![[ OPTIONAL ] CASE COLLATOR · 90667 LM3231 COMPLETE .](/img/4/91ga8yoa-ts.jpg)

Transcription

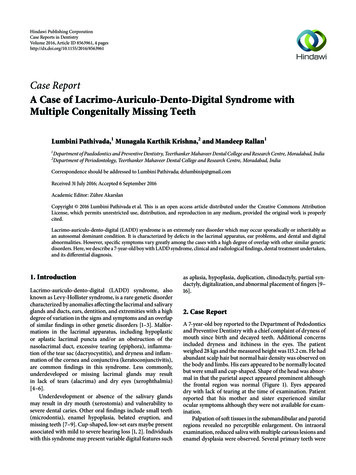

LM3231[ OPTIONAL ]CASE COLLATOR · 90667COMPLETE INSTRUCTIONS FOR THELEE LOAD-MASTERSOMELOAD-MASTERPRESSESSHIP WITHAUTO-DRUMPOWDERMEASURECASE SLIDER · TR2449FEED CRANK · LM3259FRAME · LM3223CRANK SLIDERwith SCREWSWOOD KNOB · TR2447FEED RODLM3262INDEXER · LM3243LEVER · LM3224SHELL PLATE NUT · RE1526O-RING · RE1528FEED BRACKETwith NUT · LM3260INDEXER FLIPPER · LM3244CASE EJECTOR · LM3241CASE RETAINER · LM3246 4 req.TURRET LOCK · LM3226SHOULDER SCREWS · LM3265 4 req.N–20 X 1O with NUT · FL3336BELVILLE WASHERS · LM3263 4 req.PRIMER WEDGE BAR with SCREW · LM3261FOLDING PRIMER TRAY (2-PACK)· 90606PRIMER TROUGH SMALL· 90381 LARGE· 90383PRIMER ROCKER ARM · LM3239ROCKER BOLT not visible · LM3227ROCKER SPRING not visible · TP2115Helpful setupandoperation videosavailable onleeprecision.comCARRIER · LM3238RAM · LM3237WAVE WASHER · LM3208INSIDE RAMSPENT PRIMER DOOR · LM3233DOOR SPRING · LA1075SPRING RETAINER · LM3235DRAW BOLT · LM3242YOKE · LM3236G\af – 20 NUTS · FM1371 · 4 req.LINK PIN ·LM3256GREASE FITTINGS · LM3248YOKE PIN · LM323OCONNECTING LINK · LM3229YOKE PIN CLAMP not visible · LM3232LEE PRECISION, INC. 2015 Lee Precision Inc.4275 Hwy. U · Hartford WI 53027www.leeprecision.comPrinted in USA110.21.16Lee Precision, Inc.LM3231 InstructionsCHECKED BYmjh

The Lee Load-Master is the finest reloading machineever built. To maximize its usefulness,the instructions should be read and fully understood.Lee GuaranteeLEE RELOADING PRODUCTSARE GUARANTEED not to wearout or break from normal use for two fullyears, or they will be repaired orreplaced at no charge if returned to thefactory. Any Lee product of currentmanufacture, regardless of age orcondition, will be reconditioned to new,including a new guarantee, if returned tothe factory with payment equal to halfthe current retail price. 1IMPORTANTYOU MUST DO THESE BEFORE YOU CAN RELOAD1Bolt to a sturdy bench2Install case inserter3Adjust the dies4Adjust case retainers VERY IMPORTANT5Fill primer feeder with correct primers [ See CAUTION, p. 4 ]6Adjust primer seating depth7Attach powder measure and adjust for proper charge8Fill the powder measure with the correct powderALWAYS WEAR SAFETY GLASSES WHEN RELOADING OR SHOOTINGCAUTIONAmmunition reloading can be dangerous if doneim properly and should not be attempted by personsnot willing and able to read and fol low instructionsexactly. Children should not be permitted to reloadammunition without strict parental supervision.Always wear safety glasses when reloading andshooting. Ammunition loaded with these tools anddata should only be used in modern guns in goodcondition. We do not accept responsibility forammunition loaded with these tools or data as wehave no control over the manufacture and storage ofcomponents or the loading procedure and techniques.Primers and gun powders, like gasoline and matches,can be dangerous if improperly handled or misused.Failure to follow these instructions may result inserious injury or death.2WARNINGThe greatest danger in reloading isthe double charge. Should you be interrupted whilereloading, or should anything go wrong, take everypossible precaution in making sure no round hasreceived a double charge.Only CCI or REMINGTON brand primers are safe to usewith this tool, unless you have the Explosion Deflectorinstalled.CAUTIONThe reloading of rifle ammunitionrequires extra care. Because of the extremely highpressures of most rifle ammunition, you must be sureyour cases are in good condition. Inspect them beforeeach reloading for damage and wear. Cases must betrimmed. An excessively long case will pinch the bulletin the end of the rifle chamber and cause dangerouslyhigh pressure that could damage your gun and causepersonal injury.

