Transcription

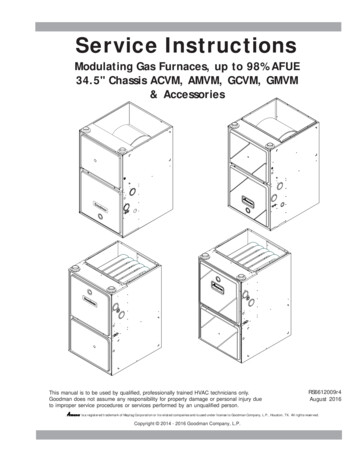

Service InstructionsModulating Gas Furnaces, up to 98% AFUE34.5" Chassis ACVM, AMVM, GCVM, GMVM& AccessoriesThis manual is to be used by qualified, professionally trained HVAC technicians only.Goodman does not assume any responsibility for property damage or personal injury dueto improper service procedures or services performed by an unqualified person.RS6612009r4August 2016is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.Copyright 2014 - 2016 Goodman Company, L.P.1

TABLE OF CONTENTSIMPORTANT INFORMATION . 2-4OPERATIONAL CHECKS . 49 - 51PRODUCT IDENTIFICATION . 5 - 8MAINTENANCE . 52ACCESSORIES . 9 - 11SERVICING TABLE OF CONTENTS . 53LIGHTING INSTRUCTIONS . 12SERVICING . 54 - 62PRODUCT DESIGN . 13 - 24TROUBLESHOOTING . 63 - 67OPERATION . 25 - 47STATUS CODES . 68SERVICE AND OPERATION . 48WIRING DIAGRAM . 69IMPORTANT INFORMATIONPride and workmanship go into every product to provide our customers with quality products. It is possible,however, that during its lifetime a product may require service. Products should be serviced only by a qualifiedservice technician who is familiar with the safety procedures required in the repair and who is equipped with theproper tools, parts, testing instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATIONIN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.IMPORTANT NOTICES FOR CONSUMERS AND SERVICERSRECOGNIZE SAFETY SYMBOLS, WORDS AND LABELSWARNINGONLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL, ADJUST, SERVICE ORREPAIR ( HEREINAFTER, “SERVICE”) THE EQUIPMENT SPECIFIED IN THISMANUAL SHOULD SERVICE THE EQUIPMENT. THE MANUFACTURER WILL NOTTO PREVENT THE RISK OF PROPERTY DAMAGE, PERSONALFLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS APPLIANCE.BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROMIMPROPER SERVICE OR SERVICE PROCEDURES. IF YOU SERVICE THIS UNIT, YOUASSUME RESPONSIBILITY FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAYRESULT. IN ADDITION, IN JURISDICTIONS THAT REQUIRE ONE OR MORELICENSES TO SERVICE THE EQUIPMENT SPECIFIED IN THIS MANUAL, ONLYLICENSED PERSONNEL SHOULD SERVICE THE EQUIPMENT. IMPROPERINSTALLATION, ADJUSTMENT, SERVICING OR REPAIR OF THE EQUIPMENTSPECIFIED IN THIS MANUAL, OR ATTEMPTING TO INSTALL, ADJUST, SERVICE ORREPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL WITHOUT PROPERTRAINING MAY RESULT IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONALINJURY OR DEATH.WARNINGHIGH VOLTAGEDISCONNECT ALL POWER BEFORE SERVICING ORINSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAYBE PRESENT. FAILURE TO DO SO MAY CAUSE PROPERTYDAMAGE, PERSONAL INJURY OR DEATH.2INJURY, OR DEATH,DO NOT STORE COMBUSTIBLE MATERIALS OR USE GASOLINE OR OTHER

IMPORTANT INFORMATIONTo locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased thisproduct. For further assistance, please contact:CONSUMER INFORMATION LINEGOODMAN BRAND PRODUCTSTOLL FREE1-877-254-4729 (U.S. only)email us at:customerservice@goodmanmfg.comfax us at: (731) 856-1821(Not a technical assistance line for dealers.)CONSUMER INFORMATION LINEAMANA BRAND PRODUCTSTOLL FREE1-877-254-4729 (U.S. only)email us at: hac.consumer.affairs@amanahvac.comfax us at: (731) 856-1821(Not a technical assistance line for dealers.)Outside the U.S., call 1-713-861-2500.(Not a technical assistance line for dealers.) Your telephone company will bill you for the call.3

