Transcription

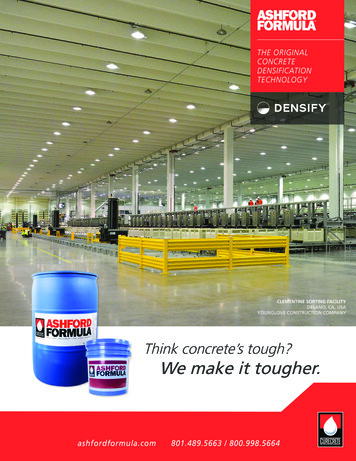

THE ENTINE SORTING FACILITYDELANO, CA, USAYOUNGLOVE CONSTRUCTION COMPANYThink concrete’s tough?We make it tougher.ashfordformula.com801.489.5663 / 800.998.5664

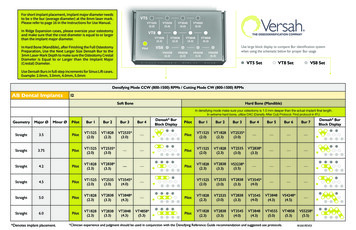

Ashford Formula is a chemically reactive liquid that penetrates theconcrete, solidifying the concrete surface components into a solid mass.It produces a permanently denser, harder, penetration and abrasionresistant concrete surface. Ashford Formula is inorganic, nontoxic, VOC free, colorless and odorless.Ashford Formula densifies concretesurfaces into a solid mass bypenetrating the concrete andchemically filling the pores from within.Ashford Formula chemically hardensthe concrete surface, increasing theabrasion resistance by 32%.ABRASIONRESISTANC EDENSIFIESDUSTPROOFSPERMANENTSHEENDENSIFYAshford Formula combines withcalcium hydroxide, becoming anintegral part of the concrete, thuscompletely dustproofing the surface.This reduces maintenance costs andprotects inventory and equipment fromconcrete dust.Ashford Formula reacts immediately,chemically stabilizing the finishedconcrete surface. It also acceleratesand enhances hydration of theportland cement, helping the concretereach its design properties.CURESOver time, Ashford Formula treatedfloors develop a wax-like sheen. Asa floor is subjected to traffic andregular cleaning, the machine-troweledconcrete self-polishes, instead oferoding or wearing away.E L I M I N AT E S H I G HMAINTENANC E C OSTSApplication of the Ashford Formula is aone-time, permanent application. Thiseliminates the need for expensivere-application materials, labor costsand facility downtime. Routine surfacecleaning is all that is required for longterm maintenance.FOR STRONGER, TOUGHER CONCRETE FLOORSFor years, concrete floors were protected with films and coatings - merely temporary solutions which wear away and require re-application. AshfordFormula takes a different approach by penetrating the concrete surface, growing crystals in the concrete itself. This reaction fills the natural pores andvoids in the concrete, densifying the surface internally.x2500NON-DENSIFIED CONCRETEA simple scratch test with a metalobject demonstrates the softness ofnon-densified concrete.This non-densified concretesample reveals the porousstructure of concrete, which leadsto wear and deterioration.x2500ASHFORD FORMULA DENSIFIED CONCRETEScratching a concrete surfacedensified with Ashford Formulareveals no erosion or dusting.Ashford Formula has strengthenedthe concrete surface from within.Ashford Formula densifies bypenetrating the concrete surface andfilling the natural pores and voidswith crystalline growth.

