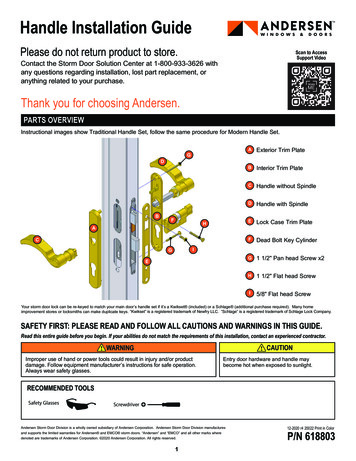

Transcription

Raven Trim

Copes-Vulcan has been providing controlvalves and desuperheaters for the power,RAVEN TrimCopes-Vulcan has been providing valves to the Power, Pulp & Paper, Oil &Gas, and Petrochemical industries since 1903, and is recognized worldwideprocess and nuclear industries since 1903.as a leader in valves for severe and critical service applications. Our strengthSPX provides a wide range of valves fortruly lies in our ability to provide innovative valve solutions for our customers’the control of pressure, temperature andapplication problems. The RAVEN Control Valve incorporates a uniqueflow-induced noise in all types of powerplants. Products include severe service andgeneral service control valves, variable orificeadvanced design that is superb at rapidly reducing flow velocities, resulting invalves that provide quiet, non-cavitating and non-erosive service. Ultimately,each RAVEN trim is specifically designed to provide the finest severe dutyvalve service by:desuperheaters, Raven , trim and steam-Reducing andconditioning valves and nuclear control valves,Attenuatingas well as custom designed specialty valves.Velocity,Copes-Vulcan is recognized worldwide as aErosion andleader in valves for severe and critical serviceapplications. Our strength lies in our abilityto provide innovative valve solutions for ourcustomers’ application needs.NoiseThe RAVEN Control Valve was developed by highly experienced engineerswho took the well-proven labyrinth disc stack type of trim and introduced twomain patented innovations: resistance to the effects of blockage and reductionin noise. The innovative designs give this well-established technology forsevere service applications even more technical advantages over othercurrently available trim designs.Finding innovative ways to help the worldmeet its ever growing demand for powerR e s i s ta n c e to t h e E f f e ct s o f B lo c k ag eis a key focus for SPX. SPX providesThe expanding passage design, combined with multiple entry points to thecreative solutions the serve global energymarkets in a myriad of ways. Our ideas arehelping build more efficient power plantsand renovate older existing facilities. SPXindividual flow passages, make blockage very unlikely. Unlike conventionallabyrinth trim designs, RAVEN has relief points built into the labyrinth design.Under normal operation, these relief points have virtually no flow throughthem. In the event of blockage,the relief points are utilized.supplies a wide range of components - fromExtensive testing has shown thatair preheaters to filter systems for nuclear,if a blockage occurs in RAVEN coal-fired, combined cycle, solar, thermaltrim, all inlet ports and outlet portsand geothermal power plants.are still utilized, minimizing anyWith operations in over 35 countries, SPXhas the global experience and regionalpresence, products and powerful ideas ittakes to help our customers compete morereduction in Cv and ensuring thatthe minimum designed numberof pressure reducing stages arestill used. In conventional labyrinthstack designs, a blockage in theeffectively, and more efficiently deliverstack eliminates the Cv of thatpower to almost any part of the world.path completely and in the caseof a partial blockage, can actuallygenerate noise.2T e s t ca s e s h ow i n g s e v e r e b lo c k ag e .All i n lets an d outlets sti ll i n us e.N e g l i g i b l e lo s s i n Cv.

