Transcription

brands you trust.Tufline High Performance Butterfly Valves

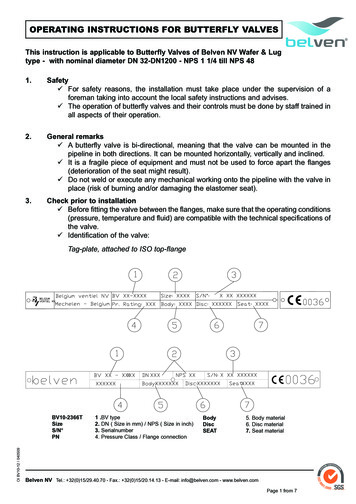

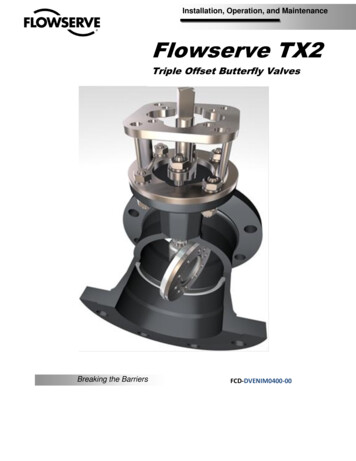

Versatile valving.Contents.PageUnique and patented features. 2Patented soft seat. 4Fire tested andhigh temperature seats. 6Special application configurationsand actuation options. 8Body styles. 9Valve dimensions, bare stem. 10Valve dimensions,manual actuators, soft seated . . 11Valve dimensions,manual actuators, fire-tested . 12Actuator mounting dimensions. 13High Performance ButterflyValve specifications. 14Cv factors. 15Pressure/temperature ratings. 16Break-away torques. 18Valve components. 20Materials of construction. 21How to specify. 22CRANE ChemPharma, Xomox &Matryx actuators. 23CRANE ChemPharma, XomoxService Centers. 23Appropriate Applications: Chemcial Processing Pulp & Paper Air Separation Oxygen Seawater HVAC Steam 2Copyright Xomox Corporation 1980,2010. All rights reserved. Xomox ,Tufline , and Matryx are registeredtrademarks of the Xomox Corporation.1 For superior sealing overprolonged periods, this patentedseat is a proven performer.Choose soft-seated, fire-testedor high-temperature designs.2 Tapered, staked pins preventloosening but permit easyreplacement.3 This positive internal over-travelstop protects both the seat anddisc.4 For longer wear under difficultconditions, the unique retainerdesign protects the seat fromerosion and abrasion.5 I n addition to durable, standardV-ring packing, customerscan also choose from optionalgraphite high-temperaturepacking or emissions controldesign. rush-resistant bearings6 Care positioned for superiorshaft stability. he captured retainer ring7 Tis overlapped by the gasketto prevent external leakageat the flange.Bearings are uniquelydesigned and positionedfor extended service life.Bonded to the interior of thestainless steel bearing is PTFE,impregnated with woven fiberglass. T his unique design resistscrushing better than conventionalfiberglass backed bearings. T he stainless steel providessuperior shaft support whilealso permitting reduced bearingthickness. This improvessealing by reducing lateral shaftmovement. he screwless retainer ring8 Teliminates potential leak pathsand simplifies maintenance.(Standard for sizes 2 through12. Optional on other sizes.) T he PTFE’s high lubricityfacilitates smoother cycling. ccentric disc mounting9 Eminimizes seat wear andlowers operating torques.For high temperature applications,electroless nickel coated stainlesssteel bearings are also available. T he woven fiberglass reinforcesand stabilizes the PTFE,preventing cold-flow.Enhanced durabilityand emissions control.There are three bearings.For enhanced durability, two of theshaft bearings are positioned closeto the disc (above and below).Bending stresses in the shaft arereduced; Shaft and disc deflectionare minimized.The third bearing is located high onthe shaft near the packing chamber.This provides greater shaft stability,assures longer packing life, andhelps control emissions.

Tufline HighPerformance ButterflyValves providesuperior performance in the mostdemandingapplications.1st OffsetDouble offset and eccentricdisc mounting extends seatlife, reducing maintenancecosts and downtime.Seats last longer and maintenanceis reduced because the eccentricallymounted disc minimizes seatdeformation and wear.5Reduced seat deformation.In the open position the disc is notin contact with the seat, so seatdeformation cannot occur.Reduced seat wear.671The service life of the seat is greatlyextended because moving contactbetween the disc and seat isvirtually eliminated.2Reduced friction also means thatoperating torque requirements arereduced. This allows the use ofsmaller, more economical actuators.93When the Tufline valve is opened,the eccentrically mounted discmoves with a cam-like action. Thedisc is lifted away from the seat.360 sealingfor sure shutoff.48Because the disc is offset, theshaft is behind the sealing surfaceof the disc.When the valve is closed, thereis an uninterrupted 360 seal aroundthe full circumference of the disc.3

