Transcription

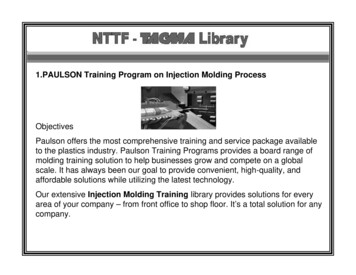

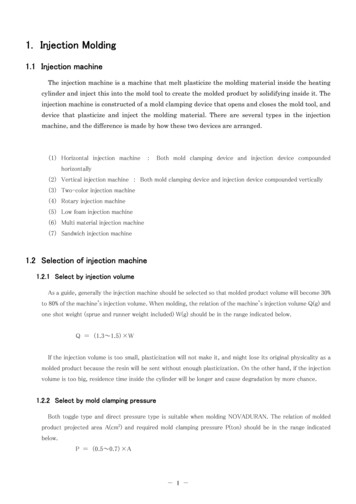

Non-affectedOffice Admin TechnicianHoursNon-operationalOperators, set up, partofsupport, shipping &handlers, maintenance &entry level techniciansTraining janitorial staffTraining Solutions from PaulsonCourseware CatalogAffectedProcessorSenior & processtechnicians, qualityauditing personnel,shift supervision, valuestream & plant managers,troubleshootersExpertSenior process &manufacturing engineers,technical operations,management,R & D personnel,senior process expertsInjection MoldingInjection Molding FundamentalsSkillUp Your Workforce with Powerful Plastics TrainingCount on Paulson to deliver premium online courseware andinstructor-led Certification seminars, and transform ordinarypersonnel into confident plastic processors. Fully understandingprocessing from the “Plastics Point of View,” (PPV), and graspingthe concept of the “Four Plastic Variables,” is knowledge thatwill always be relevant and keep you one step ahead. Physicsdoesn’t change, plastic reacts to just four things—heat, flow,pressure, and cooling. Learn that and there’s no processingproblem you can’t solve. Plus, with Paulson’s powerful online platform, Paulson University, you can train at your own pace,anywhere, anytime, and on any device. Successful plastics companies consistently turn to Paulson when they need powerful, flexible,and proven training solutions. Explore your options with Paulson and learn how you can become an in-demand skilled processor.c SkillCheck is the KeyPaulson’s knowledge assessment tool is the key to unlocking your employees’potential. Quickly and simply find out your employees strengths and weaknesses.Then we’ll guide you in creating a customized training path for each employee thatefficiently upgrades their skills.c SimTech Supercharge Your Training withInjection Molding Machine SimulationDevelop molding experts right in your manufacturing plantwith the world’s most powerful injection molding machinesimulator, SimTech. Just like airline pilots practice aviationconcepts on a flight simulator before actually flying,injection molders can practice molding skills with SimTechbefore running an actual molding machine; savingthousands of dollars, valuable machine time, and avoidingpotential risk to the machine or operator.You can practice machine set-up, molded partproblem solving, and cycle reduction all onyour computer or mobile device. Developedby Paulson engineers, SimTech is based ondecades of research and testing andwill take your employees to a wholenew level of understanding themolding process. Superchargeyour training with SimTech anddramatically improve quality,production, and profits.2Core Injection Molding Courses with Active Machine Simulation LabsTechnology of Injection Molding – Level One10–15Technology of Injection Molding – Level Two8–10Technology of Injection Molding – Level Three8–10Injection Molded Part Problems & Solutions15–20SimTech Injection Molding Simulation Lab LessonsSpecialized Injection MoldingThe Electric Injection Molding Machine5–6Efficient Mold Setting2–3Implementing Decoupled Molding5–6Hot Runner Molding Solutions8–10Statistical Process Control5–6Plastics Drying Technology2–3Design of Experiments for Injection Molders5–6Understanding Materials for Profitable Molding8–10Injection Molding Machine Maintenance2–3ExtrusionExtruder Operation and Control – Single Screw14–16Compounding with the Twin Screw Extruder14–16Sheet Extrusion Technology12–14Extrusion Blow Molding Technology12–14c SkillBuilder PET-ISBMThe SkillBuilder AdvantageThermoformingPET-Injection Stretch Blow MoldingRevolutionize the way you train with SkillBuilder, Paulson’sonline interactive lab lessons, available in English and Spanish.Learning molding concepts is one thing, safely applying them isanother. That’s where the advantage of SkillBuilder comes in.Exclusive to Paulson, SkillBuilder is a set of guided active lablessons, powered by SimTech, Paulson’s injection moldingmachine simulator, built right into each of the Paulson Universityinjection molding courses. These interactive lab lessons simulatea virtual molding environment encouraging the learner toimmediately apply and practice key injection molding conceptscovered in the online course. And having this online technicallab available in Spanish makes learning even more accessiblefor your entire team. No other plastics training solution offersthis level of learning. SkillBuilder will dramatically increase youremployees’ molding knowledge and skill.