Transcription

PALLET RACKGUIDESTYLES, TYPES AND APPLICATIONScisco-eagle.com/palletracks

EFFICIENT & SAFE STORAGE SYSTEMSHow to Build a Better WarehouseNot all rack is the same. We’ll work with you to meet your critical requirementsand load factors to make sure you get an efficient rack systemthat helps your warehouse function better. Whatever yourneeds or load type, you can count on us to help youdesign a stable, safe and space-efficient solution.shop—Craig, Employee-Owner Since 2014Systems Integration GroupA guide to rack usageThis is a common sense guide to specification, styles, accessoriesand usability. You will find quick, useful information on racks andhow you can use them more efficiently. If you have questions aboutspecifying your racks correctly, how to use them more effectively,how to make them safer, contact us for fast assistance.Inside the guideSelective vs. dynamicRack Tips: Difficult LoadsRack Tips: Decks and Load StylesRack Tips: High-Bay SystemsRack Tips: Inspecting Your RacksRack Tips: Pallet Racks & Fire PreventionSK2000 Selective RackSK3000 Structural Selective RackSelective Rack AccessoriesSpecialized Rack LoadsCarton Flow Selective RacksHow to Configure Selective RacksSelective Racks WorksheetPushback Rack Systems- WorksheetDrive-in & Drive-Through Racks- WorksheetPallet Flow Systems- Worksheet34455678910111213141516171819 Pallet Rack Buyers’ Guide Pallet Rack Blog: Dozens of Articles Selective Rack Estimator2 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

RACK TYPES: SELECTIVE VS. DYNAMICHow to Balance Selectivity and Storage Density NeedsSelective Rack: 100% access to all pallets —but with lowerstorage densitySelective rack is easily the most versatile choice—it provides 100% selectivityto every pallet position. Lets you easily change the storage mix. However,selective rack requires an aisle for every row, and has lower storage densitythan pushback or drive-in racks. It’s the most common pallet storageracking type in the world. Ideal for faster moving product in most warehouseapplications.Drive-In racks: last-in-first-out picking with excellentstorage density, lower selectivityDrive-in racks are “last-in, first-out” systems with reduced selectivity, andexcellent product density. Ideal for items that have longer life in storage, anddon’t require immediate access. Often used for cold storage applicationswhere every inch of expensive space is critical. Drive-in & drive throughsystems are ideal for items with a longer life in storage that don’t requireimmediate access.Pushback: last-in-first-out with good storage density,medium selectivity, more versatilityWhen forklifts unload pushback racks, the next pallet rolls to the front ofthe bay; when loading, pallets are pushed back in a last-in, first-out storagescheme. You can place a different SKU on every level. Pushback systemsrequire angled pitch, which consumes vertical space, and are denser thanselective, but not as dense as drive-in systems.Pallet flow: first-in, first-out; great storage density with lessselectivity and reduced handling costsPallet flow systems offer the greatest storage density. Depths are limitedonly by facility size; store a single SKU per lane. Once loaded, product rotationis automatic, as pallets flow to picking aisles. Flow systems offer automatic“first-in, first-out” product rotation. Because only two aisles are necessary,aisle space can be reduced by 75%. Fewer fork lifts, operating fewer hours, andconsuming less fuel can accomplish the same handling function.3 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

