations were almost finished andstructural work was about to begin. Theexterior of the sawmill was completedaround December 4. However, the firstcarload of logs for the sawmill arrived fivedays earlier. It was anticipated at that timethan ten million feet of logs would beunloaded at the Ford property before thewinter was over.RAILROADThe laying of the railroad tracks to theFord plant was one of the first constructionprojects. The track ran from three blockssouth of H Street along the south edgeof the Mongrain farm and was threemiles long. The spur tracks were builtfrom the Chicago, Milwaukee & St. PaulRailroad and entered each end of theplant.John Marsch, owner of the Wisconsin& Michigan Railroad, had the contract tobuild the railroad. Sixteen mules and fourhorses, arriving in two railroad cars fromSawmill Under Construction, Fall 1920Although the sawmill was first testedSaturday, July 9, 1921, it was formallyopened the following Tuesday [July 12],with a band and ceremony marking theoccasion. In the presence of C.W. Avery,general manager of the Ford Motor5

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]Company, E.G. Kingsford, vice-presidentof the Michigan Iron, Land and LumberCompany, and about 100 members of theCommercial and Rotary Clubs, the firstlogs were put through the new sawmill. At1:30 p.m., a long blast of the mill whistleannounced the start of the huge band saw.A few minutes later, spectators gathered ona platform to see the first log come up thechute from the hot pond. As it entered themill building, it was christened by M.J. Foxwith a cup of water. Then, it was rolleddown the slanting rack ready to be placedon the new carriages.log started on a rampage and headed for agroup of Rotarians.Ford Sawmill, ca. 1925-1930The mill was said to be one of the mostmodern in the world at that time. The millwas so large that the town was unable tosupply enough electricity to operate themachines.Therefore, Ford built ahydroelectric plant nearby on theMenominee River that could producesufficient electricity.Interior of Ford Sawmill, 1921Robert Jenks was selected as thesawyer and Joe Bernette as the setter toperform the first cut of timber. Both mentook their places at the controls. The logwas thrown on the carriages and locked.Jenks moved a lever and the carriage rolledslowly up to the rapidly moving band saw.The first slab was then cut and the carriagemoved into position for the second cut. Theplanks followed each other in rapidsuccession down the conveyor to theedger. The slabs went to the “hog” to beground and conveyed to the boiler room.Just twenty minutes after the saw started,planks were received off the transfer. Theprocess went smoothly except for somemomentary excitement when a large mapleInterior of Ford Sawmill, 1921The main logging company was atSidnaw, 60 miles northwest of IronMountain. Kingsford was in charge oflogging operations. The first year of theSidnaw logging camp, only about a millionboard feet of logs were taken to IronMountain. On February 17, 1922, the6

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]sawmill crew cut 205,000 feet in sixteenhours. The company’s hope was to reach250,000 feet. Over the weekend of March18-19, the day and night shifts combinedcut 273,000 feet in sixteen hours.Zam’s Services currently occupies theformer sawmill building. The building hasbeen modified and is now only one story.materials failed to arrive due to a railroadblockade. On March 10, machines werestarted in the body plant, turning out pillarsfor touring cars. The manufacture of otherparts, including sills, door frames, floorboards and top ribs, was taken up later.The first shipment of front door pillars forthe touring car model occurred March 15,1922. This carload of several thousandparts was sent to the Detroit factory.BODY PLANTS, DRY KILNS ANDMAINTENANCE BUILDINGOn September 15, 1921, the WordenAllen Company, a Chicago contractor,was awarded the contract to build thefirst body plant, which would measure360 feet by 120 feet, and six dry kilns.The body plant would turn out wooden bodyparts for Ford touring cars and sedans.The dry kilns were used for drying freshlycut, green, hardwood lumber. This lumberhad to be immediately taken from thesawmill and conditioned properly before itsuse in the manufacture of body parts.Body Plant Production, 1920’sOn May 29, 1922, plans andspecifications for a second body plant,measuring 460 feet by 120 feet, a 100foot addition to the first body plant and14 additional dry kilns were announced.The contract was awarded to theWorden-Allen Company of Chicago onJune 17 and work began on July 10.This body plant was connected to the drykilns, thus not exposing the lumber to theweather.The second plant was ofconcrete, glass and steel. A new type ofroof was employed, using concrete slabsaveraging 18 inches wide and seven feetlong. These, placed side by side, formed adurable, waterproof roof.Each slabweighed 200 pounds and 7,759 slabs wereused. Construction of the new bodyunit, addition and dry kilns werecompleted in November.Partial View of the Ford Body Plant, IronMountain, ca. 1925-1930Even though the building was nearlycompleted by December 22, 1921, the firstbody plant could not begin operations dueto a delay in the receipt and installation offittings for the dry kilns. A second delayoccurred on February 29, 1922, because7