THE RIGHT DECISIONNOW, AND FOR THE FUTUREHYUNDAINOŠOVICE, CZECH REPUBLIC2008There are so many choices and so many reasons, but the decision is simple. An Ashford Formula treated floor simply out-performs thecompetition in results and long-term cost savings, with an economical one-time investment. Properly densifying your floor means doing thejob right the first time for results that last a lifetime.SUBSTANTIALCOST SAVINGSProven long-term performance atminimal costSingle, permanent application - noneed for expensive re-applicationmaterials, labor or costly facilitydowntimeQuick application - saves valuableconstruction time and costEliminates high maintenance costs only routine cleaning is required foroptimum resultsREDUCEDENVIRONMENTAL IMPACTUse of existing concrete floors as thefinished surfacePermanent life cycle - no need forreplacement like floor coveringsCERTIFICATIONS& RECOGNITIONSTUV Tested and CertifiedZero (0) VOCsCE Declaration of ConformityProduces no fumes, vapors, off-gassing;VOC free - improves indoor air qualityContributes to LEED points forsustainable buildingREACH CertifiedApproved for use infood handling facilitiesPackaged in re-conditioned blue drumsI AM CONVINCED THAT THE ASHFORDFORMULA IS THE ONLY WAY TO GO, AND IDON’T HESITATE TO GIVE THE FORMULA ANUNQUALIFIED RECOMMENDATION.J. Keith McCoy, Chief of Maintenance, Pennzoil CompanyPENNZOIL EXECUTIVE HANGARHOUSTON, TX, USA1980

1REAL PROJECT HIGHLIGHTS15Hal Factory // CHINA2Ozeaneum Museum // GERMANY3Ajans Medya // TURKEY6 Daechun Harbor // SOUTH KOREA4 Parking Garage // CHINA5 Metro // VIETNAM7 Uline // WI, USA8 Maintenance Garage // VA, USA6A SOLID FOUNDATION, FROM THE GROUND UPYour business productivity requires a solid, DENSIFIED concrete floor.

34INDUSTRIES SERVED Correctional Facilities Exhibit Halls Parking Decks / Garages Data Centers Manufacturing Plants Retail Stores Distribution Centers Outdoor Concrete Stadiums / Sports Arenas WarehousesNote: This is not a comprehensive list. Ashford Formula and Curecrete’s line of supporting products can be used on most any concrete floor serving a multitude of industries and functions.87Your concrete floor is more than a building foundation. It is also thefoundation of your business productivity. For lifelong floor performance,long-term cost effectiveness and sustainability, worldwide corporationslike Caterpillar, CocaCola, DHL, Procter & Gamble, IKEA and Whirlpoolhave chosen Ashford Formula as their concrete densifier of choice.With its one-time application, the Ashford Formula never requiresre-treatment. It provides exceptional performance for the entire lifeof your floor. Never halt your business productivity or pay for costlyrepeated applications down the road. It’s why notable worldwidecorporations have chosen the performance of the Ashford Formula.With the longest proven track record of performance in the industry,65 years and counting, Ashford Formula is the trusted product forpermanent, superior concrete floor results.

PRODUCT INFOSHUIDENG MACHINERY COMPANYWUXI JIANGSU, CHINA2006DESCRIPTIONClear, odorless, non-toxic, non-combustible,non-flammable. Contains no VOCs.SURFACE PREPARATIONSURFACE APPEARANCE Freshly Finished Concrete (NEW):No preparation required. Existing Concrete (OLD):Sweep, scrub or strip concrete toremove any surface contaminantsor film.On smooth troweled concrete, a sheendevelops within 4-12 months. All othersurfaces retain their natural appearance. Thesheen can be accelerated by burnishing thefloor. A spiff coat can also be used to enhancethe initial sheen.USESConcrete, heavyweight concrete block,exposed aggregate and other sand/aggregateportland cement combinations.New or old concrete, rough or smooth surfaces.FUNCTIONSDensifies, dustproofs, hardens and cures.Protects against dusting, pitting, spalling,efflorescence and surface crazing. Inhibitsfreeze/thaw deterioration.PACKAGING 55 - gallon drums / 208 liters 5 - gallon pails / 19 litersEQUIPMENT CLEAN-UPAPPLICATIONOnly one permanent application is required.Apply with high-volume, low-pressure sprayeruntil flood coat is achieved. Work materialinto the surface with fine-bristled brooms,or with an auto scrubber. Keep the entiresurface wet with Ashford Formula for 30minutes. Then when the Ashford Formulabecomes slippery, flush completely with waterand squeegee dry or vacuum excess with anautomatic scrubber.*See Spec Data Sheet or ApplicationSpecifications for specific details.Use soap and water before the AshfordFormula dries.PAINTINGAllow at least seven (7) drying days beforeapplying paint on existing concrete.Allow twenty-eight (28) days for proper curingbefore painting new concrete.NOTEApply to colored concrete only after the slabis fully cured, unless installed by a factorycertified applicator.STORAGE LIFETEMPERATURE LIMITSIndefinite. Agitate before use.Apply in temperatures up to 115 F (46 C) or aslow as 35 F (1.7 C) and protect from freezingfor a period of six (6) days.Do not allow to dry on finished surfaces(glass, aluminum, stainless steel, walls, etc.) aspermanent etching may occur.Approximately 200 ft2/gal (5 m2/L).DRYING TIMECoverage may depend on the temperature andporosity of the concrete.One (1) to three (3) hours. The surface maybe used as soon as the application is completeand the surface is dry to the touch. Newlyplaced concrete requires the normal hardeningperiod.Ashford Formula is a highly effectivecompound which delivers superior results.Application should be performed by qualifiedcontractors with a clear understanding of itsapplication and uses. *See Spec Data Sheetor Application Specifications for specificdetails.COVERAGEQUICK PECDATA

