Transcription

1.5to 3 TonSeries208V 3.5to 460VConditionerSpecificationsW42HC- W60HCto 5.060hzTon Air208Vto 460V 60hzHeat Pump SpecificationsEER WA Series WALL-MOUNT 1.5 to 3 TonV to 460V 60hz Air Conditioner Specifications.Wall-Mount Air Conditioner is a selfnergywhich WALL-MOUNT is designedEERefficientWAsystem,Series1.5 to 3 Tonximum indoor comfort at a minimal costVto460V60hzAirConditioner Specifications.ng valuable indoor floor space or outsidece. This unitis the ideal productforWall-MountAir as:Conditioneris a selfplicationssuchnew construction,11EERWAWALL-MOUNT 1.5 to 3 Tonnergyefficientschoolsystem,Serieswhichis mindoorcomfortataminimalnication structures, portable structurescostorConditioner Specifications.ngfacilities.valuable indoorflooroutsideFactoryorspacefield orinstalledce.unitis erare Thisavailablespecific isjoba selfpplicationssuchas:new construction,inedefficientsystem,which is designedtsfor energyyour uniqueapplication.schoolcomfortmodernization,er offices,maximum indoorat a minimal costnicationportablestructuresut using structures,valuable indoorfloorspace or oroutsideFactoryorfieldd facilities.space.11EERThisunitistheSeriesideal installedproductforWAWALL-MOUNT 1.5 to 3 Tonavailableto460Vmeetspecificjob Conditioner Specifications.tileareapplicationsas: 60hznewconstruction,208VtosuchAirtsunique application.larfor res,AirportablestructuresorThe Bard Wall-MountConditioneris a selfctionalfacilities.Factoryor whichfield isinstalledcontainedenergy efficientsystem,designedto offermaximumindoortocomforta minimal jobcostsoriesareavailablemeetat specificwithoutforusingfloor space or outsideementsyourvaluableuniqueapplication. indoorComplieswith efficiency requirements of11EER W42HC-W60HC Series WALL-MOUNTTMThe Bard Wall-Mount Heat Pump is a self contained energyefficient heating and cooling system, which is designed tooffer maximum indoor comfort at a minimal cost withoutusing valuable indoor floor space or outside ground space.This unit is the ideal product for versatile applications suchas: new construction, modular offices, school modernization,telecommunication structures, portable structures orcorrectional facilities. Factory or field installed accessories areavailable to meet specific job requirements.ground space. This unitis the ideal productforversatile applications such as: new lecommunication structures, portable structures orcorrectional facilities. Factory or field installedaccessories are available to meet specific jobrequirements for your unique application. ASHRAE/IESNA 90.1-2016W36AB-A Wall-Mount Certified to ASNI/ARI Standard 390-2003for SPVU (Single Package Vertical Units)Intertek ETL Listed to Standardfor Wall-Mount SafetyW36AB-AHeating and Cooling Equipment ANSI/UL1995/CSA 22.2 No. 236-05 Fourth EditionCommercial Product - Not intendedfor Wall-Mount W36AB-Aresidential applicationBard is an ISO 9001:2015 Certified ManufacturerThe AHRI Certified mark indicatesManufacturing CompanyW36AB-ABardWall-Mount participation in the AHRI Certification program. For verification ofindividual certified products, go to www.ahridirectory.org.1 1 EBARDHVAC.COME R WA SE R I E S WA L L -MOU N TF O R M N O . S35 8 4 - 0121TMPAGE 1 OF 27F O R M N O . S357 3 -1118 SUPERSEDES NEWClimate Control Solutions

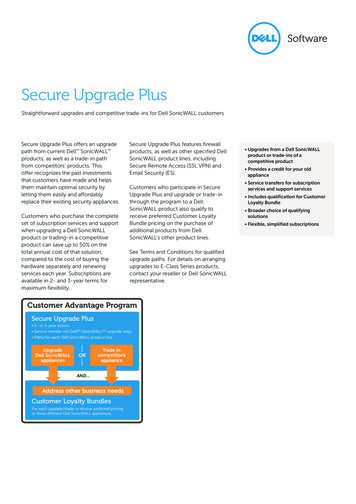

