Transcription

LIPPERTCOMPONENTS, INC.ELECTRONIC/HYDRAULICLEVELING AND SLIDEOUT SYSTEMOPERATIONANDSERVICE MANUAL

TABLEOFCONTENTSSYSTEM .Warning .Prior to Operation.Description Fluid Recommendation .Preventative Maintenance .Jacks Pump Unit Components.Slideouts.Power Units .3344556678CONTROLS . 18Features . 18Wiring Requirements . 18Air and Auxiliary Features. . 18Level Zero Point Configuration. 19Air and Aux Configuration 19Error Mode . . 20User Alarm Mode . . 20Miscellaneous . . 21Control Panel. . 22OPERATION . 23Selecting a Site .23Automatic Leveling Procedure . 23Manual Leveling Procedure . 24Jack Retract Procedures . 25Manual Override-Jacks . .26Manual Override-Power System . 27Automatic Shut-off . 28Drive-Away Protection . 28“Jacks Down” Alarm. 28SERVICE . 29“Latched Out” Procedure. 29Troubleshooting Chart. . 30Power Unit . 31Plumbing Diagrams . 32Wiring Diagram. . 34Slideout Adjustment. 36Ordering Parts . 37WARRANTY . 38Warranty Registration. 392

SYSTEMWARNINGFAILURE TO ACT IN ACCORDANCE WITH THE FOLLOWING MAYRESULT IN SERIOUS PERSONAL INJURY OR DEATH.THE USE OF THE LIPPERT ELECTRONIC LEVELING AND SLIDEOUT SYSTEMTO SUPPORT THE COACH FOR ANY REASON OTHER THAN WHICH IT ISINTENDED IS PROHIBITED BY LIPPERT’S LIMITED WARRANTY. LIPPERTELECTRONIC LEVELING AND SLIDEOUT SYSTEM IS DESIGNED AS FORLEVELING THE UNIT AND EXTENDING/RETRACTING SLIDEOUTS ANDSHOULD NOT BE USED TO PROVIDE SERVICE FOR ANY REASON UNDERTHE COACH SUCH AS CHANGING TIRES OR SERVICING THE SYSTEM.LIPPERT COMPONENTS, INC. RECOMMENDS THAT A TRAINEDPROFESSIONAL BE EMPLOYED TO CHANGE THE TIRE ON THE COACH.ANY ATTEMPTS TO CHANGE TIRES OR PERFORM OTHER SERVICE WHILECOACH IS SUPPORTED BY THE LIPPERT ELECTRONIC LEVELING ANDSLIDEOUT SYSTEM COULD RESULT IN DAMAGE TO THE MOTOR HOMEAND/OR CAUSE SERIOUS INJURY OR DEATH.WARNING! – BE SURE TO PARK THE COACH ON SOLID, LEVELGROUND.WARNING! – CLEAR ALL JACK LANDING LOCATIONS OF DEBRISAND OBSTRUCTIONS. LOCATIONS SHOULD ALSO BEFREE OF DEPRESSIONS.WARNING! – WHEN PARKING THE COACH ON EXTREMELY SOFTSURFACES, UTILIZE LOAD DISTRIBUTION PADS UNDEREACH JACK.WARNING! - PEOPLE AND PETS SHOULD BE CLEAR OF COACHWHILE OPERATING LEVELING SYSTEM.WARNING! – BE SURE TO KEEP HANDS AND OTHER BODY PARTSCLEAR OF FLUID LEAKS. OIL LEAKS IN THE LIPPERTLEVELING SYSTEM MAY BE UNDER HIGH PRESSUREAND CAN CAUSE SERIOUS SKIN PENETRATINGINJURIES.WARNING! - NEVER LIFT THE COACH COMPLETELY OFF THEGROUND. LIFTING THE COACH SO THE WHEELS ARENOT TOUCHING GROUND WILL CREATE AN UNSTABLEAND UNSAFE CONDITION AND MAY RESULT IN SERIOUSPERSONAL INJURY OR DEATH.3

