Transcription

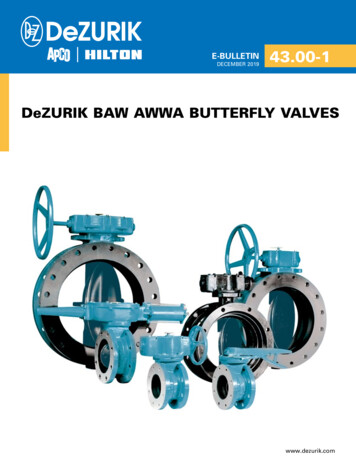

Butterfly Valve Line Up2

Valves & ControlsSince valve.co.kr3

Since 1984 when we stepped into the field of butterfly valve, we have extended a range of supplyand provided advance solutions for the stringent requirements of today s process industry on thebasis of the field experience and continuous research and development.Unicom offers a complete application of butterfly valve to the power plant, district heating, gas andoil industry, chemical plant, and general service. If you have a pressure to be controlled bybutterfly valve, then you can find a solution from SDHIGH-SEALMTDBUTT WELD troChemicalRefineriesSteel &IronPlantEngineering

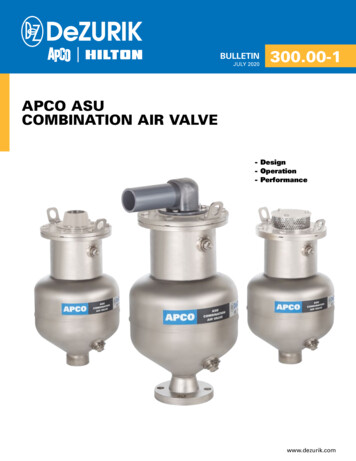

Product ProgramValve BUTT WELDUNI-SEALGRS14GTS15GFBProduction and Quality p://www.unicomvalve.co.kr5

GTDGTD designed for criticalrequirements has provenits reliability and efficiencyin a wide range of application formore than 15 years.Mechanism with an eccentricstructure minimizesan on-off torque at high pressure,providing tight shut-off .Carbon steel and stainless steelare standard materials for bodyand trim with a teflon seat.Other special materials orparticular treatment on trim andbody are available as per theapplication and service.Sealing structureTeflon coated body with titanium disc6

Flange Rating :ANSI CL. 150 / CL. 300 / CL. 600PN 10 / 16 / 25 / 40 / 64Nominal Diameter :DN50(2 ) to DN2100(84 )Temperature Range :-40 C (-40 F) to 250 C (480 F)Working Pressure :Full pressure ratingFeatures :- tight shut-off- low operating torque- compact design- excellent control characteristic- anti blowout shaft design- facile maintenanceGTD with Al-bronze body / Monel disc, shaftApplications :- general & petro chemical- oil refinery / production- steel and iron mill- sugar / paper / gas industry- shipbuilding- combined / nuclear power plant- water / sewage- other plant engineeringOperating :- manual hand lever / worm gear- pneumatic actuator- electric actuatorOptions :- anti-static device- manual operator locking device- bonnet / stem extension- internal teflon / velzona coating- low temperature design- material selection for anti-corrosion,high & low temperature: inconel, monel, titanium, CF3M,aluminum bronze, alve.co.kr7

FSDHaving a combined function ofGTD and MTD, the FSD givesa tight shut-off at nominalpressure and temperature rating.FSD sealing system consists ofreinforced teflon and metal seat.Although FSD has double seatstructure, it requires relativelylow operating torque.FSD valve works with the metalseat when a teflon seat has beenburned out.FSD provides the more reliabilityfor steam and hot air line amongits applications.Sealing structureFire test ( 11823 )

Flange Rating :ANSI CL. 150 / CL. 300 / CL. 600PN 10 / 16 / 25 / 40 / 64Nominal Diameter :DN50(2 ) to DN2100(84 )Temperature Range :-40 C (-40 F) to 250 C (480 F)Working Pressure :Full pressure ratingFeatures :- tight shut-off at fire- fire safety design- light body weight- compact design- anti blowout shaft design- facile maintenance- excellent performance in steamserviceApplications :- general & petro chemical- oil refinery / production- steel and iron mill- shipbuilding- combined / nuclear power plant- other plant engineeringOperating :- manual hand lever / worm gear- pneumatic actuator- electric actuator23http://www.unicomvalve.co.krOptions :- anti-static device- manual operator locking device- bonnet / stem extension- heating jacket- material selection for anti-corrosion,high & low temperature ;inconel, monel, titanium, CF3M,aluminum bronze, etc.http://www.unicomvalve.co.kr9

MTDPrecious metal seated butterflyvalve, MTD is applicable to hightemperature as well as nominalpressure and temperature.Eccentric sealing system assuresa low operating torque andpositive sealing.Wide selection of valve materialsensures efficient performance invarious industries.All unicom butterfly valves aretested hydraulically andpneumatically in shop in order tosecure perfect sealing andcertified by third party atrequest of clients.Sealing structure10

