Transcription

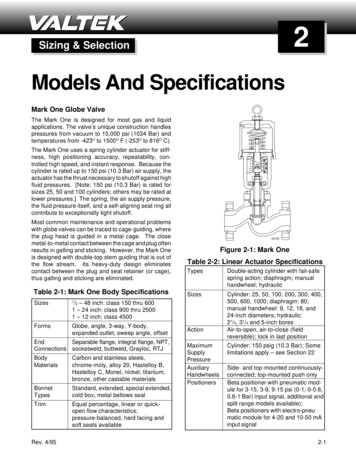

2Sizing & SelectionModels And SpecificationsMark One Globe ValveThe Mark One is designed for most gas and liquidapplications. The valve’s unique construction handlespressures from vacuum to 15,000 psi (1034 Bar) andtemperatures from -423O to 1500O F (-253O to 816O C).The Mark One uses a spring cylinder actuator for stiffness, high positioning accuracy, repeatability, controlled high speed, and instant response. Because thecylinder is rated up to 150 psi (10.3 Bar) air supply, theactuator has the thrust necessary to shutoff against highfluid pressures. [Note: 150 psi (10.3 Bar) is rated forsizes 25, 50 and 100 cylinders; others may be rated atlower pressures.] The spring, the air supply pressure,the fluid pressure itself, and a self-aligning seat ring allcontribute to exceptionally tight shutoff.Most common maintenance and operational problemswith globe valves can be traced to cage-guiding, wherethe plug head is guided in a metal cage. The closemetal-to-metal contact between the cage and plug oftenresults in galling and sticking. However, the Mark Oneis designed with double-top stem guiding that is out ofthe flow stream. Its heavy-duty design eliminatescontact between the plug and seat retainer (or cage),thus galling and sticking are eliminated.Table 2-1: Mark One Body SpecificationsFigure 2-1: Mark OneTable 2-2: Linear Actuator SpecificationsTypesDouble-acting cylinder with fail-safespring action; diaphragm; manualhandwheel; hydraulicSizesCylinder: 25, 50, 100, 200, 300, 400,500, 600, 1000; diaphragm: 80;manual handwheel: 9, 12, 18, and24-inch diameters; hydraulic:21/2, 31/4 and 5-inch boresAir-to-open, air-to-close (fieldreversible); lock in last position1Sizes/2 – 48 inch: class 150 thru 6001 – 24 inch: class 900 thru 25001 – 12 inch: class 4500FormsGlobe, angle, 3-way, Y-body,expanded outlet, sweep angle, offsetEndSeparable flange, integral flange, NPT,Connections socketweld, buttweld, Grayloc, RTJBodyMaterialsCarbon and stainless steels,chrome-moly, alloy 20, Hastelloy B,Hastelloy C, Monel, nickel, titanium,bronze, other castable materialsBonnetTypesStandard, extended, special extended,cold box, metal bellows sealTrimEqual percentage, linear or quickopen flow characteristics;pressure-balanced, hard facing andsoft seats availableRev. heelsPositionersCylinder: 150 psig (10.3 Bar); Somelimitations apply – see Section 22Side- and top-mounted continuouslyconnected; top-mounted push onlyBeta positioner with pneumatic module for 3-15, 3-9, 9-15 psi (0-1, 0-0.6,0.6-1 Bar) input signal, additional andsplit range models available);Beta positioners with electro-pneumatic module for 4-20 and 10-50 mAinput signal2-1

