Transcription

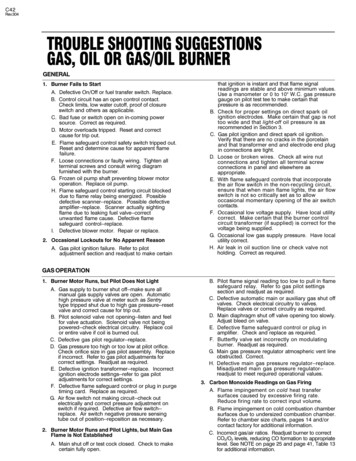

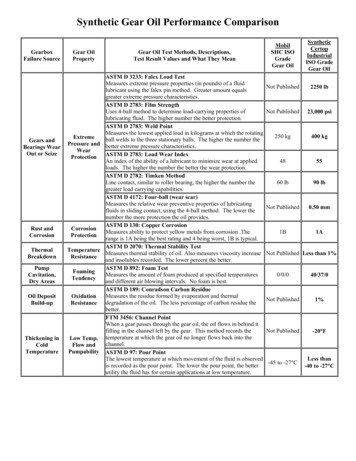

Synthetic Gear Oil Performance ComparisonGearboxFailure SourceGears andBearings WearOut or SeizeRust andCorrosionThermalBreakdownPumpCavitation,Dry AreasOil DepositBuild-upThickening inColdTemperatureGear OilPropertyGear Oil Test Methods, Descriptions,Test Result Values and What They MeanASTM D 3233: Falex Load TestMeasures extreme pressure properties (in pounds) of a fluidlubricant using the falex pin method. Greater amount equalsgreater extreme pressure characteristics.ASTM D 2783: Film StrengthUses 4-ball method to determine load-carrying properties oflubricating fluid. The higher number the better protection.ASTM D 2783: Weld PointMeasures the lowest applied load in kilograms at which the rotatingExtremeball welds to the three stationary balls. The higher the number thePressure and better extreme pressure characteristics.WearASTM D 2783: Load Wear IndexProtectionAn index of the ability of a lubricant to minimize wear at appliedloads. The higher the number the better the wear protection.ASTM D 2782: Timken MethodLine contact, similar to roller bearing, the higher the number thegreater load carrying capabilities.ASTM D 4172: Four-ball (wear scar)Measures the relative wear preventive properties of lubricatingfluids in sliding contact, using the 4-ball method. The lower thenumber the more protection the oil provides.ASTM D 130: Copper CorrosionCorrosionMeasures ability to protect yellow metals from corrosion .TheProtectionrange is 1A being the best rating and 4 being worst, 1B is typical.ASTM D 2070: Thermal Stability TestTemperatureMeasures thermal stability of oil. Also measures viscosity increaseResistanceand insolubles recorded. The lower percent the better.ASTM D 892: Foam TestFoamingMeasures the amount of foam produced at specified temperaturesTendencyand different air blowing intervals. No foam is best.ASTM D 189: Conradson Carbon ResidueMeasures the residue formed by evaporation and thermalOxidationResistance degradation of the oil. The less percentage of carbon residue thebetter.FTM 3456: Channel PointWhen a gear passes through the gear oil, the oil flows in behind itfilling in the channel left by the gear. This method records theLow Temp. temperature at which the gear oil no longer flows back into thechannel.Flow andPumpability ASTM D 97: Pour PointThe lowest temperature at which movement of the fluid is observedis recorded as the pour point. The lower the pour point, the betterutility the fluid has for certain applications at low temperature.MobilSHC ISOGradeGear OilSyntheticCertopIndustrialISO GradeGear OilNot Published2250 lbNot Published23,000 psi250 kg400 kg485560 lb90 lbNot Published0.50 mm1B1ANot Published Less than 1%0/0/040/37/0Not Published1%Not Published-20 F-45 to -27 CLess than-40 to -27 C