IMPORTANT INFORMATIONCO can cause serious illness including permanent braindamage or death.B10259-216Advertencia especial para la instalación de calentadores ó manejadorasde aire en áreas cerradas como estacionamientos ó cuartos de servicio.Las emisiones de monóxido de carbono pueden circular a travésdel aparato cuando se opera en cualquier modo.El monóxido de carbono puede causar enfermedades severascomo daño cerebral permanente ó muerte.B10259-216RISQUE D'EMPOISONNEMENT AU MONOXYDE DE CARBONECette ventilation est nécessaire pour éviter le danger d'intoxicationau CO pouvant survenir si un appareil produisant du monoxydede carbone continue de fonctionner au sein de la zone confinée.B10259-216is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.4

PRODUCT IDENTIFICATIONGPRODUCTTYPE:G: Goodman BrandA: Amana BrandMVM970603BNFURNACE TYPEV: Variable-SpeedCABINETWIDTHB: 17-1/2"C: 21"D: 24-1/2"AAMAJORREVISIONA: Initial ReleaseMINORREVISIONA: Initial ReleaseNOMINAL INPUT060: 60,000 Btuh080: 80,000 Btuh100: 100,000 Btuh120: 120,000 BtuhADDITIONALFEATURESN: Natural GasX: Low NOxSUPPLY TYPEM: Upflow/HorizontalC: Downflow/HorizontalAFUE97: 97%COMMUNICATION FEATUREM: Modulating Furnace4-Wire Communication ReadyAIRFLOWCAPABILITY@ 0.5" ESP3: 12004: 16005: 20005

