Transcription

Carbon Dioxide Sequestration in Coal at the IllinoisBasin Tanquary SiteCBM Test Updatepresented byDavid Morse (ISGS)John Rupp (IGS)Maria Mastalerz (IGS)Satya Harpalaniand theMGSC Project TeamApril 10-11, 2008CoalSeq VI ForumHouston, TexasMidwest GeologicalSequestration Consortiumwww.sequestration.org

Acknowledgements This work is being supported by the U.S. Department ofEnergy, Office of Fossil Energy, as part of the RegionalSequestration Partnerships Program, and by the IllinoisOffice of Coal Development (DCEO) through the IllinoisClean Coal Institute, under the Midwest GeologicalSequestration Consortium (MGSC)The MGSC is a collaboration led by the geologicalsurveys of Illinois, Indiana, and Kentucky

CO2 Injection into One CoalPurpose: To determine the CO2 injection andstorage capability, and the ECBM recoverypotential of Illinois Basin coal Drill multi-well injection and monitor projectobtaining coal cores for extensive analysesSimulation of CO2 injection with COMET3Water Injection PT Tests40 to 80 Day CO2 Test- Injection of up to 700tons of CO2 with 60 day soak

Coal and Coal Gas PropertiesStudied Gas ContentCoal Gas CompositionCoal Gas Isotopic CompositionPermeabilityAdsorption Isotherms- CH4, N2, and CO2Maceral Analysis and Thermal MaturityProximateShrinkage/Swelling Lab StudyChanges in mesopore and micropore characteristics

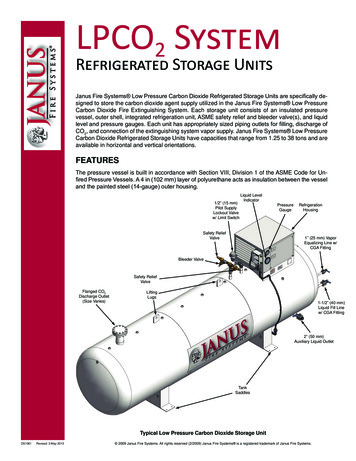

CO2 Logistics Liquid CO2 brought to site by semi- 20tons/loadDownloaded to 50 ton capacity temporarystorage unitSkid mounted CO2 pump, heater anddelivery system- convert to gas phaseGas phase injected down well

MMV(monitor, mitigation and validation) Prior to, during and after injection, ISGS willmonitor for any C02 leaks.Soil gas and shallow groundwater monitoringholes.Monitor on-site temporary storage tank and welldelivery equipment for leaks to atmosphere.High resolution air photos before and afterinjection to look for vegetative stress.

IllinoisPennsylvanianRocksShale Seals ThroughoutMajor Coal Gas/CO2Injection Targets

ProjectLocation5 miles east of Albion,IL in Wabash County

Tanquary Farm Injection Site

Springfield Coal Cleat Orientationsat Wabash Mine, 6 miles SE

CO2 Injection into CoalTanquary Farm SiteWestern Wabash County, IllinoisInjectionWell (I-1A)cecttBuFatsaecltsleaMonitor well(M-2A)Monitorwell (M-1)

Tanquary Site and Coal Cleats

Springfield Coal, Principal Target

Coal Formation Tops and Gas ContentsGallagher Drilling, L.P. Daughters et al #I-1A & #M-1NW Sec 27, T1S, R14W, Wabash Co. rin787.5792.65.14148Briar ville1142.51148.76.2429.218Houchin CreekSurvantNet CoalCanisterSamplesAverageGc (dmmf)132

Gas Content (dmmf)I1A-Danville -1I1A-Danville-2250I1A-Danville-3Gas Content dmmf (scf/ton)Springfield pringfield-5I1A-Excello Sh-150I1A-Houchin Ck-1I1A-Houchin Ck-2I1A-Seeleyville-101I1A-Seeleyville-2Increasing Depth - I1A-Seeleyville-3I1A-Seeleyville-4

Adsorption Isotherms900CO2Volume Adsorbed, scft (daf)800M1-Springfield-1 (CH4)I-1A- Springfield-1 (CH4)700600500I-1A-Springfield-2 (CH4)I-1A-Springfield-3 (CH4)400I-1A-Springfield-4 (CH4)I-1A-Springfield-5 (CH4)CH4300M1-Springfield -6 (N2)M1-Springfield -6 (CH4)200M1-Springfield -6 (CO2)N210000200400600Pressure, psia80010001200

Normalized Air-Free Desorbed Gas Composition(vol %)WellIntervalI-1ASpringfield CoalI-1ADepthH2N2CO2CH4C2 895.58.892.6288.430.07Springfield Coal896.52.731.5995.630.04I-1ASpringfield Coal897.54.701.5793.690.04I-1ASpringfield Coal898.56.901.4291.570.04I-1ASpringfield Coal901.57.091.3991.490.03M-1Springfield Coal900.52.721.6995.560.030.07

Springfield Coal DST in I-1A WellPerm: 6.8 mdFSIP 391 psiDepth: 896 ftSkin: 9.1

Well Testing Tests run in and between initial two wellsStep-rate Injection tests indicated that the coal fracpressure was 900 psi.Injection/Fall-off tests indicated permeability of 10 md,similar to DST derived perm.Interference and Pulse Tests demonstrated pressurecommunication between wellsConclude from COMET 3 modeling that we have toreduce well spacing to 100 feet to ensure significant gassaturation detectable in monitor wells during our limitedtest.

Laboratory research at ISU and IGS is beingconducted to assist in the field demonstrationproject. The main emphasis of the research is on:1) Understanding changes in mesopore and microporecharacteristics (surface area, volumes, and size distribution) as aresult of CO2 adsorption (IGS).2) Investigating the influence of maceral composition on the CO2‐adsorption derived changes in the coal (IGS)3) Determining the extent of swelling of the coal as a result of CO2adsorption or shrinkage of the coal with CH4 desorption (SIU)4) Determining the CH4, N2, and CO2 adsorption isotherms of theSpringfield and Seeleyville coals (SIU)

Injection Plan

Project Status Summary Two wells drilled, cored, DST, logged and cased Special core lab analyses at IGS and SIU in progress Completed PTA and pulse tests last October to bettermeasure permeability. These results and our COMETmodeling used to locate the final wells that will betterensure that we will see CO2 at our monitor wells withinthe injection period of 40-80 days. Drilling final coal wells anticipated in April-May 2008 Install MMV soil gas and groundwater monitor wells tocollect background data once all the coal wells drilledMay 2008 CO2 injection scheduled for June-July 2008

Midwest GeologicalSequestration Consortiumwww.sequestration.org

CO 2 Injection into One Coal Drill multi-well injection and monitor project obtaining coal cores for extensive analyses Simulation of CO 2 injection with COMET3 Water Injection PT Tests 40 to 80 Day CO 2 Test- Injection of up to 700 tons of CO 2 with 60 day soak Purpose: To determine the CO 2 injection and storage capability, and the ECBM recovery .