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]It was announced on December 29 thatmore body units would be needed due to adoubling of automobile production. OnApril 21, 1923, a contract was awardedto Worden-Allen for the construction of32 additional dry kilns, a third bodyplant, measuring 640 feet by 120 feet,and extensions to the two present plantsof 180 feet each to make all three plantsof equal size. Construction began on May10, including a maintenance buildingwhich was located east of the power plantand housed the machine shops and otherdepartments supplying repair parts for theentire plant. The maintenance buildingwas in use by September 1.Theadditions to the first two body plants werealso completed by that date and the thirdbody plant was finished with the exceptionof the laying of the concrete floor,machinery foundations and the glazing ofthe steel sash. By December 19, the firsttwo body plants were operating at fullcapacity but the third body plant had not yetbeen opened, although it was partly inoperation by August 1. Construction wasnot concluded until the fall. Because of alack of power, the unit could not be put intofull operation until March of 1924.reached to Chicago and back if placed endto end. Each concrete kiln was 220 feetin length and 20 feet in width. A singleorder for the kilns, on May 26, 1922, filled60 to 70 railroad cars.To this day, the three body plantbuildings are intact and being used variousKingsford business firms. The dry kilns arealso very visible on the property.CHEMICAL PLANTFord Motor Company announced onDecember 29, 1922, that it wasconsidering the construction of achemical plant to take care of the wasteslashings from the timber operations.The contract was awarded to the WordenAllen Company of Chicago on April 16,1923. The chemical plant was locatednorth of the sawmill with the buildingsextending westward.Carbonization and Distillation Buildings,July 14, 1924South Side of Dry Kilns, ca. 1940-1950On August 1, 1924, the machinery andother equipment of the completed chemicalplant were tested. By September 27, theplant was operating on a big scale. It wascomposed of two main buildings, each withfour- and six-story sections.Thecarbonization building, where thechemical process started, was 360 feetTwenty-six dry kilns were inoperation by January 16, 1924. Twentysix more were under construction duringthat year. Each kiln in a battery of twentysix took seven miles of piping. Total pipingin all the kilns and the plants would have8

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]long and 90 feet wide. The distillationbuilding, where the chemical productswere made, was 300 feet by 90 feet. Thebuildings were furnished with heat by asteam power plant, a unique feature ofwhich was a horizontal smoke stack 10feet in diameter and more than 200 feetlong, which connected the two big buildingsand furnished heat for wood drying. Theplant was equipped with a large chemicallaboratory of the latest design. There wasalso a modern shipping and barrelingdepartment for the proper packaging of thevarious chemical products.acetate of lime, 612 gallons of 82 per centmethyl alcohol, 61- pounds of charcoal, 15gallons of tar, heavy and light oils, creosoteand 600 cubic feet of fuel gas. All of theproducts were used at the Ford plant orsold. The charcoal was manufacturedinto briquettes and offered on themarket for fuel. The gases were used forfuel at the power plant.The chemical plant was torn down afterKingsford Chemical Company left town.Only remnants are still visible on the Fordproperty.POWER PLANTSThe original power plant wasconstructed during the fall of 1920 and thewinter of 1920-1921 and provided the plantwith power until a new power house had tobe constructed.Original Power Plant UnderConstruction, Fall of 1920Charcoal ProductionBy October 31, 1923, a 1400horsepower boiler was being water testedat the new power plant then underconstruction. Two of these boilers werebeing installed with two correspondingsmoke stacks, each 190 feet high with aninside diameter of 14 feet at the bottom and10 feet at the top. The original powerEvery scrap of wood was used – evensawdust. The plant’s capacity was 210cords of wood per day. The amount ofdaily waste products was calculated, atthe time, to be worth 11,000. Thechemical distillation plant reclaimed fromevery ton of scrap wood, 135 pounds of9