PRODUCT IDENTIFICATIONMODEL: AMVM97REV AAMODEL: ACVM97REV AAEquipment TypeAmana Brand Residential Gas FurnaceEquipment TypeAmana Brand Residential Gas FurnaceHeating StagesModulating (35% - 100% of rated input)Heating StagesModulating (35% - 100% of rated input)Cooling StagesTwoCooling StagesTwoControl TypeClimateTalk or Conventional 24 VoltControl TypeClimateTalk or Conventional 24 VoltBlower Motor Type4 Wire Variable Speed ECMBlower Motor Type4 Wire Variable Speed ECMAMVM97Installation Positions0603BN0803BN0804CN1005CN1205DNUF, Hor L/R UF, Hor L/R UF, Hor L/R UF, Hor L/R UF, Hor L/RBTUH Input Range (X 1000)21 - 6028 - 8028 -8035 - 10042 - 120A/C Capable Tons1.5 - 31.5 - 32-42-534.534.534.534.5Cabinet Hight "ACVM97Installation Positions0603BN0803BN0804CN1005CNCF, Hor L/R CF, Hor L/R CF, Hor L/R CF, Hor L/RBTUH Input Range (X 1000)21 - 6028 - 8028 -802-5A/C Capable Tons1.5 - 31.5 - 32-42-534.5Cabinet Hight "34.534.534.534.535 - 100Cabinet Width "17.517.5212124.5Cabinet Width "17.517.52121Heating CFM @ 100% Firing Rate10591316133718701940Heating CFM @ 100% Firing Rate950114613251779ECM Motor H.P.ECM Motor H.P.Draft Inducer3Ø Variable SpeedDraft Inducer3Ø Variable SpeedGas Valve24 VAC, Modulates by Pneumatic signalGas Valve24 VAC, Modulates by Pneumatic signal24 VAC Heating InputsW1 / W224 VAC Heating InputsW1 / W224 VAC Cooling InputsY1 / Y224 VAC Cooling InputsY1 / Y2Primary Heat ExchangerStainless SteelPrimary Heat ExchangerStainless SteelAccessory TerminalsEAC terminal, HUM IN / HUM OUT terminalsAccessory TerminalsEAC terminal, HUM IN / HUM OUT terminalsGas Line EntryLeft or RightGas Line EntryLeft or RightRevision AttributesFirst revision of 34.5" modulating up flow furnaceRevision AttributesFirst revision of 34.5" modulating counter flow furnaceMODEL: GMVM97REV AAMODEL: GCVM97REV AAEquipment TypeGoodman Brand Residential Gas FurnaceEquipment TypeGoodman Brand Residential Gas FurnaceHeating StagesModulating (35% - 100% of rated input)Heating StagesModulating (35% - 100% of rated input)Cooling StagesTwoCooling StagesTwoControl TypeClimateTalk or Conventional 24 VoltControl TypeClimateTalk or Conventional 24 VoltBlower Motor Type4 Wire Variable Speed ECMBlower Motor Type4 Wire Variable Speed ECMGMVM97Installation Positions0603BN0803BN0804CN1005CN1205DNUF, Hor L/R UF, Hor L/R UF, Hor L/R UF, Hor L/R UF, Hor L/RBTUH Input Range (X 1000)21 - 6028 - 8028 -8035 - 10042 - 120A/C Capable Tons1.5 - 31.5 - 32-42-52-534.534.534.534.534.5Cabinet Hight "Cabinet Width "17.517.5212124.5Heating CFM @ 100% Firing Rate10591316133718701940ECM Motor H.P.Draft Inducer3Ø Variable SpeedGas Valve24 VAC, Modulates by Pneumatic signal24 VAC Heating InputsW1 / W224 VAC Cooling InputsY1 / Y2Primary Heat ExchangerAluminized SteelAccessory TerminalsEAC terminal, HUM IN / HUM OUT terminalsGas Line EntryLeft or RightRevision AttributesFirst revision of 34.5" modulating up flow furnace6GCVM97Installation Positions0603BN0803BN0804CNCF, Hor L/R CF, Hor L/R CF, Hor L/R1005CNCF, Hor L/RBTUH Input Range (X 1000)21 - 6028 - 8028 -80A/C Capable Tons1.5 - 31.5 - 32-42-5Cabinet Hight "34.534.534.534.5Cabinet Width "17.517.52121Heating CFM @ 100% Firing Rate95011461325177935 - 100ECM Motor H.P.Draft Inducer3Ø Variable SpeedGas Valve24 VAC, Modulates by Pneumatic signal24 VAC Heating InputsW1 / W224 VAC Cooling InputsY1 / Y2Primary Heat ExchangerAluminized SteelAccessory TerminalsEAC terminal, HUM IN / HUM OUT terminalsGas Line EntryLeft or RightRevision AttributesFirst revision of 34.5" modulating counter flow furnace

