Transcription

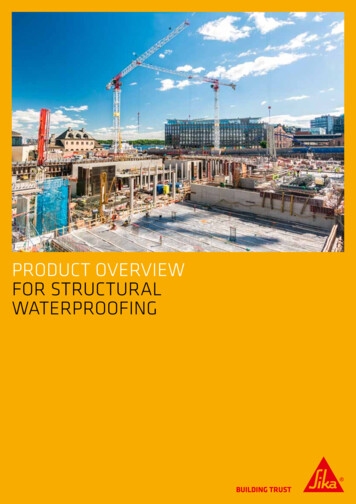

3D Printing Inroads inInjection MoldingBy Stratasys, Inc.3D printing is an exponential innovation. Regular breakthroughs in 3D printer speed, resolution, cost andreliability demonstrate the potential not only for scale but also for unlocking new possibilities. Coupledwith a fast-evolving range of printable materials, 3D printing is expanding into traditional manufacturingprocesses and being used for tools, molds, tool masters and end-use parts.One area of manufacturing that is experiencing a true paradigm shift is injection molding.By 3D printing the injection molds, manufacturers can functionally test parts in finalmaterials within days of initial designTHE 3D PRINTING SOLUTIONS COMPANY

3D Printing Inroads in Injection MoldingInjection molding is the process of injecting plasticHard Toolingmaterial into a mold cavity where it cools andFor CNC-machined metal injection molds used forhardens to the configuration of the cavity. It is themass production (millions of parts), the mold costsbest way to mass produce highly accurate andcan range from 20,000 to hundreds of thousandscomplex 3D products and parts.of dollars with lead times of two to four months.The longer lifespan of hard tools will offset theUnfortunately, the cost and time of tooling moldshigher initial cost over a higher number of partsis often compounded. For example, designmade before wearing out.mistakes require the mold be remade correctly orto create multiple iterations before the final partCreating injection molds for mass productiondesign and quality are achieved.requires steel tools, cut with a CNC millingmachine or via electrical discharge machiningIt is with these issues in mind that manufacturers(EDM). The tooling is very expensive to produce;have begun to embrace the use of 3D printedhowever, the advantage is that the metal tools aremolds to create functional injection moldingextremely durable and can be used to produceprototypes.large volumes of parts at a very low cost per part.Soft ToolingINJECTION MOLDING TOOLINGTECHNOLOGIESWhen smaller amounts – tens of thousands toThe choice of material for mold creation isparts are needed, soft tooling is an option. Madegoverned by part volume; in general, higher partin aluminum, these molds are less expensive andvolume requires harder mold material, at a higherfaster to produce. For soft tooling (aluminum) tocost to construct.produce medium volumes, soft tooling costs canhundreds of thousands – of injection moldedrange from 1,500 to 25,000, with lead times oftwo to six weeks.3D PRINTING INROADS IN INJECTION MOLDIING/ 2

3D Printing Inroads in Injection MoldingFor producing prototype parts or low volumes (10IDEAL 3D PRINTING MATERIALSFOR INJECTION MOLDSto 100 units) of final parts, 3D printing is the idealMaterial requirements for 3D printing applicationstechnology and offers several advantages, listedare constantly evolving as engineers seek tobelow. Digital ABS has become the preferredcreate new structures with new mechanical3D printing material to create the molds becauseproperties.3D Printed Toolingit offers the required thermal and chemicalproperties to withstand the rigorous injectionFor injection molding applications, the availabilitymolding process.of strong, stable plastics is critical to produce Bridge Tooling3D printed injection molds can supply the earlymarket with product samples within days ofconcept, creating watershed opportunities formarketers to launch and capture orders andmind-share for new products. Bridge productionof advance products using 3D printed moldscan cut months off product delivery schedules,stimulate early demand and accelerate marketentry. Tooling On DemandFor low-volume manufacturers, 3D printedinjection molds offer a cost-effective productionsolution that eliminates hard tooling costsand delays. Hard tooling spares are no longerrequired in inventory. When new injection moldsare needed, they are printed on demand toreplace worn or fatigued molds.parts with tight tolerances and the toughness towithstand constant use on the factory floor.Digital ABS is the best choice for 3D printinginjection molds: it combines strength andtoughness, along with high temperatureresistance. Available on PolyJet -driven 3Dprinters, dual- or triple-material jetting canproduce photopolymers that simulate a range ofdurable production plastics.Digital ABS is a two-component material designedto simulate standard ABS plastics by combininghigh temperature resistance with toughness.Material requirements for 3D printing applicationsare constantly evolving.3D PRINTING INROADS IN INJECTION MOLDIING/ 3

