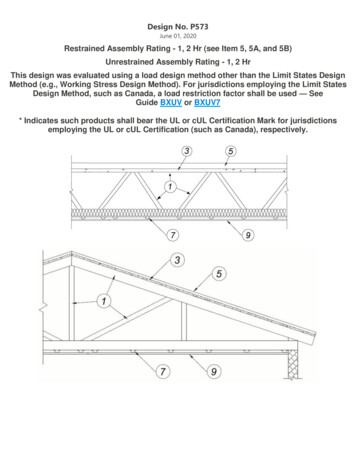

Transcription

Wood TrussesStrength, Economy,VersatilityI n t e r n a t i o n a lBuilding series NO. 2

IntroductionWood trusses are engineeredWood trusses are widely used inframes of lumber joinedsingle- and multi-family residen-together in triangular shapestial, institutional, agricultural andby galvanized steel connectorcommercial construction. Theirplates, referred to commonlyhigh strength-to-weight ratiosas truss plates.permit long spans, offeringgreater flexibility in floor planlayouts. They can be designedin almost any shape or size,restricted only by manufacturingcapabilities, shipping limitationsand handling considerations.Metal plate connected roofwood trusses and increasingly,trusses were first introduced intowood floor trusses are beingthe North American market inused in residential andthe 1950’s. Today, the majoritycommercial applications.of house roofs in Canada and theUnited States are framed withWood truss use is not limited toNorth America. They are gainingacceptance around the worldand are widely used in Europeand Japan.2I n t e r n a t i o n a lBuilding series NO. 2

We’ve Come a Long WayThe first light frame trussesIn the 1950’s the metal connectorwere built on site usingplate transformed the trussnailed plywood gusset plates.industry by allowing efficientThese trusses offeredprefabrication of short and longacceptable spans butspan trusses.demanded considerabletime to build.In North America the wood trussindustry has grown to the pointwhere more than 60% ofresidential roofs are now builtwith wood trusses. In Canada,approximately 95% of newhouses are built with woodroof trusses.When the advantages of woodtrusses are considered, it isnot surprising that their use isincreasing throughout the world. Strength: Trusses providea strong and efficient woodsystem specifically engineeredfor each application. Economy: Through effi- Research has led tocient use of wood and by pro-improved materials, designviding a system that is quicklyprocedures and manufacturinginstalled in the field, woodtechnologies for wood trusses.trusses provide an economicalframing solution. Truss plates used to con-nect the wood pieces together Versatility: Complexshapes and unusual designsare easily accommodated usinghave been optimized forstrength and cost.wood trusses. The versatility of wood trusses makes it anand grading technologies haveexcellent roof framing systemevolved to allow more efficientin hybrid construction whereuse of the wood resource.wood trusses are commonlyused with steel, concrete or Lumber manufacturingComputers have beenmasonry wall systems.widely used to optimize truss turing process more efficient.Environmental: Wood,design and make the manufac-the only renewable buildingmaterial, has numerous environmental advantages. Wood trussesenhance wood’s environmentaladvantages by optimizing wooduse for each specific application.Improvements in materials,design and manufacturingtechnologies have increasedwood truss competitiveness.W o o d T r u s s e s S t r e n g t h , E c o n o m y , Ve r s a t i l i t y3