Table 2-3: Trooper Body Specifications1, 11/2, 2, 3 and 4-inch,ANSI Class 150 and 300FormGlobeMaterials Carbon and stainless steelEndIntegral flange; NPT or socketweld forConn.1 thru 2-inch onlyTrimEqual percentage or linear available in316 Stainless Steel, 316 with TFE seat,316 with stellite, 416 heat-treatedPacking Teflon, AFP, SafeGuard and SureGuardBonnetStandard and Purge with twin packingTypesFlowFlow-under with air-to-open orair-to-close fail directionSizesE0151Table 2-4: Diaphragm ActuatorSpecificationsFigure 2-2: TrooperSizesTrooper Globe ValveThe Valtek Trooper valve is a high performance generalservice control valve with a high thrust diaphragmactuator. It is designed for use in ANSI Class 150 or 300service applications with temperatures ranging from-20 to 650 F (-30 to 345 C).In addition to its high thrust, the reversible actuator iscompact. An optional integral I/P or P/P positionerensures high positioning accuracy proportional to thevalve instrument signal. The integrally mounted positionereliminates external tubing requirements, reduces pinchpoints and keeps moving parts safe from external dirtand damage. Reversing actuator does not requirepositioner or tubing changes, extra parts, etc.The actuator accepts air supply pressures up to 60 psig(4 Barg) which allows the valve to shutoff against highpressure drops. Different spring sets are available tomeet individual application requirements. Removingthe reversible actuator from the valve is easy withValtek’s unique yoke design and yoke clamps.Many of Valtek’s standard Mark One valve features areincluded in the Trooper general service valve, including:heavy-duty, stem guides; self-centering, clamped-inseat ring; raised face integral flanges; multiple trimreductions and easy top-entry valve accessibility.The Trooper valve is available in 1, 11/2, 2, 3, 4-inch valvesizes and with carbon steel or stainless steel bodies.Valve sizes 1 thru 2-inch are also available in socketweldor NPT end hragm area: 31 and 77.5 in2(200 and 500 cm2)Air-to-open, air-to-close, reversible20 - 60 psig (1.4 - 4 Barg)Optional integral I/P or P/P positioner with 4-20 mA or 3-15 psig (0-1Barg) input signalSpring Set3-15, 4-13, 7-16, 13-27, 14-31,Range (psig) 20-43, 25-54MaterialActuator Cases – AluminumDiaphragms – CR w/ polymide fabricAccessories Top-mounted handwheel, 3-way solenoid valve, Position Pac, ExternalI/P (explosion proof), filter regulator

E0152Figure 2-3: ValdiskValdisk Rotary ValveValdisk is a lightweight rotary-style control valve designed with an eccentric and cammed disk that provideshigh capacity, tight-shutting, high-performance service.It performs at pressures from vacuum to 1000 psi, andtemperatures from -423 to 1200 F (-253 to 650 C).over-stroking and damage to the seat and to identifydisc position after line installation. The disk pulls awayfrom the seat immediately upon opening, permittingbetter throttling and minimizing seat wear.Valdisk’s wafer-style body permits easy handling. Ashort face-to-face dimension permits shorter flangebolts. (Long bolts increase the chance of leakage duringexternal fires.) Each body has a disk stop to preventThe rotary-motion cylinder actuator is similar to thelinear-motion actuator on the Mark One. Many parts areinterchangeable between the two designs, such as thecylinder and O-rings. The actuator is attached to theshaft by a single pivot point, minimizing lost motion.Table 2-5: Valdisk Body SpecificationsTable 2-6: Rotary Actuator SpecificationsSizes2 – 36 inchRatingsStyleMaterialsANSI Class 150 – 2500In-line waferCarbon and stainless steels,chrome-moly, alloy 20, Hastelloy B,Hastelloy C, Monel, nickel, titanium,bronze, other castable materialsSeat FormsSoft seat, metal seat, soft seat withmetal back-upDiscModified equal percent (inherent),Characteristics linear (easily characterizablewith positioner cam)Stand. & Opt. 2 – 12 inch: class 150, 300Class of Disc 14 – 30 inch: class 150Shaft17 – 4 PH, Nitronic 50, Inconel,MaterialsMonel, Hastelloy CNOTE: Valtek also manufactures Valdisk valves for high pressureor high temperature applications.TypesDouble-acting cylinder with fail-safespring action; Toggle-link cylinder,electric, hydraulic, electro-hydraulicSizesCylinder sizes: 25, 50, 100 and 200ActionAir-to-open, air-to-close, fail-in-place(field reversible)Max. Supply 150 psig (10.3 Barg) for sizes 25, 50Pressureand 100. 80 psig (5.5 Barg) size 200actuator only (Some limitations applysee Section 16)AuxiliaryDeclutchable; manual gear-operated;Handwheels, 12-inch handlever (sizes 1 thru 6-inch)Handlevers 18-inch handlever (sizes 8 and 10-in.)PositionersBeta and Model 80R pneumaticpositioners; Beta I/P and Model 80Relectro-pneumatic positioners (SeeTable 2-2 for input signals.)2-3