3D Printing Inroads in Injection MoldingMATERIALS CASE STUDY:NYPRO (IRELAND)Nypro is a global manufacturer of precisionplastic products for the healthcare andpackaging industries. Together with Stratasys,Nypro conducted a series of tests to assessthe performance of rapid prototyped cores andcavities with critical features.During one of the many tests conducted, sampleHigh-resolution molds created using PolyJet technology produce finefeatures in injection molded parts. Nypro created this component partto test injection molded parts.ABS parts were injection molded into a single 3DDigital ABS is suitable for parts that requiresuch as maximum pressure, cushion and corePolyJet technology’s highest possible impactand cavity temperatures were tracked. Uponresistance and shock absorption.completion of the tests, the mold was deemedprinted mold made from Digital ABS. Parametersto be stable as indicated by constant injectionThe best materials for the injection molded partspressure and cushion. By using recommendedthemselves are those that have reasonablecooling procedures, the temperature in the coremolding temperatures ( 570 F / 300 C) andand cavity did not exceed 58ºC.good flow behavior. Ideal candidates includepolyethylene, polypropylene and polyamide.Nypro concluded that the injection moldingtrials were very successful. “The process of 3DPlastics requiring processing temperatures ofprinting cores and cavities can be considered an250 C (480 F) and higher, or those that have highadvantage in terms of time, initial functionalityviscosity at their processing temperature, willevaluations and cost.”shorten the life of the mold, and in some cases,the quality of the finished part.3D PRINTING INROADS IN INJECTION MOLDIING/ 4

3D Printing Inroads in Injection Moldingpast, Seuffer created injection molded prototypesusing final production materials and metal molds.In the past, it took eight weeks for Seuffer to build ametal production mold like the one shown in above atan approximate cost of 50,000. If any changes wereneeded, new costs were incurred and more time lost.Seuffer’s management needed a way to acceleratethe process and better manage the costs. TheySeuffer saved upward of 50,000 and shaved more than 50 days off ofproduction of molds like this one.decided to acquire a PolyJet-based 3D printer as amold-making machine and chose a complex partfor the test application. Its design included shut-offCASE STUDY: ROBERT SEUFFERGMBH & CO (GERMANY)Robert Seuffer GmbH & Co, based in Germany,manufactures electronic component parts forhousehold appliances, commercial vehicle andautomotive industries. Products include interactivefans, sensors and switches.surfaces, thin walls and tall core pins that wouldnormally require multiple inserts and many hours tofit into a normal metal mold base.Seuffer 3D printed a prototype mold in less than twodays for less than 1,500 and required only threehours of component fitting and assembly.Because many Seuffer products include customerfacing interactive elements, they must be designedto withstand extended use, while protecting theinternal components from high temperatures,shock, vibration and corrosive fluids.Functional testing of Seuffer prototypes is criticalto validate their ability to perform over time. In theThis part that Seuffer produced via injection molding is ready forfunctional testing.3D PRINTING INROADS IN INJECTION MOLDIING/ 5

3D Printing Inroads in Injection Moldingmolding machines to produce its top-selling pumpand drainage systems.Like many early adopters, Whale acquired a 3Dprinter and began using it in-house for functionaltesting of prototypes.Whale is now 3D printing injection mold tools in less than 24 hours at afraction of the cost of producing metal tools.Whale began investigating the possibility of using3D printing for injection molds. They found DigitalABS had the ideal properties for low-volume part“Previously, we could not conduct performance testsproduction: high temperature resistance anduntil we had built a steel or aluminum tool and usedtoughness.it to create injection molded prototypes on actualproduction machines,” said Wilfried Zachmann,In the past, Whale outsourced its prototyping toresearch and development manager for Seuffer.service bureaus and often ordered parts from“Now we have the ability to perform functional testsChina. Metal injection molding tools took four toand modify designs faster and at much lower costs.”five weeks to produce and cost tens of thousandof pounds sterling. Tools are now designed duringthe day, 3D printed overnight and tested the nextCASE STUDY: WHALE (UNITEDKINGDOM)morning with a range of end-product materials.Whale, based in Northern Ireland, manufactures“We have already seen the technology take monthsand exports pumps, drainage and heating systemsoff of our product development process and thatfor marine, commercial vehicle and mobile homein turn minimizes risk. In fact, I estimate that we’vemarkets around the world.shortened our R&D process by up to 35 percent,”said Patrick Hurst, managing director at Whale.Injection molding is a core competency for Whale.“Add that on top of the 20 percent we’re alreadyThe company manages an in-house injectionsaving in terms of our design work – well for me,molding operation of 10 state-of-the-art injectionit’s fantastic.”3D PRINTING INROADS IN INJECTION MOLDIING/ 6