Certop Industrial Advanced Performance Gear and Bearing OilISO 68, 150, 220, 320, 460, 680Heavy duty gear and bearing oilspecifically formulated for heavyindustrial equipment.Provides superior protection against leakingseals, dry starts, water contamination,oxidation and foaming.LASTS UP TO FOUR TIMES LONGERTHAN CONVENTIONAL GEAR OILSProvides Superior Equipment Protection for: Industrial Manufacturing Construction, Mining, Agriculture Food Processing Excavation & Demolition Steel Mills & Foundries Utility Construction Paper Mills, Printing, & Packaging Concrete & Asphalt Paving Federal, State & Local AgenciesFor Peak Performance, usewith LubeMaster System PurgeHelps Eliminate Dry Start WearHelps Prevent Seals from LeakingMeets or Exceeds the FollowingPerformance Requirements:Prevents Rust and Corrosion All API GL-3, GL-4 (most GL-1and GL-2 applications)Displaces Water for Easy Drainage DIN 51517 Part 3 David Brown S1.53.101Controls Foaming Cincinnati Milacron P-59 CM ref#1100207Lowers Operating Temperature and ResistsOxidation to Prolong Oil Life US Steel #224ISO 460 & 680 Ideal for Bronze Gears AGMA 4EP to 8EP AGMA 9005, 215.02 and 250.04Wide temperature range - operates from20ºF to 275ºF.Irving, Texas Indianapolis, Indiana Kendall Park, New Jersey Sunnyvale, Californiawww.certifiedlabs.com 2002 NCH CorporationConsult the label for complete directions and precautions before using this product.Division of Certified LaboratoriesUSDA H2

CERTOP INDUSTRIAL contains a total additivepackage that sets it apart from other gear oilsAdditivesUser BenefitsSuperior grade, highly-refined base oil resists oxidation and high-temperaturebreakdown to maintain better lubricity.Keep oil on gears during high-speed operations and during idle periods.Adhesive and CohesivePolymers, Tackiness Agents Helps prevent mechanical wear, stress fractures and dry startsBlocks out corrosive elements such as acids, water, condensate and steam byRust and Corrosion Inhibitorsforming a protective barrier on equipment surfaces to prevent chemical wear.Heat seeking additive which increases the ability of the lubricant to preventExtreme Pressure (EP) Agentsthe extreme wear that can occur under loads.Extends service life of the lubricant by retarding the oxidation or breakdownOxidation Inhibitorsprocess.Cushions impact to minimize the stress, vibration and chatter that can occurShock Load Reducersunder heavy loads and during start-stop operations.Forms a lubricant film on metal surfaces in the presence of heavy loads andAnti-Wear Agentshigh temperatures. Prevents cold welding.Premium Grade Base OilFriction ReducersPlates out on metal surfaces to prevent friction and wear under heavy loads.Anti-Foam AgentsWithstand agitation and heat without forming foam conatminants. Reducepressure levels on seals and vents.PHYSICAL PROPERTIESPropertiesColorAPI Gravity:Flash Point (COC):Pour Point, F:Viscosity Index:Kinematic Viscosity, CST @ 40 C:Kinematic Viscosity, CST @ 100 C:Rust Protection:Corrosion Protection:4-Ball Wear Scar Dia., mm4-Ball Weld Load, kgTimkin OK Load, lbs.ISO 68Red29.3435510773.69.54Pass1A0.3125060ISO 150Red32.442515102164.4215.86Pass1A0.3125065ISO 220Red29.345015102220.8520.94Pass1A0.3225065ISO 320Red27.8550015107291.4625.58Pass1A0.3225065ISO 460Red26.356015104468.630.59Pass1A0.2825065ISO 680Green24565209568038.9Pass1A0.2825065IDEAL FOR USE IN:Oil filled bearings, gear boxes including enclosed gears of spur type, hypoid, spiral bevel,worm, herringbone, helical, planetary and unusual combinations of gear types. Can be usedas a cylinder oil, except for steam cylinders. Can be added as make up oil to otherIndustrial grade mineral gear oils. For Bronze Gears use CERTOP Industrial 460 & 680only.DO NOT USE FOR:Do not use CERTOP 68, 150, 220 or 320 for copper, bronze worm gears (use CERTOPIndustrial 460 or 680). Any equipment for which the manufacturer does not recommendthis type of gear lubricant.