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]house had four much shorter smokestacks.It was stated at the time that the two newsmokestacks were the highest in thepeninsula. By December 19, only part ofthe building was enclosed.Original Power Plant with Ford WaterTank, ca. 1940The power plant was constructed ofsteel and red face brick inset at variousplaces with white stone and stood out fromthe rest of the plant structures because ofits size and beauty. The imposing structurewas centrally located with respect to thesawmill, wood drying kilns and the twobuildings of the wood distillation plant.New Power House with 190-Foot TallSmokestacks, ca. 1925The big power house contained fourboilers of immense capacity. One of theboilers was used even before the buildingwas completed because the powerdemands of the plant were so great. Theold power house had a battery of eightboilers with a total rating of 2,800horsepower. Each of the new boilers wasrated at 1,361 horsepower and was capableof a 250 per cent overload. The four boilershad a capacity of 12,000 horsepower, morethan four times that of the old plant. Thenew boilers burned oil, wood and otherrefuse. Between the new power plant andthe new addition to the sawmill, there was alarge steel connecting link that contained arunway and exhaust pipes conveyingsawdust from every part of the plant for useInterior of the New Power Plant,ca. 1940-195010

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]as fuel in combination with the oil. Thebridge slanted upward from the mill to thepower house at a sharp angle.Theconstruction was of large, heavy steelgirders. By June, 1924, construction workwas almost completed.The power plant has been torn downwith the exception of the two hugesmokestacks.[NOTE: The Ford smokestacks weredemolished on Friday, September 13, 2002,at 12:10 p.m. by a crew from PaschkeDemolition, Green Bay, Wisconsin.]reserve for the hundreds of cars owned bythe workers.The original office at 207 East BrownStreet is now occupied by ColemanEngineering.[NOTE: This building was torn downwhen the First National Bank constructedits new structure which included the entirewest half of the 200 block on the east sideof South Stephenson Avenue.]DAMExploratory work on the dam site beganFebruary 13, 1922.The constructioncontract was awarded to the Stone &WebsterCompany,ofBoston,Massachusetts. Meade & Seastone, ofMadison, Wisconsin, was the firm in chargeof the engineering work. They were alsoconsulting engineers for the PeninsulaPower Company.By May 12, 1923,materials were received and work wasbegun.OFFICEOn September 9, 1920, a large quantityof bricks arrived and construction wasbegun on the Ford office building. Theoffice was located on East Brown Street atthe rear of the Carbis Meat Market on theTrenary property. It was 35 feet by 65 feeton the foundations, had two stories and apartial basement and was constructed ofbrick and reinforced concrete. The buildinghad eight large, roomy offices, four on eachfloor, and a large vault room.FredParmelee was the architect. It served asthe office building for the Ford plant and, fora while, was the place where employeeswere hired.By December 12, 1923, with thecontinued expansion in size of the plant, theBrown Street office was proving to beinadequate and, by February 1 of thefollowing year, Ford was actively planningto build a large, two-story office structure atthe plant. On May 24, plans for moving theoffices from Brown Street were begun.Construction of the new office building hadbeen held up for a while with temporaryoffice quarters being in the maintenancebuilding. The employment office was finallyhoused in a separate building, a framestructure located near the big parkingFord Hydroelectric Dam UnderConstruction, 1923-1924The dam was located southwest of thecity, about midway between the two bridgesover the Menominee River. The awardingof the contract was held up more than ayear and a half, mainly because the11

FORD COMES TO IRON MOUNTAIN: THE BIRTH OFKINGSFORD[By William J. Cummings and David Curtis, 1983]purchase of lands flooded by the backwaterhad not been completed. Some of the landowners were demanding a very high pricefor their lands.By February 1, 1924, work on the damwas progressing very rapidly.Greatheadway was made during the fall andearly winter when extremely favorableweather conditions prevailed. On June 24,the dam was completed and the threegenerators were ready to serve the Fordplant with 11,000 horsepower.Falls. It made miniature Cowboy Lake intoa much larger body of water. Power fromthe dam was transported to the sawmill andbody plants through a system ofunderground conduits. These wires carried2,300 volts of direct current to a substationthat converted the electricity to alternatingcurrent and stepped down the voltage to220.For

A number of Iron Mountain citizens had worked on behalf of the Ford Motor Company to secure options on about 900 acres of land south and west of the city limits extending to the Menominee River, according to an article appearing in the July 8 edition of The Iron Mountain Press. The article also stated that the