3D Printing Inroads in Injection Moldingprototypes from the same material that would be usedto create the final product. However, conventionalmethods of producing injection molds are oftenpainstaking, highly expensive and time-intensive – allfactors the team could not afford. So Kovács exploredthe options with the Objet 350 Connex 3D Printer.The result was impressive. The advanced prototypesAn injection molded acetal impeller from a 3D printed mold.not only passed the required safety tests, but alsoincreased cooling performance by 20 percent whilereducing the associated noise level by 7 decibels.CASE STUDY: BUDAPEST UNIVERSITY (HUNGARY )Kovács commented that PolyJet technologyDr. József Gábor Kovács, head of the Departmentprovided the team with a “complete end-to-endof Polymer Engineering Laboratory, Budapestsolution without incurring major cost or time.”University of Technology and Economics, turned to3D printing technology when faced with a designKovács was equally impressed with the partchallenge posed by a major manufacturer.quality. He noted that the prototype was “justperfect; there was no need for post-processing.”He and his team were commissioned to designa general-purpose electric fan that could provideenhanced cooling but at a significantly reducednoise level. The new design also had to pass safetytests performed under extreme load conditions likeintense temperature, multiple hours of operationand high rotation speeds.To perform the tests, the team needed an efficient,inexpensive method of producing injection moldedBudapest University 3D printed this fan blade, which is on an engineaxis ready for functional testing.3D PRINTING INROADS IN INJECTION MOLDIING/ 7

SUMMARYAccording to the Deloitte Tech Trends 2014:Exponential innovation in 3D printing technology“Exponential technologies [like 3D printing] canand an ever-expanding range of printablelead to new ‘Kodak moments,’ where existingmaterials is accelerating change in manufacturing.businesses are displaced by upstart companies3D printing injection molds makes business sense.harnessing the emerging technologies. ‘Itwill be about industries effectively leveragingThe use of PolyJet-based 3D printed molds allowstechnologies to improve their productivity andmanufacturers to take functional testing to a newcost-efficiency, resulting in more agile andlevel, by creating product prototypes from the sameadaptable businesses that can create newinjection molding design, process and materialsopportunities,’ said Robert Hillard, Deloittethat will be used to create the final product.Australia Managing Partner.”3D printed molds are unique in that, for prototypesand low volume manufacturing, they performin the same way as metal molds but are muchcheaper, easier and faster to make. With PolyJetbased 3D printing technology, manufacturers canproduce prototypes at speeds and costs far belowtraditional methods.As a result, 3D printing allows manufacturersto evaluate the performance, fit and quality ofpotential products injected in the final productmaterial and to test them in real-life conditions,before mass production starts.3D printing injection molding tools thereforecreates value for both large, high-volumemanufacturers and small, low-volume, nichemanufacturers and it’s ready to use in yourmanufacturing business today.3D PRINTING INROADS IN INJECTION MOLDING / 8

info@stratasys.comST R ATA SYS .C O MHEADQUARTERS7665 Commerce Way, Eden Prairie, MN 55344 1 888 480 3548 (US Toll Free) 1 952 937 3000 (Intl) 1 952 937 0070 (Fax)2 Holtzman St., Science Park, PO Box 2496Rehovot 76124, Israel 972 74 745-4000 972 74 745-5000 (Fax)THE 3D PRINTING SOLUTIONS COMPANYISO 9001:2008 Certified 2015 Stratasys Inc. All rights reserved. Stratasys, Stratasys logo, PolyJet, Objet, Objet24, Objet30, Objet30 Pro, Objet30 Prime, Eden, Objet Eden260V, Objet Eden260VS, Objet Eden350V, Objet Eden500V, Connex, Objet260 Connex1, Objet260Connex2, Objet260 Connex3, Objet350 Connex1, Objet350 Connex2, Objet350 Connex3, Objet500 Connex1, Objet500 Connex2, Objet500 Connex3, Durus, Rigur, Vero, VeroBlue, VeroBlackPlus, VeroClear, VeroCyan, VeroDent, VeroDentPlus,VeroGlaze, VeroGray, VeroMagenta, VeroWhitePlus, VeroYellow, Tango, TangoBlack, TangoBlackPlus, TangoGray, TangoPlus, Digital ABS and Digital ABS2 are trademarks or registered trademarks of Stratasys Inc., registered in the United Statesand other countries. ULTEM is a registered trademark of SABIC or affiliates. All other trademarks belong to their respective owners. Product specifications subject to change without notice. Printed in the USA. WP InjectionMolding EN 0915For more information about Stratasys systems, materials and applications, call 888.480.3548 or visit www.stratasys.com

Injection molding is a core competency for Whale. The company manages an in-house injection molding operation of 10 state-of-the-art injection molding machines to produce its top-selling pump and drainage systems. Like many early adopters, Whale acquired a 3D printer and began using it in-house for functional testing of prototypes.