“Powerful Training.Proven Results.unlimitedExtremely fun and forwardthinking, Paulson classes andinstructors will challenge youand enrich your skill set!”—Tony Mitchell, Senior Design Engineer, Cisco Systems4Thin Sheet Thermoforming10–12Thick Sheet Thermoforming8–10Specialized Training CoursesGeometric Dimensioning & Tolerances15–20Blue Print Reading10–14Paulson Plastics AcademyProMolder 1 Certification30ProMolder 2 Certification38ProMolder 3 Certification38Profitable Molding for Managers24ProMolder Troubleshooting30ProEx 1 Extrusion30ProEx Blow Molding22Customized Training ServicesOn-Site Custom SeminarsConsulting ServicesPaulson Training Programs, Inc.3 Inspiration Lane P.O. Box 366 Chester, Connecticut 06412800-826-1901 www.paulsontraining.com info@paulsontraining.comSpecial note: Paulsonoffers custom languageoptions for all online courses.Available in SpanishAvailable in MandarinThe Global Leader in Plastics Training

Non-affectedOffice Admin TechnicianHoursNon-operationalOperators, set up, partofsupport, shipping &handlers, maintenance &entry level techniciansTraining janitorial staffTraining Solutions from PaulsonCourseware CatalogAffectedProcessorSenior & processtechnicians, qualityauditing personnel,shift supervision, valuestream & plant managers,troubleshootersExpertSenior process &manufacturing engineers,technical operations,management,R & D personnel,senior process expertsInjection MoldingInjection Molding FundamentalsSkillUp Your Workforce with Powerful Plastics TrainingCount on Paulson to deliver premium online courseware andinstructor-led Certification seminars, and transform ordinarypersonnel into confident plastic processors. Fully understandingprocessing from the “Plastics Point of View,” (PPV), and graspingthe concept of the “Four Plastic Variables,” is knowledge thatwill always be relevant and keep you one step ahead. Physicsdoesn’t change, plastic reacts to just four things—heat, flow,pressure, and cooling. Learn that and there’s no processingproblem you can’t solve. Plus, with Paulson’s powerful online platform, Paulson University, you can train at your own pace,anywhere, anytime, and on any device. Successful plastics companies consistently turn to Paulson when they need powerful, flexible,and proven training solutions. Explore your options with Paulson and learn how you can become an in-demand skilled processor.c SkillCheck is the KeyPaulson’s knowledge assessment tool is the key to unlocking your employees’potential. Quickly and simply find out your employees strengths and weaknesses.Then we’ll guide you in creating a customized training path for each employee thatefficiently upgrades their skills.c SimTech Supercharge Your Training withInjection Molding Machine SimulationDevelop molding experts right in your manufacturing plantwith the world’s most powerful injection molding machinesimulator, SimTech. Just like airline pilots practice aviationconcepts on a flight simulator before actually flying,injection molders can practice molding skills with SimTechbefore running an actual molding machine; savingthousands of dollars, valuable machine time, and avoidingpotential risk to the machine or operator.You can practice machine set-up, molded partproblem solving, and cycle reduction all onyour computer or mobile device. Developedby Paulson engineers, SimTech is based ondecades of research and testing andwill take your employees to a wholenew level of understanding themolding process. Superchargeyour training with SimTech anddramatically improve quality,production, and profits.2Core Injection Molding Courses with Active Machine Simulation LabsTechnology of Injection Molding – Level One10–15Technology of Injection Molding – Level Two8–10Technology of Injection Molding – Level Three8–10Injection Molded Part Problems & Solutions15–20SimTech Injection Molding Simulation Lab LessonsSpecialized Injection MoldingThe Electric Injection Molding Machine5–6Efficient Mold Setting2–3Implementing Decoupled Molding5–6Hot Runner Molding Solutions8–10Statistical Process Control5–6Plastics Drying Technology2–3Design of Experiments for Injection Molders5–6Understanding Materials for Profitable Molding8–10Injection Molding Machine