Transcription

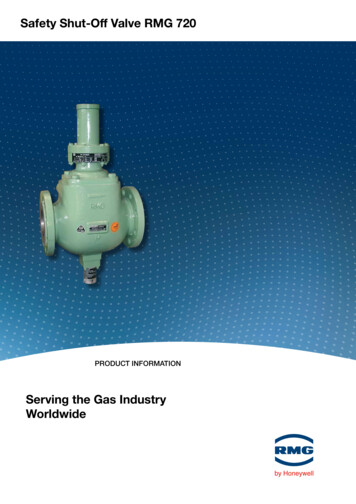

Safety Shut-Off Valve RMG 720Product informationserving the gas industryworldwide

safety shut-off valve rmg 720Application, Characteristics, Technical DataApplication main safety device for gas pressure regulating stations suitable for natural gas according to DVGW G 260, other gases on requestCharacteristics2 compact design; small face-to-face dimensions low pressure drop (valve seat diameter is same size as pipe size diameter) easy maintenance due to interchangeable cartridge assemblies version with different actuators as an optional feature shut-off reaction at diaphragm fracture electric release and remote indicationtechnical datamax. service pressure pmax- DN 25- DN 50, DN 80, DN 100sizesDN 25, DN 50, DN 80 and DN 100connections16 bar25 bar (depending on the flange version)- DN 25: DIN-flanges PN 16 and flanges acc.to ANSI 150 RF- DN 50, DN 80, DN 100: DIN-flanges PN 16, PN 25 and flanges acc.to ANSI 150 RFvalve diametersame size as nominal widthmaterialsmain valve body DN 25 and DN 50main valve body DN 80 and DN 100control unit bodyinternal partsdiaphragms, o-ringsambient temperature range class 2-20 C to 60 Cfunction and strengthacc. to DIN EN 14382 (DIN 3381)special featuresmanual releaseelectro-magnetic release at current supply / current dropelectric remote control of valve position “closed”Ex-protectionThe device does not have any potential ignition sources and thus ATEX 95 does notapply to it (applied electronic accessories comply with the ATEX n acc. to PEDcast steelcast steel, ductile ironcast aluminiumaluminium, stainless steel, brass,steelrubber-like plastic material (NBR)

safety shut-off valve rmg 720Application, Characteristics, Technical DataDN 25: setting range of the SSV measuring units K1a, K2ameasuring unitsetpoint springK1awiredia.inunderpressure releasespecificsetting rangeminimal differentialbetween responsepressure (pdo) andservice pressure (pd)*specificsetting rangeWdsu (bar)minimal differentialbetween response pres- responsepressuresure (pdu) and servicecategory**pressure (pd)*AGNo.colourmmWdso (bar) pwo (bar)1yellow2.50.050 . 0.1000.03010/52bright red3.20,080 . 0.2500.05010/53dark red3.60.200 . 0.5000.1005/2.54white4.750.500 . 1.5000.2505/2.55 bright blueK2aoverpressure release pwu (bar)1.10.010 . 0.0150.012206white1.20.014 . 0.0400.03010/57black1.40.035 . 0.1200.06052bright red3.20.400 . 0.8000.1003dark red3.60.600 . 1.6000.20010/54white4.751.500 . 4.5000.3005/2.510/55 bright blue1.10.060 . 0.1500.05010/561.40.120 . 0.4000.10050.004 . 0.0080.008150.008 . 0.0200.008blackDN 50 to DN 100: setting range of the SSV actuator units K3, K4, K5, K6, K162K3K4K5K6bright red3.25 bright blue1.10.01356black1.42bright red3.20.040 . 0.1000.0203dark red3.60.080 . 0.2500.0302.54black4.50.200 . 0.5000.0602.5/1155/2.55 bright blue1.10.005 . 0.0200.0106black1.40.015 . 0.0600.0203dark red3.60.200 . 0.8000.1002.54black4.50.600 . 1.5000.2002.5/15 bright blue1.10.015 . 0.0500.0306black1.40.040 . 0.1200.0603dark red3.60.600 . 2.0000.2004black4.51.500 . 4.5000.4005 bright blue6black0 bright blueK160.020 . 0.0501.11.420/5520/552,52.5/10.040 . 0.1200.0600.120 . 0.3000.12020/553.20.800 . 1.5000.10011black4.51.000 . 5.0000.20012grey5.02.000 . 10.000.40013brown6.35.000 . 27.500.8001*) Note: if control devices are used with both overpressure and underpressure release, then the min. gapbetween the two setpoints pdso and pdsu has to be at least 10% larger than the sum of the two differentialvalues (Δpwo Δpwu).pdso - pdsu 1.1 (Δpwo Δpwu)**) The higher response precision category is valid for the first half, the lower response precision category is validfor the second half of the setting range.3

