Transcription

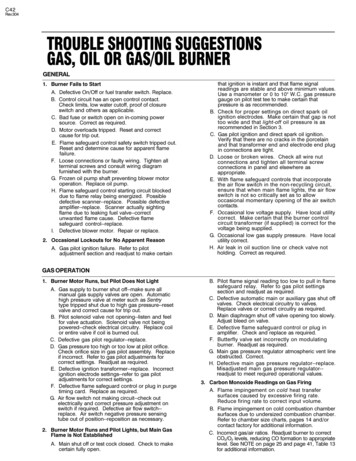

C42Rev.304TROUBLE SHOOTING SUGGESTIONSGAS, OIL OR GAS/OIL BURNERGENERAL1.that ignition is instant and that flame signalBurner Fails to StartA.Defective On/Off or fuel transfer switch. Replace.B.Control circuit has an open control contact.readings are stable and above minimum values.Use a manometer or 0 to 10" W.C. gas pressuregauge on pilot test tee to make certain thatpressure is as recommended.Check limits, low water cutoff, proof of closureswitch and others as applicable.B.source.D.recommended in Section 3.Motor overloads tripped. Reset and correctC. Gas pilot ignition and direct spark oil ignition.Verify that there are no cracks in the porcelainFlame safeguard control safety switch tripped out.and that transformer end and electrode end plugReset and determine cause for apparent flamein connections are tight.failure.F.D.Loose connections or faulty wiring.Tighten allappropriate.G. Frozen oil pump shaft preventing blower motorE.Replace oil pump.due to flame relay being energized.ensure that when main flame lights, the air flowswitch is not so critically set as to allowPossibleoccasional momentary opening of the air switchPossible defectivecontacts.Scanner actually sightingF.flame due to leaking fuel valve--correctunwanted flame cause.Defective blower motor.Occasional low voltage supply.correct.Defective flameHave local utilityMake certain that the burner controlcircuit transformer (if supplied) is correct for thesafeguard control--replace.I.With flame safeguard controls that incorporatethe air flow switch in the non-recycling circuit,H. Flame safeguard control starting circuit blockedamplifier--replace.Check all wire nutconnections in panel and elsewhere asfurnished with the burner.defective scanner--replace.Loose or broken wires.connections and tighten all terminal screwterminal screws and consult wiring diagramoperation.Make certain that gap is nottoo wide and that light-off oil pressure is asCorrect as required.cause for trip out.E.Check for proper settings on direct spark oilignition electrodes.C. Bad fuse or switch open on in-coming powervoltage being supplied.Repair or replace.G. Occasional low gas supply pressure.2.Occasional Lockouts for No Apparent ReasonA.Gas pilot ignition failure.Have localutility correct.H. Air leak in oil suction line or check valve notRefer to pilotholding.adjustment section and readjust to make certainCorrect as required.GAS OPERATION1.Burner Motor Runs, but Pilot Does Not LightA.B.Gas supply to burner shut off--make sure allmanual gas supply valves are open.AutomaticC. Defective automatic main or auxiliary gas shut offvalves.type tripped shut due to high gas pressure--resetD.Pilot solenoid valve not opening--listen and feelReplace coilE.or entire valve if coil is burned out.F.E.obstructed. Correct.Readjust as required.Defective ignition transformer--replace.H. Defective main gas pressure regulator--replace.Misadjusted main gas pressure regulator--Incorrectreadjust to meet required operational values.ignition electrode settings--refer to gas pilotadjustments for correct settings.F.Defective flame safeguard control or plug in purgetiming card.Replace as required.3.Carbon Monoxide Readings on Gas FiringA.Reduce firing rate to correct input volume.electrically and correct pressure adjustment onreplace.Defective air flow switch--Air switch negative pressure sensingtube out of position--reposition as necessary.Flame impingement on cold heat transfersurfaces caused by excessive firing rate.G. Air flow switch not making circuit--check outswitch if required.Readjust as required.G. Main gas pressure regulator atmospheric vent lineReplaceif incorrect. Refer to gas pilot adjustments forcorrect settings.Check and replace as required.Butterfly valve set incorrectly on modulatingburner.Gas pressure too high or too low at pilot orifice.Check orifice size in gas pilot assembly.Defective flame safeguard control or plug inamplifier.C. Defective gas pilot regulator--replace.D.Main diaphragm shut off valve opening too slowly.Adjust bleed on valve.Solenoid valve not beingpowered--check electrical circuitry.Check electrical circuitry to valves.Replace valves or correct circuitry as required.valve and correct cause for trip out.for valve actuation.Refer to gas pilot settingssection and readjust as required.high pressure valve at meter such as SentryB.Pilot flame signal reading too low to pull in flamesafeguard relay.B.Flame impingement on cold combustion chambersurfaces due to undersized combustion chamber.Refer to chamber size charts, pages 14 and/orcontact factory for additional information.2.Burner Motor Runs and Pilot Lights, but Main GasFlame is Not EstablishedA.C. Incorrect gas/air ratios. Readjust burner to correctCO2/O2 levels, reducing CO formation to appropriateMain shut off or test cock closed. Check to makelevel. See NOTE on page 25 and page 41, Table 13certain fully open.for additional information.