Maintenance2–3ExtrusionExtruder Operation and Control – Single Screw14–16Compounding with the Twin Screw Extruder14–16Sheet Extrusion Technology12–14Extrusion Blow Molding Technology12–14c SkillBuilder PET-ISBMThe SkillBuilder AdvantageThermoformingPET-Injection Stretch Blow MoldingRevolutionize the way you train with SkillBuilder, Paulson’sonline interactive lab lessons, available in English and Spanish.Learning molding concepts is one thing, safely applying them isanother. That’s where the advantage of SkillBuilder comes in.Exclusive to Paulson, SkillBuilder is a set of guided active lablessons, powered by SimTech, Paulson’s injection moldingmachine simulator, built right into each of the Paulson Universityinjection molding courses. These interactive lab lessons simulatea virtual molding environment encouraging the learner toimmediately apply and practice key injection molding conceptscovered in the online course. And having this online technicallab available in Spanish makes learning even more accessiblefor your entire team. No other plastics training solution offersthis level of learning. SkillBuilder will dramatically increase youremployees’ molding knowledge and skill.“Powerful Training.Proven Results.unlimitedExtremely fun and forwardthinking, Paulson classes andinstructors will challenge youand enrich your skill set!”—Tony Mitchell, Senior Design Engineer, Cisco Systems4Thin Sheet Thermoforming10–12Thick Sheet Thermoforming8–10Specialized Training CoursesGeometric Dimensioning & Tolerances15–20Blue Print Reading10–14Paulson Plastics AcademyProMolder 1 Certification30ProMolder 2 Certification38ProMolder 3 Certification38Profitable Molding for Managers24ProMolder Troubleshooting30ProEx 1 Extrusion30ProEx Blow Molding22Customized Training ServicesOn-Site Custom SeminarsConsulting ServicesPaulson Training Programs, Inc.3 Inspiration Lane P.O. Box 366 Chester, Connecticut 06412800-826-1901 www.paulsontraining.com info@paulsontraining.comSpecial note: Paulsonoffers custom languageoptions for all online courses.Available in SpanishAvailable in MandarinThe Global Leader in Plastics Training

Injection MoldingTrainingTechnology of Injection Molding5 Lessons, 8–10 HoursInjection Molding Fundamentals2 Lessons, 2 HoursA two lesson, 2 hour training program teaching new employeesand personnel the most important and fundamental aspects ofthe injection molding production floor and molding process. Thiscourse emphasizes production efficiency, safety and teamwork.Core Injection Molding Courseswith Active Machine Simulation Labs24 Lessons, 28 SkillBuilder Lab Lessons, 41–55 HoursPaulson’s core injection molding courses cover the span ofscientific molding principles from the fundamentals to advancedtopics. Each level in the series includes direct access toSkillBuilder (available in English and Spanish), Paulson’s onlineactive lab lessons using Paulson’s powerful injection moldingmachine simulator SimTech. The Technology of Injection Moldingseries is broken down into three modules to help students easilyprogress through the intensive content while building a strongbase of scientific injection molding knowledge.Technology of Injection Molding– Level5 Lessons, 14 SkillBuilder Lab Lessons, 10–15 Hours➊Build the Foundation. This robust online course is the firstin a series of Paulson’s core injection molding courses andfeatures Paulson’s innovative virtual molding machine lablessons, SkillBuilder, built right in. Learners immediately applyand practice key concepts covered in the course. Each lessonteaches technical concepts in easily digestible segments.Students learn the basic foundations of injection moldingincluding the most important, how to process plastic from the“Plastics Point of View,” (PPV) and the “Four Plastic Variables,”crucial concepts pioneered by Paulson.Technology of Injection Molding– Level3 Lessons, 7 SkillBuilder Lab Lessons, 8–10 Hours➋Optimize the Process. Employees will gain a deepunderstanding of the scientific method and the effect ofeach machine control on the four basic variables. Based ona scientific approach, this course analyzes ways to improveproductivity and build a solid optimized process. Learnedconcepts are immediately put into practice using SkillBuilderLab lessons built right in.Language OptionsGracie,the happinessambassadorPaulson offers custom languageoptions for all online courses.And many courses can becustomized to include sub-titles.