Superior sealing andextended service life.The seat is axially pliant.Unlike other seals, there is no radial stretch.When the valve opens, the seat flexes axially,returning to its original compact shape.It does not “relax” into the flow path.This seat design includes two components: A n outer segment of chemicallyinert glass reinforced PTFE. A deformation-resistant,memory-core membrane.Simply superior.This seat is simple. There are no springsto break, no O-rings to swell, and no metalhoops to corrode. Installation is also simpleand mistake-proof. Choose soft-seated,fire-tested, or high-temperature designs.The retainer eclipses the seat, protectingit from erosion and abrasion.4Figure 1.Valves closed,with right to left flow.Figure 2.Valve closed,with left to right flow.The axial movement of the seat inthe direction of the flow producesa simple, leak-tight seal. It ispressure-assisted. As line pressureincreases, the seal tightens. Fromvacuum through high pressure, tightshutoff is maintained.Bi-directional flow and shutoff areeasily accommodated. The same,simple, axial movement of the seatassures a reliable seal in eitherdirection.Figure 3.Valve open, with media flowing.Even after 100,000 cycles the seatmaintains a tight seal. The seat’sinternal pliant membrane is the“memory core” that precludes radialdeformation.To further extend seat life, theinside diameter of the retainer ringis smaller than that of the PTFEseat. This protects the seat fromerosion and abrasion.

An internal stop protectsagainst seat damagefrom disc over-travel.The closed bottom of the valvebody eliminates a potentialleak path, increasing safetyand reliability.For enhanced emissionscontrol, the patented*snap-in retainer ringis captive.To protect the seat in a butterflyvalve, the positive internal stoplimits over-travel. An improperlyadjusted actuator could force thedisc beyond the closed position.This can damage both the seat anddisc of a conventional valve that hasno travel-stop.When the valve is installed in thepipeline, the flange gasket overlapsthe captive retainer. This enhancesthe seal by preventing externalleakage at the flange.There are no screws through thestandard butterfly valve retainer ring.Sealing is thereby further improvedbecause potential leak paths areeliminated. Also, there is no bottomplug.The snap-in retainer ring speedsup maintenance and reducesdowntime.* U.S. Patent No. 4,813,650.Blow-out ProofShaftGreatly improved service lifeis assured because the seatis axially-pliant and resistsradial-stretch.FollowerPlateRetaining ringThe shaft and disc aresecurely pinned for moreefficient operation andease of maintenance.During factory assembly, twostainless steel pins mechanicallylock the disc and shaft. Thiseliminates lost motion and providesbetter control.The pins are staked to preventloosening. They pass through thedisc and shaft behind the sealingsurface.The tapered sleeves and taperedpins make replacement of the discor shaft economical because theydo not require matched drilling.5

Soft-seat sealing withfire-tested safety.For applications involving flammablemedia, the dual component seatoffers both superior sealing andfire-tested security.Proven Performance.Numerous test results demonstratethis valve’s ability to meet or exceedthe requirements of API-607 FourthEdition as well as BS SPEC 6755Part 2.The seat combines PTFE andmetal sealing elements. The metalcomponent is available in a varietyof different alloys.This seat establishes both aPTFE-to-metal seal and a dualmetal-to-metal seal.Graphiterope packingMetal seat componentPTFE seat componentMetal tometal sealPTFE tometal seal6Metal tometal sealNormal operation right to left flow.Normal operation left to right flow.This unique seat is designed forbi-directional flow control. Aspressure increases, the seat shiftsaxially in the direction of the flow.This tightens the seat contact withthe disc for sure sealing.Both the metal seat and the PTFEseat are in tight contact with thedisc. As line pressure increases,the seal tightens, axially.Fire emergency.In a fire emergency, as the PTFEportion of the seat deteriorates, themetal portion of the seat maintainsthe integrity of the seal. There is nointerruption of the seal.This also illustrates how theall-metal seat seals.

In case of fire continuous sealing.High temperature sealing.In case of fire, the metal-to-metalseal is uninterrupted. In case ofa partial burn, where the PTFEdoes not completely deteriorate,the metal-to-metal seal continueswithout interruption.With many other valves, the sealis temporarily lost during the early,critical stages of a fire.In the Tufline valve, whether thePTFE is partially or completelydestroyed, the seal is maintained.The fire-tested seat with XeniThinsert (FT20) provides bidirectionalsealing when operating temperaturesdo not exceed 600 F.The tested leak rate of theseseats is zero.Two-point, pressure-assistedsealing in the all-metal seatoperates up to 1000 F.Pressure assisted sealing.Like the membrane seat, theseseats are axially pliant. In the closedposition, flow in either directiontightens the seat against the disc.7