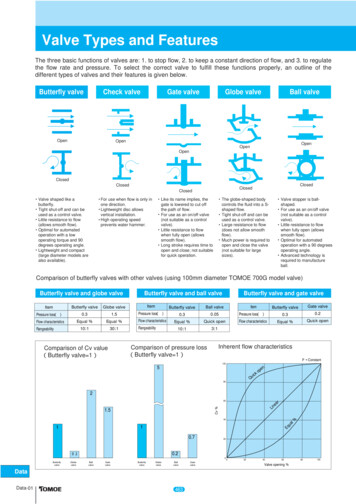

safety shut-off valve rmg 720Application, Characteristics, Technical DataDiagram for determination of pressure drop and max. permissible flow velocity (natural gas ρn 0.83 kg/m3)flow rate Qn in m3/h150300500700 10002000 3000 4000 5000 100001vmax 50m/sinlet pressu-20,3re pu in bar412DN 1005DN 8012DN 501016120size DNDN 250,010,02 0,03 0,05 0,07 0,10,2pressure drop p in bar1.) determination of pressure drop:Qn gasin m3/hThis diagram is valid for natural gas. Qn nat. gas fFor other gases please convert theflow rate into the natural gas flow. found: (pathQn gasf 1100 m3/h1,23nitrogene0,81(for other conversionmethane1,08factors please seetown gas1,23RMG-booklet)air1,26 900 m3/h2.) permissible gas velocity vmax. It can be determined by using the nominal flow rate.gas velocity control: found: (path2 ): v vmax 50 m/s0,7 1,0conversion factor f1 ): p 0,027 bar pmax 0,5 barexample: given: DN 50, pu 10 bar, Qn 1100 m3/h (town gas)0,5 pmax 0,5 barexample: given: DN 50, pu 10 bar, Qn 1100 m3/h (town gas)determination of pressure drop: Qn nat. gas 0,3

safety shut-off valve rmg 720Design and OperationRMG 720 - DN 25:RMG 720 - DN 80:measuring unitsetpoint adjustersetpoint springsswitching valve RMG 919ball mechanismmeasuring diaphragmmeasuring lineclosing springcontrol elementmain valve bodyThe safety shut-off valve (SSV) RMG 720 is designed to automatically shut off the gas flow of a gas pressureregulating station, as soon as the pressure within the system to be protected rises above or falls belowpre-set limits.The RMG 720 consists of a main valve body and a measuring unit as an actuating element. For regularmaintenance the actuating element can easily be subjected to a visual inspection. In case of failure theactuating modules can be replaced by spare units, and the repair works can be carried out in the workshopwithout having to shut down thegas pressure regulating system.All measuring units of the safety shut-off valve are equipped with a spring-loaded diaphragm to block or releasethe ball mechanism of the tripping device. The diaphragm assembly is suitable for both overpressure and/orunderpressure release. The response pressures for overpressure release and underpressure release can beadjusted independently from each other.A pressure compensating valve is integrated into the valve plate. This valve can easily be operated by handunder all pressure conditions, thus ensuring pressure balance at the valve plate before opening the main valve.From size DN 50 upwards the valve stem is provided to go through the pressure chamber. This design featureguarantees a perfect pressure balance, and any changes of service pressure have no influence on the releaseaccuracy.The SSV control element shuts off the gas flow as soon as the pressure within the system to be protected risesabove or falls below pre-set response points. This shut-off is effected by the measuring diaphragm and thetripping bush moving into the release position with the ball mechanism disengaging the valve stem to close theSSV control element. The valve can be re-set by hand only, after the outlet pressure at the measuring point hasbeen decreased or increased to a value lying within the range of the pressure differentials to be observed forre-engagement.5

