Transcription

The Truth about Palm Oil Palm Oil Milling InitiativesChew Chien Lye @ MervinResearch & Development, Sime Darby Plantation BerhadJune 17, 2019

OUTLINEThe Company Sime Darby Plantation – An Integrated Plantation CompanyThe Truth about Palm Oil Current Scenario & Challenges Facts about Palm OilPalm Oil Milling Initiatives Overview on Milling Processes & Performance Current Challenges & Research Prospect Technological Development

The CompanySime Darby PlantationAn Integrated Plantation Company

Business OverviewIntegrated Plantation CompanyCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.4

Sime Darby Plantation R&D CentreUnits & RolesPlantation Research & AdvisoryProvide technical support to maximize yield &productivity: Continuous improvement in agro-managementpractices Reduction in chemical inputs through IPM, biofertilsers& biopesticides Improve nutrient & water use efficiencyAdvanced Agricultural TechDeveloping new technologies to support R&D andPlantation operations: Labour reduction through mechanisation& automation Precision Agriculture Data analyticsBiotechnology & BreedingBreeding for continuous improvement in yield & otherdesirable economic traits: Marker assisted breeding program Optimisation production & performance of oil palmclonesProcessing TechnologyAudit & Advisory to maximise mill & refinery productrecovery: Continuous improvement in processing technologyto improve efficiency & cost Towards zero waste Waste to wealth initiativesSime Darby Seeds & Agricultural ServicesProduction & sale of elite planting materialsAgro-technology and management services to externalpartiesInnovation CentresProvide technical service to all global customers,develop new products and provide technical support torefineriesMinamas Research CentreLiberia Research CentreOPRS DamiRegional research centres providing similar functions asPRA & Breeding for the local estates.5

6Upstream Portfolio Spread Across 5 CountriesHA Landbank 1 mil ha Planted area 631,000 ha% Oil Palm 96% Rubber & Sugarcane 4% CattleExcludes Plasma/ Outgrowers’scheme ( 100,000 ha)LiberiaMalaysiaPapua NewGuinea#MT Estates 250 Mills 71 Crude Palm Oil 2.5 mil MT Palm Kernel 0.6 mil MTIndonesia(Own Production)(Own Production)COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.SolomonIslandsSDP accounts for 4% of total world CPOproduction 20% of total world certifiedsustainable palm oil

Snapshot – Downstream OperationCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.7

8The Truth about Palm OilCurrent Scenario & ChallengesFacts of Oil Palm

9Rang-tan, the story of dirty palm oilFacts about palm oil?Source: YouTubePlay it!COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

Negative Perception: Anti-Palm Oil CampaignCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

Changing Perception : Love MY Palm Oil24 March 2019 at Sime Darby Plantation, Carey Island,Selangor.April 7, 2019COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

12The TruthCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Source: European Palm Oil Alliance

13Immense Health Benefits of Palm OilSource: MPOCCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

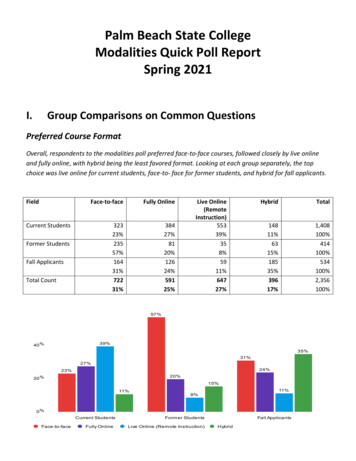

14Global Vegetable Oil Demand & SupplyPopulation Growth is a Key Driver141137111100106210183190176150174 9.7Vegetable Oil Demand & Supply vs Population8 250Mil MT30064250016.319.823.625.627.128.630.4 lation (RHS)0Demand/Capita kgSource: USDA United States Department of Agriculture, Washington https://www.fas.usda.gov/commoditiesOil World ISTA Mielke GmbH, Hamburg www.oilworld.bizAfricaNote: Europe consumption per capita for EU-28 only, excludes Russia & Eastern EuropecountriesCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS 3.93EU-284.03USkgPalm Oil Demand per 015.861024.252025.0330kg35.034044.8550Vegetable Oil Demand per Capita(2016)LatinAmericaUSChinaSource: LMC Oilseeds & Oils Report 2016, United Nations, USDA

15Immense Opportunities Await Growing population (9.7 bil by 2050) increased life expectancy, raisingconcerns over Food Security, Food Safety and Sustainability Global oils and fats consumption expected to increase From 180 mil MT to 250 mil MT in the future Dr. James Fry’s study in 2013 – that the world will lose 145 million Ha ofForest land by the year 2050 to feed the 9.7 billion people if it uses other edibleoils such as Soya, Sunflower, Rapeseed etc. With Oil Palm it will be less than 10 – 14 million Ha.145 millions hectare is equivalent to?145 millionsHa 2x the size ofFranceor43x the size ofNetherlandsor2,111x the sizeof SingaporeSource: James Fry (2016). What are the implications of a halt to all expansion in oil palm areas? PAC Seminar, Malaysian PalmOil Board.COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