C43Rev.3044.Gas High Fire Input Cannot Be AchievedA.F.appropriate.operating incorrectly, not allowing required gasG.pressure at burner train inlet. Have gas companyH.Gas cock upstream of train inlet not fully open.Gas line obstructed. Check and correct.D.Gas train main and/or leak test cocks not fullyE.Side tee (limiting) orifice (if supplied) too small.Replace with correct size.Check and correct.C.Automatic gas valve not opening fully due todefective operation. Replace gas valve.correct.B.Burner gas train components sized too small forsupply pressure. Increase component size asGas company pressure regulator or meterI.On modulating burner, butterfly valve not fullyopened. Readjust.open. Check and correct.J.Defective main gas pressure regulator. Replace.Gas supply line between gas company regulatorK.Incorrect spring in main gas pressure regulator.Replace as required.and burner inlet too small. Check supply pressureL.at meter, determine pressure drop and increaseMain gas pressure regulator vent line obstructed.Check and correct.line size as required, or raise supply pressure toM.compensate for small line. Do not raise pressureNormally open vent valve (if supplied) not closingso high that under static (no flow) conditions thewhen automatic gas valves open. Check to see ifpressure exceeds the maximum allowablevalve is fully closed when automatic valves are open.pressure to the gas train components on the burner.Replace vent valve, if not closing fully.OIL OPERATION1.Burner Motor Runs, but Direct Spark Ignited OilC.Flame is Not EstablishedA.valve if defective.Defective or incorrect size oil nozzle. Remove andD.clean or replace.B.4.Light Off Oil Flame Is Established and Proven, butDefective oil pump. Replace.Burner Will Not Attempt to Go to the HighD.Defective oil solenoid valve. Replace.Fire PositionE.Oil pump coupling loose or defective. Replace orA.C.F.temperature or pressure control could beLow oil pressure switch (if supplied) defective ordefective or not set to call for high fire. ReadjustG.Defective ignition transformer. Replace.H.Ignition electrode set incorrectly. Remove electrodesor replace control.B.C.K.correct as required.Ignition leadwire defective and grounding out spark.D.High fire 3 way solenoid valve defective. Replace.Replace.E.Hydraulic oil cylinder defective. Replace.Loose ignition plug in connections at transformerF.or electrodes. Tighten.L.Air flow switch (if provided) not making. ResetG.Linkage mechanically binding.H.On modulating system - defective modulatingM. Defective flame safeguard control or plug in purgetimer card. Replace.Air dampers held in high fire position due tomechanical binding of linkage. Readjust linkage.O.Loose wiring connections. Check and tighten allLow Oil Flame Is Established and Proven, but FlameOut Occurs in Transition from Low Fire to High FireA.B.(or leaking). Check valve operation and replaceif necessary.B.Dirty flame scanner lens. Remove and clean.Blocked or dirty scanner sight tube. Check andclean.C.Defective flame scanner. Replace.D.Defective oil nozzle causing unstable flame andFuel/air ratios incorrect, resulting in unstable orC.Defective or incorrect size oil nozzle. Replace.D.High fire oil pressure too low. Readjust.E.Air dampers set too far open at low fire, whichcauses flame to blow out in starting to high fire.Readjust dampers.F.Loose or defective oil pump coupling. Tighten orG.Defective oil pump. Replace.H.Linkage mechanically binding. Readjust.smoky flame causing scanner flame sightingproblem. Readjust ratios for clean stable flame.F.Defective flame safeguard amplifier or control.Replace as appropriate.3.Oil Flame Extremely Smoky at Light Off or in LowFire PositionOn two-step oil pump - N.O. solenoid valvedefective (not closing). Replace valve or pump.scanning problems. Replace oil nozzle.E.On Low/High/Off or Low/High/Low system - N.C.oil solenoid valve in nozzle return line not closingconnections.A.Readjust linkage.motor. Replace.5.Oil Flame Ignites, but then Flame SafeguardControl Locks Out on SafetyOn two-step pump - N.O. solenoid valve defective(not closing). Replace pump or valve.pressure or replace.N.Flame safeguard control or high fire panelswitching relay (if supplied) defective. Verify andIgnition electrodes cracked and grounding outspark. Replace electrodes.J.Loose wires or incorrectly wired. Verify wiring andtighten all connections.and reset.I.Low/High/Low or Modulating burner high firetighten as required.incorrectly set. Adjust or replace switch.2.On two-step pump - N.O. pump mounted solenoidvalve malfunctioning. Replace valve or pump.Low oil pressure. Check with gauge for correctlight-off pressure.N.C. oil solenoid valve in oil nozzle return line notopening. Check electrical circuitry and replacereplace.I.Make certain the #72 orifice into the N.C. side ofthe 3 way valve has not been removed.J.On modulating systems - fuel/air ratios set incorrectly,A.Defective or incorrect size oil nozzle. Replace.causing flame to blow out when going to high fire.B.Fuel/air ratio incorrect. Readjust.Readjust linkage.