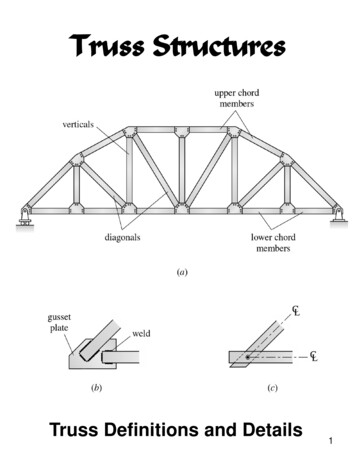

Wood Truss TechnologyTruss Designthe building designer or builderIn North America, designswill contact the truss fabricatorare based on the structuraland installation of a truss. AThe truss design is initiated bywho will supply a fullyrequirements of the Buildingtruss is designed for a specificthe building designer who mustengineered truss. The trussCodes using design standardsapplication, manufacturedspecify; the shape and span ofplate manufacturer usuallyreferenced in the Building Codesin accordance with the trussthe truss, where the truss will bedesigns the truss on behalf ofand approved material properties:design, delivered to thesupported and what the loadsthe truss fabricator.building site and safelyon the truss will be. Typically,There are a number of stepsinvolved in the productioninstalled in accordancewith the design.Figure 1: Truss Nomenclature and Common Truss ShapesPitched (triangular) TrussRoof Trusses:Light trusses are manufac-FinkPanel lengthtured to suit virtually anyLateral bracingTop chordWebsroof profile. Pitched or flat,they are only limited to thePanel pointload arrangements and theBottom chordsupport locations.Truss plateMonoPanel lengthClear spanOverall lenghtScissorsLevel returnoverhandParallel Chord (flat) TrussFlat Trusses:Panel pointTop chordTruss plate4WebBottom chordBearing pointRoom-in-AtticFlat trusses, also known asparallel chord trusses, are analternative to conventionalwood floor joist systems andare a competitive option toopen web steel joist systems.Panel lengthClear spanOverall lenghtBuilt-incamberI n t e r n a t i o n a lBuilding series NO. 2Parallel chord floor trussesmay be designed withvarying chord and webarrangements and bearingsupport details.

Structural analogues andmethodology have been Truss bearing and upliftrequirements, anddeveloped and standardized bythe National Associationsrepresenting the manufacturers Truss member bracingrequirements.of the metal plate connectors.Lumber design values aredetermined in accordance withthe wood design standards.Truss connector plates areproprietary and each plate hasdifferent structural properties.Design values for truss platesare developed through testsand analyses in accordancewith referenced standards.Approval of the design valuesis overseen by National certification organizations.Truss design is facilitated by theuse of computer software thatdesigns all truss members andconnections and produces adesign drawing with all theessential truss information.Truss MaterialsWoodLaboratory Testing of Wood TrussesAll lumber used in trusses isgraded using either a visualand 38 x 64 mm for webs. Theplate manufacturers carry out aprocess or machine stress ratingsize of the members increasesseries of tests to determine thein accordance with nationalaccording to loading, span anddesign properties for each typestandards. In the visual gradingtruss spacing. In some long-spanof plate.process, each piece of lumber isapplications, multi-ply trusses arevisually examined and the woodused to increase capacity.growth characteristics that couldMany sizes and gauges of connector plates are manufactured.grade is based on the size ofTruss platesThe most common plates use16, 18 or 20-gauge (USaffect the strength and stiffnessof the member. Each piece ofThe truss connector plates areStandard Gauge) sheet steel,machine stress rated lumberproprietary products. They arein widths of 25 mm to 250 mmundergoes a stiffness evaluationmade of galvanized steel andand lengths up to 600 mm.in addition to a visual evaluation.manufactured by high speedstamping machines that punchThe stamping results in teethThe minimum size of lumberout the plate teeth and shear thewith dimensions varying fromused is 38 x 89 mm for chordsplate to the required size. Truss6 mm to 25 mm.Included on the drawing (seeFigure 2) is: The truss geometry,5 The loads used in the trussdesign, Species, size and grade of allwood members, Size and location of allconnector plates,Truss Connector PlatesW o o d T r u s s e s S t r e n g t h , E c o n o m y , Ve r s a t i l i t y

Figure 2: Sample of a Truss Shop Drawing6I n t e r n a t i o n a lBuilding series NO. 2

Truss ManufactureThe factory manufacture of lightframe trusses is demonstratedin Figure 3. Since wood trussesare custom made, the varietyof roof pitches and locationof lumber members entailscomplex cutting patterns. Eachmember must fit snugly in place.The computer design of trussesgenerates fabrication instructions.These indicate the size and gradeas well as the precise cuttingpatterns for each of the chord andweb members. The type, size,location and orientation of theTruss Handling,Installation andStorageTrusses are strong in the verticalposition but can be damagedat the plate joints if bent in thelateral direction. Trusses shouldbe unloaded in bundles andstored on level ground, butnever in direct contact with theground. Trusses should alwaysbe protected from the elements.During unloading and erection,proper lifting equipment must beOnce the pieces have been cutuse heavy rigging equipment.on opposing faces at the jointsand pressed into the lumberusing hydraulic presses orrollers. When the pressing ofthe plates has been completed,the trusses are checked for platetooth penetration and moved toa storage area.Trusses must be braced todesigner or the buildingensure safety and performance.designer. Permanent bracingTo do so, trusses are placedprovides lateral support toaccording to installationcompression web and chordprocedures and guidelinesmembers and prevents overallprovided by the truss fabricator.lateral displacement of theDuring construction, the installerroof assembly.tions provided by the trussprovides temporary bracingto keep the trusses plumb andcorrectly spaced and to preventdamage or collapse causedby lateral loads such as wind.Permanent bracing is alsoprevent damage. Trusses lessthan 6 m can be installed byidentical truss plates are placedinstalled according to specifica-used to ensure safety and toconnector plates are also indicated.and arranged using a template,Truss Bracinghand while trusses over 18 mGroups of trusses can beassembled on the ground andlifted together into position. Thisprevents lateral strain on thejoints and resists wind loads priorto final installation of sheathingor permanent bracing.Figure 3: Manufacture of Light Frame TrussesMaterial receivingand storageAutomated truss designand cutting schedulesCutting of membersTemplate outlineTruss assemblyPlate placementPlate pressingBundling andshippingW o o d T r u s s e s S t r e n g t h , E c o n o m y , Ve r s a t i l i t y7

