Transcription

Targeted Vibration Control DuringInternal ConstructionThe Neue Galerie New YorkBy Arne Johnson and Mark DeMairoBuilding and Project DescriptionAny major construction project presents a number ofchallenges, which are even more complex in an operatingmuseum. Aside from technical issues, which are inherentto all museums, protection of guests, staff, the building,and works of art must be considered, along with logistics.At first take, one may reason that projects at smaller institutions would be easier to manage, but that is only true interms of their magnitude. The issues are the same, and insome ways may be more complicated, due to limited access,and proximity of work to critical areas.The Neue Galerie New York is a 15-year-old house museumlocated along Museum Mile in Manhattan (Figure 1). Thesupplemental chiller project was in the planning stage forseveral years. Architects were chosen based on their extensiveexperience with the Landmarks Preservation Commission; asNeue Galerie is a landmarked building within a historicaldistrict, the new rooftop condenser would need approval.Mechanical Electrical Plumbing Structural (MEPS) consultantswere chosen based on their experience working on museumprojects, specifically in the New York metropolitan area.Although there was a relatively small amount of demolitionand structural work, several factors led to the decision toengage Wiss, Janney, Elstner Associates (WJE), an engineering firm specializing in the investigation, testing, andrepair of existing buildings, including management ofconstruction vibrations at museums. Firstly, several galleriesbelow the worksite were to remain open, one of whichcontained the iconic painting Woman in Gold (1907) byGustav Klimt, and other irreplaceable items in the collection.Secondly, although there were no visible signs of structuralfailure, we had to verify how vibrations would transmitFigure 1. General view of the Neue Galerie New York.18PAPYRUS SUMMER–FALL 2017through, and possibly affect, the 103-year-old building.Thirdly, the majority of the work would take place within20 feet (6 meters) of two adjacent occupied residentialbuildings and the existing chiller plant, and we had to besure that there would be no impact.There were many technical and logistical challengesinvolved, particularly the need to have a comprehensiveunderstanding of the possible risks to staff and visitors, tothe Neue Galerie’s irreplaceable works of art, and to thelandmark building itself. This complexity was compoundedby the need to keep the museum running, while gettingthe job done within strict time constraints.Initial plans were to have a modular chiller with anenclosure fabricated offsite and lifted into place, requiringrelatively simple mechanical and electrical attachments.This would have had very little impact on museum operations and would have greatly simplified structural andwaterproofing issues. Design considerations, includingstrict noise criteria, rendered this method untenable; amuch more invasive process had to be undertaken. Oncethe equipment was selected, the architectural and structuralconcerns had to be addressed, in addition to securingapprovals from the Department of Buildings and theLandmarks Preservation Commission.Cooperation and communication between all departmentswere critical, and swift once the approvals were obtained.The museum’s registrar and curators were involved in theprocess, and were very instrumental in getting severalissues resolved. The strong desire to keep the museumpartially opened was contingent on having Woman in Goldand a number of other irreplaceable works on display.In the end, we were able to close the galleries directlybelow the work area, keeping only two critical galleries open.Controlling and monitoring contractors—while protectingthe art and building from normal hazards such as fire, water,air contaminants, etc. during the construction process—was accomplished by enhancing our already tight protocols.The more challenging aspect was vibration monitoring andcontrol. A customized plan was developed to establish preconstruction conditions, working parameters, and a systemthat would immediately stop work if threshold parameterswere exceeded.In order to execute the more elaborate project, athree-phase plan was developed.Pre-construction preparation phaseThis phase occurred during removal of the spring exhibition,and prior to construction operations (approximately60 days). The major work tasks included:

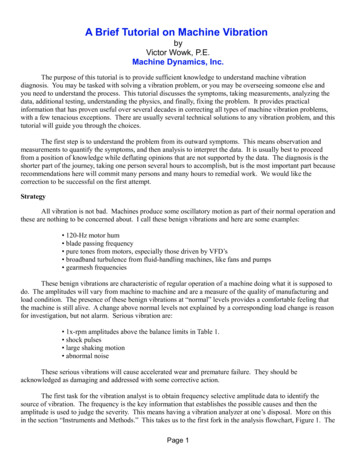

Construction of a temporary office space within thebuilding.Table 1General Steps for Vibration Control DuringMuseum Construction Projects (after Johnson, et al, 2013) Enhancement of the IT network to be VPN-capable. Development and implementation of a constructionaccess and emergency plan, including special trainingfor security and facilities staff. Complete overhaul and testing of the only elevator in thebuilding, to ensure its reliability throughout the project. Complete servicing and protection of the buildingmechanical plant immediately adjacent to the construction area, which had to remain functional andaccessible for continuous operation, monitoring andservicing throughout the project.Construction phaseThe second phase had to be completed within a 30-dayrestricted window, between removal of the spring exhibitionand in advance of the installation of the new exhibition. Thistime constraint left the project with little or no room forerror. The goals achieved by the second project phase were:Step 1 Field vibrationtrials using actualconstructionmethods Step 2Preconstructionplanning Maintenance of a watertight building envelopethroughout.Step 3 Development of avibration controlspecification Step 4Field vibrationtrials using actualconstructionmethodsVibration Control—General Methodology1A.P.Johnson and W.R. Hannen, “Vibration Control During MuseumConstruction Projects,” Journal of the American Institute for Conservation,2013, Vol. 52 No. 1, pp. 30-47.2A.P. Johnson and W.R. Hannen, “Vibration Limits for Historic Buildings,Art Collections and Similar Environments,” APT Bulletin, Journal ofPreservation Technology, Vol. 46:2-3, 2015, pp. 66-74.3A.P. Johnson and W.R. Hannen, U.S. Practice in Vibration Control DuringMuseum Construction Projects, International Council of MuseumsConservation Committee (ICOM-CC) conference proceedings,September 2016, Paris, France. Selection of vibration criteria for theproject, considering the following:—Potential damage thresholds andtypical art/building protectionlimits—Results of ambient vibrationmonitoring—Recommendations of a collectionsspecialist or conservator regardingthe specific art objects to beprotected Development of art stabilizationand deinstallation plans, if any, withinput from the collections specialistor conservator. Installation and waterproofing of a new structuralsteel-supported exterior wall and roof.Given the strict limitations necessitated by the nature ofthe facility, very careful control of construction vibrationswould be required during the internal demolition andstructural work associated with the second phase. Asdetailed in previous articles authored by WJE,1, 2, 3 the fivegeneral steps summarized in Table 1 should be consideredAmbient (background) vibrationmeasurements within the museum. Estimation, based on the test data,of the actual levels of vibration thatthe Museum is likely to experience,due to planned construction activities. Demolition of parapet, roof, and load-bearing walls.Concluding PhaseThe final project phase began after the opening of the fallexhibition. It involved completing the necessary electricalwork, followed by the actual installation of the chiller androoftop condenser—all concluding before the holidayrigging moratorium and a high volume of museum visitors.Work over the winter months continued, and includedfinalizing details of electrical work, pipe-fitting, and finishingwork in preparation for commissioning the new systems inearly spring.In-situ vibration measurements at themuseum using artificially-inducedeffects to simulate constructionactivities, if warranted.See referenced article for details tobe included, as customized for eachproject.Requirements for pre- and postconstruction surveys of buildingand works of art. At the start of construction, performvibration measurements in themuseum during simulated activities,using actual equipment and methodsproposed for use by the contractor. Verification that measured vibrationsare within adopted protection limits.Step 5Vibrationmonitoringduringconstruction Review of contractor’s vibrationcontrol plan, and means-and-methodssubmissions. Continuous vibration monitoringthroughout the construction processwithin the museum (in front of artbeing protected). Monitoring system providingimmediate notifications of abovelimit measurements, and any suchevents evaluated and resolved beforeconstruction is allowed to resume. Regular inspection of art objects byMuseum staff.PAPYRUS SUMMER–FALL 201719