Typical product applicationsPOWER/Auxiliary Power UnitsBoiler Feed ControlBoiler Feed Pump Minimum Flow (Bypass)Inter Stage Attemperator Water ControlBoiler Drum Level ControlSoot Blower Header ControlTurbine BypassStart-Up Steam VentSpray Water ControlDeaerator Level ControlCondenser Steam DumpSampling SystemsOil and GasP r ov e n S u p e r i o r T e c h n o lo gyThe actual gaseous flow through RAVEN trims shows theFeed Gas RegulatorOverboard Water Dump ValvesWater Injection SystemsPump Min Flow ValvesFire Water Pump Discharge Valves & MinFlow ValvesMethanol InjectionVapor Recovery SystemsFlue Gas Expander BypassFirst Stage Separator Level Controlvisible attachment phenomenon wherein the flow stream clingsto each obstruction in its path, effectively taking the line of leastresistance. Also, despite the multiple relief points in the flow path,it can clearly be seen that the fluid does not recombine within theRAVEN trim. The flow streams remain virtually separate fromeach other, ensuring the best velocity control.Gas Transportation/StorageGas Injection/ProductionActive/Monitor Valve SystemsCompressor AntisurgeGas to FlareFuel Gas RegulationSurge ReliefSilencersLNGCompressor AntisurgeAcid Gas SeparatorPump Recirculation ValvesHot Gas Bypass ValvesJoule Thompson ValvesGas to FlareEmergency Depressurising ValvesPetrochemicalCompressor AntisurgeFeed Gas RegulationExpander BypassProcess Gas DepressurisingGas to FlareAmine Pump Let Down and RecircsAux Power Unit ValvesLiquid Amminia Let DownsThis is representative of the type of application where RAVEN trim can be usedto ensure long trouble-free operation. This list is by no means exhaustive.3

Noise Test (Typical) Test Nos. 1612, 1712, 1812R e d u ct i o n i n N o i s e95Labyrinth type trims have been widely accepted over the last25 years as being the best solution in cases where high noiseand vibration are likely. Their wide acceptance is based on the90velocity of the medium within the trim. Copes-Vulcan engineershave taken this technology one step further. They found that bysplitting the outlet flow of each labyrinth path into three or moresmall mass flows (rather than the one large flow) noise could beN o i s e ( d BA )principles of reducing mass flow and strictly controlling the8580reduced by up to 3 dBA more than in a similar design labyrinthwith the same number of pressure reducing stages. Size for size,75RAVEN has been proven quieter that the leading competitor inextensive laboratory testing.700102030405060708090100% P r e s s u r e D i f f e r e n t i a l Ac r o s s Tr i mR AVEN P r ov i d e s Tr u e V e lo c i t y C o n t r o lCopes-Vulcan’s RAVEN Control Valves offer a proven solutionC o mp e t i to r A L a by r i n t h Tr i mC o mp e t i to r B L a by r i n t h Tr i mR av e n Tr i mfor severe service applications where a true velocity control trimis the best, or possibly the only, answer. The combined effect ofnumerous narrow flow channels, each with many sharp turns andS tac k e d D i s c T e c h n o lo gya continually expanding flow path, is to remove kinetic energyRAVEN’s low velocities are achieved through the use of a trim cagefrom the fluid while gradually lowering its pressure. By limitingmade by bonding together a series of individual discs. Each discthe fluid velocities inside the valve, RAVEN trim precludeshas a pattern of carefully controlled orifices and channels with aproblems typically associated with high velocity such as erosion,multitude of sharp turns etched into its surface. As the trim’s plugnoise, vibration and poor control. The additional benefit for liquidtravels within the cage, the fluid is throttled and forced to travelflow is the elimination of cavitation and the damage it can do toan extremely torturous path with each turn effecting a stage ofa valve, its trim, and the downstream piping.pressure drop.Trim Exit VelocityK i n eti c E n e r gyCr i te r iaE qu iva le nt Wate rVe loc ityps ia / k PaFt/ M pe r S e c on dConti n uousSe rvice,S i n g l e P h as eFlu i ds70(450)100(30)Cav i tat i n g a n dM u lt i P h as e F l u i dO u t l e t ( F l as h i n g )40(275)75(23)V i b r at i o n S e n s i t i v eSyst e m11(75)40(12)S e rv i ceC o n d iti o n s