HOC Advanced Performance Hydraulic OilISO 22, 32, 46, 68, 100, 150, 220Single-grade hydraulic oil specificallyformulated for construction andheavy industrial equipment.Provides superior protection againstleaking seals, contaminants, pump wear,and erratic operation.HYDRAULIC OIL OF CHOICE FOR ALMOSTEVERY SINGLE-GRADE APPLICATIONProvides Superior Equipment Protection for Industrial Manufacturing Construction, Mining, Agriculture Food processing Excavation & Demolition Steel Mills & Foundries Utility Construction Paper mills, printing, & packaging Concrete & Asphalt paving Federal, State & Local AgenciesControls Seal Swell to Help PreventSeals From LeakingHighly Resistant to OxidationControls Water and Other ContaminantsControls FoamingPrevents Rust and CorrosionPrevents Pump and Cylinder WearFor Peak Performance, usewith LubeMaster System PurgeMeets or Exceeds the FollowingPerformance Requirements Dennison-Abex HF-1, HF-2,HF-O Vickers I-286-S and M-2950-S Ford M6C32 GM LH Specs: 04, 06, 03 JCB AW VG-32 Parsons AMCA AW Hydraulic DIN 51524 part 2USDA H2Ideal for Use With Vane Pumps,Piston Pumps, Gear PumpsIrving, Texas Indianapolis, Indiana Kendall Park, New Jersey Sunnyvale, Californiawww.certifiedlabs.com 2002 NCH CorporationConsult the label for complete directions and precautions before using this product.Division of Certified Laboratories

HOC contains a total additive packagethat sets it apart from other hydraulic oilsAdditivesUser BenefitsPremium Grade Base OilS eal ConditionersLeak InhibitorsRust and Corrosion InhibitorsOxidation InhibitorsDemulsifiersAnti-Wear AgentsAnti-Foam AgentsS ludge InhibitorsS hock Load ReducersFriction ReducersMetal DeactivatorsPour Point DepressantsSuperior grade, highly-refined base oil resists oxidation and high-temperature breakdown to maintainbetter lubricity.Special compounds that soften and condition seals to keep them from hardening and cracking.M ost seal leaks occur because many oils cause seals to shrink. Special agents provide a controlledswell to bring the seals back to their normal size.Blocks out corrosive elements such as acids, water, condensate and steam by forming a protectivebarrier on equipment surfaces to prevent chemical wear.Extends service life of the lubricant by retarding the oxidation or breakdown process.Separates water from oil to keep metal surfaces dry. Allows excess water to be drained fromequipment.Forms a lubricant film on metal surfaces in the presence of heavy loads and high temperatures.Prevents cold welding.Inhibit oil foaming during operation to reduce seal pressure, prevent pump cavitation wear anddecrease air entrapment that can cause erratic operation.Keeps seals cleaner by preventing the build-up of sludge, varnish and lacquer.Cushions impact to minimize the stress, vibration and chatter that can occur under heavy loads andduring start-stop operations.Plates out on metal surfaces to prevent friction and wear under heavy loads.Prevent corrosion on yellow metals such as bronze, copper and brass.Keeps oil flowing properly in cold temperatures. Lowers frictional drag and keeps equipmentrunning in temperatures down to -20 degrees.PHYSICAL PROPERTIESHO C 22HO C 32HO C 46HO C 68HO C 100HO C 150HO C 220API Gravity 60/60 2627.2897.3287.3687.4047.441Specific oration Rate: 0.01 0.01 0.01 0.01 0.01 0.01 0.01Fire Coc. F435475480495515520550Flash Point: FViscositySAE 100150220cSt. @ 40 C2332.34767.5102155225cSt. @ 100 C4.255.456.68.661215.218.1Viscosity IndexFour Ball Wear T est, ScarDiameter, MM (AST M D2266):Vickers Pump Wear T est, mgSteelPour Point 26262420181212-30-35-30-30-25-10-20IDEAL FOR USE IN:Heavy duty straight hydraulics, all Sperry-Vickers vane and piston pumps for standard operation (200 psi, 1200 rpm,150-175 F) or severe operation (3000 psi, 2400 rpm, 200 F).DO NOT USE FOR:Brake systems, transmissions, aircraft, Lucas hydraulic pumps or other silver-lined pumps (use Lubemaster Mult-Oil ). Not for systems requiring water-based hydraulic oils. Not for universal multi-purpose powertransmission systems found in rubber-tired backhoes and tractors (use Lubemaster OIL-ALL ).