when protecting works of art from construction vibrations.The level of effort and details of each of these steps shouldbe adjusted to fit the specifics of each project, and theneeds of each institution.WJE has previously published on the comprehensiveapplication of these steps for large museum constructionprojects, such as the recent expansions of the Art Instituteof Chicago and Saint Louis Art Museum. However, formore moderate construction initiatives—such as the chillerproject at the Neue Galerie New York—a more targetedapproach is often possible.and museum staff, it was agreed that the five general stepsof vibration control would be consolidated into two phases:a vibration verification phase and a vibration monitoringphase, as described below.Vibration Control Approach Targetedto the ProjectVibration control considerations for the chiller projectbegan with the Neue Galerie commissioning a preliminaryassessment, which involved WJE staff visiting the museumfor a day, meeting with involved parties, viewing the areaswhere the construction was planned, speaking with curatorialstaff regarding the fragility of nearby objects, and reviewingthe drawings of the existing and planned construction. Areport was then prepared regarding the vulnerability of thebuilding and collection to construction vibrations, along withspecific recommendations for vibration control measures.The most significant vibration-causing activities wereidentified as demolition of the fifth-floor brick masonrywalls (approximately 15 feet (4.5 meters) long by 12 feet(3.7 meters) high, (see Figures 2 and 3) and localizeddemolition of existing concrete encasements to attachnew steel framing members.Because the only access to the work area was through theinside of the building, the contractor’s means and methodswere limited to relatively light methods, with the largesttools anticipated to be electric chipping hammers. Basedon prior experience, WJE made preliminary estimates ofvibration transmission in the building. Vibration levels inthe second-floor galleries where works of art would bepresent were predicted to be less than a conservative limitfor protection of art.4 However, it was noted that vibrationtransmission within an existing building is difficult topredict without site-specific testing, especially when thevibration source is within the building itself.Since the preliminary assessment identified that theplanned work would have relatively little impact on themuseum collection, and after consultation between WJEFigure 2. Brick masonry removal area at fifth floor, adjacent to newchiller location.4Severalother institutions have recently used a vibration limit ofapproximately 0.10 in/sec peak particle velocity (PPV), typicallyincreasing with vibration frequency, for the protection of works of art.Research conducted by the authors indicates that this is a conservativelimit for the protection of art that is in reasonably sound condition.Refer to References 1 through 3 for further explanation and specialconsiderations. Given the unique nature and value of the objects beingprotected at each institution, it is prudent that the museum select thevibration limit for each project, based on engineering input, evaluationof objects by art experts, and consideration of the degree of protectionversus the cost of protection.20PAPYRUS SUMMER–FALL 2017Figure 3. Interior view of load-bearing masonry walls to be removedon fifth floor.

Vibration Verification PhaseAmbient vibration monitoring. First, WJE installedvibration monitors (Figure 4) at key locations in themuseum, and collected ambient (background) vibrationdata for approximately one month. Ambient levels rangedfrom 0.02 to 0.07 in/sec PPV5—common values for buildingsof this type. For comparison, human perception of vibrations begins at approximately 0.03 in/sec; a conservativelimit for the protection of art objects in reasonably soundcondition is 0.10 in/sec; and a limit for protection ofbuildings from threshold cracking in plaster wall finishesis 0.50 in/sec.floor, one on the third floor, and one on the second floornear the installed art (see Figure 6). The monitoring systemwas networked, remotely accessible in real time, andprogrammed to provide immediate notifications of anyabove-limit measurements. Two alert levels were utilized:a lower level of 0.075 in/sec PPV to serve as a caution toSubmission review and preconstruction planning. Next,WJE reviewed the contractor’s submissions and interviewedthe contractor regarding their proposed means and methods.Cautions were provided to limit vibratory effects of theproposed methods, including avoiding dropping heavyconstruction materials from any height; limiting impacttools to electric chipping hammers and hand tools, unlessspecialized testing was performed to validate other equipment; using short bursts rather than continuous operationof chipping equipment; sawcutting to isolate areas prior todemolition; placing absorptive materials on horizontalsurfaces where debris collects; and using debris carts withpneumatic rather than hard rubber tires. In parallel, themuseum conducted pre-construction surveys of the buildingand collection, including inspection, documentation, andstabilization as necessary of interior finishes, light fixtures,glass ceiling panels, and similar items that might bevulnerable to vibration. Museum staff also evaluated artlocated near the construction, such as verifying that lightobjects on smooth surfaces were secured against shifting.Vibration trials. To confirm that vibration transmissionwould be within acceptable limits, WJE recommendedspecific field trials at the beginning of the work. Thecontractor simulated work using actual equipment andmethods, while vibrations were measured using multiplesensors placed temporarily on each floor level. As summarized in Table 2, the most significant vibrations measuredduring the trials were 0.085, 0.044, and 0.021 in/sec PPVon each of the floors. The largest vibrations were caused bydropping heavy debris and the impact of a sledgehammer.Work by chipping hammers produced lower vibrations(0.02 in/sec PPV maximum). The trials verified thatvibrations at the location of the nearest work of art onthe second floor would be well below the art-protectionlimit of 0.10 in/sec PPV that the museum had adopted.Figure 4. Looking down at typical vibration monitor installation.Figure 5. Dropping terracotta blocks with plaster finish from aheight during vibration trials.Vibration Monitoring PhaseAs a final safeguard to protect the works of art, a vibrationmonitoring system was deployed and operated continuouslythroughout the demolition and structural work. Basedon the results of the ambient monitoring and field trials,monitors were installed at four locations: two on the fourth50.10in/sec 2.5 mm/secFigure 6. Enclosure (red arrow) constructed around vibrationmonitor in second-floor gallery.PAPYRUS SUMMER–FALL 201721