/////// WALL-MOUNT NOMENCLATUREW60HC-A0ZXPXXXXUNIT SERIESWall-MountNOMINAL CAPACITY42- 3.5 Ton48 - 4 Ton60 - 5 TonFUNCTIONALITYH Heat PumpREVISIONC Revision LevelPLACEHOLDERD - DehumidificationVOLTAGEA - 230 Volt 1 Phase 60 HzB - 230 Volt 3 Phase 60 HzC - 460 Volt 3 Phase 60 HzELECTRIC HEAT00 - 0Kw with Lug Connection0Z - 0Kw with Circuit Breaker05 thru 20kw with Circuit BreakerSee Electrical Specs for further detailsVENT PACKAGEX - Fresh Air DamperA - Fresh Air Damper w/ExhaustB - Block Off PlateM - Comm. Ventilator, ON/OFFV - Comm. Ventilator, ModulatingD - Economizer, 0-10V No ControlsY - Full Flow Economizer, JADE Dry BulbZ - Full Flow Economizer, JADER - Energy Recovery VentCOIL & COATING OPTIONSX - Standard1 - Phenolic Coated Evaporator2 - Phenolic Coated Condenser3 - Phenolic Coated Evaporatorand Condenser4 - Coated Coils and condensersection5 - Coated coils, inside and outside of unit11 E E R W H S E R I E S WA L L - M O U N TTMFILTERX - 1" MERV2 Disposable FilterW - 1" MERV2 Permanent FilterP - 2" MERV8 Disposable FilterM - 2" MERV11 Disposable FilterN - 2" MERV13 Disposable FilterCOLOR AND CABINET FINISHX - Beige baked enamel finish1 - White baked enamel finish4 - Buckeye Gray baked enamel finish5 - Desert Brown baked enamel finish8 - Dark Bronze baked enamel finishS - Stainless SteelA - AluminumPLACEHOLDER"X"for future useACCESSORIES AND CONTROLS OPTIONSX – Standard controls.E – Standard controls and Low Ambient Control (LAC).F – Standard controls, LAC, Alarm Relay (ALR) and Filter Switch.J - Standard controls, ALR, LACQ – Standard controls and Outdoor Thermostat (ODT)R - Standard controls, LAC, and Outdoor Thermostat (ODT)S – Standard controls and PTCR Hard Start Kit.T – Standard controls, LAC, ODT, and PTCR Hard Start Kit.PAGE 2 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// ENGINEERED FEATURESNEW! EXCLUSIVE *Non-Fiberglass Foil Faced Insulation: Environmentally friendly high“R” value non-fiberglass insulation that is made with recycled denim and cottonmaterials used with a FSK foil face that is both durable and cleanable.Durable Cabinet Construction: Multiple cabinet construction options are availablefor different outdoor conditions. Optional cabinet coatings may be ordered forextreme outdoor environments. Front access control panel location.Green Fin Hydrophilic Evaporator Coil: Green fin stock is used to help prevent moldgrowth, aid with condensate drainage, and provide a limited amount of protection tocorrosive particulates in the airstream.Optional Mechanical Dehumidification: Models are available with hot gas reheatdehumidification for energy efficient humidity removal. Electronic Expansion Valvesare standard for all dehumidification models.Field or Factory Installed Vents: Multiple ventilation options are available aseasily installed kits with electrical plugs, or Factory installed options that canbe removed for service. Economizer operation includes improved airpath forminimized recirculation.Reliable, Easy-to-Use Controls: Easily accessible through front control panel locations.A lockable hinged access cover to circuit protection is provided. Phase rotationmonitor is standard on all 3 phase models. Adjustable compressor on/off delay timer(CCM) with diagnostic lights is standard on all models.ECM Indoor Brushless DC Motor Technology: 5 speed dual shaft motor provides quietairflow operation when used with a twin blower assembly. Motor overload protectionstandard on all models.Electric Strip Heat: Reliable, comfortable heater packages feature an automaticlimit and thermal cut-off safety control. Heater packages can be factory or fieldinstalled.Easy Filter Access: A separate filter door is provided for ease of filter accessduring routine unit maintenance. 