PRIOR TO OPERATIONThe leveling system shall only be operated under the following conditions:1. The coach is parked on a reasonably level surface.2. The coach “PARKING BRAKE” is engaged.3. The coach transmission should be in the neutral or park position4. The ignition is in the run position, or engine is running.5. Be sure all person, pets and property are clear of the coach whileLippert Leveling System is in operation.SYSTEM DESCRIPTIONPlease read and study the operating manual before you operate the system.The Lippert Electronic Leveling and Slideout System is an electric/hydraulicsystem. A 12V DC electric motor drives a hydraulic pump that moves fluidthrough a system of hoses, fittings and jacks to level and stabilize the coach.The Lippert Electronic Leveling and Slideout System is totally integrated into thechassis of the coach at the manufacturer.There are no serviceable parts within the electric motor. If the motor fails, pumpmust be replaced.Disassembly of the Pump Assembly voids the warranty.Mechanical portions of the Lippert Electronic Leveling and Slideout System arereplaceable. Contact Lippert Components, Inc. to obtain replacement parts.FOR REPLACEMENT PARTS, CALL LIPPERT AT:(866) 524-7821.COMPONENT DESCRIPTION The Lippert Electronic Leveling and SlideoutSystem consists of the following major components:Lippert jacks are rated at a lifting capacity appropriate for your coach. Each jack hasa 9" diameter (63.5 square inch) shoe on a ball swivel for maximum surface contacton all surfaces. (12” dia. - 113 sq. in. shoe also available).Each jack is powered from a central 12VDC motor/pump assembly, which alsoincludes the hydraulic oil reservoir tank, control valve manifold, and solenoid valves.The Lippert Electronic Leveling and Slideout System is controlled electronicallyfrom the driver’s seat of the coach. The control panel is mounted in the dash.The system can be operated in a manual mode or a fully automatic mode.The slideouts on this sytem are actuated by hydraulic cylinders integrated intothe box of the slideout frames. Some rooms will have one cylinder per room,others will have two. Consult the manuafacturer of the coach or the pumpschmeatic provided with this manual to find out the cylinder configuration on yourunit.4

FLUID RECOMMENDATIONThe Lippert Electronic Leveling and Slideout System is pre-filled, primed and readyto operate direct from the manufacturer. Type “A” Automatic Transmission Fluid(ATF) is utilized and will work. ATF with Dexron III or Mercon 5 or a blend of both isrecommended by Lippert Components, Inc.In colder temperatures (less than 10 F) the jacks may extend and retract slowlydue to the fluid’s molecular nature. For cold weather operation, fluid speciallyformulated for low temperatures may be desirable.Please consult factory before using any other fluids.PREVENTATIVE MAINTENANCE PROCEDURES1. Change fluid in RESERVOIR ONLY every 36 months.a) Check fluid only when jacks and slideouts are fully retracted.b) Always fill the reservoir with the jacks and slideouts in the fully retractedposition. Filling reservoir when jacks are extended will cause reservoir tooverflow into its compartment when jacks and slideouts are retracted.c) When checking fluid level, fluid should be within 1/2” of fill spout lip.2. Check the fluid level every month.3. Inspect and clean all Pump Unit electrical connections every 12months. If corrosion is evident, spray unit with WD-40 or equivalent.4. Remove dirt and road debris from jacks and slideout arms as needed.WARNINGARNING:Your coach should be supported at both front and rear axles withjack stands before working underneath.Failure to do so may result in personal injury or death.5. If jacks are down and slideouts extended for long periods, it is recommended tospray exposed leveling jack and slideout cylinder rods with a silicone lubricantevery seven days for protection. If your coach is located in a salty environment, itis recommended to spray the rods every 2 to 3 days.IF YOU HAVE ANY PROBLEMS OR QUESTIONS CONSULT YOUR LOCALAUTHORIZED DEALER OR CALL LIPPERT AT:(866) 524-7821.5