PRODUCT IDENTIFICATIONMODEL #MFG #DESCRIPTIONAFE18-60AN/AFossil Fuel Kit. The AFE18-60A control is designed for use where the indoor coil is located above/downstreamof a gas or fossil fuel furnace when used with a heat pump. It will operate with single and two stage heatpumps and single and two stage furnaces. The AFE18-60A control will turn the heat pump unit off when thefurnace is turned on. An anti-short cycle feature initiates a 3 minute timed off delay when the compressor 1251303FP1251304FMedia Air Cleaner. For use with current architectural grey Goodman and Amana Brand 96% variable speed,modulating furnace models. The Amana (AMU*) and Goodman (GMU*) Media Air Cleaner is a high efficiencyair filtration device designed to remove dirt, dust, pollen and other microscopic particles from the air passingthrough it. Flexible performance range up to 2,000 CFM capacity. The air cleaner should be installed in thesystem so that all the system air is circulated through the air cleaner. The air cleaner will only remove theairborne contaminants delivered to it. Maximum performance is obtained when the system blower is set forcontinuous operation. Carbon filters (optional) are available.Electronic Air Cleaner. For use with current architectural grey Goodman and Amana Brand 96% variablespeed, modulating furnace models. The High-Efficiency Electronic Air Cleaner is designed to remove aircontaminants down to .01 microns. Carbon filters (optional) remove odors. Dual indicator lights show unitoperation at a glance. Electronic proving switch cycles the air cleaner On/Off with the system fan. Durablepowder-coat paint finish resists corrosion.N/ACounterflow Subbase Kit. For use with Goodman , & Amana Brand modulating 34.5" furnace models.These kits are available for the following furnace widths: 17.5" wide (CFSB17), 21" wide (CFSB21) and 24"wide (CFSB24). The kits must be used to prevent excessive temperature from reaching combustible materials,if the furnace is installed on a combustible floor. This subbase effectively separated the furnace base andplenum from combustible materials. To ensure safe installation, do not install the counterflow floor basedirectly on carpeting, tile, or other combustible material other than wood flooring.CTK01AACommunicating Thermostat Kit- Digitally communicating touchscreen thermostat, a necessary part of anycommunicating system. Designed for use with compatible Amana Brand or Goodman Brand Air Handlersor Furnaces and outdoor split AC or Heat Pump units. This thermostat supports up to three stages of heat, twostages of cooling, dual fuel applications, dehumidification, filter maintenance reminders, outdoor temperaturedisplay and advanced menus including diagnostics. The CTK01AA kit includes a communicating touchscreenthermostat and sub base, 230V-24V 40va transformer, terminal blocks(2), wire jumpers,mounting screws, installation manual and homeowner guide.CTK01BACommunicating Thermostat Kit- Digitally communicating touchscreen thermostat, a necessary part of anycommunicating system. Designed for use with compatible Amana Brand or Goodman Brand Air Handlersor Furnaces and outdoor split AC or Heat Pump units. This thermostat supports up to three stages of heat, twostages of cooling, dual fuel applications, dehumidification, filter maintenance reminders, outdoor temperaturedisplay and advanced menus including diagnostics. The CTK01BA kit includes a communicating touchscreenthermostat and sub base, terminal blocks(2), mounting screws, installation manual and homeowner guide.CTK02**CTK02**Communicating Thermostat Kit- Digitally communicating thermostat, a necessary part of any communicatingsystem. Designed for use with compatible Amana Brand or Goodman Brand Air Handlers or Furnaces andoutdoor split AC or Heat Pump units. The CTK02** thermostat features full color, high definition display,advanced programming options including humidification control & heat and cool maximum temperaturesettings, a USB plug allowing dealers the ability to insert pre-programmed operating parameters and dealerinformation by use of an online data entry system.CTK03A*CTK03A*Communicating Thermostat Kit- Digitally communicating touchscreen thermostat from Honeywell. Designedfor use with compatible Amana Brand or Goodman Brand Air Handlers or Furnaces and outdoor split AC orHeat Pump units. The CTK03A* thermostat features full color high definition display, can be used withRedLINK wireless accessories.CTK04A*Communicating Thermostat Kit- Digitally communicating touchscreen thermostat from Honeywell. Designedfor use with compatible Amana Brand or Goodman Brand Air Handlers or Furnaces and outdoor split AC orHeat Pump units. The CTK04A* thermostat features full color high definition display, can be used withRedLINK wireless accessories. Split system inverter capable.CFSB17CFSB21CFSB24CTK01CTK01BACTK04A*7