C44Rev.3046.White Smoke Formation on Oil FiringA.B.Defective nozzle replace. Dirty nozzle meshfilter clean or replace.Oil/Air ratios incorrect due to excess air, or oilflow is too low. Readjust for proper fuel input, COC. Oil supply pressure to nozzle too low. Readjust.and smoke reading.D.27.Gray or Black Smoke Formation on Oil FiringA.E.closing (or leaking). Check valve operation andsurfaces due to undersized chamber, orThis could also result in carbon formation onreplace if necessary.F.valve or pump.page 14, Figure 16 and page 14, Table 7 forG. Oil pump coupling loose (slipping) or defective.Replace.size, change nozzle spray angle in order toB.shorten or narrow the flame as required.H. Linkage mechanically binding. Readjust.Defective or dirty oil nozzle. Replace or cleanI.required nozzle bypass pressure.C. Incorrect oil/air ratios. Readjust burner to correctCO2and smoke levels.J.Oil pressure too low resulting in poor atomization.is in excess of 10" HG, consult line sizing charton page 12. Make line size changes, if required.Impingement of raw oil spray on the blast tubechoke ring or oil nozzle air diffuser. Make certainK.nozzle adapter shoulder, except on C5-OB,L.M. Suction line check valve or foot valve operatingincorrectly. Check and correct.the unit. See page 35 and 36, Figures 30, 31 and32 for additional information. Position the oil gun8.N. Vent system on oil tank blocked creating vacuumassembly fore or aft in the blast tube to assist inon tank, with high vacuum and lowered oil flowelimination of oil spray on the blast tube choke ring.to burner. Check and correct.Oil High Fire Input Rate Cannot Be AchievedA.Manual valves in suction line not fully open.Check and correct.C5-GO-30B and larger burners or other specialapplications indicated on burner data shippedwithBlocked or dirty suction line oil filter. Replace orclean.that the diffuser is seated firmly against the oil8.Oil suction line too small or partially blocked.Make vacuum test while at high fire. If the vacuumReadjust.E.On modulating burner, oil nozzle return linemetering valve set incorrectly. Readjust to attainnozzle.D.On two-step pump - N.O. pump mounted oilsolenoid valve defective (not closing). Replacechamber surfaces. Refer to chamber sizing,additional information. If chamber is the correctOn Low/High/Off and Low/High/Low systems N.C. oil solenoid valve in nozzle return line notImpingement on cold combustion chamberincorrect oil nozzle spray angle for application.Oil pump defective. Replace.Additional trouble shooting information can be found inOil nozzle size too small. Remove nozzle andthe Flame Safeguard Control bulletin supplied with thecheck markings.burner.Replace with correct size nozzle.MAINTENANCEGeneral InformationOnly qualified service technicians should make mechanicalor electrical adjustments to the burner and/or associatedcontrol equipment.Preventative maintenance can usually be performed bybuilding maintenance personnel.Always follow the information provided in the OwnerOperating Instructions on page 51. These should beconspicuously posted in the burner room at the time of theinitial burner installation and start up.Always turn the power supply off to the burner and closemanual fuel valves as appropriate for routine maintenance.Make sure that combustion and ventilation fresh air sourcesto the burner room remain clean and open.Periodically check all electrical connections and makesure the flame safeguard control chassis is firmly connectedto its wiring base.Refer to manufacturer s product bulletins supplied withthe burner for maintenance on the flame safeguardcontrol and other components.