N a rr ow Wa l l D e s i g n A l low s M o r eLo n g - L i f e a n d R e l i a b i l i t yS tag e s o f Dr o p P e r D i s cDue to the velocity control techniques utilized in RAVEN, vibrationBy its very design, RAVEN trim allows for many more stagescan be virtually eliminated. High velocity is a root cause of noiseof drop than conventional torturous path trims. Superior to otherand vibration, which often can cause seal failure, instrumentationvelocity control trims, RAVEN , through the use of a consistentproblems and cracking of valve components.narrow wall design, typically is more efficient at passing flow orallowing more turns or stages of drop in a given valve size.H i g h R a n g e a b i l i t y App l i cat i o n sDue to the characterization achievable within the disc stack,M a n u fact u r e d to E x act i n g To l e r a n c e srangeabilities to 200:1 or as required by the application can beBy manufacturing the flow channels to extremely close tolerances,achieved. Wherever a split range, two valves in parallel installation isRAVEN’s calculated or predicted versus actual pressure drops arebeing considered using conventional valves, it is usually much moresignificantly more accurate than competitors. Hence, velocities areattractive, both commercially and technically, to combine both valvesmore uniform throughout the entire trim, further guarding againstinto a high rangeability RAVEN Control Valve. Typical applicationsnoise, erosion and cavitation. The unique methods employed toinclude pipeline packing, boiler feed pumps, etc.produce the individual discs and then bond them together providethe uniform flow passages and a high strength stack assembly.A n t i s u r g e Va lv e sThese valves require tight shutoff, fast-acting pneumatic control,low hysteresis, and since they can operate for extended periods,low noise. Operating speeds of one second can be reliably achievedusing pneumatic actuation.D e pr e s s u r i z i n g a n d V e n t Va lv e sSince they operate normally in the closed position, a tight shutoff iscritical to prevent valve degradation due to leakage. Copes-Vulcanhas a well-proven zero leakage design seat that can be usedtogether with RAVEN as required.M u lt i p l e R e l i e f P o i n t s P r e v e n tB lo c k ag eC u s to m D e s i g n e d f o r E ac h App l i cat i o nMost RAVEN trims contain multiple relief points in the flow pathEvery RAVEN trim is custom designed to meet the needs toas a standard feature. These relief points allow entrained debristhe toughest liquid, steam and gas services in the Oil and Gas,to clear the main fluid flow, or in the case of significant pathPetrochemical, Power and Process industries meeting NACEblockage, they provide an effective bypass route of the fluid. WithMR0175 where necessary. The number of pressure reducingthe benefits of the relief points being obvious, the actual fluid flowstages is governed by two factors: velocity control and noisestreams still remain virtually separate or discrete from each otherrequirements. Either velocity or noise can be the factor determiningfor best velocity control.the number of stages required. As per the latest ISA guidelines,RAVEN is designed to control velocity of the fluid within the trimS e v e r e D u t y C o n s t r u ct i o n w i t hAct uato r Op t i o n sA RAVEN Control Valve typically consists of an SD SevereDuty valve operated by either a powerful Series 700 or 1000pneumatic diaphragm actuator or a Series 200 piston actuator.When required, electric, electro-hydraulic, hydraulic or gas-poweredactuators can also be supplied.to 100 ft./sec. (30m/s) (or the equivalent velocity head in case ofgases). Dependent upon the differential pressure across the trim,the stages required to control the velocity are calculated. The lowerthe noise specification, the more stages required. The trim is alsocharacterized to account for changes in flow and differentialpressure at different valve openings.