PRODUCT IDENTIFICATIONMODEL #MFG #DESCRIPTIONN/AConcentric Vent Kit. For use with Amana Brand Modulating furnace models. This kit is designed to allowterminations of a direct vent furnace to be "concentrically" vented through a wall or roof. This kit allows a singlepenetration to support terminations for both the vent/flue and the combustion air intake pipe. The DCVK-20 (2")and DCVK-30 (3") kits are certified for models listed above. See specification sheets on future models for useof the vent kit.P1227801FDehumidistat. For use with Goodman & Amana Brand two-stage variable speed modulating furnacemodels. Wall mounted, 24 volt humidity control available as a Dehumidistat used to reduce the airflow in the airconditioning mode when necessary to lower the humidity in an occupied home to prevent dew build-upassociated with high humidity levels. This control features a moisture-sensitive nylon element and alsoprovides positive ON-OFF settings for manual operation. The control is a normally closed switch that opens onhumidity rise causing the blower to switch to a lower speed to control the humidity within the structure.EFR02N/A External Filter Rack Kit. For use with Goodman and Amana Brand 97% upflow, variable speed *MVM 34.5"modulating gas furnaces. This kit is intended to provide a location, external to the furnace casing for installationof a permanent filter. The rack is mounted over the indoor air blower compartment area of either side panel,and provide filter retention as well as a location for attaching return air ductwork.0170K00000SN/ASide Wall Only Concentric Vent Kit. For use with 96% modulating furnace models. This kit is to be used with2" - 3" vent systems. The vent kit must terminate outside the structure. This kit is NOT intended for use withsingle pipe (indirect vent) installations.0170K00001SN/ASide Wall Only Concentric Vent Kit. For use with 96% modulating furnace models. This kit is to be used with2" vent systems. The vent kit must terminate outside the structure. This kit is NOT intended for use with singlepipe (indirect vent) installationLPLP03N/ALP Gas Low Pressure Kit. Designed for application on Goodman and Amana Brand's 80% and 90% singlestage, two-stage and modulating furnaces converted to LP gas. The kit monitors gas line pressure with apressure switch and will open the circuit to the gas valve if the LP tank pressure gets low.LPM-09N/ALP Conversion Kit Converts a 34.5" modulating furnace to operate on L.P. gas. The kit contains an L.P. gasvalve and a set of six L.P. orifices.RF000142N/ADrain Coupling Kit For use when the drain/vent elbow has been removed in a horizontal left installation. Thiskit prevents condensate from getting in the inducer and routes the condensate to a drain.DCVK-20(CVENT-2)DCVK-30(CVENT-3)DEHUM18MFG. #DESCRIPTIONPCBKF2011st Revision toModulating ControlBoardSoftware revision to allow ECM motor to store shared dataPCBKF2022nd Revision toModulating ControlBoardSoftware revision for operation with Daikin Inverter

CN**XXXXXXXX*CVM971005CN**XXXXXXXXLPM-09XL.P. KitXLPLP03XLow LP Tank ProtectionXEFR02XExternal Filter ntric Vent Kit (3")XCVENT-2XConcentric Vent Kit (2")X0170K00001SXConcentric Side WallVent Kit (2")X0170K00000SXConcentric Side WallVent Kit tionCTK01*CTK02*CommunicatingThermostat KitCom Thermostat KitModulating, High M971005CN**XXXXXXXXXXXXXXXXXCom Thermostat KitModulating, High DefCTK04*CTK03*RF000142Drain CouplingKitCom Thermostat KitModulating, High DefCFSB21XCounterflow Subbase21"XCFSB17XCounterflow Subbase17.5"ASAS / GSAS*MVM970803BN**ElectronicAir CleanerXAMU / GMUXMedia Air CleanersXAFE180-60AXFossil Fuel S97% Mod Furnace Accessories9

ACCESSORIESEXTERNAL FILTER RACK (EFR02)Used on 97% Upflow Modulating FurnacesSLOTS IN FILTERCLEAR SCREWSON UNITBLOWER DECKSCREWSUNIT SIDEPANELFRONTOF UNITFILTER RACK ASSEMBLY(FACE FILTER OPENINGTOWARDS FRONTOF UNIT)BASEOF UNITRETURN AIRCUTOUT AREALOWER EDGESCREWCONCENTRIC VENT CONVERSION KIT (DCVK-20 & DCVK-30 [CVENT-2 & CVENT-3*])The DCVK-20 (2") or the DCVK-30 (3") is a concentric vent See the section in this manual under "Vent Flue and Comkit approved with furnaces listed in this manual.This concentric vent kit allows for vertical or horizontalvent termination. The illustrations give a brief view ofthe kit and its application.bustion Air Pipe Terminations" for more information orconsult the Installation and Operating Instructions (IOVent619*).Combustion AirVentStrap(Field Supplied)Maintain 12" (18" for Canada)minimum clearance above highestanticipated snow level. Maximum of24" above roof.Combustion AirRoof Boot/Flashing(Field Supplied)VentSupport (Field Supplied)Flush to1" maximumCombustion Air45 Elbow(Field Supplied)45 Elbow(Field Supplied)VentDCVK(Horizontal Installation)DCVK-20 & DCVK-30 are also known as CVENT-2 & CVENT-310DCVK(Vertical Installation)Combustion Air