Flange Rating :ANSI CL. 150 / CL. 300 / CL. 600PN 10 / 16 / 25 / 40 / 64Nominal Diameter :DN50(2 ) to DN2100(84 )Temperature Range :-50 C (-60 F) to 650 C (1200 F)Working Pressure :Full pressure ratingFeatures :- inherent fire safety design- metal to metal sealing- low operating torque- anti blowout shaft design- facile maintenance- robust design- fitness for high temperaturesteam serviceApplications :- general & petro chemical- oil refinery / production- steel and iron mill- shipbuilding- combined / nuclear power plant- other plant engineeringOperating :- manual hand lever / worm gear- pneumatic actuator- electric actuatorTitanium V/V(Jacket type)Options :- stellite / ENP on disc- anti-static device- manual operator locking device- bonnet / stem extension- heating jacket- material selection for anti-corrosion,high & low temperature ;inconel, monel, titanium, CF3M,aluminum bronze, etc.Control V/V assembly alve.co.kr11

BWDBWD series, which has two(2) metalseats, is primarily demanded bya district heating system andthermal plant where aMaintenance Free valve isrequired.Since the BWD valve is weldedonto the pipeline, it is made ofbest grade of materials anddesigned for a long life anda reliable performance.BWD, which is available for bothbuttweld and flange endconnection, has a wide range ofapplication from vacuum tohigh pressure and from low tohigh temperature.Double metal seated sealingsystem provides inherent firesafety characteristic and efficientflow throttle capacity.Sealing structure12

Flange Rating :ANSI CL. 150 / CL. 300Nominal Diameter :DN200(8 ) to DN1500(60 )Temperature Range :Up to 650 C (1200 F)Working Pressure :Full pressure ratingFeatures :- butt weld end- tight shut - off at bi-flow direction- double metal seated sealing- light weight, compact design &easy Installation- robust construction- anti blowout shaft design- maintenance free designApplications :- district heating system- gas industry- combined thermal power plantOperating :- manual worm gear- pneumatic actuator- electric actuatorOptions :- manual operator locking device- bonnet / stem extension- stellite on disc with an inconel seat- disc ENP omvalve.co.kr13

GRSFlange Rating :ANSI CL. 150 / PN 10Nominal Diameter :DN40(1.5 ) to DN1500(60 )Temperature Range :-20 C (-4 F) to 120 C (250 F)Working Pressure :Max. 10 BarFeatures :- general applications- bi-directional positive sealing- easy maintenance- anti blowout shaft design- inherent anti-corrosion- rubber liner body seatApplications :- general & petro chemical- oil refinery / production- steel and iron mill- shipbuilding- water treatment- sea waterOperating :- manual hand lever / worm gear- pneumatic actuator- electric actuatorOptions :- teflon v-packing- anti-static device- stem extension- monel / al-bronze body and discGRS type is an elastomer seatedbutterfly valve used for the processdemanding positive shut-off and effectiveflow control.GRS with silicon seat14

GTSFlange Rating :ANSI CL. 150 / PN 10Nominal Diameter :DN50(2 ) to DN300(12 )Temperature Range :-40 C (-40 F) to 175 C (350 F)Working Pressure :Max. 6 BarFeatures :- virgin PTFE liner- one piece PFA encapsulateddisc-stem- silicone back-up ring- bi-directional sealing- double structured stem packing- low operating torqueApplications :- general & petro chemical- pulp / paper- food and beverage- steel and iron mill- sugar refining- sewageGTS, sustainable for anti-corrosive andchemical application, consists of two splitbodies and one piece of disc-stem thatare fully lined with teflonOperating :- manual hand lever / worm gear- pneumatic actuator- electric actuatorOptions :- anti-static device- manual operator locking device- plain disc (non-coated)- mirror polished discLife cycle alve.co.kr15

GFBGFB, double flanged butterflyvalve, has an eccentric structureenabling smooth operation andtight shut-off at any condition.Rubber lining is applicable tothe inner body for anti-corrosionduty to prevent rust and corrosionon the body.Basically GFB has a ringseat made of rubber,yet, as an option,it has a teflon or metal seat asper working condition.Sealing systems1Teflon seat162Metal seat3Rubber seat

Flange Rating :ANSI CL. 150 / CL. 300AWWA C 504Nominal Diameter :DN150(6 ) to DN2250(90 )Temperature Range :- Rubber Seat : Up to 120 C (250 F)- Teflon Seat : Up to 250 C (480 F)- Metal Seat : Up to 650 C (1200 F)Working Pressure :Full pressure ratingFeatures :- long life- low operating torque- availability for various applicationsfrom water treatment to fire safe- anti blowout shaft design- facile maintenanceApplications :- general & petro chemical- refinery- oil production (on / off shore)- steel and iron mill- shipbuilding- water / sewage- power plant- seawaterOperating :- manual hand lever / worm gear- pneumatic actuator- electric actuatorOptions :- internal rubber lining- anti-static device- manual operator locking device- stem extension- special material as per .unicomvalve.co.kr17

Production and Quality AssuranceFactory has been modernized withfacilities such as a precision machineshop, measuring and test shop,R & D section, production engineering.Highly qualified staffs usingprogrammed machining centers withaccurate fixtures guarantee consistencywith high production standards.Machining centerBoring machineTurning machineHydro & Air leak test machine18

All materials used for manufacturing aremaintained in accordance with strict qualityassurance program and subjected to stringentquality surveillance. Prior to be dispatched, allproducts are inspected under the internationalstandards and approved test plans.A modernized quality assurance systemundertakes inspection and test, monitoring andcontrolling quality.Measuring shop and fixtures1Control system23Low Temperature testing with helium ( 1 2 3 e.co.kr19

Precious metal seated butterfly valve, MTD is applicable to high temperature as well as nominal pressure and temperature. Eccentric sealing system assures a low operating torque and positive sealing. Wide selection of valve materials ensures efficient performance in various industries. All unicom butterfly valves are tested hydraulically and