Wood Truss Advantages and ApplicationsFlexibilityand Versatility7. Vaulted ceilings are8. Wood trusses are veryusing simply installed connectionseasily made: bottom chordsversatile and compatible withto join the roof to the walls.of pitched trusses can beother structural products. They canLong spans without interme-sloped, or parallel chordbe connected to other trusses, or9. Hinged connector platesdiate supports create largepitched trusses bearing oncombined with other components,used with mono-pitch trussesopen spaces that architectssupports at different elevationssuch as glulam and steel beams.allow modular homes to beand designers can use withcan be used. Attic trusses areIn North America, wood roofassembled with conventionalcomplete freedom. Partitionsdesigned to provide living areastrusses are commonly supportedroof pitches, greatly enhancingcan be moved withoutwithin the roof space.on concrete or masonry wallstheir appearance.compromising the structuralintegrity of the building.1. Truss shapes have almostunlimited variety, thus allowingfor distinctive roof shapes.2. Many restaurant chainschoose to expose their corporate1identity in the roof design oftheir buildings.3. Metal plate connected trussesare used to create arches ofall types.4. Wood trusses used inspecialized applications such3as agricultural and commercialbuildings provide spansexceeding 25 m.85. As a testament to theirstrength, wood trusses areused in concrete formwork,scaffolding and falsework forindustrial projects.6. The open web configurationof roof and floor trusses allowseasy placement of plumbing,electrical, mechanical andsanitary services.I n t e r n a t i o n a lBuilding series NO. 24WTCA2WTCA

88659WTCA978W o o d T r u s s e s S t r e n g t h , E c o n o m y , Ve r s a t i l i t y

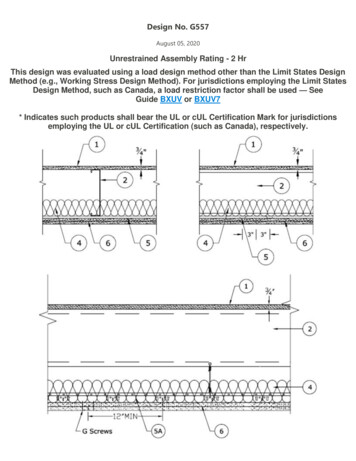

Performancesystem is simplified. Wood Additional stiffness canNot all truss assemblies require asheathing can be easily attachedbe built into the floor trussfire resistance rating. The buildingSince they were first introducedto the top chord to provide theand floor system to reduceoccupancy, the building size,in the 1950’s, metal plateunderlay for the roofing mem-floor vibration.number of exits and the use ofconnected wood trusses havebrane or floor finish. Ceilings candemonstrated an excellent trackbe readily connected to the truss record and are recognized inbottom chords and insulation isfire safety in buildings are spec-Building Codes throughouteasily installed in the truss cavity.ified in the Building Codes.Fire-resistance ratings, basedNorth America.Floor TrussesRoof Trusses sprinklers will determine whatDesign requirements for Wood trusses eliminateTop chords of floor trussesprovide a wide 89 mm surfaceon-site framing problems.for easier nailing and increasedAccurate fabrication and constantglue contact area with the sheath-quality control assure trusses areing material. This helps build auniform in size and shape andfloor system that is stable andprovide required structuralquiet for the life of the structure.on standardized tests, are ameasure of the fire resistanceof roof and floor assemblies.Depending on sheathing,ceiling construction, andinsulation, truss assemblies haveachieved fire resistance ratingsup to 2 hours.fire resistance rating is required. Floor truss assemblies canalso be optimized to reducesound transmission. In apartments, this limits noises fromupper or lower units. For furtherinformation on fire and soundperformance refer to “FireResistance and SoundTransmission in Wood-FrameResidential Buildings”.integrity to a building. Wood trusses can be con-structed and spaced to optimizeMetal truss platelumber strength and conservePrefabricated roof trusstimber resources. For examplesmaller dimension lumber is usedin the truss webs and the typicalThermal insulationcentre optimizes roof framing.When wood trusses are usedas the principal framing members,10constructing the roof or floor3Source: Forintek Canada Corp. and Ministère des Ressources naturelles, de la Faune et des Parcs du QuébecI n t e r n a t i o n a lBuilding series NO. 2Asphalt shinglesCedar shinglesVapour barrierroof truss spacing of 600 mm on Roof sheathingRoofing paper