1” and 2” filters are available with a rating ofup to MERV13.Enclosed Condenser Motor: An enclosed casing condenser motor with ball bearingsis used for reliable operation and extended motor life. Enclosed condensermotors are standard on all units.Improved Condenser Coil Cleaning: Removable fan shroud side panels allow foreasy condenser coil intake surface cleaning.High Efficiency Cooling: Scroll compressors for quiet, efficient cooling. Designedwith R-410A (HFC) non-ozone depleting refrigerant in compliance with theMontreal protocol and 2010 EPA requirements. A liquid line filter-drier toprotect the system from moisture is standard on all units.11 E E R W H S E R I E S WA L L - M O U N TTMPAGE 3 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// UNIT MODES OF OPERATIONCooling Operation: The Bard WH Series WALL MOUNT products offer single stage cooling operation using R410Arefrigerant. Copper tube/Aluminum fin coils are used to provide high efficiency and easy serviceability. Scrollcompressor technology delivers years of quiet, reliable operation.Heating Operation: The Bard WH Series WALL MOUNT products offer single stage heat pump operation and optionalsingle or two stage heating operation using resistance heaters. Circuit breaker disconnect protection is standard inall units equipped with electric heat. The reversing valve is energized (B) for heat pump operation.Mechanical Dehumidification Operation: The Bard WH Series WALL MOUNT products offer optional dehumidificationthat removes moisture from air entering the unit. A three-way valve, reheat coil, and electronic expansion valve(EEV) are standard with all models. The dehumidification circuit incorporates an independent heat exchanger coilin the supply air stream. This coil reheats the supply air after it passes over the cooling coil without requiring theelectric resistance heater to be used for reheat purposes. This results in very high mechanical dehumidificationcapability from the air conditioner on demand without using electric resistance reheat.Ventilation Operation: The Bard WH Series WALL MOUNT products offer optional ventilation that brings outdoorair into the structure. Vent options can be factory or field installed, and can be used to bring in outdoor air foroccupants, save energy by using outdoor air for free cooling, or positively pressurize a structure. Exhaust air optionsallow room air to be vented outdoors when fresh air is being brought into the structure. Energy recovery options arealso available for occupied structures which condition the air being brought in to save energy when ventilation isnecessary regardless of outdoor temperature./////// ADVANCED FEATURE DESCRIPTIONSECM Indoor Blower Motor: Energy efficient indoor blower motors use EC constant torque technology with5 pre-programmed speeds. By selecting the needed speed, the WALL MOUNT product can reduce orincrease airflow. A NEMA48 frame enclosure is used. A medium and high speed tap can be userselected to offer the maximum CFM possible with the blower assembly. Efficient 5 speed ECM constant torque motor. 24VAC power used for speed selection.Fully potted electronic control module for moisture protection.6000V surge protection.Dual shaft design with open air over (OAO) enclosure.Outdoor Fan Motor: Outdoor fan motors use ball bearing construction and are fully enclosed for increasedlife expectancy. Single speed PSC motor. Totally enclosed motor housing protects motor windings and internal components from corrosion. Ball bearing design reduces motor wear from “windmill” affect when not in operation.Non Fiberglass Cabinet Insulation: The WH MOUNT products use advanced non-fiberglass insulationthat is made with recycled denim materials. High "R" value, enhanced sound absorption, and reduceddelamination are some of the features of this revolutionary product. Easy to clean and ramage resistant Foil FSK Facing. Fiberglass and Formaldehyde free. Meets ASTM E84, UL 723, NFPA 90A and 90B Standards. Thermal performance ASTM C518 k .27@1” & 900gsm11 E E R W H S E R I E S WA L L - M O U N TTMPAGE 4 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