– Level➌Master Injection Molding. This course teaches the “why”behind injection molding and is designed for those wishingto be at the expert molding level. The lessons focus onthe relationship between machine controls, the four plasticvariables, and part properties. Understanding this relationshipallows a molder to best optimize the molding cycle.Implementing Decoupled Molding 3 Lessons, 5–6 HoursExtrusion TrainingThermoformingTraining course developed in cooperation with RJG, improvesprocess consistency by separating the molding process into3 phases: filling, packing and cooling.Extruder Operation and Control –Single Screw9 Lessons, 14–16 HoursThin Sheet Thermoforming6 Lessons, 10–12 HoursHot Runner Molding Solutions5 Lessons, 8–10 HoursTraining on the fundamentals of single screw technology, includingparts and operation, plastics used for extrusion, extruder controls,safety procedures, troubleshooting and more.Course describing different manifold and gate designs, startupand shutdown techniques, troubleshooting and maintenanceprocedures for hot runner molding processes.Injection Molded Part Problems &Solutions with SkillBuilder11 Lessons, 7 SkillBuilder Lab Lessons, 15–20 HoursThis course is designed to train in the recognition and analysisof part defects utilizing the four plastic variables contributingto the defect. Topics covered include: Voids, Sink Marks, ShortShots, Flash, Weld (Knit) Lines, Splay (Silver Streaks), Jetting,Burn Marks, Warp, Cracks and Part Breakage and ControllingMolded Part Dimensions.Statistical Process Control3 Lessons, 5–6 HoursFocuses on increasing SPC skills, how to maintain correctSPC procedures and how to document and train new personnelin SPC requirements.Plastic Drying Technology2 Lessons, 2–3 HoursAvailable in SpanishAvailable in Mandarin“Whether you have experienceprocessing plastic or are newto it, Paulson definitely teachesyou everything you need toknow to advance your skills!”—Mackenzie Chanthavisouk, Anchor PlasticsSpecialized InjectionMoldingElectric Injection Molding Machine3 Lessons, 5–6 HoursThis course covers electric machine design, cycle and parts,the effects of each control and specific operating techniques tooptimize routine operations including clamp settings and screwcontrols; all specific to the electric machine environment.Efficient Mold Setting2 Lessons, 2–3 HoursTraining course demonstrating how to efficiently set up a mold,troubleshoot mold problems, and properly remove and preparemold for storage.Training course demystifying plastic drying by explaining howplastic drying is done, how to check dryer operations, and how totroubleshoot problems caused by incomplete moisture removal.Design of Experiments for Injection Molders3 Lessons, 5–6 HoursCo-authored with Launsby Consulting, providing 5 hours of trainingon how to design an experiment by explaining common terminologyand exploring various design of experiment techniques.Compounding with the Twin Screw Extruder8 Lessons, 14–16 HoursTraining on the fundamentals of compounding with a twin screwextruder, including parts and operation, raw materials used, plasticbehavior, optimizing controls, safety and startup procedures,troubleshooting and more.Sheet Extrusion Technology7 Lessons, 12–14 HoursTraining designed for use in conjunction with our 9-lesson singlescrew extrusion course. Providing overview of sheet extrusiontechnology ranging from parts and operation to controlling plasticflow in the die to troubleshooting the sheet extrusion line.Extrusion Blow Molding7 Lessons, 12–14 HoursTraining on the fundamentals of extrusion blow moldingtechnology, including process and equipment, plastic behavior,operating controls, operating procedures, processing conditionsand problems and solutions.Understanding Materials for Profitable Molding10 Lessons, 8–10 HoursA collection of individual lessons on 10 commonly used materialsproviding an overview of chemical & physical properties as well asmolding characteristics of a specific raw material type. Lessonsinclude: Polycarbonate (PC), Polypropylene (PP), Polyethylene(PE, LDPE, HDPE, LLDPE, UHMWPE), Nylon (PA), ABS,Polystyrene (PS), Acrylic (PMMA), Acetyl (POM), Polyester (PBT),Thermoplastic Elastomers (TPE).Injection Molding Machine Maintenance2 Lessons, 2–3 HoursInstructional program demonstrating the proper machinemaintenance procedures for all hydraulic injectionmolding machines.