C45Rev.304PERIODIC CHECK LISTItemFrequencyChecked ByRemarksGages, monitors, and indicatorsDailyOperatorMake visual inspection and record readingsInstrument and rvice TechnicianVerify heat exchanger manufacturer s settingsAnnuallyServiceTechnicianCheck with combustion testMonthlyOperatorMake visual inspection of linkage, check forin logsettingsMake visual check against heat exchangermanufacturer s recommended specificationsFiring rate controlFlue, vent, stack, or outletdamperVerify heat exchanger manufacturer s settingsproper operationCombustion airMonthlyOperatorAll sources remain clean and openIgnition SystemWeeklyOperatorMake visual inspection, check flame signalstrength if meter-fitted(see Combustion safety controls)Fuel ValvesPilot and mainWeeklyOperatorOpen limit switch-make aural and visual checkcheck valve position indicators and checkfuel meters if so fittedPilot and main gas or main oilAnnuallyService TechnicianPerform leakage tests-refer to valvemanufacturer s instructionsCombustion safety controlsFlame failureWeeklyOperatorClose manual fuel supply for (1) pilot,(2) main fuel cock, and/or valves(s):check safety shutdown timing; logFlame signal strengthWeeklyOperatorIf flame signal meter installed, read and log;for both pilot and main flames, notify serviceorganization if readings are very high, verylow, or fluctuating; refer to flame safeguardmanufacturer s instructionsPilot turndown testsAs required/annuallyService TechnicianRequired after any adjustments toflame scanner mount or pilot burner;verify annually-refer to flamesafeguard manufacturer s instructionsAs required/annuallyService TechnicianSee Pilot turndown testsHigh limit safety controlRefractory hold inAnnuallyService TechnicianRefer to heat exchanger manufacturer sOperating controlAnnuallyService TechnicianRefer to heat exchanger manufacturer sLow draft, fan, air pressure,MonthlyOperatorRefer to this manual and control manufacturer sHigh and low gas pressure interlocksMonthlyOperatorRefer to instructions in this manualLow oil pressure interlocksMonthlyOperatorRefer to instructions in this manualFuel valve interlock switchAnnuallyService TechnicianRefer to valve manufacturer s instructionsPurge switchAnnuallyService Technicianinstructionsinstructionsand damperinstructionsRefer to fuel/air control motor manufacturer sinstructionsLow fire start interlockAnnuallyService TechnicianRefer to fuel/air control motor manufacturer sinstructionsAutomatic changeover controlAt least annuallyService TechnicianUnder supervision of gas utility(dual fuel)Inspect burner componentsService TechnicianRefer to this manual and controlcomponent manufacturer s instructionsRemove oil drawer assemblyAnnuallyService TechnicianRemove and cleanCheck blower motor and blowerAnnuallyService TechnicianRemove and cleanAnnuallyService TechnicianRemove and cleanwheel for cleanliness. Removeand clean as necessaryRemove, inspect and clean gaspilot assemblyRefer to heat exchanger manufacturer s instructions forgeneral inspection procedures and for specific testing andinspection of all liquid level controls, pressure/temperaturerelief and other applicable items.If you have any questions about the procedures listedabove-or questions relating to components or devices onyour unit not specifically covered in the above-contact ourService Department at(620)421-0480 for assistance.