PALLET RACK TIPSA Guide to Storing Difficult, Bulky and Long LoadsStoring rolls and reelsRolls, reels and other spooling loads can be stored on pallet racks. Toaccomplish this, special reel pockets are placed on the upright andthen fitted with a horizontal bar. Rolled items like film, wiring, cablesor paper are placed on the bar, and can be dispensed. The capacitiesfor these racks must be understood, since the loads are dynamic.Reel pockets have capacities (calculated per pair) that must betaken into account.Long item storageMany companies need to store specialized loads, such as rolls, dies, tubes, fragile items andmore. With the right hardware and design, almost anything can be safely and efficiently stored.Rack Decking Load GuideRack loads aren’t just simple weight vs. structure. The dimensions,shape and size/density of the load also factor in.Weight vs. load placement for rack deckingKnowing the weight and type of load that will sit on a wire deck isvital. Below are some of the most common loading scenarios withdescriptions and examples of each.Universally distributed loadsAs defined by ANSI 26.2, universally distributed loads are “any staticload evenly distributed over the entire surface on the rack deckindependent of the support system.”Many long items can be better stored on cantilever than palletracks, but there are applications where pallet rack fits better in thestorage strategy of your facility. We’ve done projects, for instance,where long rolls of film or fabric can’t be stored on cantilever armsbecause the arm would dent fragile materials and full support isneeded. You may already have pallet racks and want to adapt themto store longer loads. Pallet racks can be adapted with relative easefor these applications.Types of mis-loads A line load distributes its weight in a concentrated line and isn’tuniformly distributed, which may place the entire load pressure on thedeck. In the example below, the weight rests on the wire instead of thechannel supports, which may cause the decking to deform and fail. Any load not uniformly distributed over the entire surface of thedecking section is a concentrated load. When you have multiple palletsizes stored in the same rack system, the chances of a concentratedand unbalanced load increases. A point load can be defined as any load that has its weightconcentrated on individual points versus uniformly distributed.This means the load needsto rest over all the supportchannels and the majority ofthe deck surface and comewithin 2” of the front and rearload beams to achieve the fullcapacity rating.Line loadHere, the bulk of the weigh rests on the wire,instead of the channel supports, which can causethe decking to deform—and potentially to fail.Concentrated loadAll of the weight of this pallet is placed in the centerof the deck, putting the entire load on 2 of the 4support channels.Point loadAbove: This bulk container has 4 feet restingon the deck. All the points sit only wire mesh,causing deflection and potential failure.4 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

PALLET RACK TIPSLoading & Unloading Tall RacksHow to Inspect Pallet RackTo prevent accidents, regularly inspect your pallet racks fordamaged components. In general, split welds, rust and dents shouldalways be noted. The rack must be straight, plumb t and should bebolted to the floor to achieve its full capacity.Loading and retrieving pallets from tall bays can be problematic,resulting in dangerous load drops or damage. It’s difficult becausedrivers can’t see the load or the rack beam. Drivers may not be able to tell if the tines are lined up correctly on the palletwhen their forks enter it, making it possible to bump or shift. When depositing a pallet at height, it’s not easy to tell if it’s positioned to restboth front and back on the beams or centered correctly. Rack capacities are based on evenly-distributed loads, so it’s important thatthe pallets are square and centered.What can you do to reduce risks?Load the rack with adequate clearancesLoad your racks with acceptable tolerances above and to the sidesof each pallet and the frames. You should have 10” head clearancebetween the top of load and the bottom of the beam above it.Add technology to help drivers seeTechnology is only anenhancement to training. It can’tprevent accidents on its own,but can help drivers see andunderstand the situation better.Options include cameras that letdrivers see the load and beam,laser tine guides, tine levelingalarms and more.Install product/pallet fall protection systemsIf forklift drivers bump a pallet and knock it—or a pallletized cartonor other load—off, then protective systems like safety netting,straps, back beams/bars or wire panels can stop the fall and helpprevent damage and injuries.Upright frames and base platesDamaged uprights should always be addressed—byreplacement or repair. Install post protectors foreconomical protection. Check the footplates for damage aswell as for missing floor bolts, dust or floor cracks.Load beamsDeflection is often caused by overloading, but couldalso be the result of a beam that was damaged insome other way. Whatever the cause, that beamshould be checked, and potentially replaced if thedeflection is outside acceptable tolerance. Also checkthe beam for dislodged connectors or bolts.Deformed struts or bracesStruts are the horizontal steel bars that connect two upright posts.Braces are the diagonal steel that connect struts. If either is bent,it’s an indication of issues with loading, impacts or capacity.Rack environment & usageMake sure the rack isn’t being overloaded or loaded with unbalancedloads that can stress it past its capacity rating. Aisle clutter is afrequent cause of rack collisions (and subsequent collapses) andshould be avoided.5 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