“PET-ISBMPET-Injection Stretch Blow Molding2 Sections, 2 HoursPolyethylene terephthalate, usually referred to as PET, is the mostcommon plastic used for many injection blow molded packaginggoods. Paulson’s comprehensive, interactive training course onPET – Injection Stretch Blow Molding Process, teaches the PETprocessor the characteristics of PET and how to efficiently andsafely process it.With Paulson you learn! The information gained in the ProMolder classis too valuable not to continue on multiple levels.”—Paul Boettcher, Le Seur Inc.Co-authored with industry expert Mark Strachan, this courseoffers complete training on all aspects of the thermoformingprocess. Topics covered include operation of the machineryused in thermoforming, the function of each component in thethermoforming line, plastic behavior during the thermoformingprocess, sheet extrusion fundamentals, optimizing operatingcontrols, safety around the thermoforming machinery andthermoforming for maximum efficiency and profit.Thick Sheet Thermoforming Technology5 Lessons, 8–10 HoursTraining on the fundamentals of the thermoforming process;types of machines, in-line and rotary, the five phases of thecycle, and the effects of each phase on quality and production.Personnel will become familiar with the causes of part variationsresulting from heating, forming or cooling errors, and the aftermolding effects that can cause additional shrinkage and warp.SpecializedEngineering TrainingGeometric Dimensioning &Tolerancing (GD&T)10 Lessons, 15–20 HoursA complete offering of Geometric Dimensioning andTolerancing (GD&T) training by industry leader Tec-Ease, Inc.GD&T is recognized around the world as the only effective wayto define part geometry of mechanical parts by using a systemof symbols, rules and definitions. Advantages include cleardesign intent, shorter cycle time from concept to launch,fewer engineering changes, and less trouble-shooting atstartup. GD&T is standardized and mathematized whichmeans that anyone who knows the Standard, knows whatthe drawing means.Blue Print Reading7 Lessons, 10–14 HoursIndustrial prints are an integral part of documentingmanufacturing processes. This 16-hour course, developedby industry leader Tec-Ease, is intended for all personnelwho need to understand the meaning of drawings and prints.Emphasis is placed on understanding multiview relationships,and symbology. Numerous exercises involving print readingwill be utilized throughout.Paulson PlasticsAcademyExperience world-class instructor-led Certification seminarswith the Paulson Plastics Academy held virtually or in-personin multiple technical facilities nationwide. Taught by expertinstructors, seminars are designed to teach key scientificprinciples and crucial optimizing strategies for injection molders,extrusion processors, blow molders, and thermofomers.Paulson seminars can take your personnel from beginner toexpert with intense instruction in the foundations of processingplastic as a scientific process. All seminars are vendor-neutraland include a free screening test to ensure proper placement.Hands-on learning with machine time is included when possibleand most classes engage attendees with Paulson’s exclusiveand powerful injection molding machine simulator SimTech.Additional seminars include Profitable Molding for Managersand a highly popular troubleshooting course.Customized TrainingServicesCustom OnSite Training and Consulting ServicesNeed training tailored to your particular needs and operations?We can bring our expertise to you by hosting a personalizedseminar with our technical instructors in your facility. We alsooffer consulting services to help you navigate specific moldingor plastic material challenges either in a scheduled onlineteams meeting or with an in-person visit.Paulson provides a number of additional training products andservices that can be customized to meet your specific trainingneeds, including: Training Needs Analysis OnSite Program Review & Support Customized ReportingUnparalleled CustomerService & Technical SupportPaulson customers enjoy personal attention with a dedicatedsuccess manager, excellent tech support, onboardingassistance, advancements, and bonus training materials.And, you’ll always reach a live person when you call the Paulsonoffice. Paulson is your source for powerful plastics training.

