Transcription

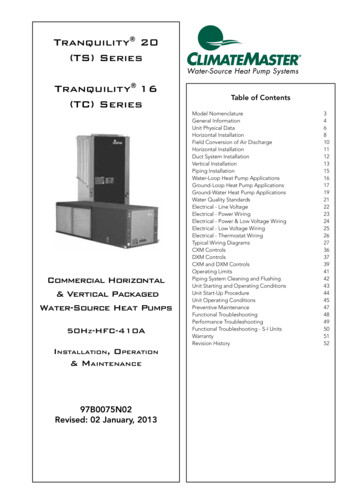

Tranquility 20(TS) SeriesTranquility 16(TC) SeriesCommercial Horizontal& Vertical PackagedWater-Source Heat Pumps50HZ-HFC-410AINSTALLATION, OPERATION& MAINTENANCE97B0075N02Revised: 02 January, 2013Table of ContentsModel NomenclatureGeneral InformationUnit Physical DataHorizontal InstallationField Conversion of Air DischargeHorizontal InstallationDuct System InstallationVertical InstallationPiping InstallationWater-Loop Heat Pump ApplicationsGround-Loop Heat Pump ApplicationsGround-Water Heat Pump ApplicationsWater Quality StandardsElectrical - Line VoltageElectrical - Power WiringElectrical - Power & Low Voltage WiringElectrical - Low Voltage WiringElectrical - Thermostat WiringTypical Wiring DiagramsCXM ControlsDXM ControlsCXM and DXM ControlsOperating LimitsPiping System Cleaning and FlushingUnit Starting and Operating ConditionsUnit Start-Up ProcedureUnit Operating ConditionsPreventive MaintenanceFunctional TroubleshootingPerformance TroubleshootingFunctional Troubleshooting - S-I UnitsWarrantyRevision 2434445474849505152

CLIMATEMASTER WATER-SOURCE HEAT PUMPSPackaged UnitsR e v i s e d : 0 2 J a n u a r y, 2 0 1 3This Page Intentionally Left Blank2C l i m a t e M a s t e r W a t e r- S o u r c e H e a t P u m p s