Comparison of ISO 46 Hydraulic OilHydraulic Oil Test Methods, Descriptions,Test Result Values and What They MeanCertified LabsHOC ISO46Hydraulic OilASTM D 2602: Viscosity by Cold CrankingSimulatorMeasures the apparent viscosity of the oil at0 C. The results are related to the crankingcharacteristics of the oil. The lower theviscosity reading, the less stress on the pump. 2200cpASTM D 2270: Viscosity IndexMeasures variation in viscosity due to changesin temperature. The higher the number, themore stable the oil will be at varyingtemperatures and conditions109ASTM D 2882: Vickers Vane Pump WearTestMeasures wear characteristics of hydraulicfluids. The lower the number, the less wearoccurs during operation and the longer thepumps will stay in service.Vickers 35VQ25 Hydraulic Pump WearTestMeasures wear in three successive 50-hour testruns with total ring and vanes wear must bebelow 90 mg in each of the three tests.ASTM D 943: Oxidation StabilityMeasures the oxidation stability of the oil inhours. The higher the number, the more stablethe fluid.ASTM D 892: Foaming Tendency testMeasures the foaming characteristics of oilafter agitation. Most hydraulic fluids showfoam tendencies 15 to 30 minutes afteragitation. The shorter the time in minutes, theless foaming will occur.MobilDTE ISO46Hydraulic OilHydraulicOil PropertyHOC has better lowtemperature flowwhich reducesequipment warmuptime.Mobil Does NotPublish This DataHydraulic OilOperatingViscosity4.5mg983mg 5 minutesASTM D 1401: Water SeparationMeasures the time it takes for water to separate 10 minutesfrom oils. The less amount of time it takes toseparate, the better.HOC has a wideroperating viscositywith a 20% increasein film strength.This will extendhydraulic pump life.Mobil Does NotPublish This Data Extreme Pressure HOC provides 50%better pump wearand Anti-Wearprotection.Mobil Does NotPublish This Data8000 hrsPerformance BenefitMobil Does NotPublish This DataHOC provides threeExtreme Pressuretimes the pump wearand Anti-Wearprotection.OxidationResistanceHOC has excellentoxidation resistanceproperties. 50 minutesFoamingHOC prevents foambuild-up whichcontributes to pumpcavitation and systemfailure.20 minutesEmulsificationHOC has excellentwater separationproperties.

Comparison of ISO 46 Hydraulic OilASTM D 92: Flash PointMeasures the lowest temperature at whichapplication of the test flame causes the vaporsabove the surface of the liquid to ignite. Thehigher the temperature the better (safer).460 F429 FFlash Point andOperating RangeOperating RangeThe temperature range at which the oil is fully-30 to 375 Ffunctional. The greater the range, the better theproduct.Mobil Does NotPublish This DataASTM D 189: Carbon ResidueMeasures the residue formed by evaporationand thermal degradation of the oil. The lowerthe percentage of carbon residue, the better.Mobil Does NotPublish This Data0.4%DepositsHOC has a wideroper

ASTM D 2270: Viscosity Index Measures variation in viscosity due to changes in temperature. The higher the number, the more stable the oil will be at varying temperatures and conditions 109 98 Hydraulic Oil Operating Viscosity HOC has better low temperature flow which reduces equipment warm- uptime.