An adaptable designfor specialized service.This is an extremely versatilevalve. Choose from options andreconfigurations that meetspecific application requirements.In each case, the valve maintainsthe superior sealing characteristics and long-term economy ofthe standard Tufline design.Vacuum service.Standard valves can be used to25 mm mercury (Hg). Specialcleaning, to minimize outgassing,is required for service to1 x 10-6 mm of mercury.Steam.Standard valves with reinforcedPTFE (ST2) seats can be usedin saturated steam applicationsup to 135 psia and 350 F.XeniTh high-temp (ST20 & FT20)seats can be used for saturatedand super-heated steam applications up to 600 F.Valves with CF8M stainless steelbodies are recommended for usein steam applications.Steam jacketed and internallysteam traced (STJ Option).For processing solidifying or agglomerating media, the Tufline STJ offers apatented 3-point heating system. Thedesign includes an integral, full bodysteam jacket, a steam traced shaft,and steam tracing of the fullcircumference of the disc.XeniTh “ST” and “FT” HPBV’s areavailable in ASME Class150 and 300design sizes 2” thru 24”. Lug and waferdesigns in wide variety of Body anddisc materials are available. OperatingTemperatures up to 600 F.Oxygen and chlorine.Valves designated for oxygen orchlorine service are thoroughlycleaned and dried per Tuflineoxygen and chlorine cleaningstandards. After they are tested,valves are packaged and sealedin plastic containers.NACE trim.Valves are available to meet thelatest NACE specifications formaterials used in sour environments: NACE MR0175 / ISO15156 and NACE MR0103-2003.This valve performs well inapplications such as sour gas,sour oil, or other medias that cancause sulfide stress cracking orchloride stress cracking.8Fugitive emissions control.The Tufline emissions controlvalve is available with an auxiliarylive-loaded packing option.There are two full sets of packingseparated by a lantern ring. Alsoavailable is an optional leak-off port(XP option).

Body styles to meet your needs.This Tufline valve is available in three different body stylesand a variety of seat materials.Wafer Style.Figure numbers801, 803, and 806.The snap-in seat retainerring provides a full 100%gasket sealing width.Lug Style with snap-inretainer.Uni-directional dead end service.Cryogenic.Both full and semi-cryogenicmodels are available. The bodiesare stainless steel. The seats area combination of stainless steeland Kel-F. Axially pliant sealingassures tight shutoff.See Xomox Bulletin 333767for additional information.Figure numbers 811, 813, and 816.Designated for full pressure deadend service with the seat retainerring located against the upstreamflange. The snap-in seat retainerring provides a full 100% gasketsealing width.Lug Style with boltedretainer.Bi-directional dead end service.Rail tank car.This bottom-mounted, bottomoperated Tufline valve is availablewith a steam jacketed body anda steam traced shaft and disc,as well as a stainless steel bodyFigure numbers 821 and 823.Designated for full pressure deadend service with the seat retainerring located either against theupstream flange or exposeddownstream.The screw-affixed seat retainerring provides a minimum65% gasket sealing width, asspecified by API 609.9

DimensionsBare StemSee page 13 for actuatormounting dimensions.****Alignment hole allows clearance forspecified bolt size.**Defines number of flange boltsrequired. Number of alignment holesvaries by size and pressure class.Class 150 / 285rPBWafer LugEWafer 54.815.388.50838.62 10.74 5.776.009.50832.50 16.06 16.56 3.25 10.88 13.13 7.457.12 11.7583102.81 19.25 20.28 3.50 12.98 16.00 9.279.00 14.25 127123.19 21.25 22.53 3.50 15.23 18.76 11.05 10.00 17.00 12714P1P2/8-11 1.94.11.49/8-11 .38 3.804.223.62 25.68 26.11 3.50 16.25 20.99 12.59 11.62 18.75 121-813.13 4.374.69164.00 29.18 29.18 3.50 18.50 23.50 14.43 13.12 21.25 161-815.00 5.105.45184.50 31.12 31.12 3.50 21.00 25.25 16.30 14.12 22.75 161 /8-8 16.88 5.736.35205.00 36.56 36.56 5.75 23.07 27.50 18.15 15.50 25.00 201 /8-8 18.81 6.417.03246.06 41.06 41.06 5.75 27.25 32.25 21.59 17.75 29.50 201 /4-8 22.63 7.458.26SizeAHJ21.753.254.004.622.1931.88 10.00 10.33 3.255.386.0042.12 11.51 12.10 3.256.7552.25 12.61 13.16 3.257.6262.25 13.75 14.28 3.2588.748.76CMN111Class 300 / 740rPSizeABWafer LugCEWafer Lu

Performance Butterfly Valves provide superior perfor-mance in the most demanding applications. 1st Offset. Figure 1. Valves closed, with right to left flow. The axial movement of the seat in the direction of the flow produces a simple, leak-tight seal. It is pressure-assisted. As line pressure increases, the seal tightens. From vacuum through high pressure, tight shutoff is maintained. Figure .