C46Rev.3049.BURNER START UP INFORMATION & TEST DATAThe following information shall be recorded for each burner start up:Power Flame Model No.Invoice No.Serial No.Installation NameStart Up DateStart Up Contractors NamePhoneName of Technician Performing Start UpType of Gas NaturalLPOtherFuel Oil Grade No.Gas FiringGas Pressure at Train InletBurner in Off Position W.C.Gas Pressure at Train InletFlame Signal ReadingsStack Outlet Test Point DraftPilotLow FireLow FireHigh FireHigh FireLow FireHigh FireCO or O2Gas Pressure at Firing Head2Net Stack Temperature(Specify)High FireLow FireHigh FireGas Pressure at Pilot Test TeeCombustion EfficiencyCOLow Fire%Low FireHigh Fire%High FirePower SupplyVoltsPhHzLow FireHigh FireLow FireNOx MeasuredInput Rate BTU/HRLow FireLow FireHigh FireHigh FireControl Circuit VoltsBlower Motor amps at high fireOver Fire DraftLow FireHigh FireOil FiringHigh Fire Vacuum Reading at OilFlame Signal ReadingNet Stack TemperaturePump InletPilotLow Fire H.G.Gas Pressure at Pilot Train Inlet(If applicable)Gas Pressure at Pilot Test Tee(If applicable)Oil Nozzle Supply PressureHigh FireHigh FireCombustion EfficiencyGPH Firing RateLow Fire%Low FireHigh Fire%High FireNOx Measured2or O2(Specify)Low FireHigh FireOil Nozzle Bypass PressureHigh FireBachrach Scale Smoke NumberLow FireLow FireHigh FireHigh FirePower SupplyVoltsLow FireCOLow Fire(If applicable)PhHzControl Circuit VoltsBlower Motor amps at high fireOver Fire DraftLow FireHigh FireStack Outlet Test Point DraftRemote Oil Pump Motor amps at highfireLow FireHigh FireLow FireHigh Fire

C47Rev.304Control SettingsGeneralGasOperating control cut out settingLow gas pressure switchin.Low oil pressure switchOillbs.Operating control cut in settingHigh gas pressure switchin.High oil pressure switchlbs.Limit control cut out settingLimit control cut in settingOperation ChecklistChecked For Proper Operation of:YesNoYesNoLow water cut off()()Barometric damper()()High water cut off()()Boiler room combustion air and ventilation()()Flame safeguard control ignition failure()()provisions correctFlame safeguard control main flame failure()()Oil tank vent system checked()()Burner air flow switch()()All oil lines checked for leaks()()Induced draft fan controls()()All gas lines checked for leaks()()Over fire draft controls()()Gas lines and controls properly vented()()Fresh air damper end switch()()Other system components (specify)()()NotifiedNOTESof following system deficiencies:

C48Rev.304

C49Rev.304

C50Rev.304

2001 South 21st St., Parsons, KS 67357, 620-421-0480, 620-421-0948 FAXC51 Rev.304POWER FLAME INCORPORATED10.OWNER OPERATING INSTRUCTIONSFOR YOUR SAFETYWARNINGImproper installation, adjustment, alteration, service orIf you smell gas:1. Open windows.3. Extinquish any open flame.2. Do not touch electrical4. Call your gas supplierswitches.immediately.Do not store or use gasoline or other flammable liquids andmaintenance can cau

E. With flame safeguard controls that incorporate the air flow switch in the non-recycling circuit, ensure that when main flame lights, the air flow switch is not so critically set as to allow occasional momentary opening of the air switch contacts. F. Occasional low voltage supply. Have local utility corre