Transcription

Air Valve Basic TrainingOWEA Collection System SpecialtyConferenceDan Barr, PEBurgess & Niple, Inc.

Overview Why Air Valves?Types of ValvesValve LocationsSizing ValvesValve SpecificationsInstallationsQuestions

Overview Information based on:– AWWA Manual of Water Supply Practices M51Air‐Release, Air/Vacuum & Combination Air Valves– Manufacturers' published information– Our experience in design and the field

Why Air Valves?

Why Air Valves?Effects of Air and Vacuum Pockets in Pipelines Higher Headloss and Binding Pipe Breaks Erratic operation of pumps, meters, andcontrol valves Collapsed pipes

Why Air Valves?Sources of Air Entry in Pipelines Dissolved Air or Gas (2% at 1 atm) Air Valves Pumps Filling Empty Pipelines

Why Air Valves?Sources of Vacuums in Pipelines Draining Pipelines Water Hammer

Types of Air Valves

Simple, right?Super High Capacity Compound Lever Air Release ValveDual Body Wastewater Combination Air Valve w/ High Capacity Air ReleaseAir and Vacuum ValveStainless Steel Air & Vacuum ValveWastewater Combination Air Valve Pressure Sewer Air Release Valve Universal Air Release Valve“Minimatic” Air Release ValveWastewater Air/Vacuum ValveSewage Air ValvesSlowClosing Air/Vacuum Valves KINETIC Air & Vacuum Valve to 4“KINETIC Slow‐Closing Air & Vacuum ValveFoot Valve Simple Lever Air Release ValveCombination Vacuum Breaking and Air Release ValveLow Vol. Pressure Air Release ValveShort Body Wastewater Air & Vacuum ValveAir and Vacuum Sewer Valve Negative Pressure ValvePressure Air Release ValveHydraulically Controlled Air/Vacuum ValvesMidget ValveHigh Capacity Simple Lever Air Release Valve Single Body Wastewater Combination Air ValveAir Valves for Vertical Turbine Pumps High Capacity Wastewater Air Release ValveWell Service Air ValveUniversal Sewer Air Release ValveVacuum Relief Air Inlet ValvesAir Release Valve (Simple Lever Type)Stainless Steel Single Body Wastewater Combination Air ValveAll Stainless Steel Air Release ValveKINETIC Custom Slow Closing Combination Air ValveWastewater Air & Vacuum ValveHigh CapacityCombination Air Valve (Single Housing Type)Compound Lever Air Release ValveAir Release Valve (Compound Lever Type)Stainless Steel Wastewater Combination Air ValveDeep Well Valve Compact KINETIC Combination Air ValveAir Release Valves (Sewage)Short Body Wastewater Air Release Valve Vacuum Relief ValveVacuum Breaking ValveDual Body Wastewater Combination Air ValveCombination Air ValveSewage Air Release ValveBody Wastewater Combination Air ValveKINETIC Custom Combination Air Valve Short CombinationSewer ValveVacuum Relief Air Valve Compound Lever Air Release ValveKINETIC Deep Well Pump Air & Vacuum ValveDual Air Valve KINETIC Slow Closing Combination Air ValveAir/Vacuum Valve w/ Optional Surge Suppression ValveWastewater Air Release ValveCombination Vacuum Breaking and Air Release Valve for Wastewater KINETIC Combination Air Valve

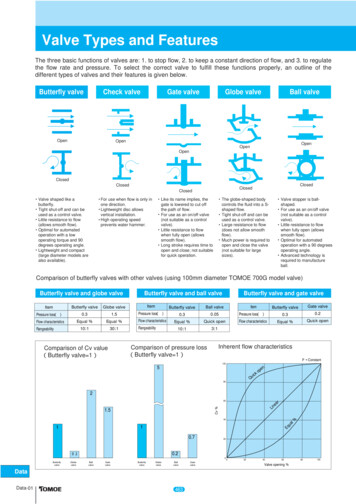

Types of Air ValvesThree Basic Types Air Release Valves Air / Vacuum Valves Combination Air Valves

Air Release Valves Automatically releases small pockets ofaccumulated air while the pipeline operatesunder pressure.

Air Release Valve Operation Pipeline FlowingAir TrappedAir ReleasedRepeat Cycle

Air / Vacuum Valves Designed to automatically:– Exhaust large quantities of air during pipelinefilling.– Admit large amounts of air when the internalpressure drops below atmospheric.

Air / Vacuum Valve Operation Pipe FillsEmpty Valve OpenCloses

Air / Vacuum Valve Operation Pipe Drains Air Intake

Air / Vacuum Valve Cycle Pipe DrainsEmptyFills AirValveIntakeClosesOpen

Combination Air Valves Perform both as air release and air/vacuumvalves.