LCI HYDRAULIC JACKDDAFig. 2Fig.1CAPACITY - 7,000 lb.STROKE - 13.75 in.H - 18 1/4 in.D - 2 3/8 in.A - 2 1/2 in.9” SHOE-STANDARD12” SHOE-OPTIONALHH113314175176CAPACITY - 12,000 lb.STROKE - 15 in.H - 19 1/2 in.D - 2 3/8 in.9” SHOE-STANDARD12” SHOE-OPTIONALFOUND ON FR GT UNITS357QS AND 391ALL 4 JACKS ARE 12K.LCI HYDRAULIC PUMP UNIT COMPONENTSIsolator ValvePressure SwitchHydraulic Switching ValveFlow DividerFittingsTrombettaPump ManifoldValve Block12V DC Motor6Reservoir

LCI HYDRAULIC SLIDEOUTS117691 - Kitchen SlideoutOn Model - GT 349118069 - Kitchen SlideoutOn Model - GT 340114797 - Kitchen SlideoutOn Model - GT 375112809 - Main Room SlideoutOn Models - GT 323; GT 326; GT 342;GT 359; GT349118126 - Main Room SlideoutOn Models - GT 388; GT 340; GT 350124244 - Bedroom SlideoutOn Models - GT 323; GT 326; GT 342;GT 359; GT 370; GT 375; GT 340; GT 349124244 - Bedroom SlideoutOn Model - GT 3507

SLIDEOUT RETURNMAIN ROOMF-TYPE FITTINGORANGE HOSELEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSEBEDROOM SLIDEOUTCYLINDER LOCATIONELBOW FITTING-PORT 5PURPLE W/WHITE STRIPE WIREBLACK HOSERIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSEISOLATOR VALVE LOCATIONGREEN WIRESLIDEOUT RETURNELBOW FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLFLOW DIVIDERPRESSURE SWITCHLEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSE8

MOTOR FORWARDBLACK 2 GA.BATTERY POWERWHITEQUICK DISCONNECTFLUSH AND FILLPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYKITCHEN CYLINDER LOCATIONELBOW FITTING-PORT 6TAN WIREBLACK HOSEMAIN ROOM CYLINDER LOCATIONF-TYPE FITTING-PORT 6ORANGE WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSEOEMLEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEFR - GEORGETOWN319MODEL NOS.LIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARYPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDWG. NO.DRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFLIPPERT COMPONENTS, INC. IS PROHIBITED.2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAX149086

BEDROOM SLIDEOUT- (DINETTE ON 3600 GTX)CYLINDER LOCATIONELBOW FITTING-PORT 5PURPLE W/WHITE STRIPE WIREBLACK HOSELEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSESLIDEOUT RETURNBEDROOMSTRAIGHT WITHELBOW FITTINGORANGE HOSERIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSEISOLATOR VALVE LOCATIONGREEN WIRESLIDEOUT RETURNLEFT SIDEELBOW FITTINGORANGE HOSESLIDEOUT RETURNRIGHT SIDEELBOW FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLFLOW DIVIDERPRESSURELEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSELEVELING 2 SLIDEOUTS WITH FLOW DIVIDER(L 2 W/FD)10S

MOTOR FORWARDBLACK 2 GA.BATTERY POWERWHITEPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYQUICK DISCONNECTFLUSH AND FILLMAIN ROOMCYLINDER LOCATIONF-TYPE FITTING-PORT 6ORANGE WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSELEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEFR - GEORGETOWNSWITCHOEM MODEL NOS.-359359RE-370-3600GTXLIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARYPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDWG. NO.DRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFLIPPERT COMPONENTS, INC. IS PROHIBITED.2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAX149084

LEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSEBEDROOM SLIDEOUT CYLINDER LOCATIONELBOW FITTING-PORT 5PURPLE W/WHITE STRIPE WIREBLACK HOSERIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSESLIDEOUT RETURNBEDROOMSTRAIGHT WITHELBOW FITTINGORANGE HOSEISOLATOR VALVE LOCATIONGREEN WIRESLIDEOUT RETURNELBOW FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLLEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSEPRESSURE SWITCH12

