Transcription

XL FLOOR MACHINESMODELS:17 XL, 17 XL CS & 20 XL17 DS XL & 20 DS XL1500 XL & 2000 XLOPERATING & MAINTENANCEINSTRUCTIONSINTRODUCTIONREAD THIS BOOKThis operator’s book has important information for the useand safe operation of this machine. Read this book carefully before starting the machine. Keep this book and tellall operators to read the book. If you do not follow theinstructions, you can cause an injury or damage equipment,furniture or buildings.The contents of this manual are based on the latest productinformation available at the time of publication. Triple Sreserves the right to make changes or improvements to itsmachines without notice.For additional information refer to the Triple S websitewww.triple-s.com or write to:Triple S2 Executive Park DriveBillerica, MA 01862FOR YOUR CONVENIENCE, RECORD THISIMPORTANT INFORMATION:Carefully inspect all components to ensure that there is noconcealed freight damage. If such damage is discovered,file a “CONCEALED DAMAGE REPORT” immediatelywith the delivering carrier.MODELSERIAL NUMBERPART NUMBERDATE PURCHASED

TABLE OF CONTENTSSAFETY INSTRUCTIONS4SINGLE SPEED MACHINES (175 rpm)OPERATING PROCEDURESILLUSTRATION - Models 17 XL, 17 XL CS & 20 XLPARTS LIST & WIRING DIAGRAM - Models 17 XL, 17 XL CS & 20 XLAC MOTOR PARTS LISTDUAL SPEED MACHINES (175 & 300 rpm)5678OPERATING PROCEDURESILLUSTRATION - Models 17 DS XL & 20 DS XLPARTS LIST - Models 17 DS XL & 20 DS XLDC MOTOR & WIRING DIAGRAM9101112SAFETY INSTRUCTIONS14UHS MACHINES (1500 & 2000 rpm)OPERATING PROCEDURESILLUSTRATION - Models 1500 XL & 2000 XLPARTS LIST - Models 1500 XL & 2000 XLDC MOTOR & WIRING DIAGRAM15161718WARRANTY POLICY203

IMPORTANT SAFETY INSTRUCTIONSTo assure the safe operation of this machine, you must read and understand all warnings and instructions in this book. If youdo not understand, ask your supervisor.READ ALL INSTRUCTIONS BEFORE USING THIS MACHINEWARNING: To reduce the risk of fire, electric shock, or injury:1.2.3.4.5.6.7.8.9.You must be trained to operate this machine. This machine is to be operated for its intended use only.Do not operate this machine unless it is completely assembled.Always use a three-wire electrical system connected to the electrical ground. For maximum protection against electricalshock, use a circuit that is protected by a ground fault circuit interrupter. Consult your electrical contractor.To prevent electric shock, always remove the electrical plug from the electrical outlet before doing any repairs or maintenance and when leaving the machine unattended.To prevent electric shock, keep the machine surface dry. Do not subject to rain. Store the machine in a dry building area.Clean the machine with a dry cloth only.Machines can cause an explosion when near flammable materials and vapors. Do not use this machine with or near fuels,grain dust, solvents, thinners, or other flammable materials. Do not use flammables to clean this machine.A qualified or authorized person must do maintenance and repairs.To prevent damage to the power cord, do not move this machine over the power cord. Always lift the power cord over themachine. Do not pull or carry cord, use cord as a handle, close a door on cord, or pull cord around sharp edges or corners.Keep cord away from heated surfaces.Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped, damaged, left outdoors,or dropped into water, return it to a service center.Grounding InstructionsThis machine must be grounded. If it should malfunction or break down,grounding provides a path of least resistance for electric current to reducethe risk of electric shock. This machine is equipped with a cord having anequipment-grounding conductor and grounding plug. The plug must beinserted into an appropriate outlet that is properly installed and groundedin accordance with all local codes and ordinances.WARNING - Improper connection of the equipment-grounding conductorcan result in a risk of electric shock. Check with a qualified electricianor service person if you are in doubt as to whether the outlet is properlygrounded. Do not modify the plug provided with the machine - if it will notfit the outlet, have a proper outlet installed by a qualified electrician.This machine is for use on a nominal 120-volt circuit, and has a groundedplug that looks like the plug illustrated in figure A. A temporary adapterthat looks like the adapter illustrated in figures B and C may be used toconnect this plug to a 2-pole receptacle as shown in figure B if a properlygrounded outlet is not available. The temporary adapter should be used onlyuntil a properly grounded outlet (figure A) can be installed by a qualifiedelectrician. The green colored rigid ear, lug, or the like extending fromthe adapter must be connected to a permanent ground such as a properlygrounded outlet box cover. Whenever the adapter is used, it must be heldin place by a metal screw.NOTE: In Canada, the use of a temporary adapter is not permitted by theCanadian Electrical CodeEXTENSION CORDSUse only three-wire 12/3 or larger gauge approved extension cords that havethree-prong grounding type plugs and three-pole receptacles that accept theappliance’s plug. Replace or repair any damaged cords or plugs.NOTE: Do not use adapters shown in figures B & C in CanadaWhen servicing, refer to authorized person only. Use only identicalreplacement parts.4