//////////////CAPACITY AND EFFICIENCY RATINGSMODELSW42HCW48HCW60HCCooling BTUH EER 42,00011.047,50011.054,50011.0High Temp Heating (47F) BTUH COP 39,0003.342,5003.352,5003.3Low Temp Heating (17F) BTUH COP 24,6002.325,0002.133,5002.3 Cooling and Heating Capacities are certified in accordance with ANSI/ARIStandard 390-2003. EER Energy Efficiency Ratio. COP Coefficient of Performance. Energyefficiency data is certified in accordance with ANSI/ARI Standard 390-2003.SPECIFICATIONS 3-1/2 TON THROUGH 5 TONMODELSElectrical Rating – 60 HzW42HC-AW42HC-BW42HC-CW48HC-AW48HC-B230/208 - 1230/208-3460 - 3230/208 - 1230/208 - 3460 - /20810.1/11.74605.3Operating Voltage RangeW48HC-CCompressor--Circuit AVoltageRated Load AmpsBranch CircuitSelection CurrentLock Rotor AmpsCompressor 32.424” - 29001/32.424” - 29001/31.024” - 29001/32.424” - 30001/32.424” - 30001/31.024” - 30001/2 ECM2.4Constant TorqueECM1/2 ECM2.4Constant TorqueECM1/2 ECM1.2Constant TorqueECM3/4 ECM3.3Constant TorqueECM3/4 ECM3.3Constant TorqueECM3/4 ECM1.7Constant TorqueECM1350 - .151350 - .151350 - .151550 - .201550 - .201550 - 60HC-C230/208 - 1230/208 - 3460 - 15.14607.4Fan Motor & CondenserFan Motor--HP--RPMFan Motor--AmpsFan--DIA/CFMBlower Motor & Evap.Blower Motor—HP-SPDBlower Motor—AmpsMotor TypeCFM Cooling & E.S.P.w/Filter (Rated-Wet Coil)Filter Sizes (inches) STD., 2 requiredBasic Unit Weight-LBS.Barometric Fresh Air Damper (X)Barometric Damper w/ Exhaust (A)Blank-Off Plate (B)Commercial Room Ventilator (M, V)Economizer (D, Y, Z)Energy Recovery Ventilator (R)MODELSElectrical Rating – 60 HzOperating Voltage RangeCompressor--Circuit AVoltageRated Load AmpsBranch CircuitSelection CurrentLock Rotor AmpsCompressor oll1/32.424” - 31001/32.424” - 31001/31.024” - 31003/4 ECM3.8Constant TorqueECM3/4 ECM3.8Constant TorqueECM3/4 ECM1.7Constant TorqueECM1750 - .201750 - .201750 - 2441316144244Fan Motor & CondenserFan Motor--HP--RPMFan Motor--AmpsFan--DIA/CFMBlower Motor & Evap.Blower Motor—HP-SPDBlower Motor—AmpsMotor TypeCFM Cooling & E.S.P.w/Filter (Rated-Wet Coil)Filter Sizes (inches) STD., 2 requiredBasic Unit Weight-LBS.Barometric Fresh Air Damper (X)Barometric Damper w/ Exhaust (A)Blank-Off Plate (B)Commercial Room Ventilator (M, V)Economizer (D, Y, Z)11 E E R W H S E R I E S WA L L - M O U N TTMPAGE 5 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// OPTIONAL SHIPPING CRATESOptional crates are available to help protect your valuable WALL MOUNT investment during shipping. Constructed fromOSB sheathing with steel corner posts, and sized for standard truck transportation. Treated for pests in accordance with theInternational Plant Protection Convention, Publication 15, Annex 1. Packaging is acceptable for international shipments.CRATE NO.UNITS USING CRATE8620-304W42HC, W48HCStandard Unit CrateDESCRIPTION8620-305W60HCStandard Unit Crate/////// COOLING APPLICATION DATA - OUTDOOR TEMPERATURE kMODELRETURN 275/62W60HC80/6785/72COOLING CAPACITY75 F80 F85 F90 F95 F100 F105 F110 F115 F120 F125 FTotal CoolingSensible CoolingTotal CoolingSensible CoolingTotal CoolingSensible CoolingTotal CoolingSensible CoolingTotal CoolingSensible CoolingTotal CoolingSensible CoolingTotal CoolingSensible CoolingTotal CoolingSensible CoolingTotal CoolingSensible ACITY MULTIPLIER FACTORS Low ambient control allows for compressor operation down to 0 F.k Outdoor temperatures shown are measured at the condenser section air inlet.l Return air temperature F.