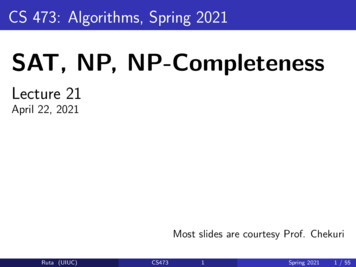

ancesistReATED SAMPLTREEF OR MU 32.5%LA .10.10.1UNASO RDHFreased AbrasionIncPERFORMANCE CRITERIALessWearINCREASEDABRASION RESISTANCEASTM C 779 - Depth of WearAbrasion Resistance to Revolving Disks:An improvement of 32.5% over untreatedsamples after 30 minutes.REFTILEWETDRY999ASTM C 1028 - Friction888777666The co-efficient of friction on steel-troweled samples:reference tile vs. Ashford Formula(a higher ratio represents a less slippery surface):Wet - 0.69 vs. 0.47 // Dry - 0.86 vs. 0.71555444333222111ORD FORMUHFLA 13.3%LEASTM C 856 - Petrographic Examination(Density of the Paste)ATED SAMPENHANCED CURINGUNETRC3O9GREATERIMPACT RESISTANCEASTM C 805 - Rebound NumberThe number of unhydrated cement grains remainingon the surface - depth of 150 - 250 τµm.Fewer unhydrated cement grains mean better curing.PERMEABILITYUsing a 7 ft. (2.13 m) headof water on a 4.91 in2(124.71 mm2) area treatedwith Ashford Formula onlyallowed a rate of 0.00073oz (0.022 cc) / hour. Afterseveral days the samplebecame damp, but noobservable local seepage.WEATHERINGASTM G 23 - LightExposure DegradationASH 2OAdhesion of Coatings:For epoxy, a 22% increasein adhesion over untreatedsamples. No change inadhesion for polyurethane.AFHIGHER FRICTIONAFASTM D 3359 Surface AdhesionSeepage RateREFTILEAFBONDINGImpact Resistance by Schmidt Hammer:An increase of 13.3% over untreated samples.Exposure to ultraviolet lightand water: No evidenceof adverse effects on thesamples treated withAshford Formula.This technical informationis provided as a generalperformance profile forevaluating the appropriateuse of Ashford Formula.Independent laboratoriesobtained the testperformance results undercontrolled environments.Curecrete Distribution,Inc. makes no claim thatthese tests, or any othertests, accurately representactual design and/or usageenvironments.