E0153E0168Figure 2-4: Valdisk 150Valdisk 150 Rotary ValveThe Valdisk 150 high-performance rotary valve is designed to control ANSI Class 150 processes. It is available in a wafer or lug-style body providing tight shutoff ata low cost with quick delivery schedules.The Valdisk 150 rotary valve is available in size 2 thru36-inches with an operating temperature range of -100 to 400 F (75 to 205 C).Table 2-7: Valdisk 150 Body SpecificationsSizes (inches)Body FormsBody RatingShutoff RatingOperatingTemperatureFire SeatRatingActuatorTypesPositionerSignals2-42 – 36-inchWafer, lugANSI Class 150ANSI Class VI-100 to 400 F (-73 to 204 C);-20 F (-29 C) for carbon steelAPI 607Pneumatic (sq.in.): 25, 50, 100,200; electro-pneumatic; manual(see rotary actuator specifications,page 8)Pneumatic: 3-15, 3-9, 9-15 psig(0-1, 0-0.6 and 0.6-1 Barg), additional range and split-range modelsavailable; electo-pneumatic:4-20, 10-50mAThe typical liquid pressure recovery factor (FL) of theValdisk 150 rotary valve is better than most butterflyvalves, reducing the tendency to cavitate or choke.The Valdisk 150 has an eccentric-cammed disc thatrotates out of the seat upon opening. This double-offsetdisc design reduces seat wear and leakage and allowsa low breakout torque requirement.A floating self-centering seat is held in place by aninternal seat retainer that increases sealing capacity asit aligns with the disc.Table 2-8: Materials of ConstructionBody, disc,retainerCarbon steel, stainless steel, Alloy 20,Hastelly C, Inconel, Monel, nickelShaft17-4 PH (std.), stainless steel,Alloy 20, Hastelloy C, Inconel, Monel,Nitronic 50BearingRyload (rolled stainless steel withTeflon insert)PackingTeflon V-ring (std.), Grafoil,SafeGuard, SureGuardSeatTeflon energized with Viton O-ring

E0004aFigure 2-5: MaxFloMaxFlo Rotary Plug ValveThe MaxFlo is a high performance rotary control valveusing an eccentric plug which provides high rangeability,zero breakout torque and durable trim with a significantincrease in valve life.Designed for use in a wide variety of applications ranging from petrochecmical to low content slurry and pulpservice to severe service, the MaxFlo can handle pressure drops up to 1450 psig (100 Barg). Operationtemperatures can range from -150 F to 800 F (-100 Cto 430 C).The eccentric plug provides rangeability greater than100:1, compared to 50:1 for typical globe valves and20:1 for most butterfly valves. The shutoff rating reachesClass IV for metal seats and Class VI for soft seats.NACE certification is also available.MaxFlo will fail either open or closed in the event of airor signal loss. Flow with the shaft upstream for failclosed and shaft downstream for fail-open.A high thrust cylinder actuator and eccentric plug allowhigh flow capacities in rugged applications giving Valtek'sMaxFlo rotary control valve the advantage.Table 2-9: MaxFlo Body centric rotary plug1 – 12-inchANSI Class 150, 300, 600Stainless steel, carbon steelFlanged, flangeless17-4 (std.), 316L with Stellite overlay17-4 (std.), 316L with Stellite overlayPTFE (soft)Teflon V-ring, Braided TFE/Kevlar,Grafoil, SafeGuard, SureGuardHigh thrust cylinder sizes 25, 50 100,200-square inch and manualPositioner Beta positioner with pneumatic orelectro-pneumatic module2-5