% of Rated Airflow-10Rated 10Total BTUHSensible BTUH0.9750.9501.01.01.021.0550 F60 F/////// HEATING APPLICATION RATING AND OUTDOOR TEMPERATURE F kMODEL0 F5 F10 F15 F20 F25 F30 F35 F40 F45 F55 F65 FW42HCBTUH 18600WATTS 3020COP 1.80520300 22000 239003040307031001.957 2.100 2.25925900 28000 30200 32500 34900 37400 40100 42800 45700 4860031303160320032503290335034003460353036002.425 2.597 2.766 2.931 3.109 3.272 3.457 3.625 3.794 3.956W48HCBTUH 18600WATTS 3330COP 1.63720300 22200 243003350338034201.776 1.925 2.08226500 28900 31400 34200 37100 40100 43400 46800 50400 5420034603500355036003660372037903860393040102.245 2.420 2.592 2.784 2.971 3.159 3.356 3.553 3.758 3.961W60HCBTUH 25300WATTS 3920COP 1.89227500 29800 322004000408041602.015 2.141 2.26834800 37600 40400 43400 46500 49700 53100 56600 60300 6400042404310438044504520458046404700476048202.405 2.557 2.703 2.858 3.015 3.180 3.354 3.529 3.713 3.891Performance given for 70 F DB indoor return air at rated CFM. Data includes defrost operation below 45 outdoor temperature. Supplemental Electric heaters are recommended for applications requiring heating below a 15 F outdoor temperature.k Outdoor temperatures shown are measured at the condenser section air inlet.§/////// R410A UNIT CHARGE RATESUNITSTD. UNIT - LBS.DEHUM. UNITS - 11 E E R W H S E R I E S WA L L - M O U N TTMPAGE 6 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// INDOOR AIRFLOW CFM @ STATIC PRESSURES - EC BLOWER CONSTANT TORQUE MOTOR WITH ADJUSTMENT SPEEDSESPW42HC BLOWER TAPS - DRY/WET COIL CFMW48HC BLOWER TAPS - DRY/WET COIL CFMIn H2OBlower andVent OnlySpeed Tap 2Default LOCooling andHeatingOptional MEDCooling andHeatingOptional HICooling andHeatingBlower andVent OnlySpeed Tap 2Default LOCooling andHeatingOptional MEDCooling andHeatingOptional HICooling 1650/15551795/17051845/1755.3"1315/1235Not Used1315/12351510/14151590/15001580/1480Not Used1580/14801735/16401780/1690.4"1240/1140Not Used1240/11401435/13451515/14301500/1400Not Used1500/14001665/15651715/1620.5"1165/1030Not Used1165/10301360/12751435/13551410/1305Not Used1410/13051595/14801655/1545ESPW60HC BLOWER TAPS - DRY/WET COIL CFIn H2OBlower andVent OnlySpeed Tap 2Default LOCooling andHeatingOptional MEDCooling andHeatingOptional HICooling 35.3"1785/1690Not Used1785/16901890/18201955/1880.4"1715/1605Not Used1715/16051825/17501900/1820Above data is with 1” standard throwaway filter and 1” washable filter.For optional 2” pleasted filter - reduce ESP by .15in.See installation instructions for maximum ESP information on various KW application.Five factory programmed speed taps (torque settings) are available for the indoor blower motor, and are selected through differentunit modes of operation. These modes are energized by 24VAC signals from the low voltage terminal block located inside the controlpanel by a thermostat or other controlling device.1. Blower and Ventilation Only Speed is the CFM amount for continuous fan and ventilation without a call for cooling.2. Speed Tap 2 is not used.3. Default LO Cooling and Heating Speed is the indoor CFM amount for cooling operation using the default blower speed tap selection. This speed is labeled as LO on the speed selection terminal strip inside the unit control panel. All units ship with cooling andheating operation at LO cooling and heating speed, and provides the optimal airflow amount for normal use.4. Optional MED Cooling and Heating Speed is selected manually during unit setup and provides a higher indoor CFM for hi staticduct applications and increased airflow. This speed is labeled as MED on the speed selection terminal strip inside the unit controlpanel.5. Optional HI Cooling and Heating Speed is selected manually during unit setup and provides the highest allowable indoor