16Immense Opportunities Await Palm Oil plays a critical role in helping to feed 3 billion people in more than 150countries worldwide Feeding another 2 billion people by the year 2050 is NO small feat Palm Oil will remain relevant as it is now an Irreplaceable part of the GlobalFood Supply Chain Palm Oil is expected to account for 55% of the Global Edible Oil Consumptionin the next 35 years!(Source: Global Oils & Fats. June 2017)COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

17Palm Oil Milling InitiativesOverview on Milling Processes &PerformanceCurrent Challenges & Research ProspectTechnological Development

18Oils Processing

19From Oil Palm Tree to Edible Palm OilEstatePlantingRefineryMillPalm ning processThreshing &Digesting(Oil extraction)HarvestingPackaging lingCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.QualityInspectionShipping/Delivery

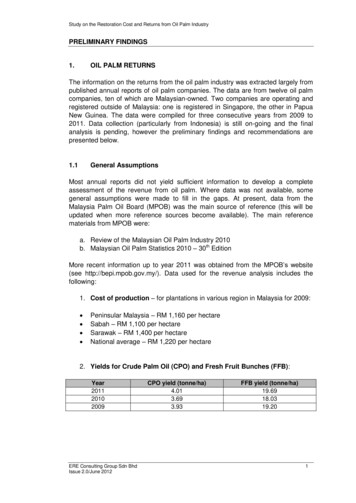

20Palm Oil MillingCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Oil Extraction Rate (OER) 20-22%Oil Losses 1.40-1.60%

21Research/Improvement hingEmptybunch23Digestion4PressingDilution waterFibre & Nut5ClarificationRecycled oil13149Purification8Sludge ll15CentrifugationSludgeCrude palm oilFibreNut gKernel16Treatment plantTreated POMECOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

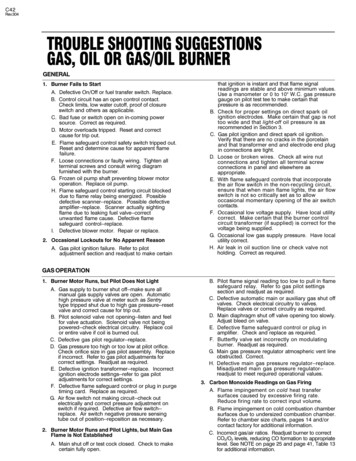

22Today’s Mill ChallengesStagnant process Same process for the past 30-40 years Stagnant oil extraction and mill efficiency Increase of operational costAdditional NewRequirement New parameter such as 3-MCPD and GEHigh EnergyUtilisation andCarbon FootprintStricter Emission andDischarge LimitPerceptionWeatherLabour Issue Solid waste as fuel – tendency for low boiler efficiency Malaysian commitment for 40% Carbon Emission reductionby year 2020 More stringent effluent and boiler emission standard More CAPEX and OPEX utilisation Consumer perception on non-hygienic means of oil palmfruits handling and processing during milling GMP, HACCP, HALAL Certifications, etc El Nino affected the production of palm oil in Malaysia,reduce productivity and increase cost of production Increase in wages Human errorCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

23Research/Improvement ementStandardHigh Efficiency93% Oil96% KernelLow ProcessingCostRM20-25/FFBHigh ValueProductsCPO, KernelGreen MillPower 25-30kWPOME 0.7-0.75/FFBEnvironmentalFriendlyDOE complianceZero DischargeLiquid wasteSolid wasteAutomation/MechanizationManpower, humanerror, hazardCompact MillMultiple unitoperationLarge footprintMinimal Labour70-80 pax/millHigh SafetyStandardLTIFRCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Food GradeFactory

24Example:High Efficiency Improvement

25High Efficiency Improvement OER is Oil Extraction Rate.Oil Input OER Oil LossesTarget0.60%0.40%0.30%0.10% 1.40%Oil loss in press fibreOil loss in final effluentOil loss in empty bunchOil loss in decanter cakeTotal oil lossshellmesocarpkernel

26High Efficiency ImprovementSeparate Mesocarp ExtractionHot WaterScrew ation /Fibre & NutseparationStage I - Maceration& Nut SeparationStage II - Tricompression ScrewPress1st PressingStationStage IIIHydrationStage IV - Tricompression paratorCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

27High Efficiency ImprovementInorganic Enhancer Evaluation conducted in 4months period Results illustrates a 95%confident internal for a meandifference of 1% increase foroil recovery rateCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