Mounting Your PressAttach your press to a sturdy workbench with ¼” bolts. Three are required.Mounting distance is the same as the LeePro 1000 and Turret Press. Screws are notrecommended. Be sure that the mountingpads are fully flush with the front edge ofyour workbench. This insures sufficientclearance for the ram.It is suggested that ample room be available to the left of the press. This will beyour work area and a handy place for yourbullets. Only a small area need be keptavailable to the right of the press for emptycases and loaded rounds.Installing the Lee Pro AutoDisk Powder Measurechange from a very large case to an extremely small case.The following is best performed withoutprimers and the turret not installed.Insert the round end of the ¼ squareshaft into the feed bracket, making surethat it is turned with a flat side square tothe press. The crank wire should enter theend hole of the case slider. Tighten the setscrew. Tighten the top screw of the crankslider; use bottom screw to adjust force ofshell insertion.Cycle press to assure free motion. At thePlace the pendant about five beads fromthe end of the chain. Some chain shoulddangle below the pendant as the weighthelps the chain slide through the carrierhole on each cycle.Place the buffer spring on top of thependant. Lace the chain from the bottomof the attach plate to the Pro Auto-DiskPowder Measure.upper most ram travel, place a case in frontof the shell slider, cycle lever, again placecase in front of slider, cycle lever. If thecase collides with the case in shell plate,remove feed rod and unscrew feed bracketone or more full turns. When tighteningfeed bracket, be sure to allow E/af” clearance between carrier tongue and squarerod—about the thickness of a pencil.With the carrier in the down position,thread the chain through the outer mosthole in the Pro Auto-Disk actuator lever.Raise the ram slightly and pass one fullbead through the hole. At this point thechain should be taut between the carrierand the actuator lever. Pass the remainingchain through the inner most hole and pullit tight.Case CatcherAs the shell plate is rotated, at the bottom of the stroke, the loaded round isejected down the chute to the right. TheThe loaded round catcher is held by a special bracket which must be attached toyour bench with the screws provided. Theleft end of the bracket should be parallelwith the Load-Master right mounting lug.Case InserterCases are slid close to the shell plateon the downstroke of the ram and pushedinto the shell plate as the ram starts upward. This unique action is achieved witha crank connected to an angled slide withthe crank slider. The feed bracket can beeasily adjusted in or out as required tofully insert the case. Once set, usually nofurther adjustment is needed unless youTighten top screw. Adjust shell insertion pressure with bottom screw.Do not install 4-tube case feeder untilpress is set up and tested.Fine adjustment is easiest done wherethe chain attaches to the powder measure.The chain passes through two holes in thelever and it will never move, yet it is easilyadjusted.Helpful setup and operation videos available on leeprecision.com3