CFMamount. Not recommended for standard unit operation. This speed is labeled as HI on the speed selection terminal strip inside theunit control panel.11 E E R W H S E R I E S WA L L - M O U N TTMPAGE 7 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// ELECTRICAL SPECIFICATIONS — W**HC SERIESMODELRatedVolts Single CircuitknFieldMaximumPowerExternal Fuseor Ckt. Brkr. Wire SizenGroundWireW42HC-A00, A0ZA04A05 230/208-1A10m A151111 or 21 or 2325358848445606090908664410101088W42HC-B00, B0ZB05230/208-3B09l B1511112439515135456060886610101010W42HC-C00, C0ZC05C09l 5566187871105060709090125866332460-3W48HC-A00, A0ZA04A05230/208-1A10m A15m A2011112222j MinimumCircuitAmpacityCkt. A Ckt. BDual Circuitk MaximumnExternal Fuse orField PowerCkt. BreakerWire SizeCkt. A Ckt. B Ckt. A Ckt. BnGroundWire SizeCkt. A Ckt. 306101010W48HC-B00, B0ZB05B09 230/208-3l B15l 8HC-C00, C0ZC05C09l 3W60HC-A00, A0ZA05A10 230/208-1m A15m A2011111orororor2222W60HC-B00, B0ZB09230/208-3l B15l B181112295656N/A406060N/A866N/A101010N/AW60HC-C00, C0ZC09l C15111142828203030121010121010460-3(1) The “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electrical Code (latest version), Article 310 for powerconductor sizing.CAUTION: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay special attention to note 8 of Table 310 regarding AmpacityAdjustment Factors when more than three (3) conductors are in a raceway.(2) Maximum size of the time delay fuse or circuit breaker for protection of field wiring conductors.(3) Maximum KW that can operate with the heat pump on is 9KW. Full heat available during emergency heat mode.(4) Maximum KW that can operate with the heat pump on is 10KW. Full heat available during emergency heat mode.(5) Based on 75 C copper wire. All wiring must conform to the National Electrical Code and all local codes.IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly sized fuses & conductor wires in accordance with the NationalElectrical Code & all local codes.NOTE: MOCP (Maximum Overcurrent Protection) value listed is the maximum value as per UL 1995 calculations for MOCP (branch-circuit conductor sizes in this chart arebased on this MOCP). The actual factory installed Overcurrent Protective Device (Circuit Breaker) in this model may be lower than the maximum UL 1995 allowable MOCPvalue, but still above the UL 1995 minimum calculated value or Minimum Circuit Ampacity (MCA) listed.11 E E R W H S E R I E S WA L L - M O U N TTMPAGE 8 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// ELECTRICAL SPECIFICATIONS — W**HCD DEHUM SERIESMODELRatedVolts Single CircuitknMaximumFieldExternal FusePoweror Ckt. Brkr. Wire SizenGroundWireW42HCDA00, A0ZA05230/208-1A10A15111 or 234608686456090908633101088W42HCDB00, 10W42HCDC00, HCDA00, A0ZA05230/208-1A10A1511 or 21 or 21 or 23561878750709090863310888W48HCDB00, 010W48HCDC00, 0HCDA00, A0ZA05230/208-1A10A1511 or 21 or 21 or 2416793936080100100843310888W60HCDB00, B0ZB09 230/208-3B15111285555406060866101010W60HCDC00, 3j MinimumCircuitAmpacityCkt. A Ckt. BDual Circuitk MaximumnExternal Fuse orField PowerCkt. BreakerWire SizeCkt. A Ckt. B Ckt. A Ckt. BnGroundWire SizeCkt. A Ckt. 066101010101010(1) The “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electrical Code (latest version), Article 310 for powerconductor sizing.CAUTION: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay special attention to note 8 of Table 310 regarding AmpacityAdjustment Factors when more than three (3) conductors are in a raceway.(2) Maximum size of the time delay fuse or circuit breaker for protection of field wiring conductors.(3) Maximum KW that can operate with the heat pump on is 9KW. Full heat available during emergency heat mode.