28High Efficiency ImprovementMembrane Oil Recovery SystemMembraneOil & BiosolidRecovery SystemFiltered POMERaw POMESS – 2-5%Oil – 0.5-1.2% To reduce biological loadof raw POME i.e BOD,COD, SS, etc. 50-60% BOD & CODreduction To ease and reduceeffluent treatment plantcost. To support compliance tothe new DOE effluentdischarge limit.Biosolid Biosolid recovery beforeeffluent treatment plant(ETP)COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Oil Maximising oil recovery/minimising oil losses

29Example:Environmental Friendly

30Environmental FriendlyDepartment of Environment (DoE) has circulated new draft in 2015: More stringent on treated effluent discharge Proposed to be enforced by July, 2016 but deferred after hearingcomments from industries.COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

31Environmental FriendlyFresh Fruit Bunches(FFB)SterilisationSterilliser condensateEmpty FruitsBunch (EFB)ThreshingDigestion/PressingOil RoomClarification/OilPurification &Sludge SeparationKernel RecoveryPlantDepericarpingNut CrackingKernel/Shell SeparationDecanter solidHydrocyclone/claybath wasteFibreShellBoiler &Power GenerationEffluentTreatmentPlantCPOKernelCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Fibre: 12-13% to FFBShell: 6-8% to FFBCentr.waste/decanter h.phasePower HouseEFB: 22-23% to FFBExcess fibreExcess shellBoiler ash/clinkerAnaerobic solidAerobic solidFinal DischargeWaterPOME: 60-75% to FFB

32Environmental FriendlyFresh Fruit Bunches(FFB)SterilisationSterilliser condensateCompostThreshingMulching in oilpalm plantationDigestion/PressingOil RoomCentr.waste/decanter h.phaseEmpty Fruits Bunch(EFB)Clarification/OilPurification &Sludge SeparationKernel RecoveryPlantDepericarpingNut CrackingKernel/Shell SeparationPower HouseOrganicfertilizerHydrocyclone/claybath wasteDecanter solidFibreCompostShellExcess fibreExcess shellBoiler ash/clinkerBoiler &Power GenerationEffluentTreatmentPlantCPOAnaerobic solidAerobic solidFinal DischargeWaterKernelCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Road surfaceSurface landfill/compostOrganic fertilizerBiogasRecycled as processWater or boiler waterfeed

33Environmental FriendlyEffluent Treatment SystemFFBComposting PlantPolishing PlantOil MillAerobicEFBCoolingPondAnaerobicCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

34Example:High Value Products -Oil Quality Improvement

35Palm Oil Washing with Bio-based SolutionBASTreatedOilPure Oil ntQuality Improvement Plant Improve the CPO quality (FFA, 3-MCPD) Highly Commended for Palm Oil Award, IChemE 2018 Patent filing:WO2016167638A1 (PCT Filing)PI 2018702151 (Malaysia)P00 2017 03656 (Indonesia)COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Storage TankSludge OilTank

36Separate Loose Fruits Processing Improve the CPO quality Reduce Steam Consumption Reduce Oil Loss in EFB Patent filing:PI 2018000689 (Malaysia)COPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

37Example:Technology Advancement Improvement

38Experimental PlantPilot Plant Carey IslandFundamental StudyControl TrialsLaboratory to pilot scale trialsExperimentalStation Bestari JayaPilot to commercial study200 sensorsPilot to commercial trialMill optimizationCOPYRIGHT 2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.

THANK YOUmervin.chew.chienlye@simedarbyplantation.com

40Appendix

41The TruthGlobal Oilseed Harvested Area (mil ha)Sunflower Oil PalmOil202782Rapeseed33OilOthers126Soya BeanOilSource: FAO, Oil World 17/18Green cover for 97% of the total oilpalm areasThe oil palm industry is a net carbonsinkOil Palm plantations are capable ofremoving as much CO2 as tropicalforestsSource: MPOC, The New Straits Times, MPOB, Oil World 17/18, Palm OilAction Group Australia, The Guardian 2014COPYRIGHT@2019 SIME DARBY RESEARCH SDN. BHD. ALL RIGHTS RESERVED.Source: MPOC Annual Report 2017

42Behind beef, soy is the second largest agricultural driver of deforestation worldwide.Source: WWF 2018

43The company inability/our-sustainability-journey

agricultural-practices/new-planting

y/crosscheck

y/responsible-agriculture-charter

GenomeSelectTM100 ha20161000ha pa16% yieldimprovement feed 15 millionpeople withoutany extra landFull replant202247

Membrane Oil Recovery System Raw POME SS –2-5% Oil –0.5-1.2% Membrane Oil & Biosolid Recovery System Maximising oil recovery/ minimising oil losses il To reduce biological load of raw POME i.e BOD, COD, SS, etc. 50-60% BOD & COD reduction To ease and reduce effluent treatment