PALLET RACK TIPSPallet rack beam capacities are pretty simple. They’re rated per pair for evenlydistributed, properly-positioned loads. But upright capacities are more complexbecause their capacity is calculated on vertical beam spacing. The largest vertical gapdictates the capacity, so be aware of tall loads, which can stress a rack more than a squat,heavy loads because extra beams act as lateral support. Get these factors right, andyour rack will be safe and stable. If you need help, call us today.—Denise, Employee-Owner Since 2015Systems Integration Project ManagershopRacks, Flue Space, Load Spacing & Fire PreventionFlue spaces are clear vertical lines of sight from the floor up tothe ceiling within rack storage areas. The National Fire ProtectionAssociation (NFPA) requires that pallet rack flue space shouldremain clear at all times so that any fires can successfully vent uprather than out, allowing sprinkler systems to activate faster.Send flames up, not outThe vertical rise of flames also helpsslow fire spreading horizontallythrough a rack system, which cancause more damage and burn longerthan if a fire rises.3. Make sure the space between rack rows is adequate. Row spacers arefrequently installed to produce precise longitudinal flue space, as theymake certain there is enough space between rows.What can you do to helpreduce issues with flue spaceobstruction?1. Leave adequate space between palletloads. NFPA requires 6” horizontal fluespace between loads. A 92” beam allowsfor two pallets with 6” between themand 3” between each pallet and theframes on either side.2. Make sure your pallets and loads are theright size for the depth of your rack. Youshould allow the pallet to hang over theback beam in a double row, and maintainadequate longitudinal flue spacebetween rows.4. Use wire or perforated decks. Solid decks or particle boards don’t allowflames to escape up, and also impede sprinklers.5. Don’t let forklift drivers push the back of the pallet too far into the fluespace between back-to-back rack rows. Make sure your pallet loads arenot too deep for your rack system. You can also install back beams, nets orsafety straps that don’t allow push-through.According to NFPA, American fire departmentsrespond to an estimated average of 1,210 fires inwarehouses every year. Because fire suppressionsystems affect rack structure design andgeometry, your system must be carefully planned.6 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

SELECTIVE RACK SYSTEMSImpact-Resistant SK2000 Selective RacksLonger-lasting & impact-resistantThousands of preconfigured pallet racksSafer and stronger than conventional pallet rack, SK2000 fullyenclosed tubular racks have 44 times more torsional strength thanopen back racks. Seamless, fully welded structural tubing increasesdurability, cleanliness and structural integrity.cisco-eagle.com/fullracksWe can help you build standard racks, racks with wire decking,safety netting, security cages and integrated carton flow. Let’s solveyour storage problems.Pallet rack with integrated carton flowtracks on lower beam levels.Beams: 3-rivet connection & channel rib strength Beams are seamlessly welded, high-strength structural steel tubing with noledges or cracks to catch pallets or trap moisture/debris. 1/16” stiffening ribs built into the beam face for strength Exclusive safety clip and stiffening rib design resists disengagement fromthe upright. Engages with an audible snap.Fully enclosed uprightsThe industry’s only 100% tubular rack,with greater resistance to torsional forkliftimpact than open-back roll formed columns.Utilizes a tapered keyhole connection slot,interchangeable with several other racksystems, and allows 2” vertical beamadjustments.See Steel King Upright FramesPallet rack with wire back panels andsecurity cages.Racks withwire deckingincluded.Pallet racks with safety nets included.7 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

STRUCTURAL SELECTIVE RACKFor videos and more, visit www.cisco-eagle.com/structuralStructural rack is used for a variety of dynamic storage applications, but can also be used in selectiveracking, if the situation warrants—typically in areas where forklift collisions and abuse are more likely, forvery heavy loads, washdown areas and more. See the table below or call us for guidance. Built with hot rolled structural channel steel, for difficultindustrial environments. Popular in harsh-duty applications like freezers, coolers,and distribution facilities C-channel construction makes it easier to clean andwash down than roll form racks Beam connectors constructed of heavy 5-gauge steelplates, featuring a wrap-around design Upright frames are punched on 4” vertical centers. Beamconnector clips specially punched allow for verticaladjustablility in 2” incrementsCompare: roll form vs. structural for selective rack applicationsFactorStructural RacksRoll-Form RacksOverall strengthVery strong with welded connections, heavier steeland higher capacitiesExcellent for standard warehousing applicationsImpactresistanceBulkier construction offers improved resistance, butthis depends on foot plate weld strengthsFully enclosed tubular uprights are more impactresistance than open back alternativesWashdowncapabilitiesBecause structural has open, c-channel construction,it’s easier to wash down for clean, food and similaroperationsCan be washed, but not as easily as c-channelstructural racksCapacityHigher capacities than roll-form. Beam ties are usuallyadded to increase capacity. Bolted connections addstrength to structural systemsCapacities typically lower than structural racksCostTypically more expensiveTypically less expensiveWeightHeavier than roll-formLighter than structuralShipping costsMore costly to ship due to weightLess costly to ship due to lighter weightOutdoor useUsed more often outdoors (is easier to galvanize)Can be used outdoors, but is less typicalInstallationDue to bolt connections, structural is costlier andslower to installFaster installation due to teardrop connectionsFlexibilityOffers fewer available accessories. More difficult toadjust beam levels. Structural is used for more typesof racks (pushback, drive-in, etc)More flexible due to a range of accessories. Easierbeam adjustment8 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

