Transcription

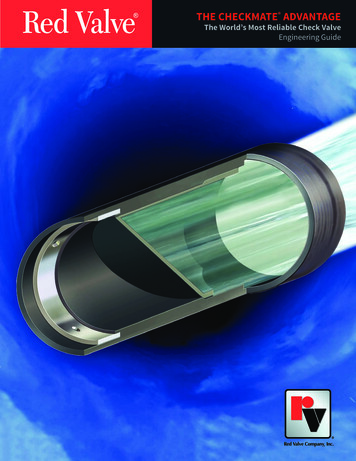

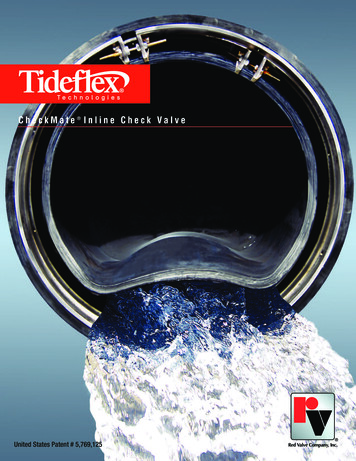

CheckMate Inline Check ValveUnited States Patent # 5,769,125

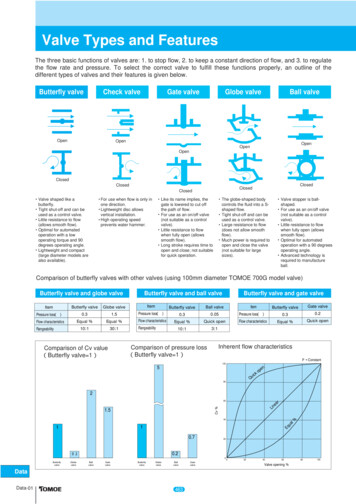

CheckMate : Your Final Move to Eliminate Backflow! CheckMate : It’s AWinning Move!The Ideal CSOApplicationYear after year, millions of dollarsare spent in the United States whena CSO system allowsreceiving waters to enter into thesewage treatment plant. Tideflex Technologies’ patentedCheckMate Valve was developedfor CSO and diversion chamberapplications.The CheckMate is an inline checkvalve designed to be installedat the upstream or downstreamside of a diversion chamber.The entire valve is constructed ofrubber, makingit rust-free and resistant to greaseand oilstypically found in wastewater.Additionally, with sevenelastomers to select from,the CheckMate can bemanufactured to resistchemicals found in industrialwastewater applications.The CheckMate Valve boastsextremely low headloss, and itsinherent design makes it theCheckMate Engineered Features2 Extremely Low Headloss 25-Year Life No Moving Mechanical Parts Self-draining Operates on Differential Pressure Simple Installation 4" (100 mm) - 60" (1,500 mm) Size Silent, Non-slamming 100% Elastomer Durable Construction, Similar to Truck Tire Extensive Independent Hydraulic Testing Virtually No Maintenance, Except for Periodic Inspection Less than 1" of Head Pressure Opens the Valve, Eliminating Standing WaterCheck Valves

CHECKMATE VALVEDesigned for Inline ServiceENOPGWINOLFSEDOLCThe CheckMate Valve’s unique design allows for near 100% flow, or a tight close to eliminate backflow problems completely.The CheckMate is easy to install. Simply insert the valve inside any size pipe and clamp from the upstream or downstream end. No modificationto the pipe or structure is required to install the CheckMate , resulting in large savings. Because the CheckMate is recessed in the pipe,another benefit is environmental permitting for outfall may not be required as the valve does not extend out into the water body.Tideflex CheckMate Check ValveCheckMate :The Lowest Headlossof Any Check Valve!A major advantage of the CheckMate Inline Check Valve is its extremely lowheadloss. This is particularly beneficial inlow-lying areas. CheckMate Valves drainwith very low head pressure and aresensitive enough to open with as little as1" of water.* Red Valve will provide headlossflowcharts for yourapplication requirements.specificCheck Valves3

CheckMate Applications: Simply Versatile! Odor ControlLightweight CheckMate Inline Check Valves prevent sewersystems’ offending odors from escaping, while still allowingwater to discharge when needed. The CheckMate Valveis designed to eliminate the backflow of unwanted methaneand hydrogen sulfide gases that typically result in complaints aboutodor from the general public.Drainage and Outfall LinesCheckMate Inline Check Valves have become a frequentlyspecified solution for commercial and residential areas wherecomplete, dependable backflow prevention is necessary. TheCheckMate Valve’s maintenance-free, passive operationprovides years of trouble-free service - even when the valve ispartially buried.Interceptor and Manhole InstallationsCheckMate Inline Check Valves are used for interceptor andmanhole installations because they are ideal for preventingwater from backflowing into a sewage treatment plant. TheCheckMate Valve’s innovative inline design allows it to beinstalled without modifications to structures such as interceptors,manholes and vaults.Stormwater RunoffThe CheckMate Inline Check Valve is the valve of choice forboth municipalities and commercial property owners instormwater and general drainage applications. Because theCheckMate Valve utilizes dissimilar elastomers and fabric in thehinge area, there are no mechanical parts to warp or corrode.It is maintenance-free!4Check Valves

CHECKMATE VALVEDesigned for Inline Service60" CheckMate Valve being shipped to Australia for inline application.18" CheckMate Valve installed at county park in Seattle forparking lot drainage. This simple installationtook a total of twenty minutes from start tofinish.Maintenance-Free, Totally Passive OperationFlapgate valves are mechanical and have moving parts with inherent problems of corrosion, faulty function and wear. Replacing traditionalflapgate valves with the CheckMate Inline Check Valve eliminates these issues.Like the Tideflex Check Valve, the CheckMate has a 100% fabric and elastomer unibody construction that eliminates corrosion problems.Because the CheckMate is made with a unibody construction, there are no one-piece mechanical components to catch debris, corrodeor fail. The result is savings - both in time and costs.TestingCheckMate Inline Check Valves are tested using thesame strenuous methods as the Tideflex Check Valve.The CheckMate Valve is proven to operatemaintenance-free.The valve can successfully withstand severe winterfreezes, typhoons, hurricanes and flooding. TheCheckMate also minimizes damage to wetlands,beaches and residential areas, eliminates hydraulicsurges to wastewater treatment plants and savesmunicipalities millions of dollars in maintenanceand treatment costs.Check Valves5

CheckMate Performance Sample SpecificationPART 1: GENERAL1.01 SUBMITTALSA. Submit product literature that includes information on theperformance and operation of the valve, materials of construction,dimensions and weights, elastomer characteristics, headloss,flow data and pressure ratings.B. Upon request, provide shop drawings that clearly identify thevalve materials of construction and dimensions.1.02 QUALITY ASSURANCEA. Supplier shall have at least twelve (12) years experience in thedesign and manufacture of “CheckMate ” style elastomeric checkvalves.B. Manufacturer shall have conducted independent hydraulictesting to determine headloss, jet velocity and vertical openingheight characteristics on multiple sizes of CheckMate valvesranging from 4" through 72". The testing must have beenconducted for free discharge (discharge to atmosphere) andsubmerged conditions.PART 2: PRODUCTS2.01 “CHECKMATE ” ELASTOMERIC CHECK VALVESA. Check Valves are to be all rubber and the flow operated checktype with slip-in cuff or flange connection. The entireCheckMate Valve shall be ply reinforced throughout the body,disc and bill, which is cured and vulcanized into a one-pieceunibody construction. A separate valve body or pipe used as thehousing is not acceptable. The valve shall be manufactured withno metal, mechanical hinges or fasteners, which would be usedto secure the disc or bill to the valve housing. The port area of thedisc shall contour down, which shall allow passage of flow in onedirection while preventing reverse flow. The entire valve shall fitwithin the pipe I.D. Once installed, the CheckMate Valve shall notprotrude beyond the face of the structure or end of the pipe.B. The downstream end of the valve must be circumferentially incontact with the pipe while in the closed positions.C. Slip-in style CheckMate Valves will be furnished with a set ofstainless steel expansion clamps. The clamps, which will securethe valve in place, shall be installed inside the cuff portion of thevalve, based on installation orientation, and shall expandoutwards by means of a turnbuckle. Each clamp shall be predrilled allowing for the valve to be pinned and secured intoposition in accordance with the manufacturer’s installationinstructions. Flange style CheckMate Valves will be furnishedwith a stainless steel, ANSI 125/150 drilled, retaining ring unlessspecified otherwise.D. Manufacturer must have flow test data from an accreditedhydraulics laboratory to confirm pressure drop and hydraulicdata. Company name, plant location, valve size patent number,and serial number shall be bonded to the check valve.2.02 FUNCTIONA. When line pressure exceeds the backpressure, the linepressure forces the bill and disc of the valve open, allowing flowto pass. When the backpressure exceeds the line pressure, thebill and disc of the valve is forced closed, preventing backflow.2.03 MANUFACTURERA. All valves shall be of the slip-in or flanged CheckMate asmanufactured by Tideflex Technologies , A Division of Red ValveCompany, Carnegie, PA 15106. All valves shall be manufacturedin the U.S.A.PART 3: EXECUTION3.01 INSTALLATIONA. Valve shall be installed in accordance with manufacturer’swritten Installation and Operation Manual andapproved submittals.3.02 MANUFACTURER’S CUSTOMER SERVICEA. Manufacturer’s authorized representative shall be availablefor customer service during installation and start-up, and to trainpersonnel in the operation, maintenance and troubleshooting ofthe valve.B. If specified, the manufacturer shall also make customerservice available directly from the factory in addition toauthorized representatives for assistance during installationand start-up, and to train personnel in the operation,maintenance and troubleshooting of the valve.6Check Valves