(4) Maximum KW that can operate with the heat pump on is 10KW. Full heat available during emergency heat mode.(5) Based on 75 C copper wire. All wiring must conform to the National Electrical Code and all local codes.IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly sized fuses & conductor wires in accordance with the NationalElectrical Code & all local codes.NOTE: MOCP (Maximum Overcurrent Protection) value listed is the maximum value as per UL 1995 calculations for MOCP (branch-circuit conductor sizes in this chart arebased on this MOCP). The actual factory installed Overcurrent Protective Device (Circuit Breaker) in this model may be lower than the maximum UL 1995 allowable MOCPvalue, but still above the UL 1995 minimum calculated value or Minimum Circuit Ampacity (MCA) listed.11 E E R W H S E R I E S WA L L - M O U N TTMPAGE 9 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// SOUND DATA - DBA @ 5 FT. AND 10 FT.*DUCTFREEINDOOR COOLING OPERATION @ 5 FT.INDOOR COOLING OPERATION @ 10 FT.UnitStandardGrillesWith WMSC5With WMSC5and WAPR-11WMSC5,WARP-11,WAPFB51StandardGrillesWith 2.7W60HC56.55248.447.453.3DUCTEDSUPPLYINDOOR COOLING OPERATION @ 5 FT.OUTDOOR @ 5 FT.With WMSC5and WAPR-11WMSC5,WARP-11,WAPFB51Standard 71.4OUTDOOR @ 10FT.INDOOR COOLING OPERATION @ 10 FT.UnitStandardGrillesWith WMSC5With WMSC5and WAPR-11StandardGrillesWith WMSC5With WMSC5and WAPR-11Standard 6.8Integrated values calculated per ANSI/ASA S12.60-2009/Part 2, Section 5.2.2.1, Integrated Sound Vales are also applicable for use in learning spaces for LEED schools;EQ Prerequisite 3 - Minimum Acoustical Performance, OPTION 1. Using methods prescribed in ANSI S12.60, classroom must achieve a maximum background noise levelof 45 dBa. Results Referenced Were Recorded In The Bard Manufacturing Company, Inc. Sound Lab Facility. Actual Field Application Results May Vary With ClassroomDesign and Construction Methods./////// HEATER PACKAGES - FIELD INSTALLED W**HC SERIES UNITS Designed for adding Electric Heat to 0 KW Units ETL US & Canada Listed Circuit Breaker Standard on 230/208V Models Toggle Disconnect Standard on 460V ModelsAirConditionerModelsW42HC-A00 Models230/208-1-B00 Models230/208-3-C00 Models460-3Heater Model #KWHeater Model #KWHeater Model MCBC-06CEHW6HC-C09EHW4HC-C150Z091511 E E R W H S E R I E S WA L L - M O U N TTMPAGE 10 OF 27F O R M N O . S35 8 4 - 0121 SUPERSEDES 0920

/////// ELECTRIC HEAT TABLE - REFER TO ELECTRICAL SPECIFICATIONS FOR AVAILABILITY BY UNIT MODELNOMINALKWAT 240V 76.7521.710.0BTUH12.533.315.0AT 208V 8,26015.00BTUHAT 460V 5,35920,47818.734,130AT 480V 3416.5620.856,51972.151,195(1) These electric heaters are available in 230/208V units only.(2) These electric heaters are available in 480V units only./////// WALL MOUNT TM VENTILATION OPTION SELECTION CHARTVENTCODEFIELD INSTALLKITXUNITOPERATIONDESCRIPTIONFAD-NE5W42HC, W48HC, W60HCBarometricAir damper provides slight positiveroom pressure during blower operation,No room air exhaust.AFAD-BE5W42HC, W48HC, W60HCBarometricAir damper provides slight positiveroom pressure during blower operation,barometric room air exhaust.BBOP5W42HC, W48HC, W60HCNo VentilationInsulated plates used to seal ventintake and exhaust openings.24V On/OffVent Provides motorized spring returnon/off operation to bring in outdoor airand exhaust room air. No intake hoodrequired.MCR

1.5 to 3 Ton 208V to 460V 60hz Air Conditioner Speci cations 11EER WAe ideal prSeries WALL-MOUNT 1.5 to 3 Ton 208V to 460V 60hz Air Conditioner Specifications. The Bard Wall-Mount Air Conditioner is a self contained energy efficient system, which is designed to offer maximum indoor comfort at a minimal cost