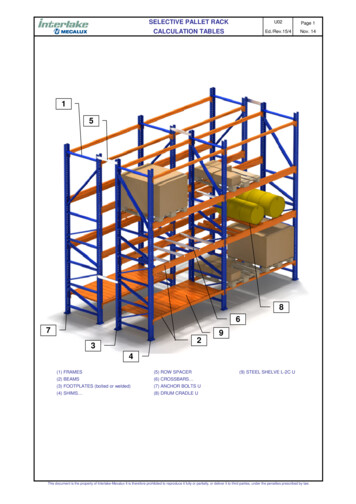

PALLET RACK ACCESSORIESSupports and spacersProtect rack from falls, pilferagePallet Supports: For pallets not deep enough tofit on standard rack frame depths. Use two perpallet position.Frame Spacers: Keeps space between rackrows and pallet overhang uniform. Frames upto 120” tall, use 2 per frame; 144” to 216” tall,use 3 spacersReduce product spills and increase securityby installing wire mesh panels and gateson your rack. Contact us for assistanceretrofitting your racks with this protectionsystem. Security enclosures with swinginggates help guard inventory—pallets, casepick inventory or other bulky itemsRack safety netting protects people, productcisco-eagle.com/racknetReduces the chances of fallinginventory from damaging itself,other product or anyone standingbeneath. Rack nets are configuredby total pallet weight, falltrajectories, impact velocities &weight distribution—they’re meantto withstand a specific impact.Pallet rack wire deckingcisco-eagle.com/wiredecksWire decking provides visibility,easier product handling, palletstability and ventilation. Tough wireconstruction with underlying metalsupports is strong and stable.Meets applicable fire safety codes.Column ProtectorsAll uprights should be guarded against forklift collision damage.Steel guards, poly guards and other types are available. The typeneeded depends on your application, forklift type and other factors.Rack safety straps help reduce“push through” damagecisco-eagle.com/rackstrapHelp reduce pallets & loads from pushinginto flue space or falling into work areas.Add as many straps as necessary to eachbay for securing your goods. Helps enforceflue space for fire prevention. Installs withsimple teardrop connectors and no tools.shopWhether it’s wire decks that help support pallets andloads, frame guards that deflect forklift hits, safetynetting that catches falling loads or pallets, pull-out shelves that preventergonomic problems or other accessories, we can help you find ways tomake your rack work better for you.—Jeremy, Employee-Owner Since 2006Ecommerce Manager9 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

SPECIALIZED RACK APPLICATIONSHeavy-Duty Die RacksOver-Dock-Door RacksStore dies, motors, jigs, fixtures and moreDie racks feature a solid metal shelf design allowing die placementanywhere along the shelf, and can accommodate a variety of diesizes. Shelf design allows dies to slide on or off a shelf for easyaccess and storage.Utilize dead space above your dock doorsUtilizes space above dock doors to store empty pallets & other lightloads neatly and safely without occupying valuable floor space.This is frequently wasted space you can reclaim for these types oflighter loads.Pallet Racks for Any Application Narrow aisle & very narrow aisle racks: the space between aisles is minimized inthese systems, reducing aisles up to 40%. Mobile aisle racks: in these systems, rack sections move on floor mounted rails toopen up access aisles. This is a very high-density storage system. Specialty storage racks: can be built to store odd sized and specialty loads such astires, furniture, bar stock odd components, long parts, oddly-balanced loads, vehicles,super-heavy-duty loads and more.10 www.cisco-eagle.com/palletracks Toll-Free: 888.877.3861ANNIVERSARY1970-2020

CARTON FLOW PALLET RACKFor videos and more, visit www.cisco-eagle.com/cartonflowshopCarton flow saves tons of space and makes picking faster,but it also reduces wasted motion. Order pickers can walkas far as 12 miles a day. This much walkingmakes them tired, more error-prone andless productive. Goods-to-person letsthem spend more time doing productivework like picking and packing.—Tom, Employee-Owner Since 2015Account ExecutiveFlow Storage & Pallet RacksMounting considerationsA common gravity flow application is to mount shelves offlow storage on pallet rack so you can mix & match gravityflow and bulk pallet storage in the same structure.What rack types?Dedicated flow storagePallet racks are frequently con

Pallet racks can be adapted with relative ease for these applications. Rack Decking Load Guide : Rack loads aren’t just simple weight vs. structure. The dimensions, shape and size/density of the load also factor in. Weight vs. load placement for rack decking: