Transcription

ZERO LEAKAGETRIPLE OFFSET VALVESVANESSATRIPLE OFFSET VALVES

2TRIPLE OFFSET VALVESVANESSA

THE KNOW HOWTURNING AN IDEA INTO A NEW CATEGORY OF VALVESVANESSA WAS THE FIRST COMPANYIN THE WORLD TO INTRODUCE ATRIPLE OFFSET VALVE WITH TRUEZERO LEAKAGE* PERFORMANCE,CREATING A NEW INDUSTRYCATEGORY USING A TECHNOLOGYNOT PREVIOUSLY AVAILABLE WITHOTHER STANDARD QUARTER TURNVALVES.Our triple offset design completelyeliminates any rubbing action of thesealing elements during the 90 degreesof rotation, positioning Vanessa asthe ultimate process valve. Based onthese new and revolutionary concepts,we have achieved worldwide successacross the Oil & Gas, Process andPower industries.If you ask one of our customers thereasons why they choose us, youare likely to hear a recurring word:‘reliability’. Our engineering expertise,state-of-the-art technology andmanufacturing capabilities ensure wecontinue to provide the most reliabletriple offset valves across a wide rangeof applications for our customersworldwide.DESIGNED TO DELIVER BETTERPERFORMANCE.Vanessa was a pioneer in the useof 3D Cad, Finite Element Analysisand Computational Fluido Dynamiccalculations to design a valve capableof delivering better performanceengineered in the most efficient way.The complex geometry of Vanessavalves requires precision engineeringand using advanced technologyfor fixture tooling and inspectionequipment. 3D measuring machinesare used to check body and discs withtolerances in the order of fractionsof millimeters to be verified andvalidated during different stages ofmanufacturing.‘ We have been using VanessaTriple Offset valves in ourTank Farms & Offshorefacilities for the past tenyears for all of our fiveexpansion phases and havefound their performance tobe extremely satisfactory.’Terminal ManagerMajor O&G End UserThese advanced tools have allowedus to continuously improve theproduct design, enhance robustness,ensure long term durability andadapt the valve to provide the bestfit solutions to our customers. * Zero Leakage means no visible leakagewhen tested at high pressure with waterand low pressure with air according toexisting international standards.VANESSATRIPLE OFFSET VALVES3

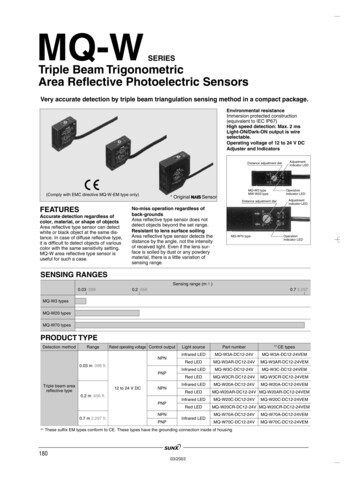

SEALING ELEMENTS WHICH ALLOW TRUE ZERO LEAKAGE ACROSS AWIDE RANGE OF PRESSURE CONDITIONS.OFFSET 2OFFSET 1OFFSET 3THE TRIPLE OFFSET CONCEPTTHE VANESSA CONE-TO-CONE SEALING MECHANISMIS ACHIEVED BY QUARTER TURN ROTATION AND ISBASED ON THREE OFFSETS WHICH ELIMINATE ANYRUBBING THROUGHOUT THE 90 ROTATION:OFFSET 1 The shaft is placed behindthe plane of the sealing surface. Thepurpose of this offset is to have acontinuous seat path.OFFSET 2 The shaft is placed to oneside of the pipe / valve centerline. Thepurpose of this offset is to allow thedisplacement of the seal from the seatduring the 90 opening.OFFSET 3 The seat and seal conecenterlines are inclined in respect to thepipe / valve centerline. This third offsetcompletely eliminates rubbing.4TRIPLE OFFSET VALVESVANESSA

THE PRODUCTCONTINUOUS IMPROVEMENTS TO OUR PRODUCT DESIGNENSURE LONG TERM DURABILITY AND RELIABILITYTHE VANESSA TRIPLE OFFSET VALVEHAS BECOME A MARKET LEADERTHANKS TO ITS UNIQUE SEALINGELEMENTS WHICH ALLOW TRUEZERO LEAKAGE ACROSS A WIDERANGE OF PRESSURE CONDITIONS.The standard Vanessa seal ring ismanufactured from Duplex stainlesssteel while the body seat is a weldoverlay of Stellite grade 21, whichensures durability and protects theseat from potential damage caused byextended usage. Differently from balland butterfly valves (position-seated),Vanessa is torque-seated. Due to theelasticity and the radial compressionof the seal ring, the contact pressureis uniformly distributed around theseating surface guaranteeing true zeroleakage.Every Vanessa valve is tested for zeroleakage on multiple test benchesthat allow ‘open face’ testing withcontrolled torque. The visual inspectionof the valve sealing surfaces underpressure ensures there is no possibleleakage, even during the relativelyshort duration of the test imposed byinternational standards.‘ We hereby certify thatthe performance of thesevalves is excellent and canbe used for such criticalapplications [VCM, EDC, HCI,Coke particles] in any otherchemical / petrochemicalplant.’Senior Manager PVC/VCMMajor Petrochemical End User* Stellite is a registered tradename of DeloroVANESSATRIPLE OFFSET VALVES5

6TRIPLE OFFSET VALVESVANESSA

BallGateVanessaGlobeTHE SOLUTIONSA PREMIUM QUALITY VALVE THAT MINIMIZES YOUR COST OF OWNERSHIPYOU WOULD NOT USUALLYASSOCIATE A PREMIUM PRODUCTWITH COST SAVINGS. HOWEVER, THEREALITY IS QUITE DIFFERENT WITHVANESSA VALVES.In fact, our customers regularlyreplace existing gate, ball and globevalves achieving substantial reductionof space and weight, while benefittingimmediately from lower installationcosts.Vanessa triple offset valves providethe ideal solution for all applicationswhere positive isolation is required.The quarter turn design and very lowrunning torque also allow for accurateflow and pressure control, with theVanessa valve providing true isolationand control capabilities in a singleproduct against the usual need for twodistinct valves. Low torque also meanslow cost of actuation.So what happens when you install andstart operating the valve? Vanessa isdesigned to be virtually maintenancefree and does not require plannedmaintenance in most applications,providing extra cost savings across itslifecycle.SAFELY REPLACE YOUR EXISTINGVALVES WITH VANESSA.Replacing an existing valve can be anecessity but also a strategic choice.Vanessa valve’s bi-directional zeroleakage and inherently fire safe designallows our customers to easily replacegate, ball and globe valves and, withour long face-to-face valves (designedin accordance to ASME B16.10), thisoperation can be carried out withoutthe need of any piping modification.‘ We have several hundredVanessa Triple Offset Valvesoperating in molecularsieve service and thesehave been working veryeffectively since initialinstallation four years ago[ ] Triple Offsets are nowour standard for valve typefor this difficult duty andwe are more than happy torecommend them to otherusers’.Engineering ManagerMajor Process LicensorUsing Vanessa can also contributeto reducing systemic failures therebyimproving the overall Safety IntegrityLevel (SIL); in fact using triple offsetvalves with an appropriate actuatorselection it is possible to configurethe product to assist the requiredprotective function.VANESSATRIPLE OFFSET VALVES7

‘ Your team demonstrated a great capability to adjust anddeal in a very professional way with very tough constraints.’Senior Instrumentation EngineerMajor Chemical & Petrochemical End User8TRIPLE OFFSET VALVESVANESSA

THE CAPABILITIESWE CAN DELIVER: LARGE SCALE MANUFACTURING IN ACTIONWITH OUR HISTORY OF CONSISTENTGROWTH OVER THE YEARS, WE HAVEEXPANDED OUR MANUFACTURINGFACILITIES SEVERAL TIMES ANDNOW VANESSA OCCUPIES A 50,000SQUARE METER SITE AND ISCAPABLE OF PRODUCING OVER30,000 VALVES PER YEAR.There is also a separate productionfacility based on Advanced FlowManufacturing technology producingup to 1,000 valves per month(sizes 3” to 24”) to delivery times asshort as four weeks.Besides a proven track record ofdelivering outstanding products fordecades to hundreds of satisfiedcustomers, our high quality standardsare acknowledged by certificationsincluding ISO 9001, ISO 14001 andOHSAS 18001.Furthermore, through the introductionof rigorous manufacturingmethodologies such as ‘Lean’ and‘Six Sigma’, we are committed tooperational excellence and highintegrity processes throughout ourbusiness.Valves of all sizes and ratings canbe tested with helium in one of ourcryogenic testing facilities. The largestof these fully computerized testingfacilities is equipped with a 20 toncrane, a 30,000 liter liquid nitrogentank and cameras to ensure operationand control in total safety.A WORLDWIDE IN-HOUSE SUPPORTFOR OUR CUSTOMERS.Our goal is to ensure that ourcustomers receive services matchingthe same outstanding level of qualitywe deliver through our products.As part of an international groupVanessa has a truly global presencethrough a network of sales offices,service centers, valve automationcenters and local inventory.This is extended to training and serviceoperations in all the major industrialmarkets allowing us to look afterour customers throughout a valve’slifecycle.VANESSATRIPLE OFFSET VALVES9

DOUBLE FLANGED SHORTDOUBLE FLANGED LONGDOUBLE FLANGED CRYOGENICWAFERBUTTWELDLUGJACKETEDHIGH TEMPERATURETOP ENTRY CRYOGENICTHE APPLICATIONSONE PRODUCT, HUNDREDS OF APPLICATIONSOVER 300,000 VANESSA VALVESARE SUCCESSFULLY INSTALLEDWORLDWIDE ON A WIDE RANGE OFAPPLICATIONS INCLUDING OIL &GAS, POWER, PROCESS AND MANYOTHER DEMANDING INDUSTRIES.From cryogenic up to extremely hightemperatures, we offer solutions tocritical and non-critical applicationsensuring the highest reliability and,more importantly, total safety of yourfacilities.Suitable from full vacuum to 250bars, Vanessa valves are available insizes between 3” and 140” and can beconfigured in wafer, lug, double flangedand butt weld body styles across10TRIPLE OFFSET VALVESVANESSAvirtually all bills of materials. Our valveshandle fluids ranging from H2 gas tohigh viscosity liquids, from food grade totoxic and corrosive. The most commonprocess functions are: IsolationFlow & pressure controlON-OFFSwitchingEmergency / safety operationsHIPPS Major equipment protective function,including: - Turbine backflow- Turbine supply & bypass- Compressor blow-off & anti-surgeFor detailed technicalinformation about ourproducts,visit our onlinecatalog at:www.vanessavalves.it/catalog

OIL & GASPOWERPROCESSOTHER INDUSTRIESupstreamdownstreampipeline & storagesupply & servicerenewables*fossilsdistrict heatingnuclearchemical & coalpetrochemicaldesalination plantswaterworksfood & beverageiron & steelother miningautomotiveshipyardsaerospace* solar, geothermal and hydroVANESSATRIPLE OFFSET VALVES11

PENTAIR VALVES & CONTROLS VANESSA MANUFACTURING PLANT VIA PIACENZA 29018 LUGAGNANO VAL D’ARDA (PC) ITALY. WWW.PENTAIR.COM/VANESSAAll Pentair trademarks and logos are owned by Pentair, Inc. All other brand or product names are trademarks or registered marks of their respective owners.Because we are continuously improving our products and services, Pentair reserves the right to change product designs and specifications without notice.Pentair is an equal opportunity employer.VANCBR-09003-EN-1210 2012 Pentair, Inc. All Rights Reserved.

and butterfly valves (position-seated), Vanessa is torque-seated. Due to the elasticity and the radial compression of the seal ring, the contact pressure is uniformly distributed around the seating surface guaranteeing true zero leakage. Every Vanessa valve is tested for zero leakage on multiple test benches that allow ‘open face’ testing with controlled torque. The visual inspection of .