MOTOR FORWARDBLACK 2 GA.BATTERY POWERWHITEQUICK DISCONNECTFLUSH AND FILLPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYMAIN ROOM CYLINDER LOCATIONELBOW FITTING-PORT 6ORANGE WIREBLACK HOSEKITCHEN CYLINDER LOCATIONELBOW FITTING-PORT 6TAN WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSELEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEOEMFR - GEORGETOWN340-350B-391MODEL NOS.LIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARY2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAXPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFDWG. NO.149088

LEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSEBEDROOM SLIDEOUTCYLINDER LOCATIONELBOW FITTING-PORT 5PURPLE W/WHITE STRIPE WIREBLACK HOSERIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSEISOLATOR VALVE LOCATIONGREEN WIRESLIDEOUT RETURNLEFT SIDEELBOW FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLSLIDEOUT RETURNBEDROOMSTRAIGHT WITHELBOW FITTINGORANGE HOSEPRESSURE SWITCHLEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSELEVELING 2 SLIDEOUTS NO FLOW DIVIDER(L 2 NO/FD)14

MOTOR FORWARDBLACK 2 GA.EBATTERY POWERWHITEQUICK DISCONNECTFLUSH AND FILLPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYMAIN ROOM CYLINDER LOCATIONELBOW FITTING-PORT 6ORANGE WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSELEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEOEMFR - GEORGETOWN315-350MODEL NOS.LIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARY2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAXPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFDWG. NO.149085

BEDROOM SLIDEOUTCYLINDER LOCATIONELBOW FITTING-PORT 5PURPLE W/WHITE STRIPE WIREBLACK HOSELEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSERIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSESLIDEOUT RETURNBEDROOMSTRAIGHT WITHWITH FITTINGORANGE HOSEISOLATOR VALVELOCATIONGREEN WIRESLIDEOUT RETURNF-TYPE FITTINGORANGE HOSESLIDEOUT RETURNF-TYPE FITTINGORANGE HOSETONFRRREAQUICK DISCONNECTFLUSH AND FILLLEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSEPRESSURESWITCHFLOW DIVIDERLEVELING 3 SLIDEOUTS WITH FLOW DIVIDER(L 3 W/FD)16

MOTOR FORWARDBLACK 2 GA.BATTERY POWERWHITEPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYKITCHEN CYLINDER LOCATIONF-TYPE FITTING-PORT 6TAN WIREBLACK HOSEMAIN ROOM CYLINDER LOCATIONF-TYPE FITTING-PORT 6ORANGE WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSEOEMFR - GEORGETOWNMODEL NOS.LEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDWG. NO.DRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFLIPPERT COMPONENTS, INC. IS PROHIBITED.LIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARY2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAX149087

LEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSERIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSEISOLATOR VALVE LOCATIONGREEN WIRESLIDEOUT RETURNLEFT SIDEELBOW FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLLEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSEPRESSURE SWITCHLEVELING 1 SLIDEOUT NO FLOW DIVIDER(L 1 NO/FD)18

MOTOR FORWARDBLACK 2 GA.BATTERY POWERWHITEPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYQUICK DISCONNECTFLUSH AND FILLMAIN ROOM CYLINDER LOCATIONELBOW FITTING-PORT 6ORANGE WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSELEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEOEMFR - GEORGETOWN338MODEL NOS.LIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARYPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDWG. NO.DRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFLIPPERT COMPONENTS, INC. IS PROHIBITED.2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAX149083

LEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSEBEDROOM CYLINDER LOCATIONF-TYPE FITTING-PORT 5ORANGE WIREBLACK HOSERIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSESLIDEOUT RETURNLEFT SIDEF-TYPE FITTINGORANGE HOSESLIDEOUT RETURNRIGHT SIDEF-TYPE FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLFLOW DIVIDERLEVELING JACKS RETURNPRESSURE SWITCHF-TYPE FITTINGORANGE HOSELEVELING 2 SLIDEOUTS WITH FLOW DIVIDER(L 2 W/FD)20

MOTOR FORWARDBLACK 2 GA.BATTERY POWERWHITEQUICK DISCONNECTFLUSH AND FILLPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYMAIN ROOM CYLINDER LOCATIONF-TYPE FITTING-PORT 6ORANGE WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSELEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEOEMFR - GEORGETOWNMODEL NOS.373LIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARYPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDWG. NO.DRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFLIPPERT COMPONENTS, INC. IS PROHIBITED.2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAX145941

RIGHT REAR JACK LOCATIONELBOW FITTING-PORT 3RED WIREBLACK HOSELEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIREBLACK HOSEISOLATOR VALVELOCATIONGREEN WIRESLIDEOUT RETURNBEDROOMELBOW FITTINGORANGE HOSESLIDEOUT RETURNROAD SIDEELBOW FITTINGORANGE HOSESLIDEOUT RETURNROAD SIDEELBOW FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLFLOWDIVIDERSLIDEOUT RETURNMAIN ROOMELBOW FITTINGORANGE HOSEPRESSURE SWITCHLEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSE22

MOTOR FORWARDBLACK 2 GA.BEDROOM SLIDEOUT LOCATIONELBOW FITTING-PORT 7PINK WIREBATTERY POWERBLACK HOSEWHITEPUMP RETRACTBLACK w/STRIPEQUICK DISCONNECTBATTERY GROUNDFLUSH AND FILL BLACK & BROWN DOUBLE WIREBLACK SINGLE WIREMOTOR REVERSEBLACK 2 GA.PUMP EXTENDGRAYMAIN ROOM CYLINDER LOCATIONELBOW FITTING-PORT 6ORANGE WIREBLACK HOSEMAIN ROOM CYLINDER LOCATIONF-TYPE FITTING-PORT 6ORANGE WIREBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSEFR - GEORGETOWN357QSLEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSELIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARY2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAXPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFLIPPERT COMPONENTS, INC. ISDWG. NO.179866

ISOLATOR VALVE LOCATIONGREEN WIRELEFT REAR JACK LOCATIONELBOW FITTING-PORT 1BLUE WIRERIGHT REAR JACK LOCATIONBLACK HOSEELBOW FITTING-PORT 3RED WIREBLACK HOSEQUICK DISCONNECTFLUSH AND FILLSLIDEOUT RETURNLEFT SIDEELBOW FITTINGORANGE HOSESLIDEOUT RETURNRIGHT SIDEELBOW FITTINGORANGE HOSEQUICK DISCONNECTFLUSH AND FILLFLOW DIVIDERLEVELING JACKS RETURNF-TYPE FITTINGORANGE HOSEPRESSURE SWITCHLEVELING 1 SLIDEOUT WITH FLOW DIVIDER24(L 1 W/FD)

MOTOR FORWARDBLACK 2 GA.BATTERY POWERWHITETPUMP RETRACTBLACK w/STRIPEBATTERY GROUNDMOTOR REVERSEBLACK & BROWN DOUBLE WIREBLACK 2 GA.BLACK SINGLE WIREPUMP EXTENDGRAYMAIN ROOM CYLINDER LOCATIONF-TYPE FITTING-PORT 6ORANGE WIRBLACK HOSERIGHT FRONT JACK LOCATIONELBOW FITTING-PORT 4PURPLE WIREBLACK HOSELEFT FRONT JACK LOCATIONELBOW FITTING-PORT 2GREEN WIREBLACK HOSEFR - GEORGETOWN359WHREGLIPPERT COMPONENTS, INC.A LIPPERT COMPONENTS SUBSIDIARY2766 COLLEGE AVE.GOSHEN, IN 46528(574) 535-2085 PHONE(574) 534-7618 FAXPROPRIETARY ANDTHE INFORMATION CONTAINED IN THISDRAWING IS THE SOLE PROPERTY OFLIPPERT COMPONENTS, INC. ANYREPRODUCTION IN PART OR AS A WHOLEWITHOUT THE WRITTEN PERMISSION OFDWG. NO.139288