OPERATING PROCEDURES - SINGLE SPEEDWARNING! For the safe operation of this machinefollow the instructions given in this manual and thetraining given by your supervisor. Failure to do so canresult in personal injury and/or damage to machine andproperty!OPERATIONDO NOT OPERATE MACHINE IN AN EXPLOSIVEENVIRONMENT!Pull out on the “Watch Dog” Safety Lock button and startthe machine by depressing either the left or right switchlevers.Plug the machine’s power cable into a properly groundedoutlet (see Safety Instructions). Next, adjust the handleheight to a comfortable position.This machine is intended for commercial use.Both hands should be placed on the handle when the machineis in operation. The machine will glide sideways over thefloor by a slight raising and lowering of the handle. Raisethe handle slightly to go to the right. Lower the handleslightly to go left. Releasing the switch lever stops themachine at once.PREPARATIONTo prepare the machine for operation, make sure it is ofcorrect voltage and properly assembled.Your new floor machine operates in the normal side to sidemotion of a conventional single disc machine. Be preparedbefore starting by removing all obstructions or other obstacles in the area to be cleaned. Check the proper applicationrecommendations and procedures found on the label of yourcleaning or finish container. IF IN DOUBT, CALLYOUR SUPERVISOR .For Spray Buffing: A diluted spray of about one part waterto one part solution is recommended. Heavier spray buffsolutions will bog down the machine, load up the pad andadversely affect the machine’s efficiency.MAINTENANCEWARNING! NEVER USE THIS MACHINE WITHFLAMMABLE OR EXPLOSIVE MATERIAL!AFTER EACH USE: Store the machine in a clean dryarea. Wipe the entire machine and cord down with a cleancloth. Remove the pad or brush and clean thoroughly. Wrapthe machine’s electrical cord onto the handles and the cordhook provided. CHECK the cord and plug for nicks, cuts ordamage. Report these to your supervisor for correction.For Scrubbing or Polishing: Select the correct cleanSSS floor pad or brush (your Triple S Distributor can assistyou). If in doubt, ask your supervisor.NEVER OPERATE THE MACHINE WITHOUT THEFLOOR PAD OR BRUSH INSTALLED!WARNING! Always disconnect the machine’s electricalplug from the electrical outlet before performing anyservice, maintenance, pad changing or inspection of themachine.To properly attach the brush, UNPLUG THE FLOORMACHINE, place the handle in the vertical position, thentilt the machine back until the handle rests on the floor.Straddle the handle, facing the motor, and grasp the brushwith the block toward you. Place the brush or pad clutchplate over the three lugs on the motor drive adapter. Twistthe brush right to lock it into position. To remove the brush,UNPLUG THE MACHINE and follow the same procedureas above, but by twisting the brush off with a firm jerk to theleft. Remove the brush or pad driver when the machine isnot in use. This will help prevent brush damage and reducewobble problems.MOTOR: The motor is lubricated for life under normaluse. No oiling or greasing is necessary. However, if themachine is used in dusty areas or is used for spray buffing,the motor should be cleaned. Blowing the motor out withcompressed air or with the exhaust from a vacuum is suggested. Keeping the motor clean will allow the clear passage of air for ventilation and prevent overheating. If youhave any questions regarding the maintenance of your floormachine, ASK YOUR SUPERVISOR.5