A da p ta b l e F low D i r e ct i o nFlow can be either over or under the plug depending upon thefluid, the service and, in some instances, the piping configuration.T i g h t S h u to f fEquipped with various plugs (eg. unbalanced, balanced, tandem,etc.), RAVEN can provide shutoff classes ranging fromANSI/FCI 70-2 Class IV to VI and MSS-SP-61. For particularapplications Copes-Vulcan can also supply our patentedZERO leakage design.E a s i ly S e r v i c e dQuick-change design with no threaded or welded-in parts. Seatring is a separate replaceable item.R e s i sts Plugg i ng an d Galli ngA pressure-balancing groove inboard of the I.D. of eachdisc allows the plug to be completely balanced around itscircumference, and provides a landing area for entrained debris,thus precluding plug galling. Additionally, bypasses in the flowpath allow for entrained debris to clear the main fluid flow path.R e t r o f i t s / Up g r a d e sRAVEN trim can be readily tailored to fit valves previouslysupplied with other trims styles, and valves manufactured byother suppliers. This has a cost benefit in that a new body is notrequired. This shortens delivery times considerably. Most refitscan be carried out with the valve in position at site within one day.Tr i m R e c o mm e n dat i o n s M atc h e d to t h eApp l i cat i o nCopes-Vulcan, unlike other manufacturers, offers a widevariety of performance-proven trim styles. This enables us toselect the correct trim for every application without restriction.In applications requiring a high number of pressure reducingstages, RAVEN trim is the ideal solution. In less severeapplications, a more economical trim style can be applied. It isour policy to quote the most economical trim that will satisfy aparticular application.

RAVEN SpecificationsT u r n s / S tag e s o f P r e s s u r e Dr o pC o d e s & S ta n da r d sApplication specific up to 60 or moreDue to our specialist design capabilities, RAVEN Valves can bemanufactured to meet virtually any standard in the world. Some ofRang eab i lity100:1 or greaterthese standards are listed below:ISO 9001CE AccreditationTr i m C h a r act e r i s t i c sEqual percentage, linear or customizedASME Section 1 S StampSection III N & NPT StampsSection III NCA 40C StampVa lv e S i z e s1.5–36" (38–914mm) and customized sizesP r e s s u r e R at i n g sANSI 150–4500CSA Z299.3 & Z299.4MSSP61NA V Ships 250-1500-1ANSI B16.34, NQA 1, N45.2. B31.1MIL I 45208A, Q9858, STD 2132B o dy S t y l e sStraight-through globe, offset globe/Z pattern, angle styleB o dy E n d sFlanged, butt weld (to any standard or special requirement) orclampedS ta n da r d Tr i m M at e r i a l s Disc Stacks: 300 or 400 Series stainless steel, Inconel or othermaterials as required Plug & Seat: hardened 420 stainless steel, Stellited 316stainless steel or other materials as required.S ta n da r d B o dy / B o n n e t M at e r i a l sCarbon steel, chrome moly, stainless steel, and other castable orforged materials.Act uato r s : Series 1000 Pneumatic Diaphragm Actuators Series 200 Piston Actuators Electric Hydraulic Actuators Gas Powered Actuators Stepper ActuatorsAPI 598

Raven TrimGlobal locationsS PX F low T e c h n o lo gyS PX F low T e c h n o lo gyS PX F low t e c h n o lo gyS PX F low t e c h n o lo gy5620 West RoadRoad Two, Industrial Estate25 International Business Park6F Treasury BuildingMcKean, PA 16426Winsford, Cheshire CW7 3QL#03-03/12 German Centre1568 Hua Shan RoadUnited States of AmericaEnglandSingapore 609916Shanghai 200052 1 814 476 5800 44 1606 552041 65 6264 4366PR China 86 21 2208 5888Based in Charlotte, North Carolina, SPX Corporation (NYSE: SPW) is a global Fortune 500 multi-industry manufacturing leader.For more information, please visit www.spx.comS PX F low T e c h n o lo gy5620 West Rd.McKean, PA 16426P: (814)476-5800F: (814)476-5854E: cv@spx.comSPX reserves the right to incorporate our latest design and material changes without notice or obligation.Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless confirmedin writing. Please contact your local sales representative for product availability in your region. For more information visit www.spx.com.The green “ ” is a trademark of SPX Corporation, Inc.ISSUED 08/2012CV-1160-USCOPYRIGHT 2012 SPX Corporation

RAVEN has been proven quieter that the leading competitor in extensive laboratory testing. Raven PRovides tRue velocity contRol Copes-Vulcan's RAVEN Control Valves offer a proven solution for severe service applications where a true velocity control trim is the best, or possibly the only, answer. The combined effect of