CONTROLS-LEVELING SYSTEMLEVELING FEATURES Automatic extension of jacks from full retract position (with automaticground detection).Automatic leveling of jacks.Manual leveling of jacksAutomatic retraction of jacks (with automatic full retract detection).Air bag suspension features (configurable on/off).Emergency retract/User alarm mode (jacks not retracted and park brakedisengaged).Automatic jack error detection and error mode.Configuration mode for Air features.Configurations mode for Leveling Zero Point.SYSTEM WIRING REQUIREMENTS Battery power (2 ga. SAE J1127. Type SGX).Battery ground (2 ga. SAE J1127. Type SGX).Logic power (switched via ignition)Power brake signal (open park brake disengaged, GND park brakeengaged).4-wire harness connecting Controller to Touch Panel.Jacks status input-Switched to GNDJacks not all up – switch closed to groundJacks all up – switch openAIR AND AUXILIARY FEATURESSystem has the option to control external Air and Auxiliary features.When enabled, the feature works according to the following logic: Air bag pressure automatically lowered when starting the auto or manualsequence to maximize lift of jacks. An Auxiliary mode activated when starting an auto retract sequence to fillair bags. Auxiliary is active when jacks are all retracted and park brake isdisengaged to fill airbags.26

LEVEL ZERO POINT CALIBRATIONBefore auto-leveling features are available, the Level Zero point must be set.This is the point to which the system will return when an auto leveling cycle isinitiated.To set the zero point (controller module must be fully secured in production intentlocation), first run a manual leveling sequence to get the vehicle to the desiredlevel point. Then activate the Level Zero point configuration mode.This mode is enabled by performing the following sequence:1. Turn panel off. Then turn panel on.2. Perform the following:-Press the FRONT switch 5 times.-Press the REAR switch 5 times.3. At this point all LED outputs will blink, and the buzzer will be off.4. You are now in IDLE mode ready to set Zero Point.5. With a carpenter’s level, manually level the coach. This will give theleveling controls the reference point for the Zero Point Configuration.6. When coach is completely leveled manually press the RETRACT ALLswitch 3 times to set the zero point.For DIESEL UNITS with Airbag Suspensions ONLY:NOTE: You may also enter zero mode per above at anytime the system isin IDLE mode. The user then has control to extend any pair of jacks whilein zero mode in order to position the vehicle properly prior toprogramming.AIR AND AUXILIARY FEATURE CONFIGURATIONFor DIESEL UNITS with Airbag Suspensions ONLY: Feature is entered ONLY after zero mode programming.At this point the WAIT LED will blink for 20 seconds. You are now in Air/Auxiliary Feature Configuration mode.To enable Air Auxiliary features, perform the following: Press the RETRACT ALL switch 3 times User must do this within 20 seconds of entering this mode.To disable Air features, perform the following: Do nothing After 20 seconds, module will exit mode with features disabled.27

ERROR MODEIf any problem is detected with the jacks, the system will enter error mode. Errormode may be recognized by the blinking of LEFT, LEVEL and RIGHT LEDs.The following errors are detected by this system: Jack over current/short circuit. Jack under current/ open circuit. Jack extending too long (ground not detected after 2 min.). Jack retracting too long (fully retracted not detected after 2 min.). Out of stroke detection during auto cycle (if enabled).The user must respond by pressing ON/OFF switch, which resets operation.All normal features are disabled in Error mode.If panel loses communication with the controller for more than 5 seconds, thepanel will blink the JACKS DOWN, PARK BRAKE andON/OFF (if included) LEDs.USER ALARM MODEIf the alarm system detects that the park brake has been disengaged while atleast one jack is not fully retracted and the sensor value changes in any axismore than a predefined amount, the panel will signal this error to the user.When in alarm mode, all LEDs will flash and the buzzer will beep. The StatusLEDs will show the system status.The system performs an automatic retract.No other features are available in this mode.28

MISCELLANEOUS The system will automatically shut down after 4 minutes of no operation.Auto leveling cycle cannot be started until all jacks are fully retracted.Make sure jacks are retracted before attempting to auto level (unit willperform full retract automatically if jacks are not down on the request ofan auto cycle).System will refuse any operation when a low voltage condition is present.System will automatically alarm and retract if park brake is disengagedand jacks are not retracted with any change in sensor readings. In alarmmode, the only available feature is to retract all jacks.Please note the Wait LED shows the status of Air/ Auxiliary features.Please note that the LEDs blink differently when in special controller modes(error, alarm, and configuration). Learning how to recognize these modes isimportant. Excess slope LED blinks whenever the Y axis (vehicle length) is over5o from programmed level point.“LATCHED OUT” WARNINGFLASHINGLCILATCHED ERROR mode is “WAIT,” “JACKS DOWN,” “PARK BRAKE,” “EXCESSSLOPE” AND “LOW VOLTAGE” lights flashing.1.2.3.4.Battery voltage below 10.0V DC.Retract time over 67 seconds in auto retract.This is the only LATCHED ERROR MODE.All revisions prior to “G” controllers treat this error as regular ERRORmode.To RESET, push all 4 diamond-shaped jack buttonsat the same time.29

30EXCESS ANGLE LED-COACH MAY NOT BEABLE TO BE LEVELED IN CURRENT LOCATIONAND MUST BE MOVED TO A MORE LEVELLOCATION.ENGAGE PARK BRAKE LED-FLASHESWHEN PARK BRAKE IS DISENGAGED; OFFWHEN PARK BRAKE HAS BEEN ENGAGEDLOW VOLTAGE LED-INDICATES VOLTAGEHAS DROPPED BELOW SAFE OPERABLELEVEL.JACKS DOWN LED-INDICATES JACKS AREIN ANY VARIOUS STATE OF EXTENSIONAND NOT FULLY RETRACTED.WAIT LED-INDICATES TO THE OPERATORTO PAUSE PRIOR TO OPERATING THESYSTEM. RESUME OPERATION WHENTHE LED GOES OFF.LEFT BUTTON-CONTROLS EXTENSIONAND RETRACTION OF LEFT REAR JACK.MANUAL OPERATION LED- INDICATESCONTROLS CAN BE OPERATEDMANUALLY TO LEVEL COACH.WAITAUTOLEFTEXCESS ANGLEREARFRONTALLJACKSRETRACTRIGHTONOFFFig. 4READ AND UNDERSTAND OPERATORS MANUAL BEFORE USINGDO NOT USE JACKS FOR TIRE REMOVAL OR VEHICLE SERVICE.ENGAGE PARK BRAKELOW VOLTAGEJACKS DOWNMANREAR BUTTON-CONTROLS EXTENTION ANDRETRACTION OF BOTH REAR JACKS.RETRACT ALL JACKS BUTTON- RETRACTSALL JACKS AUTOMATICALLY.SEE PAGE 16 FOR RETRACT PROCEDURESRIGHT BUTTON- CONTROLS EXTENTIONAND RETRACTION OF RIGHT REAR JACK.COACH LEVEL LED- INDICATES THATCOACH HAS BEEN LEVELED.ON/OFF BUTTON- TURNS LEVELINGSYSTEM ON AND OFF.FRONT BUTTON- CONTROLS EXTENTION ANDRETRACTION OF BOTH FRONT JACKS.AUTOMATIC OPERATION LED- INDICATESCONTROLS CAN BE OPERATEDAUTOMATICALLY TO LEVEL COACH.LCI ELECTRONIC LEVELINGAUTOMATIC OPERATION BUTTON- PLACESCONTROL PANEL IN AUTOMATIC MODE.CAUTION!MANUAL OPERATION BUTTON- PLACESCONTROL PANEL IN MANUAL OPERATION MODE.CONTROL PANEL

