Transcription

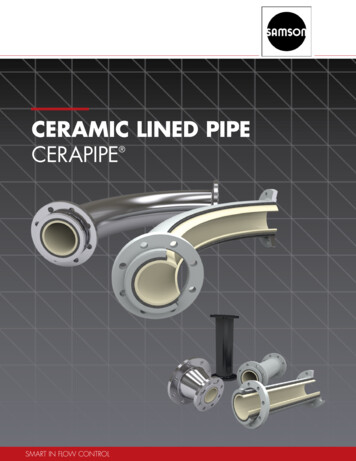

CERAMIC LINED PIPECERAPIPE SMART IN FLOW CONTROL

CERAPIPE CERAMIC LINED PIPECeramic Lined Pipe forPneumatic ConveyingCeramic Lined Wye& Tee JointsCeramic Lined Extensions& ReducersMonolithic CeramicElbowsWear MonitoringCeramic Liner withGRP HousingCeramicOrifice PlateCERAFLEX FlexibleCeramic Hose

FEATURES & BENEFITSSOLID CERAMIC INTERNAL PARTSVAbrasion resistant ceramics ensure a long service lifeVMonolithic ceramic liners available in many sizesVCeramic liner of alumina Al2O3 or silicon carbide SiSiCVSolid ¼” (6 mm) ceramic liner (no coating)Ceramic LinerFillerMetal Housing & FlangeDESIGN OPTIONS AVAILABLEVSuitable for replacement of bothsteel and lined pipeVInlet and outlet can be protectedwith a ceramic collar diskVFlanges & housings availablein various dimensions andmaterialsVWide range of ceramic linedcomponents to suit anyrequirement

COMMON APPLICATIONSSteel Mills & Blast FurnacesVVVVRutile, substitute fuels, soot (blast furnace)Sinter dust (sinter plant)Coat dust (PCI-EAF)Lime, magnesium (pig iron desulphurization)FoundriesVMolding sandMetal industryVSuction systems (e.g. metal swarf)Plastics IndustryVPneumatic conveying of copper concentrate ina copper smelterPneumatic transportation of glass fiber reinforcedplasticsFood IndustryVPneumatic transportation of mineral feed, rice,and muesliSanitationVPneumatic transportation of enamelWaste Incineration PlantsVVSuspension in the HCL pre-washerFlue DustGlass PlantsVPneumatic conveying of soot from a blastfurnaceShards, sand, quartzCement PlantsVClinker dust, lime, cement, slag, flue dust, plasterPigment ProductionVTitanium oxide, iron oxideDye ProductionVVTitanium oxide suspensionIron oxide suspensionSubstitute For Deflection PotsVPipe elbows with small radiiCeramic Lined Pipe for PneumaticConveying/Transportation

CERAMIC MATERIALSHardness and Wear ResistanceAbrasion from entrained solids in liquid flows,high viscosity slurries, pneumatic conveying, andmany other demanding services can drasticallyreduce the life of most traditional metal pipes.Lined pipes utilizing ceramic materials thatexhibit hardness values substantially higher thanmost metals can maximize the life of the pipe.Vickers Hardness 1 in GPa25002200 3Si3N4ZrO2Corrosion ResistanceCompared to other wear resistant materials,ceramic materials are much more corrosionresistant and can be used in a broad range ofcorrosive applications. Ceramics are completelyresistant to most solvents, aqueous brines, andacids, even at relatively high temperatures.Thermal Shock ResistanceCeramic components maintain their shape andstrength as well as physical characteristics upto extremely high temperatures. However, rapidchanges in temperature (thermal shock) canprove challenging for ceramics.CERAPIPE ceramic lined pipes are availablein several materials to handle even the mostdemanding applications.SSiCSilicon CarbideAl2O3Aluminum OxideSi3N4Silicon NitrideZrO2Zirconium OxideThermo Shock Resistance in Si3N4Steel

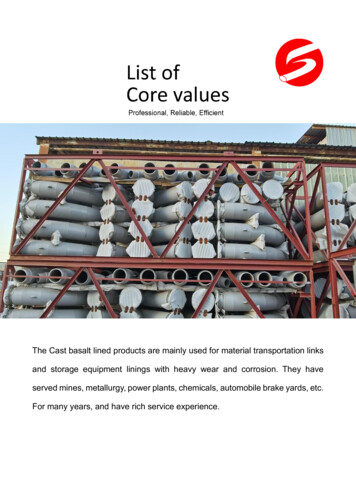

TECHNICAL DETAILSCERAMIC LINED ELBOW AND STRAIGHT PIPENominal SizeNPS ½ to 8Pressure RatingANSI Class 150 and aboveTemperature Range-22 to 662 F (-30 to 350 C)CERAMIC LINED HOSENominal SizeNPS ½ to 3Pressure RatingANSI Class 150Maximum Pressure145 psi (10 bar)Temperature Range14 to 197 F (-10 to 90 C)CERAMIC ORIFICE PLATENominal SizeNPS ½ to 14Pressure RatingANSI Class 150 and aboveBore DiameterOn requestTemperature Range-22 to 662 F (-30 to 350 C)SAMSON Controls Inc.4111 Cedar Blvd. Baytown, TX 77523-8588 USAPhone: 1 281-383-3677 · Fax: ngroup.com2019-07 NA 109CERA SYSTEM is the leading technological pioneer in industrial valves and pipe components with ceramiclinings. Conventional valve materials cannot meet the demands of all industrial applications. Where they fail,high-performance ceramic materials open up new opportunities. Ceramics prove to be beneficial whereverstandard materials reach their limits with respect to wear resistance, corrosion, and high temperatures.

TECHNICAL DETAILS CERAMIC LINED ELBOW AND STRAIGHT PIPE Nominal Size NPS ½ to 8 Pressure Rating ANSI Class 150 and above Temperature Range-22 to 662 F (-30 to 350 C) CERAMIC LINED HOSE Nominal Size NPS ½ to 3 Pressure Rating ANSI Class 150 Maximum Pressure 145 psi (10 bar) Temperature Range 14 to 197 F (-10 to 90 C) CERAMIC ORIFICE PLATE