the contractor, and a project limit level of 0.10 in/sec PPV,independent of frequency.When the monitoring system issued an email notificationthat the alert level had been exceeded at a monitor, thecontractor was required to stop all construction work untilthe vibration engineer analyzed the data and advised allparties on the cause, significance, and appropriate remedialactions. If the event was due to construction activities, thecontractor was required to revise their methods beforeproceeding. The museum’s facilities director was intimatelyinvolved in the field trials and the responses to notificationsof vibration events. This greatly reduced engineering timeand facilitated rapid resolution of all issues.The maximum vibration amplitude recorded on thesecond floor, where works of art were present, was approximately 0.03 in/s PPV—a small margin of the art-protectionlimit. The vibrations recorded at the fourth floor exteriorwall demonstrated that any vibrations transmitted to theabutting residential building were well below disturbinglevels. Vibrations at the fourth-floor monitor, directly belowthe fifth floor demolition, occasionally exceeded alert levels,which served as a useful caution to the contractor.means and methods, and reliably protected art objectsthroughout the construction process. Looking back onthe project, the authors attribute this success to thefollowing factors: Vibration control can be targeted to suit a moderatelysized museum construction project. The five generalsteps summarized in Table 1 are typically appropriatefor a large-scale museum construction project, but amore customized, streamlined plan can often be devisedfor more modest construction works. Such a plan can bemore economical and workable within the constraints ofa smaller project. Trust, communication and collaboration betweenmuseum staff, consultants, and contractors are essentialon any day in the work environment, and are evenmore important when planning and executing a majorconstruction project in a museum.Factors for Success Re-examining and enhancing security, operations andemergency procedures is key. This includes modificationof building inspections, along with scheduling extratime for training and normal building operations, asthey are all affected by construction activities andvibration control procedures.The vibration control measures devised for this projectfacilitated effective advance planning by the museum onthe possible effects of construction vibrations, allowed thecontractor to perform the construction using reasonable It proved useful to have outside peer review of modifiedplans. No one knows museum security and operationsbetter than museum colleagues, and they will giveunbiased views.Table 2Maximum Vibration Levels Measured During Trials (in/sec, PPV)4th Floor3rd Floor2nd nry parapet0.0080.0090.0080.0040.0070.004Concrete beam encasementat roof level0.0070.0070.0060.0030.0040.003Fifth-floor masonry -floor concrete .0070.0210.006Masonry parapet0.0290.0140.0220.0030.0180.004On terracotta near top offifth-floor wall0.0520.0190.0170.0110.0120.004On solid masonry near bottomof fifth-floor wall0.106*0.0310.0440.0070.0220.004Test Activity and LocationElectric Chipping HammerHeavy Debris Dropped from HeightChunk of terracotta droppedonto fifth floorSledgehammer*Based on high values, the impacts of sledgehammers were restricted to softer materials such as terracotta and plaster or brickwork that hadalready been broken up using chipping hammers.22PAPYRUS SUMMER–FALL 2017

It is important for a museum to evaluate and articulateits needs and constraints to consultants and contractors,since every project is different and each facility’soperation is unique.Arne Johnson, P.E. is a structural engineer and Principal with 28 yearsof experience at Wiss, Janney, Elstner Associates in Northbrook,Illinois. His areas of practice include vibration testing andmonitoring, structural evaluation, and structural repair andrehabilitation. Arne can be reached at ajohnson@wje.com. Finally, it is crucial to identify and hire trustworthy,excellent and appropriately experienced consultants.True professionals possess the ability and the willingnessto customize their services for each project, based on itssize and complexity.Mark DeMairo, P.E. is Associate Director at the Neue Galerie inNew York, and member of IAMFA since 1994. Mark has 35 yearsexperience in design, construction and operations of institutionswith the majority being museums. Mark can be reached atmarkdemairo@neuegalerie.org.Figure 7. Completed chiller installation: from roof (left) and in new fifth-floor mechanical room (right).PAPYRUS SUMMER–FALL 201723

of vibration control would be consolidated into two phases: a vibration verification phase and a vibration monitoring phase, as described below. 20 PAPYRUS SUMMER -FALL 2017 Figure 2. Brick masonry removal area at fifth floor, adjacent to new chiller location. Figure 3. Interior view of load-bearing masonry walls to be removed on fifth floor.