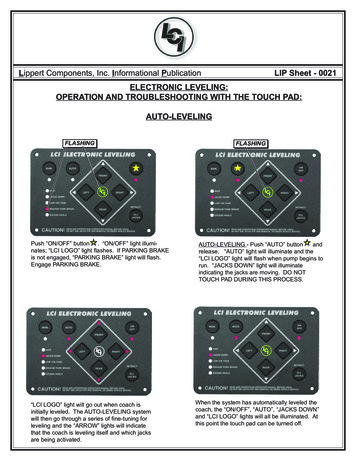

OPERATIONSELECTING A SITEWhen the coach is parked on an excessive slope the leveling requirements mayexceed the jack lift stroke capability. If the coach is parked on an excessive slope,the coach should be moved to a more level surface before the leveling system isdeployed.AUTOMATIC LEVELING PROCEDURENOTE: REFER TO FIG. 4 FOR QUESTIONS REGARDING LOCATION ANDFUNCTIONS OF THE LIPPERT COMPONENTS, INC.ELECTRONIC LEVELING SYSTEM.NOTE: Coach must be running for LCI Electronic Leveling System tooperate.1. Push ON/OFF button on Control Panel. The system is now operationaland the electronic level lights will become active.2. Check to see that the Control Pad ENGAGE PARK BRAKE light is notflashing.NOTE: Engage Parking Brake if ENGAGE PARK BRAKE light isflashing.3. Push the AUTO button to begin the automatic leveling cycle.WARNING: After starting the automatic leveling cycle it is very important thatyou do not move around in the coach until the unit is level and thegreen LCI logo light illuminates in the center of the touch pad.Failure to remain still during the leveling cycle could have anaffect on the performance of the leveling system.4. If further adjustments are necessary, simply push and hold the MANbutton for approximately 5 seconds until the light under this button isilluminated. Push the appropriate leg button to override the system andlevel the coach to your liking.WARNINGARNING!NEVER LIFT ALL THE WHEELS OFF THE GROUNDTO LEVEL THE COACH!Lifting all wheels of the ground may resultin serious personal injury or death.5. Push ON/OFF button to de-energize the system.31

MANUAL LEVELING PROCEDURESNOTE: When leveling your coach, the coach should be leveled fromFRONT TO REAR first (step 2-4). When the coach is level fromFRONT TO REAR, then level the coach from LEFT TO RIGHT(step 5).NOTE: Coach must be running for LCI Electronic Leveling System tooperate.1. Push ON/OFF button on control panel. The system is now operational and theON/OFF light will be lit. If ON/OFF light is not lit, see PRIOR TO OPERATION,page 4.2. Push and hold MAN button for 5 seconds.3. Push FRONT button until jacks contact the ground.4. Push REAR button until jacks contact the ground.5. Push button FRONT or REAR; if bubble is towards front of coach push REARbutton; if bubble is towards rear of coach, push FRONT button. Keep buttondepressed until bubble is centered.6. Push LEFT or RIGHT button; if bubble is towards left of coach, push RIGHTbutton; if bubble is towards right of coach push LEFT button. Keep buttondepressed until bubble is centered in vial.NOTE: The right and left jacks are used to level the coach side to side.Pushing the LEFT button on the control panel will extend both leftjacks. Pushing the RIGHT button on the control panel will extendboth right jacks. Jacks always work in pairs, both front jackstogether, both right side jacks, etc.7. Repeat steps 2 through 5 if needed.8. Turn power off to leveling system by pushing ON/OFF button.9. Visually inspect all jacks to ensure all shoes are touching ground.Should one of the rear jack shoes not be touching the ground, press thecorresponding LEFT or RIGHT rear jack buttons to lower thecorresponding jack to the ground.WARNINGARNING!NEVER LIFT ALL THE WHEELS OFF THE GROUND TO LEVEL THE COACH!Lifting all wheels of the ground may result in serious personal injury or death.32

JACK RETRACT PROCEDURES1. Energize the system by pushing ON/OF

professional be employed to change the tire on the coach. any attempts to change tires or perform other service while coach is supported by the lippert electronic leveling and slideout system could result in damage to the motor home and/or cause serious injury or death. warning! - be sure to park the coach on solid, level ground. warning!