E0154Figure 2-6: ShearStreamShearStream Ball ValveThe Valtek ShearStream ball valve features a segmented V-notch ball to reduce clogging, to improveshearing action and to exceed 300:1 rangeability. Theone-piece body provides high performance by preventing piping forces from altering the seat tightness (as isthe case with two-piece bodies).ShearStream’s bi-directional Flex-locTM seal is pressure-assisted to provide better than ANSI Class IVshutoff with a metal seal and bubble-tight shutoff with asoft seal. A flow ring is also available for throttlingapplications with Class II leakage. The self-centeringseal improves shutoff, allows for easier installation andrequires no shims.ShearStream maintenance is easy. The seal can bereplaced without removing the ball and shaft. The shaftis also serviceable from the outboard end of the valve.The body features a full, uninterrupted gasket surfacefor improved gasket alignment. The actuator and packing box are completely interchangeable with the Valdiskrotary valve.2-6Table 2-10:ShearStream Body SpecificationsSizesRatings1 – 16 inchANSI Class 150, 300, 600: 1,11 2,2, 3, 4, 6, 8, 12-inch;ANSI Class 150, 300: 10, 16-inchStyleEndConnectionsBody MaterialsIn-line ballFlangeless (standard), separableflange, integral flange316 stainless steel, carbon steel,other materials as required317 stainless steel with hardchrome plating, Stellite faced17-4 PH, Nitronic 50Bi-directional Flex-loc metal seal,soft seal, flow ringEqual percentage, linearCounterclockwise (as viewedfrom the actuator)Refer to ValdiskBall MaterialsShaft MaterialsSeal FormsCharacteristicBall Rotation(to open)Actuator

Severe Service ValvesValtek has engineered several special trims to handlehigh pressure drop service. The trims are designed toeliminate cavitation, reduce high noise levels andhandle flashing applications often associated with highpressure drop service.The ChannelStream cartridge uses specially designedchannels and intersecting holes (plenums) in series toprevent single point, large pressure recovery which cancause cavitation and hydrodynamic noise.For less serious cavitation applications, Valtek offers aCavControl retainer that minimizes cavitation damageby controlling the location of imploding vapor bubbles.The MegaStream attenuator reduces gaseous noiselevels up to 15 dBA with staged pressure reductionthrough a series of drilled-hole cylinders.Tiger-Tooth stacks effectively reduce gaseous andhydrodynamic noise levels up to 30 dBA and eliminatethe damaging effects of cavitation in liquids.E0157FLOWFigure 2-9: Tiger-ToothE0155Figure 2-7: ChannelStreamTable 2-11:Severe Service Valve SpecificationsSizes1 – 42 inch thru ANSI Class 6001 – 24 inch thru ANSI Class 25001 – 12 inch thru ANSI Class 4500FormsGlobe, angle, Y-body, expandedoutlet, fabricated angleBodyMaterialCarbon and stainless steels,chrome-moly, alloy 20, Hastelloy B,Hastelloy C, Monel, nickel, titanium,bronze, other castable materialsTrimLiquid Applications: ChannelStreamcartridge, CavControl retainer,Tiger-Tooth; Gas Applications: MegaStream attenuator, Tiger-ToothLinearA

Many of Valtek’s standard Mark One valve features are included in the Trooper general service valve, including: heavy-duty, stem guides; self-centering, clamped-in seat ring; raised face integral flanges; multiple trim reductions and easy top-entry valve accessibility. The Trooper valve is available in 1, 1 1 / 2, 2, 3, 4-inch valve sizes and with carbon steel or stainless steel bodies .