Combination

Combination Air Valve Operation

Locating Air ValvesAlong a Pipeline(Or Thinking like an Air Bubble)

Locating Air ValvesInstall valves where airwill be trapped orvacuum pockets willform!

Locating Air ValvesAlong a Force MainLift StationManholePumps Operating and Line is Full

Locating Air ValvesAlong a Force MainLift StationManholePumps Operating and Line is Full

Locating Air ValvesAlong a Force MainAir ReleaseLift StationAir ReleaseManholePumps Operating and Line is Full

High PointsPotential VacuumLift StationManholePumps Stopped and Line is Draining

High PointsLift StationManholePumps Start and Vacuum Pockets Close with Pressure Spikes

High PointsCombination Air ValveLift StationCombination Air ValveManholePumps Stopped, Line is Drained, and High Points are Full of Air

High PointsManholeLift StationAny Air Valves?

High PointsManholeLift StationNo Vacuum Points!

High PointsAir TrappedLift StationManhole

High PointsAutomatic Air ReleaseLift StationManual Air ReleaseManhole

Pumps Carefully review deep pump installationswhen over 20 feet deep. May need Air/Vac valve Examples include: vertical turbines and deepsubmersibles.

Pumps Line Full Pump On

Pumps Pump Off Vacuum Develops

Pumps Pump Turns On Pumps AgainstVacuum Slams CheckValve

Pumps Add Air/Vac Valve Air Enters System toEliminate Vacuum

Pumps Add Air/Vac Valve Air Enters System toEliminate Vacuum Air Released atControlled Rate

Sizing Valves

Air Release Convert pipeline flow rate to Cubic Feet perMinute (CFM). Multiply CFM by 0.02 to estimate dissolved airin water. Determine the working pressure at the valve. Refer to Orifice Air Capacity Table in AWWAmanual or manufacturer tables.

Air Release

Air/Vac Valves Determine required valve size for both fillingand draining independently Use the larger diameter for air/vac valve sizing

Pipeline Filling Calculate the venting flow rate in CFM.Venting Flow Rate Fill Rate (CFM) * [(PressureDifferential across valve 14.7 psi)/14.7 psi] Refer to sizing tables to select Air/Vac valvediameter. Use a 2 psi differential generally.

Pipeline Filling

Pipeline Draining or VacuumPrevention Determine the allowable negative pressure forthe pipeline with a safety factor. Assume 5.0psi for a max. Calculate the slope of the pipeline in ft/ft. Use following figure to determine therequired CFM. Refer to table to select the required air/vacvalve diameter.

Pipeline Draining or VacuumPreventionTable for Determining Air Flow when Draining Pipelines

Pipeline Draining or VacuumPreventionTable for Sizing Air/Vac Valves when Draining Pipelines

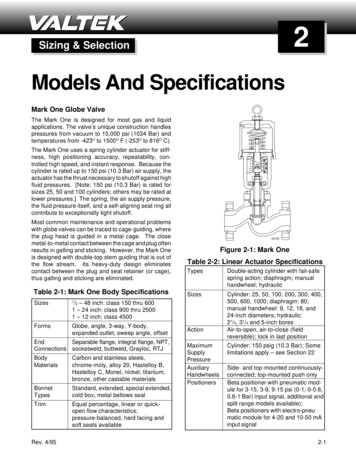

Valve Specifications

Air Release Valves Orifice Size (1/16” to 1”)NPT Inlet size (1/2” to 3”)Maximum Working Pressure (75 psi and up)Minimum Sealing Pressure (softer seats neededwhen under 25 psi) Valve Materials (Ductile or Cast Iron, St. Stl) Accessories (check valve, back flush, flowregulators, etc.) Service (Wastewater or Clean Water)

Air/Vac Valves Similar to Air Release ValvesInlet/Outlet sizes (1” to 20”)Type of Connections (NPT and Flanged)Maximum Working Pressure (150 to 300 psi)

Combination Air Valves All of the above Body Configuration (Single versus Dual)Dual BodySingle Body

Installation and O&M

Installation Connections– Inlet piping and isolation valve should besame size as valve inlet– Short Inlet Piping and Vent Lines

Installation Location– Need protection from freezing,contamination, flooding, and vandalism– Needs access– Watch valve clearances

Operation and Maintenance Inspections and Flushing–At least annually–More often for valves that operatecontinuously–Watch for external leakage

QUESTIONSDan Barr, PE – dbarr@burnip.com(614) 459‐2050

Slow Closing Air/VacuumValves Vacuum Relief Air Inlet Valves Simple, right? Types of Air Valves Three Basic Types Air Release Valves Air / Vacuum Valves Combination Air Valves. Air Release Valves Automatically releases small pockets of .