THE SMART SOLUTION FOR ENERGY EFFICIENCYPackaged UnitsR e v i s e d : 0 2 J a n u a r y, 2 0 1 3Model NomenclatureGeneral Overview For All H & V SeriesTSV 024 A VF20 C L T SSERIESTS Tranquility Single StageSTANDARDS StandardCONFIGURATIONSUPPLY AIR FLOW &MOTOR CONFIGURATIONV Vertical UpH HorizontalD Vertical DownOption Supply IT SIZE009 - V012 - V018 - V024 - V, U030 - V, U036 - V, U042 - U048 - U060 - U070 - UMotorPSCPSCPSCPSCRETURN AIR FLOW CONFIGURATIONL Left ReturnR Right ReturnHEAT EXCHANGER OPTIONSREVISION LEVELA 006-012, 024-070B 018StandardMotorized ValveNon Coated Air Coil Tin Plated Air CoilCopper Cupro-Nickel Copper Cupro-NickelCNAJTSUWVOLTAGEV 220-240/50/1U 380-420/50/3WATER CIRCUIT OPTIONS0 None2 HWG (Coil Only)6 HWG (Coil Only) w/Auto Flow Regulator 2.5 GPM/Ton7 HWG (Coil Only) w/Auto Flow Regulator 3.0 GPM/Ton8 Auto Flow Regulator 2.5 GPM/Ton9 Auto Flow Regulator 3.0 GPM/TonCONTROLS}}F CXMG DXMH CXM w/LONJ DXM w/LONT CXM w/MPCU DXM w/MPCCE Approvedfor EuropeO CXMQ DXMV CXM w/LONW DXM w/LONY CXM w/MPCZ DXM w/MPCCE Approvedfor Europe withDisconnectCABINETOPTION RANGE1AJK2CLM3ENP4GRSULTRAQUIETNOYESNOYES1” FILTER 2” FILTER 1” FILTER 2” ONOYESNOYESNOYESNONO8TCH036AUF30ALBSS STANDARDMODEL TYPESUPPLY AIR OPTIONSTC TRANQUILITY COMPACT (HFC-410A)B BACK DISCHARGE, HORIZONTAL ONLYY BACK DISCHARGE, HIGH STATICHORIZONTAL 015 - 060T TOP DISCHARGE, VERTICAL ONLYV TOP DISCHARGE, HIGH STATICVERTICAL 015 - 060, But Not 041S STRAIGHT DISCHARGE, HORIZONTAL ONLYZ STRAIGHT DISCHARGE, HIGH STATICHORIZONTAL 015 - 060CONFIGURATIONH HORIZONTALV VERTICALUNIT SIZE006 - V009 - V012 -V015 - V018 - V024 - V030 - V, U036 - V, U042 - U048 - U060 - URETURN AIR OPTIONSL LEFT RETURNR RIGHT RETURNF FRONT RETURN, VERTICAL 009 - 030 and 041 ONLYV LEFT RETURN S.S. DRAIN PANW RIGHT RETURN S.S. DRAIN PANZ FRONT RETURN S.S. DRAIN PAN ,VERTICAL 009-030 AND 041 ONLYHEAT EXCHANGER OPTIONSA Copper Water Coil w/Coated Air CoilC Copper Water Coil w/Non-Coated Air CoilJ Cupro-nickel Water Coil w/Coated Air CoilN Cupro-nickel Water Coil w/Non-Coated Air CoilREVISION LEVELA CURRENT REVISION FOR ALL SIZESVOLTAGEV 220 - 240/50/1U 380 - 420/50/3{CEAPPROVEDCONTROLSF CXMG DXMH CXM w/LONJ DXM w/LONT CXM w/MPCU DXM w/MPCFUTURE USE0 NONECABINET INSULATION1 EXTENDED RANGE2 EXTENDED RANGE w/ULTRA QUIET3 STANDARD RANGE4 STANDARD RANGE w/ULTRA QUIETNOTE: Above model nomenclature is a general reference. Consult individual engineering guides for detailed information.c l i m a t e m a s t e r. c o m3

CLIMATEMASTER WATER-SOURCE HEAT PUMPSPackaged UnitsR e v i s e d : 0 2 J a n u a r y, 2 0 1 3General InformationSafetyWarnings, cautions, and notices appear throughout thismanual. Read these items carefully before attemptingany installation, service, or troubleshooting of theequipment.DANGER: Indicates an immediate hazardous situation,which if not avoided will result in death or seriousinjury. DANGER labels on unit access panels must beobserved.WARNING: Indicates a potentially hazardous situation,which if not avoided could result in death or seriousinjury.CAUTION: Indicates a potentially hazardous situationor an unsafe practice, which if not avoided could resultin minor or moderate injury or product or propertydamage.NOTICE: Notification of installation, operation, ormaintenance information, which is important, but whichis not hazard-related.WARNING!WARNING! The EarthPure Application and ServiceManual should be read and understood before attemptingto service refrigerant circuits with HFC-410A.WARNING!WARNING! To avoid the release of refrigerant into theatmosphere, the refrigerant circuit of this unit must beserviced only by technicians who meet local, state, andfederal proficiency requirements.CAUTION!CAUTION! To avoid equipment damage, DO NOT usethese units as a source of heating or cooling during theconstruction process. The mechanical components andfilters will quickly become clogged with construction dirtand debris, which may cause system damage.WARNING!WARNING! All refrigerant discharged from this unit mustbe recovered WITHOUT EXCEPTION. Technicians mustfollow industry accepted guidelines and all local, state,and federal statutes for the recovery and disposal ofrefrigerants. If a compressor is removed from this unit,refrigerant circuit oil will remain in the compressor. Toavoid leakage of compressor oil, refrigerant lines of thecompressor must be sealed after it is removed.InspectionUpon receipt of the equipment, carefully check theshipment against the bill of lading. Make sure all unitshave been received. Inspect the packaging of eachunit, and inspect each unit for damage. Ensure thatthe carrier makes proper notation of any shortages ordamage on all copies of the freight bill and completesa common carrier inspection report. Concealeddamage not discovered during unloading mustbe reported to the carrier within 15 days of receiptof shipment. If not filed within 15 days, the freightcompany can deny the claim without recourse. Note: Itis the responsibility of the purchaser to file all necessaryclaims with the carrier. Notify your equipment supplierof all damage within fifteen (15) days of shipment.StorageEquipment should be stored in its original packaging ina clean, dry area. Store units in an upright position at alltimes. Stack units a maximum of 3 units high.Unit ProtectionCover units on the job site with either the originalpackaging or an equivalent protective covering.Cap the open ends of pipes stored on the job site.In areas where painting, plastering, and/or sprayinghas not been completed, all due precautions mustbe taken to avoid physical damage to the units andcontamination by foreign material. Physical damageand contamination may prevent proper start-up andmay result in costly equipment clean-up.Examine all pipes, fittings, and valves before installingany of the system components. Remove any dirt ordebris found in or on these components.4C l i m a t e M a s t e r W a t e r- S o u r c e H e a t P u m p s