PROPER MAINTENANCEOPTIMAL PERFORMANCE.for a lifetime.MAINTENANCE PROGRAMAn effective maintenance program that includes routine scrubbing with stiff bristle brushes, ample down pressure, and proper amounts of water anddetergent will enhance the floor’s performance significantly. Implementation of the following maintenance program will allow the Ashford Formula tocontinue to react with the concrete, lifting contaminants away from the concrete and allowing the marble-like sheen to develop.Scrub Floor OFTEN: Minimum routine cleaning 2 - 3 times per week with CreteClean Plus with Scar Guard provides superior results.Clean Spills QUICKLY: After densification is complete, concrete will resist contamination and moisture penetration of most liquids.Corrosive or aggressively staining contaminants should be removed quickly to avoid possible staining.RECOMMENDED SUPPLIES Automatic ScrubberCapable of 125 - 150 lbs. of downward pressure. Black Stripping Pads or Medium-Aggressive Nylon BrushesAccelerates the sheen and creates a more uniformappearance. Detergent: CreteClean Plus with Scar Guard Performance enhancing detergent specifically designedto clean densified and densified-polished concrete floors.Regular use helps decrease the visibility of minor scratchesand blemishes and helps maintain the concrete sheen. Large Volumes of WaterWater used while cleaning the concrete surface will actuallyaccelerate the reaction between Ashford Formula and theconcrete. Oil Emulsifier & Acrylic Stripper: CreteStrip Use directly on stain for spot treatment. Polypropylene or Stiff-Poly BrushesRegular mainentance after sheen develops.RECOMMENDED PRODUCTSOIL EMULSIFIER,& ACRYLICSTRIPPER:DETERGENT:SINGLE DOSE 5 gal. (19 L) pails Single dose pouch for mop and bucket 5 gal. (19 L) pails 55 gal. (208 L) drums Single dose bottle for auto scrubber 55 gal. (208 L) drumsCASE STUDY: NORTH POINT TOYOTAThe use of truck soap hadcaused this floor to have a dullappearance. After a propermaintenance program wasimplemented, the natural sheenfrom the Ashford Formula wasonce again visible.NORTH POINT TOYOTALITTLE ROCK, AR, USA

TBC DISTRIBUTIONSUMMERVILLE, SC, USA2010Photo Credit: Leslie Burden. Reprinted with permission from the Charleston Regional Business Journal.The TRUTH is.How you treat your floor now, determineshow your floor will treat you down the road.LIFELONG, OPTIMAL PERFORMANCECleaning your Ashford Formula floor is convenient, economical and will result in a floor that has a marble-like sheen that improves with age. WithAshford Formula, there is no surface film or coating present to peel, blister or require expensive replacement and repeated applications. The floor’sperformance, as well as the satin sheen that develops over time, is enhanced by proper cleaning and maintenance. Following a proper maintenanceprogram as outlined here will ensure optimal floor performance for a lifetime.EXPECTATIONS FROM A PROPERLY MAINTAINED FLOORIMMEDIATELY AFTER TREATMENTThe hardening and dustproofing will take effect within the normal curing period on new concrete and within 24-48 hours on existingconcrete. The floor will have a normal concrete appearance or a slight sheen (broom-finished or rough-textured concrete will retain itsnatural concrete appearance).The density and hardness of the floor will be immediately enhanced. However, care should be taken not to gouge the floor with nails, etc.after the initial placement.To accelerate the sheen, the floor can be burnished with a high speed propane burnisher and a black stripping pad at 1800 to 3000 RPMs,or cleaned daily using an auto-scrubber equipped with medium-aggressive nylon brushes. A spiff coat can also be done to enhance theintial sheen.3-6 MONTHS AFTER TREATMENTIf the standard maintenance program is followed, smooth-troweled floor surfaces will develop a sheen.Note: A sheen will not develop on floors with an open, porous finish, or on floors with a broom finish.On steel-troweled floors, water typically begins to bead on the surface.12 MONTHS AFTER TREATMENTA hard shell-finished surface will develop.Surface is resistant to oil penetration and moisture contamination.