CHECKMATE VALVEDesigned for Inline ServiceMounting Styles and ConfigurationsUpstream ClampDownstream ClampFlowFlowDownstream FlangedUpstream FlangedFlowFlowDownstream Flanged Thimble InsertUpstream Flanged Thimble InsertFlowFlowFlange shape and bolt pattern can be customized.Flangeless thimble inserts are available.CHECKMATE VALVENOMINALPIPE SIZE 4727787107012071394158117942007219426043023*Larger sizes available upon request.NUMBEROF CLAMPS1111111111222222223BACK 0131313131012121212121212666666644443**Shorter lengths available.Check Valves7

The best choice for the toughest applications.In addition to the Checkmate Inline Check Valve, Tideflex Technologies offers a complete line of check valves.TF-1 CHECK VALVESThe Tideflex TF-1 Curved Bill Check Valve is designed withenhanced sealing to improve headloss. The improved TF-1design allows the valve to handle long-term water weight whilemaintaining structural integrity. The spine is at a greatervertical angle, making it able to withstand the cantilevereffect when water is flowing throughthe valve. The TF-1 is constructedof rubber, making it immuneto rust, corrosion andweathering.SERIES 35-1 CHECK VALVES600 N. Bell Ave.Carnegie, PA 15106PHONE:412/279-0044FAX:412/279-7878The flat-bottom Series 35-1 features an integral rubberflange, allowing them to be mounted to flanged outfall pipesor directly to headwalls where the pipe is flush.The flange size drilling conforms to ANSI B16.10,Class 150#, or can be constructed with DIN, 2632 and otherstandards. The Series 35-1 CheckValve is furnished complete with steelor stainless steel backup ringsfor installation.www.tideflex.comThe information presented in this catalog isprovided in good faith. Red Valve Company,Inc. and Tideflex Technologies reserves theright to modify or improve its designspecifications without notice and does notimply any guarantee or warranty for any of itsproducts from reliance upon the informationcontained herein. All orders are subject toRed Valve Company, Inc. and Tideflex Technologies’ standard terms and warrantyand are subject to final acceptance by RedValve Company, Inc. and Tideflex Technologies.Viton is a registered trademark of DuPontDow Elastomers. Hypalon is a registeredtrademark of DuPont PerformanceElastomers. Tideflex, Red Valve, and theRed Valve “rv” logo are registeredtrademarks of the Red Valve Company, Inc. 2009 Red Valve Company.All rights reserved.RECYCLABLEPAPERCMCV 09/11SERIES 39 CHECK VALVESThe Tideflex Series 39 Inline Check Valve features afabric-reinforced elastomer check sleeve housed in a cast ironbody with ANSI 125/150 flanges, allowing for easy installationinto any piping system. The valve’s operation is silent, nonslamming and maintenance free. Sliding, rotating, swingingand plunging parts are completelyeliminated. The body isequipped with flush portsand a clean-out port andcan be epoxy coated.

CheckMate Valve was developed for CSO and diversion chamber applications. The CheckMate is an inline check valve designed to be installed at the upstream or downstream side of a diversion chamber. The entire valve is constructed of rubber, making it rust-free and resistant to grease