THE SMART SOLUTION FOR ENERGY EFFICIENCYPackaged UnitsR e v i s e d : 0 2 J a n u a r y, 2 0 1 3Pre-InstallationInstallation, Operation, and Maintenance instructionsare provided with each unit. Horizontal equipmentis designed for installation above false ceiling or in aceiling plenum. Other unit configurations are typicallyinstalled in a mechanical room. The installation sitechosen should include adequate service clearancearound the unit. Before unit start-up, read all manualsand become familiar with the unit and its operation.Thoroughly check the system before operation.Prepare units for installation as follows:1. Compare the electrical data on the unitnameplate with ordering and shippinginformation to verify that the correct unit has beenshipped.2. Keep the cabinet covered with the originalpackaging until installation is complete and allplastering, painting, etc. is finished.3. Verify refrigerant tubing is free of kinks or dentsand that it does not touch other unit components.4. Inspect all electrical connections. Connectionsmust be clean and tight at the terminals.5. Remove any blower support packaging (water-toair units only).6. Loosen compressor bolts on units equipped withcompressor spring vibration isolation until thecompressor rides freely on the springs. Removeshipping restraints.7. Some airflow patterns are field convertible(horizontal units only). Locate the airflowconversion section of this IOM.8. Locate and verify any hot water generator (HWG),hanger, or other accessory kit located in thecompressor section or blower section.CAUTION!CAUTION! All three phase scroll compressors must havedirection of rotation verified at start-up. Verification isachieved by checking compressor Amp draw. Amp drawwill be substantially lower compared to nameplate values.Additionally, reverse rotation results in an elevated soundlevel compared to correct rotation. Reverse rotation willresult in compressor internal overload trip within severalminutes. Verify compressor type before proceeding.CAUTION!CAUTION! DO NOT store or install units in corrosiveenvironments or in locations subject to temperature orhumidity extremes (e.g., attics, garages, rooftops, etc.).Corrosive conditions and high temperature or humidity cansignificantly reduce performance, reliability, and servicelife. Always move and store units in an upright position.Tilting units on their sides may cause equipment damage.CAUTION!CAUTION! CUT HAZARD - Failure to follow this cautionmay result in personal injury. Sheet metal parts may havesharp edges or burrs. Use care and wear appropriateprotective clothing, safety glasses and gloves whenhandling parts and servicing heat pumps.NOTICE! Failure to remove shipping brackets fromspring-mounted compressors will cause excessivenoise, and could cause component failure due toadded vibration.c l i m a t e m a s t e r. c o m5