See how our “One Complete System”of concrete floor products workstogether to enhance the performanceof your concrete floors.ISOONE COMPLETE SYSTEMFOR ALL YOUR DENSIFIEDAND DENSIFIED-POLISHEDCONCRETE FLOORINGNEEDSPREPFILL & REPAIR.ONE EXPERT SOURCE65QUALITYA quality floor, paired with quality products, equals superior flooring results.Let our products take your floor to the next level.YEARS65 YEARS OF LIVINGPROOF THATABSOLUTELY CAN’TPERFORMANCEBE DISPUTEDFrom start to “finish,” our One Complete System of concrete floor productsoutperforms the competition and will ehance your concrete floors’performance durability, longevity and appearance.Whether old or newconcrete, our productswill enhance your floor’sperformance, ensuring itsdurability and longevity fora lifetime.VALUEYour floors, done right, and done once, will save you time and money inthe long term. Products that don’t perform, and which require repeatapplications, hamper your business’ productivity and bottom line.THE “ORIGINAL”CONCRETE DENSIFER1989Built in 1949, the Casa de Cadillac dealership in Sherman Oaks, CA, USA is one of the earliestdocumented floors treated with the Ashford Formula. This facility is on the California historicalregister. Still in use today, the concrete floor has provided more than six decades of continuousservice and attests to the longevity and durability of the Ashford Formula.2OO9

C YA N A T E.DENSIFYDENSIFY-POLISHFINISHCLEANTHE DIFFERENCE“GREEN” BY DESIGNThe Ashford Formula and the concept of concretedensification was “green” well before going “green”ever became a movement. The permanent effects of thisunique combination will save significant time, money andenergy in the long term.FROM THE VERYBEGINNINGThe Ashford Formula’s green qualities make it an exceptional choice for today’s sustainable and greenbuilding initiatives. It has been widely specified for use on projects that have garnered LEED Certified,LEED Silver, LEED Gold and LEED Platinum status.SUSTAINABILITY BENEFITSLEED PLATINUM1Energy Cost SavingsThe John and FrancesAngelos Law Center2 Reduce Life Cycle ImpactsUniversity of Baltimore3 No Off-Gassing2O144Improved Thermal Comfort5 Increased Daylighting;Light Reflection20YEARSORLIFETIMEPRODUCT PERFORMANCE WARRANT YAs if 65 years isn’t proof enough of the AshfordFormula’s enduring performance, CurecreteDistribution, Inc. offers a standard 20-YearProduct Performance Warranty on AshfordFormula floors, as well as a Lifetime* ProductPerformance Warranty - the longest warrantyoffered in the industry - when maintained withCreteClean Plus with Scar Guard .*Qualifying conditions apply.CURECRETE SETTING THESTANDARD,RAISING THEBAR

Curecrete Distribution, Inc. has been providing leadership in the concrete densification industry for more than 65 years. Curecretecontinues to lead with an unwaivering commitment to superior products, best practices and industry expertise.CURECRETE DISTRIBUTION, INC.CONTACT1203 W. Spring Creek PlaceSpringville, UT 84663, USATECHNICAL INFO(801) 489-5663(800) 998-5664(801) 489-5663(800) ormula.comwww.curecrete.comCUSTOMERSERVICE(801) 489-5663(800) 998-5664customercare@curecrete.comREPRESENTATIVES &INTERNATIONALDISTRIBUTORSAshford Formula is sold through a network ofmanufacturer representatives and internationaldistributors. To contact your representative ordistributor, please visit:www.ashfordformula.com/repsA S O L I D F O U N D AT I O N , F R O M T H E G R O U N D U PBecause your business productivity requires a solid, DENSIFIED concrete floor.

portland cement, helping the concrete reach its design properties. Application of the Ashford Formula is a one-time, permanent application. This eliminates the need for expensive re-application materials, labor costs and facility downtime. Routine surface cleaning is all that is required for long-term maintenance. Ashford Formula combines with