Installing the LeeAuto-Drum Powder MeasureSee product instructions for setup.Verify Powder DispensedIt is always important to check the setting of any adjustable powder measure.Insert case into shell plate, verify hopperis turned on by turning counterclockwise,raise the ram and dispense a charge.Remove charged case, empty chargeon to scale pan to determine the weight.Make adjustments to measure if it islight or heavy, see powder measureinstructions for adjustment.Preliminary TestingWhen you operate the lever you mustmake complete strokes, stop to stop. Failureto complete the up stroke (lever down) cancause index flipper to put in a “half-cocked”position at mid-stroke and cause press tobind. Continued pressure may damage theejector pawl. If for whatever reason you shortstroke the press, pay attention to the indexeras it pulls out of the carrier at mid-stroke. Ifyou feel it bind — STOP — and pull the indexer out manually to the edge of the framebefore completing the down stroke.FIGURE 1ROTATIONCAMCycle the lever up and down a fewtimes to get the feel of your machine. Asthe ram starts up the case slider shouldmove in and then retract. Theindexer rod flipper will beturned slightly to the left atmid-stroke and back again atthe very top of the stroke. [FIG. 1]About halfway down, the indexer will be pulled toward youby a raised rib and moved tothe right by the sloping projection on the frame.[FIGURES 2 AND 3]4Near the bottom of the stroke the leverwill push against the indexer and smoothlyrotate the shell plate exactly 72. Always move the ram fully to the stopsat both ends of the stroke. Be gentle at thestops. Repeatedly slamming the lever hardagainst the stops will break something. Youhave full control of the speed of ram traveland index. While you can go as fast as youlike and the machine will not malfunction,going too fast will cause the powder to flingout of your cases while indexing and notpermit you to feel when things go wrong.For this reason, we strongly suggest a slowto moderate lever speed. Highest production is achieved with fast lever travel during the mid stroke and learn to slow yourtravel at both ends of the stroke. Remember that large charges of rifle powder needtime to flow, so you must pause sufficientlyfor all of the powder to enter the case.One Last Step! Very Important!At 4 of the 5 loading stations the casesare held in the shell plate with case retainers. The retainers are made to swing outso you can easily remove a case from anyposition. They must be set so that they holdthe case fully into the shell plate. If youpush them in too far the case will correctlyposition them as it passes.Place a single case in the shell holderand set the case retainers against the caserim in all four stations. The case retainersprecisely position the case so that it will becentered to enter the dies and most important to center over the new primerin the second station.Install Primer ExplosionDeflectorThe explosiondeflector mounts to theupper right-hand side ofthe Load Master frame.Two holes cast intothe frame, into whichthe two screws providedwill self tap. Remember,the LoadMaster primeson the up stroke ofthe carrier, so the deflector should bebetween you and the primer tray when thecarrier is all the way up.CAUTIONSome .45 brass now useSMALL pistol primersFilling the Primer FeederSlide the flow control to open. Unfold trayand place on top of box of 100 Remingtonor CCI brand primers. Only Remington orCCI brand primers are safe to use unlessyou have installed the explosion deflector.Do not use Federal or any brand of primersother than CCI or Remington without theexplosion deflector in place. Flip tray overto deposit primers.Shake the tray side to side to uprightprimers. Fold cover and slide the flowcontrol to LOCK. Attach the tray to thetrough. Slide the flow control to ON. Tapthe side of the tray several times to fill thetrough. The trough will remain filled due tothe agitator bumps on the frame. A primerwon’t feed unless a case is present to pushthe primer lever back.Only CCI or Remington brand primers are safeto use with this tool unless you have the optional explosion deflector. Other brands, especiallyFederal primers, explode with such force thatserious injury can occur with their use.Primer Explosion Deflector must be installed if usingbrands of primers other than CCI or Remington.FIGURE 2FIGURE 3KICK-OVERRAMPSet Primer Depth AdjustmentThe N–20 screw that bears againstthe priming rocker arm may require somefine adjusting to seat primers to your liking. Make very small adjustments and testafter each. There is sufficient spring in thelinkage to accommodate slight differencesin cases.Helpful setup and operation videos available on leeprecision.com

OperationAlways move the lever fully to the positive stops at both end of lever travel.Be gentle when you come to the stopsto avoid damage. Cases are not perfectand rims may be damaged. It is importantto always watch to see that the case fullyenters the shell plate.Always keep the primer trough full withCCI or Remington brand primers. No otherbrand is safe to use without the explosiondeflector installed.After the fourth stroke of the lever thesized, primed and charged case should bein a position to start the bullet into the casemouth or rest it on the case mouth if youare loading rifle cases.That’s all there is to it. The Lee LoadMaster is the nicest press you’ll ever use.WARNINGThe greatest danger in reloading is the doublecharge. Should you be interrupted while reloading or should anything go wrong, go wayout of your way to be positive that no round hasreceived a double charge.Cases can be easily removed from everystation by swinging out the case retainer.No case feeder is available for mostrifle cases. Rifle cases should be droppedin front of the case slider at the top of thestroke. It will be automatically inserted intothe shell plate after the index is completed.Keep Your Press CleanIt is especially important to frequentlyclean out the openings in the shell platewhich hold the shell. Dirt or gunpowder willkeep the case from fully entering the shellplate. This will cause feeding, priming andalignment problems.Frequently check the primers to be surethey are seated properly. If dirt falls on thepriming punch, it will deface the primer.Unless it is extreme, it will cause no harm.To remove the dirt, depress the primerrocker arm to raise the punch and wipe itclean with your finger.ram should be oiled before every use and itwill last forever.Automotive engine oil is the best. Anykind of oil is better than none. DO NOT USEWD-40 or dry lubricants. These do not offer sufficient protection.A very tiny amount of grease in the center hole of the shell plate and the squareindexer rod will greatly extend the life ofthe carrier and make it work smooth assilk.Changing The TurretChanging calibers is quick and easy because of the removable turret. It is precisely aligned with the knurled lock screw onthe left. Loosen the screw so the turret canbe rotated about W” and lifted out. Whenreplacing, make certain the lock screw engages the groove in the turret

Filling the Primer Feeder Slide the flow control to open. Unfold tray and place on top of box of 100 Remington or CCI brand primers. Only Remington or CCI brand primers are safe to use unless you have installed the explosion deflector. Do not use Federal or any brand of primers other than CCI or Remington without the explosion deflector in .