ACCESSORIESSIDE WALL VENT KIT (0170K00000S)LPM-09 LP CONVERSION KITThis side wall only vent kit #0170K00000S is to be usedwith 2” - 3” vent systems. This kit is NOT intended foruse with single pipe (non-direct vent) installations.The vent kit must terminate outside the structure and maybe installed with the intake and exhaust pipes located sideby-side or with one pipe above the other.See the section in this manual under "Vent Flue and Combustion Air Pipe Terminations" for more information orconsult the Installation Instructions (IO-635).This furnace is factory equipped to operate on Natural Gasbut may be field converted to operate on LP gas. To convert a *MVM97 or *CVM97 furnace to operate on LP gas,the LPM-09 conversion kit must be used. The LPM-09 kitcontains a modulating gas valve ready for use with LP gas,as well as a set of 1.25 mm orifices to replace the factoryinstalled natural gas orifices. Do not attempt to convert amodulating furnace gas valve. Factory burners are suitable for both gases, L.P. and Natural. Burner replacementis not required when the furnace is converted for use withL.P. gas.SIDE WALL VENT KIT (0170K00001S)This side wall only vent kit #0170K00001S is to be usedwith 2” vent systems. This kit is NOT intended for usewith single pipe (non-direct vent) installations.The vent kit must terminate outside the structure and maybe installed with the intake and exhaust pipes located sideby-side or with one pipe above the other.See the section in this manual under "Vent Flue and Combustion Air Pipe Terminations" for more information orconsult the Installation Instructions (IO-805).AFE18-60A DUAL FUEL ACCESSORYWhen installing the modulating furnace with a heat pump,the preferred installation would include a communicatingthermostat. A communicating thermostat provides controlof gas heat and heat pump operation and eliminates theneed for a separate dual fuel control. A legacy dual fuelthermostat could also be used with 24 volt wiring to control the gas furnace and heat pump. If a communicatingthermostat or legacy dual fuel thermostat are not used,the AFE18-60A kit must be added to provide control of theequipment. This control is mounted indoors near the furnace and provides terminals for thermostat, furnace, andheat pump wiring. The AFE18-60A may be used with orwithout a separate outdoor thermostat.OT18-60A OUTDOOR THERMOSTATFor use in a legacy dual fuel installation to lock-out theheat pump at a selected temperature.LPLP03 LOW LP GAS PRESSURE SHUT-OFF KITInstallation of the LPLP03 kit is recommended on every LPconverted furnace to protect the furnace against low LPgas supply pressure. Low LP supply pressure can cause poorcombustion and carbon in the heat exchanger. The LPLP03kit will open the electrical circuit to the gas valve in theevent of low supply pressure. The kit contains a pressureswitch, gas fittings and electrical harness to connect theswitch in series with the gas valve.CFSB17 OR 21 COUNTER FLOW BASEThe CFSB base must be used when installing a *CVC97 furnace in the vertical position on a combustible floor withouta coil under the furnace.11