safety shut-off valve rmg 720Dimensions, Connections and WeightsDDbreathing linebreathing lineCEmeasuring lineCwith RMG 919measuring lineDNDNBB6Ewith RMG 919AAdimensions in mmsizemain valveDNmeasuring unitK1a and K2abodyAB2518429050CDK3E*K4CK5 und K6BCDEBDE*BCDE*254480310236535485315 Ø 178 540485315 Ø 128 54080298565355236670570355 Ø 178 670570355 Ø 128 670100352565355236670570355 Ø 178 670570355 Ø 128 670230 Ø 100 280connectionsmeasuring lines and ventpipe connection without brazing with compression joint acc. to DIN 2353linespipe 12 x 1.5 (screw joints M 16 x 1.5)weightssize255080100weight in kg*8194349*) approximate data, deviations depend on measuring unit

safety shut-off valve rmg 720Type Descriptionsize DNmaterial EN-GJS400-18-LTmaterial GS21Mn5Nflanges acc. toflanges acc. toPN 16PN 16ANSI 150 RFPN 25-10 008 31310 008 657-50-10 008 30810 008 65310 008 3088010 008 30310 008 30910 008 65410 008 31410010 008 30410 008 31010 008 65510 008 31525measuring unitsetting range in barsize DN25measuringunitupper cutoff Wdolower cutoff Wdu0,050 . 1,5000,010 . 0,120K1a0,400 . 4,5000,060 . 0,400K2a0,020 . 0,05050,0,040 . 0,50080,0,200 . 1,5001000,600 . 4,5001,000 . 25,000,004 . 0,0200,005 . 0,0600,015 . 0,1200,040 . 0,300K3K4K5K6K16accessoriesrelease by current supplyE1release by current dropE2manual releaseHAremote indication of valve position “closed”Fspecial feature (to be specified in detail)special featureSo*) These RMG-part numbers are plotted to the identification platespecial featureK5 / E1 / HA / F - Somanual release-electric remote control of valve position „closed“body with accessoires*50electro magnetic releasesize of body-SSV-measuring unittypeRMG 720sizeexample7

For More InformationTo learn more about RMG sadvanced gas solutions, contactyour RMG account manager or visitwww.rmg.comGERMANYENGLANDHoneywell Process SolutionsHoneywell Process SolutionsRMG Regel Messtechnik GmbHBryan Donkin RMG Gas Controls Ltd.Osterholzstrasse 45Enterprise Drive, Holmewood34123 Kassel, GermanyChesterfield S42 5UZ, EnglandTel: 49 (0)561 5007-0Tel: 44 (0)1246 501-501Fax: 49 (0)561 5007-107Fax: 44 (0)1246 501-500Honeywell Process SolutionsCANADARMG Messtechnik GmbHHoneywell Process SolutionsOtto-Hahn-Strasse 5Bryan Donkin RMG Canada Ltd.35510 Butzbach, Germany50 Clarke Street South, WoodstockTel: 49 (0)6033 897-0Ontario N4S 0A8, CanadaFax: 49 (0)6033 897-130Tel: 1 (0)519 5398531Fax: 1 (0)519 5373339Honeywell Process SolutionsRMG Gaselan Regel Messtechnik GmbHUSAJulius-Pintsch-Ring 3Honeywell Process Solutions15517 Fürstenwalde, GermanyMercury Instruments LLCTel: 49 (0)3361 356-603940 Virginia AvenueFax: 49 (0)3361 356-836Cincinnati, Ohio 45227, USATel: 1 (0)513 272-1111Honeywell Process SolutionsFax: 1 (0)513 272-0211WÄGA Wärme-Gastechnik GmbHOsterholzstrasse 45TURKEY34123 Kassel, GermanyHoneywell Process SolutionsTel: 49 (0)561 5007-0RMG GAZ KONT. SIS. ITH. IHR. LTD. STI.Fax: 49 (0)561 5007-207Birlik Sanayi Sitesi, 6.Cd. 62. Sokak No: 7-8-9-10POLANDTR - Sasmaz / Ankara, TurkeyHoneywell Process SolutionsTel: 90 (0)312 27810-80Gazomet Sp. z o.o.Fax: 90 (0)312 27828-23ul. Sarnowska 263-900 Rawicz, PolandTel: 48 (0)65 5462401Fax: 48 (0)65 5462408RMG 720.002007-07 2010 Honeywell International Inc.

The safety shut-off valve (SSV) RMG 720 is designed to automatically shut off the gas flow of a gas pressure regulating station, as soon as the pressure within the system to be protected rises above or falls below pre-set limits. The RMG 720 consists of a main valve body and a measuring unit as an actuating element. For regular