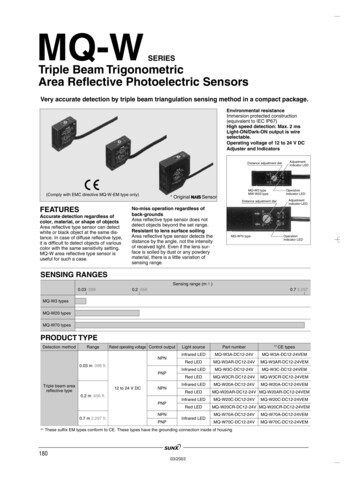

MODELS:17 XL, 17 XL CS & 20 XL17 XL CS ITEMS NOT SHOWN:508681 - Tank Assembly, 4 gallon505903 - Pad Driver Assembly6

MODELS: 17 XL, 17 XL CS & 20 XLITEMPART NO.QTY.ITEMPART NO.1W323DDESCRIPTIONScrew, 6-32x1 Pan Hd.237962009DESCRIPTIONBolt, Carriage 5/16-18 x 2-1/2QTY.12980016Washer, #6 Ext. Tooth238962005Screw, 1/4-20 x 3/8 Allen13500801Bracket, Switch Mounting139505010Turn Knob14911135Switch140980007Washer, 5/16 Flat25508301Spring141908004Handle Cord16507001Plunger142509920Yoke, Handle17500802Bracket, Switch143504702Insulator-Switch18962002Screw, 10-32 x 1/2 Oval Hd.244509823Washer, Felt19504810Interlock Asm.-Switch145962010Screw, 1/4-20 x 1 HH410962011Screw, 10-32 x 3/4 Oval Hd.246506820Plug Button111486404Switch Cover Plate147507480Shaft, Handle Pivot112509821Washer, Rubber248508040Bumper Strap, 17”113920005Nut, 3/8-24 Hex1508041Bumper Strap, 20”114508020Switch Assembly (or 505003)149962015Screw, Bumper Strap215505121Lever, Switch Left150501846Base Casting-17”116505120Lever, Switch Right1501848Base Casting-20”117920001Nut, 10-32 Elastic Stop151509820Washer, Fiber418509830Washer, Handle Tube152507722Wheel Axle Shaft119503320Flange, Strain Relief153508221Spacer, Wheel Shaft120505720Handle Nipple254504421Wheel Hinge221481304Switch Housing,w/o Circuit Brkr.155980005Washer, Wave222515150Warning Label156509780Wheel, 4” - 17”223501210Bumper, Handle1509781Wheel, 5” - 20”224962003Screw, 10-32 x 3/4 Pan Hd.157925002Pin, Wheel Hinge225962006Screw, 1/4-20 x 1/2 Pan Hd.658507320Snap Ring, Wheel226503730Handle Grip259507721Shaft Wheel, 2-5/161501501Cap, Protective End2507723Shaft Wheel, 3-3/8127980015Washer, #10 Shakeproof260502110Bumper Clip328508520Strain Relief-Complete161962001Screw, Bumper Clip3502020Strain Relief-Brass Clamp162980004Washer, 1/4 Flat429962015Screw, 10-32 x 3/8 Pan Hd.263980002Washer, 1/4 Lock630980018Washer, #10 Countersunk164501241Base Bumper, 17”132509082Handle Tube1501283Base Bumper, 20”133504420Cord Hook165962019Screw, Cap334502430Cord Asm.-50 ft., Orange167502373Drip Cover135502021Clamp-Handle171505249Motor (see next page)136500820Arm, Handle Support2503523Gear Unit (see next page)1HANDLESWITCHSINGLE PHASEGROUNDEDPOWER SUPPLY115 VOLTS60 M)(N.O.)GREENPOWERSUPPLYCORDHANDLECORDSWITCH HOUSING7MOTOR