LIGHTING INSTRUCTIONSFOR YOUR SAFETYREAD BEFORE OPERATINGLIRE AVANT DE METTREEN MARCHELIREWARNING: If you do not follow these instructionsexactly,a fire or explosion may result causing propertydamage, personal injury or loss of life.AVERTISSEMENT: Quiconque ne respecte pas àla lettre les instructions dans le presént manuelrisque de déclencher un incendie ou une explosionentraînant des dommages matériels, des lesionscorporelles ou la perte de vies humaines.A. This appliance does not have a pilot. It is equippedwith an ignition device which automatically lightsthe burner. Do not try to light the burner by hand.A. Cet appareil ne comporte pas de veilleuse. Il estmuni d'un dispositif d'allumage qui allumeautomatiquement le brûleur. Ne pas tenterB. BEFORE OPERATING smell all around the appliancearea for gas. Be sure to smell next to the floorbecause some gas is heavier than air and willsettle on the floor.d'allumer le brûleur manuellement.B. AVANT DE LE FAIRE FONCTIONNER,renifler tout autour de l'appariel pour decélerune odeur de gaz. Renifler prés du plancher, carWHAT TO DO IF YOU SMELL GAScertains gaz sont plus lourds que l'air etDo not try to light any appliance.peuvent s'accumuler au niveau du sol.Do not touch any electric switch;do not use any phone in your building.QUE FAIRE S'IL Y A UNE ODEUR DE GAZNe pas tenter d'allumer d'appareils.Ne toucher à aucun interrupteur; ne pas vous servirdes téléphones dans le bâtiment.Appelez immédiatement votre fournisseur de gaz depuisun voisin. Suivez les instructions du fournisseur de gazSi vousnepouvez rejoindrelefournisseur degaz,Immediately call your gas supplier from a neighbor'sphone. Followthegassupplier'sinstructions.If youcannot reachyour gas supplier,call thefiredepartment.C. Use only your hand to push in or turn the gas control lever.appelez le service des incendies.»Never use tools. If thelever will not pushinor turn byC. Ne pousser ou tourner lamanetted'admission du gazhand, don't try to repair it, call a qualified servicequ'à la main. Ne jamais emploer d'outil à cette fin.technician. Forceor attemptedrepair may result ina fireor explosion.Si lamanettereste coincée, ne tenter pas delaréparer; appelezun technicienqualifié. Quiconquetente de forcer la manette ou de la réparer peutD. Do not use thisapplianceif anypart hasbeenunderwater.provoquer uneexplosionouunincendie.»Immediately call a qualified service technician to inspectthe appliance and to replace any part of the controlD. Ne pas se servir de cet appareil s'il a été plongé dansl'eau, même partiellement. Faire inspecter l'appareilpar un technicien qualifié et remplacer toutr partie dusystéme de contrôle et toute commande qui ont étéplongées dans l'eau.»systemandany gascontrol whichhas beenunderwater.OPERATING INSTRUCTIONSMISE EN MARCHE1. ARRÊTEZ Lisez les instructions de sécurité dans la. section supérieure de cette étiquette.1. STOP. Read the safety infrmation above onthis label.2. Set the thermostat to lowest setting.3. Turn off all electric power to the appliance.4. This appliance is equipped with an ignition2. Régler le thermostat à la température la plus basse.device which automatically lights the burner.Do not try to light the burner by hand.5. Push the gas control lever to "OFF" Position.Do not force.6. Wait five (5) minutes to clear out any gas. Thensmell for gas, including near the floor. If youthen smell gas, STOP. Follow "B"ROBINET A GAZMANUEL, EN POS"ON/MARCHE"in the safety. information aboveon this label if you don't smellgas, go to next step.7. Push gas control leverto "ON".8. Replace access panel.9. Turn on all electricpower to the appliance.GASINLETARRIVEEDU GAZ10. Set thermostat to desired setting.11. If the appliance will not operate,follow the instructions "To TurnOff Gas To Appliance" and call yourMANUAL GASLEVER SHOWNIN "ON" POS3. Couper l'alimentation électrique de l'appareil.4. Cet appareil menager etant dote d'un systemed'allumage automatique, ne pas essayer àallumer le brûleur manuellement.5. Pousse le levier du contrÔle du gaz a "OFF/ ARRET"position.6. Attendre cinq (5) minutes pour laisser echapper tout legaz. Renifler tout autour de l'appareil, y compris prés duplancher, pour déceler une odeur de gaz. Si c'est le cas,ARRÊTEZ. Passer à l'etape B des instructions de securitesur la portion superieure de cette etiquette.S'il n'y a pas d'odeur de gaz, passer à l'etàpe suivante.7. Pousse le levier du contrôle du gaz à "ON/MARCHE"GASposition.INLET8. Remettre en place le panneau d'accés.9. Mettre l'appareil sous tension.ARRIVEE10. Régler le thermostat à la température désirée.DU GAZ11. Si l'appareil ne se met pas en marche, suivre lesinstructions intitulées Comment couper l'admissionde gaz de l'appareil et appeler un technicienROBINET A GAZMANUEL, EN POS"ON/MARCHE"MANUAL GASLEVER SHOWNIN "ON" POSqualifié ou le fournisseur de gaz.service technician or gas company.POUR COUPER L'ADMISSIONTO TURN OFF GAS TO APPLIANCEDEGAZDEL'APPAREIL1. Set the thermostat to lowest setting.2. Turn off all electric power to the applianceif service is to be performed.3. Push the gas control lever to "OFF" Position.1. Régler le thermostat à la température la plus bassé.2. Couper l'alimentation électrique de l'appareil s'ilfaut procéder à des operations d'entretien.3. Pousse le levier du contrôle du gaz à "OFF/ ARRET"position.Ne pas forcer.4. Remettre en place le panneau d'accés.Do not force.4. Replace control access panel.0140F01910 - A120140F01910 - A