Injection MoldingTrainingTechnology of Injection Molding5 Lessons, 8–10 HoursInjection Molding Fundamentals2 Lessons, 2 HoursA two lesson, 2 hour training program teaching new employeesand personnel the most important and fundamental aspects ofthe injection molding production floor and molding process. Thiscourse emphasizes production efficiency, safety and teamwork.Core Injection Molding Courseswith Active Machine Simulation Labs24 Lessons, 28 SkillBuilder Lab Lessons, 41–55 HoursPaulson’s core injection molding courses cover the span ofscientific molding principles from the fundamentals to advancedtopics. Each level in the series includes direct access toSkillBuilder (available in English and Spanish), Paulson’s onlineactive lab lessons using Paulson’s powerful injection moldingmachine simulator SimTech. The Technology of Injection Moldingseries is broken down into three modules to help students easilyprogress through the intensive content while building a strongbase of scientific injection molding knowledge.Technology of Injection Molding– Level5 Lessons, 14 SkillBuilder Lab Lessons, 10–15 Hours➊Build the Foundation. This robust online course is the firstin a series of Paulson’s core injection molding courses andfeatures Paulson’s innovative virtual molding machine lablessons, SkillBuilder, built right in. Learners immediately applyand practice key concepts covered in the course. Each lessonteaches technical concepts in easily digestible segments.Students learn the basic foundations of injection moldingincluding the most important, how to process plastic from the“Plastics Point of View,” (PPV) and the “Four Plastic Variables,”crucial concepts pioneered by Paulson.Technology of Injection Molding– Level3 Lessons, 7 SkillBuilder Lab Lessons, 8–10 Hours➋Optimize the Process. Employees will gain a deepunderstanding of the scientific method and the effect ofeach machine control on the four basic variables. Based ona scientific approach, this course analyzes ways to improveproductivity and build a solid optimized process. Learnedconcepts are immediately put into practice using SkillBuilderLab lessons built right in.Language OptionsGracie,the happinessambassadorPaulson offers custom languageoptions for all online courses.And many courses can becustomized to include sub-titles.– Level➌Master Injection Molding. This course teaches the “why”behind injection molding and is designed for those wishingto be at the expert molding level. The lessons focus onthe relationship between machine controls, the four plasticvariables, and part properties. Understanding this relationshipallows a molder to best optimize the molding cycle.Implementing Decoupled Molding 3 Lessons, 5–6 HoursExtrusion TrainingThermoformingTraining course developed in cooperation with RJG, improvesprocess consistency by separating the molding process into3 phases: filling, packing and cooling.Extruder Operation and Control –Single Screw9 Lessons, 14–16 HoursThin Sheet Thermoforming6 Lessons, 10–12 HoursHot Runner Molding Solutions5 Lessons, 8–10 HoursTraining on the fundamentals of single screw technology, includingparts and operation, plastics used for extrusion, extruder controls,safety procedures, troubleshooting and more.Course describing different manifold and gate designs, startupand shutdown techniques, troubleshooting and maintenanceprocedures for hot runner molding processes.Injection Molded Part Problems &Solutions with SkillBuilder11 Lessons, 7 SkillBuilder Lab Lessons, 15–20 HoursThis course is designed to train in the recognition and analysisof part defects utilizing the four plastic variables contributingto the defect. Topics covered include: Voids, Sink Marks, ShortShots, Flash, Weld (Knit) Lines, Splay (Silver Streaks), Jetting,Burn Marks, Warp, Cracks and Part Breakage and ControllingMolded Part Dimensions.Statistical Process Control3 Lessons, 5–6 HoursFocuses on increasing SPC skills, how to maintain correctSPC procedures and how to document and train new personnelin SPC requirements.Plastic Drying Technology2 Lessons, 2–3 HoursAvailable in SpanishAvailable in Mandarin“Whether you have experienceprocessing plastic or are newto it, Paulson definitely teachesyou everything you need toknow to advance your skills!”