MODELS: 17 XL, 20 XL CS & 20 XLAC MOTOR PARTS LISTITEM PART NO.DESCRIPTIONQTY.505251Motor & Gear Asm., 1.5HP 115V 60CY505249Motor Only, 1.5 HP503523Gear Asm.Only -10:1 for 1.5 HP-3 PlanetA504209Ring Gear Housing1B902007Bearing1C504208Planet Gear Hsing,10:1-3 Idler1D902005Bearing1EScrew6FScrew6GMotor Cord1Run Capacitor1ICover, Run Capacitor1JCover, Start Capacitor1Start Capacitor1LBolt4MEnd Bell1NStator Asm (No Capacitors), Chrome1HK9113059113041O902003Bearing, Motor Top1P911306Stationary Switch1Q911307Rotary Switch (For 60 Cycle)1Rotor Assembly (No Bearings or Switch)1RS502927End Bell-Motor Lower1T502317Cover, Ring Gear1U902015Bearing1V902005Bearing2X502460Coupling -Planet Gear2/3BB902016Bearing-Planet Shaft4/6CC503511Gear-Planet2/35035108

OPERATING PROCEDURES - DUAL SPEEDWARNING! For the safe operation of this machinefollow the instructions given in this manual and thetraining given by your supervisor. Failure to do so canresult in personal injury and/or damage to machine andproperty!OPERATIONDO NOT OPERATE MACHINE IN AN EXPLOSIVEENVIRONMENT!Pull out on the “Watch Dog” Safety Lock button and startthe machine by depressing either the left or right switchlevers.Plug the machine’s power cable into a properly groundedoutlet (see Safety Instructions). Next, adjust the handleheight to a comfortable position.This machine is intended for commercial use.Both hands should be placed on the handle when the machineis in operation. The machine will glide sideways over thefloor by a slight raising and lowering of the handle. Raisethe handle slightly to go to the right. Lower the handleslightly to go left. Releasing the switch lever stops themachine.PREPARATIONTo prepare the machine for operation, make sure it is ofcorrect voltage and properly assembled.Your new floor machine operates in the normal side to sidemotion of a conventional single disc machine. Be preparedbefore starting by removing all obstructions or other obstacles in the area to be cleaned. Check the proper applicationrecommendations and procedures found on the label of yourcleaning or finish container. IF IN DOUBT, CALLYOUR SUPERVISOR .For Spray Buffing: A diluted spray material of about onepart water to one part solution is recommended. Heavierspray buff solutions will bog down the machine, load up thepad and adversely affect the machine’s efficiency.MAINTENANCEWARNING! NEVER USE THIS MACHINE WITHFLAMMABLE OR EXPLOSIVE MATERIAL!AFTER EACH USE: Store the machine in a clean dryarea. Wipe the entire machine and cord down with a cleancloth. Remove the pad or brush and clean thoroughly. Wrapthe machine’s electrical cord onto the handles and the cordhook provided. CHECK the cord and plug for nicks, cuts ordamage. Report these to your supervisor for corr

XL FLOOR MACHINES MODELS: 17 XL, 17 XL CS & 20 XL 17 DS XL & 20 DS XL 1500 XL & 2000 XL OPERATING & MAINTENANCE INTRODUCTION INSTRUCTIONS READ THIS BOOK This operator’s book has important information for the use and safe operation of this machine. Read this book care-fully before starting the machine. Keep this book and tell all operators to read the book. If you do not follow