PRODUCT DESIGNAdhere to the following warnings and cautions when installing, adjusting, altering, servicing, or operating thefurnace. To ensure proper installation and operation,thoroughly read this manual for specifics pertaining to theinstallation and application of this product.WARNINGTO PREVENT POSSIBLE PROPERTY DAMAGE , PERSONAL INJURY ORDEATH DUE TO ELECTRICAL SHOCK , THE FURNACE MUST BE LOCATED TOPROTECT THE ELECTRICAL COMPONENTS FROM WATER .WARNINGTO PREVENT PERSONAL INJURY OR DEATH DUE TO IMPROPERINSTALLATION , ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE,REFER TO THIS MANUAL . FOR ADDITIONAL ASSISTANCE ORINFORMATION , CONSULT A QUALIFIED INSTALLER , SERVICER AGENCY ORTHE GAS SUPPLIER .WARNINGIF THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWEDEXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTYDAMAGE , PERSONAL INJURY OR LOSS OF LIFE.DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS ANDLIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE .WHAT TO DO IF YOU SMELL GAS: D O NOT TRY TO LIGHT ANY APPLIANCE. D O NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE ANY PHONEIN YOUR BUILDING . IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBOR’SPHONE. FOLLOW THE GAS SUPPLIER’ S INSTRUCTIONS. IF YOU CANNOT REACH YOUR GAS SUPPLIER, CALL THE FIREDEPARTMENT.INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIEDINSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER.WARNINGCO can cause serious illness including permanent braindamage or death.B10259-216Advertencia especial para la instalación de calentadores ó manejadorasde aire en áreas cerradas como estacionamientos ó cuartos de servicio.THIS PRODUCT CONTAINS OR PRODUCES A CHEMICAL OR CHEMICALSWHICH MAY CAUSE SERIOUS ILLNESS OR DEATH AND WHICH AREKNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER , BIRTHDEFECTS OR OTHER REPRODUCTIVE HARM .WARNINGHEATING UNIT SHOULD NOT BE UTILIZED WITHOUT REASONABLE,ROUTINE, INSPECTION , MAINTENANCE AND SUPERVISION . IF THEBUILDING IN WHICH ANY SUCH DEVICE IS LOCATED WILL BE VACANT,Las emisiones de monóxido de carbono pueden circular a travésdel aparato cuando se opera en cualquier modo.El monóxido de carbono puede causar enfermedades severascomo daño cerebral permanente ó muerte.B10259-216RISQUE D'EMPOISONNEMENT AU MONOXYDE DE CARBONECARE SHOULD BE TAKEN THAT SU

furnace is turned on. An anti-short cycle feature initiates a 3 minute timed off delay when the compressor goes off. AMU1620 AMU1625 AMU2020 AMU2025 GMU1620 GMU1625 GMU2020 GMU2025 P1251305F P1251306F P1251307F P1251308F N/A Media Air Cleaner. For use with current architectural grey Goodman and Amana Brand 96% variable speed, modulating .