—Mackenzie Chanthavisouk, Anchor PlasticsSpecialized InjectionMoldingElectric Injection Molding Machine3 Lessons, 5–6 HoursThis course covers electric machine design, cycle and parts,the effects of each control and specific operating techniques tooptimize routine operations including clamp settings and screwcontrols; all specific to the electric machine environment.Efficient Mold Setting2 Lessons, 2–3 HoursTraining course demonstrating how to efficiently set up a mold,troubleshoot mold problems, and properly remove and preparemold for storage.Training course demystifying plastic drying by explaining howplastic drying is done, how to check dryer operations, and how totroubleshoot problems caused by incomplete moisture removal.Design of Experiments for Injection Molders3 Lessons, 5–6 HoursCo-authored with Launsby Consulting, providing 5 hours of trainingon how to design an experiment by explaining common terminologyand exploring various design of experiment techniques.Compounding with the Twin Screw Extruder8 Lessons, 14–16 HoursTraining on the fundamentals of compounding with a twin screwextruder, including parts and operation, raw materials used, plasticbehavior, optimizing controls, safety and startup procedures,troubleshooting and more.Sheet Extrusion Technology7 Lessons, 12–14 HoursTraining designed for use in conjunction with our 9-lesson singlescrew extrusion course. Providing overview of sheet extrusiontechnology ranging from parts and operation to controlling plasticflow in the die to troubleshooting the sheet extrusion line.Extrusion Blow Molding7 Lessons, 12–14 HoursTraining on the fundamentals of extrusion blow moldingtechnology, including process and equipment, plastic behavior,operating controls, operating procedures, processing conditionsand problems and solutions.Understanding Materials for Profitable Molding10 Lessons, 8–10 HoursA collection of individual lessons on 10 commonly used materialsproviding an overview of chemical & physical properties as well asmolding characteristics of a specific raw material type. Lessonsinclude: Polycarbonate (PC), Polypropylene (PP), Polyethylene(PE, LDPE, HDPE, LLDPE, UHMWPE), Nylon (PA), ABS,Polystyrene (PS), Acrylic (PMMA), Acetyl (POM), Polyester (PBT),Thermoplastic Elastomers (TPE).Injection Molding Machine Maintenance2 Lessons, 2–3 HoursInstructional program demonstrating the proper machinemaintenance procedures for all hydraulic injectionmolding machines.“PET-ISBMPET-Injection Stretch Blow Molding2 Sections, 2 HoursPolyethylene terephthalate, usually referred to as PET, is the mostcommon plastic used for many injection blow molded packaginggoods. Paulson’s comprehensive, interactive training course onPET – Injection Stretch Blow Molding Process, teaches the PETprocessor the characteristics of PET and how to efficiently andsafely process it.With Paulson you learn! The information gained in the ProMolder classis too valuable not to continue on multiple levels.”—Paul Boettcher, Le Seur Inc.Co-authored with industry expert Mark Strachan, this courseoffers complete training on all aspects of the thermoformingprocess. Topics covered include operation of the machineryused in thermoforming, the function of each component in thethermoforming line, plastic behavior during the thermoformingprocess, sheet extrusion fundamentals, optimizing operatingcontrols, safety around the thermoforming machinery andthermoforming for maximum efficiency and profit.Thick Sheet Thermoforming Technology5 Lessons, 8–10 HoursTraining on the fundamentals of the thermoforming process;types of machines, in-line and rotary, the five phases of thecycle, and the effects of each phase on quality and production.Personnel will become familiar with the causes of part variationsresulting from heating, forming or cooling errors, and the aftermolding effects th

Core Injection Molding Courses with Active Machine Simulation Labs Technology of Injection Molding - Level One 10-15 Technology of Injection Molding - Level Two 8-10 . (Knit) Lines, Splay (Silver Streaks), Jetting, Burn Marks, Warp, Cracks and Part Breakage and Controlling Molded Part Dimensions. Injection Molding Training Injection .