CLIMATEMASTER WATER-SOURCE HEAT PUMPSPackaged UnitsR e v i s e d : 0 2 J a n u a r y, 2 0 1 3Unit Physical DataTranquility 20 Single-Stage (TS) Series (50Hz)Model009Compressor (1 Each)012018024030036RotaryFactory Charge HFC-410A 2.272.273.86PSC Fan Motor & Blower (3 Speeds)Fan Motor [W]3793124149249373373560746746High Static Fan Motor [W]N/AN/A149249373373560560746Not AvailableBlower Wheel Size (dia x w) - [mm]6X56X59x79x79x710 x 1010 x 1010 x 1011 x 1011 x 6 x 406Upflow Only406 x 406Upflow Only610 x 508711 x 508711 x 508711 x 635813 x 635813 x 635914 x 635914 x 6351 - 406 x 762;1 - 508 x 762Water Connection SizeFPT (in)HWG Connection SizeFPT (in)Coax VolumeVolume [liters]Vertical Upflow/DownflowAir Coil Dimensions (h x w) - [mm]406 x 508406 x 508610 x 610711 x 610711 x 610711 x 7622 - 406 x 7622 - 406 x 7621 - 406 x 762;1 - 508 x 762Weight - Operating, [kg]6668114121122148188189200201Weight - Packaged, [kg]7173119125126153192193205206406 x 406406 x 406457 x 686457 x 787457 x 787508 x 889508 x 1016508 x 1016508 x 1143508 x 11431 - 457 x 508;1 - 508 x 6101 - 457 x 508;1 - 508 x 6102 - 508 x 6102 - 508 x 610Standard Filter - [25.4mm]Throwaway, qty [mm]HorizontalAir Coil Dimensions (h x w) - [mm]406 x 508406 x 5082 - 457 x 4572 - 457 x 4572 - 457 x 4571 - 305 x 508;1 - 508 x 635Weight - Operating, [kg]7173117121122148188189200201Weight - Packaged, [kg]7277121125126153192193205206Standard Filter - [25.4mm]Throwaway, qty [mm]All units have dual vibration isolation compressor mounts for quiet operation, thermal expansion valves for refrigerant metering, and 22.2 mm & 28.6 mm electricalknockouts to accommodate field wiring.FPT - Female Pipe ThreadCondensate Drain Connection is 3/4” FPTUnit Maximum Water Working PressureOptionsBase UnitMax Pressure kPa2,068Internal Motorized Water Valve (MWV)2,068Internal Auto Flow Valve2,068Use the lowest maximum pressure rating when multiple options are combined.6C l i m a t e M a s t e r W a t e r- S o u r c e H e a t P u m p s

THE SMART SOLUTION FOR ENERGY EFFICIENCYPackaged UnitsR e v i s e d : 0 2 J a n u a r y, 2 0 1 3Tranquility 16 (TC) Series (50 Hz)TC Series006009012015018024030036RotaryCompressor (1 7 x 127127 x 127152 x 127254 x 254279 x Coax Volume ir Coil Dimensions (H x W) mm254 x 381254x381254 x 381508 x 438508 x 438508 x 438508 x 438610 x 552610 x 552610 x 718610 x 718Filter Standard - 25.4mmThrowaway mm254 x 457254x457254 x 457508 x 508508 x 508508 x 508508 x 508610 x 610610 x 6101-356 x 610,1- 457 x 6101-356 x 610,1- 457 x 610Weight - Operating kg474852697286899299119126Weight - Packaged kg5152567274889295102123129254 x 381254 x 381254 x 381406 x 559406 x 559406 x 559406 x 559508 x 635508 x 635508 x 889508 x 889508 x 711 or(2) 508 x 3561-508 x 610,1-508 x 3561-508 x 610,1-508 x 356Factory Charge HFC-410A - kgPSC Fan Motor & BlowerFan Motor Type/SpeedsFan Motor (Watts)Blower Wheel Size (Dia x w) mm203 x 178229 x 178229 x 203Water Connection SizeVerticalHorizontalAir Coil Dimensions (H x W) mm254 x 457254 x 457254 x 457406 x 635406 x 635457 x 635457 x 635508 x 711 or(2) 508 x 356Weight - Operating kg474752697286899299119138Weight - Packaged kg515256727488929

CLIMATEMASTER WATER-SOURCE HEAT PUMPS 6 ClimateMaster Water-Source Heat Pumps Packaged Units Revised: 02 January, 2013 Unit Physical Data Tranquility 20 Single-Stage (TS) Series (50Hz) Model 009 012 018 024 030 036 042 048 060 070 Compressor (1 Each) Rotary Scroll Factory Charge HFC-410A [kg] 0.88 0.96 1.13 1.59 1.64 1.98 2.27 2.27 3.86 4.08