Cost EffectivenessFor example, framing a houseWood trusses are often moretwo times faster than witheconomical than steel orconventional wood framing.concrete in pitched or flatAll construction has an impactTrusses do not contribute toroof applications.on the environment. We canwaste generated at the siteminimize the environmentaland make cleanup less costly.burden associated with construc-Pilferage is also reduced becausejob site ready to install, reducingtion by choosing building assem-wood trusses generally cannotconstruction time significantly.blies that minimize energy usebe used on other projects.and emissions. Wood trusses arrive at theEnvironmentalBenefitswith wood trusses is more than In most cases, wood trussescan be installed without the useof heavy machinery. They arelight in weight and can be easilyhandled and lifted into place. Wood trusses can beinstalled by local tradesmen.They require less carpentrylabour and, in typical applications, often eliminate the needfor iron workers, welders, riggersand other costly trades. Truss fabricators and platemanufacturers can provideguidance and technical supportWood is the only renewableconstruction material. Framingwith wood trusses minimizesthe depletion of finite naturalresources. Compared to other buildingmaterials, wood takes much lessenergy to process and minimizesair and water pollution. Wood trusses are energyefficient. They have excellentthermal properties, especiallywhen compared with otherframing materials such as steel.They create large cavities thatare easy to insulate.to designers or buildersconfronted with design orinstallation difficulties. Thissupport helps reduce the timeinvested in completing aconstruction project.W o o d T r u s s e s S t r e n g t h , E c o n o m y , Ve r s a t i l i t y11

For more informationplease contact our office at:Canada Wood Head OfficeWebsite: www.canadawood.orgCanada Wood China, BeijingRoom 1507, Kuntai International Mansion,No.12 B Chaowai Street, Beijing 100020Tel: (86-10) 5925-1255Fax: (86-10) 5925-1258Email: info@canadawood.cnCanada Wood China, Shanghai425 Hong Feng Road, Pudong New Area,Shanghai 201206Tel: (86-21) 5030-1126Fax: (86-21) 5030-3241Email: info@canadawood.cnCanada Wood Korea3rd Fl., 203 Bldg., #203-7, Yangjae-dong,Seocho-gu, Seoul, Korea 137-893Tel: (82-2) 3445-3835/4Fax: (82-2) 3445-3832Email: info@canadawood.or.krCanada Wood France (Europe)8 Esplanade Compans Caffarelli,31000 Toulouse, FranceTel: (33-5) 62-30-51-42Fax: (33-5) 62-30-50-00Email: europe@canadawood.orgCanada Wood JapanTomoecho Annex-11 9F3-8-27 ToranomonMinato-kuTokyo 105-0001, JapanTel: (81-3) 5401-0531Fax: (81-3) 5401-0538Email: info@canadawood.jpPublications in this series:1.2.3.4.5.Moisture and Wood-Frame BuildingsWood Trusses – Strength, Economy, VersatilityFire Resistance and Sound Transmission in Wood-Frame Residential BuildingsSustainability and Life Cycle Analysis for Residential BuildingsThermal Performance of Light-Frame Assemblieswww.cwc.caCanada Wood UKSuite 8, St-Albans HousePO Box 1, Farnborough, Hants,United KingdomGU14 6WETel: (44-1252) 522545Fax: (44-1252) 522546E-mail: office@canadawooduk.orgwww.naturallywood.comA publication of the Canadian Wood Council. Funding support provided by Canada Wood partners: Canadian Plywood Association Quebec Wood Export Bureau SPF Group

Light trusses are manufac-tured to suit virtually any roof profile. Pitched or flat, . 16, 18 or 20-gauge (US Standard Gauge) sheet steel, in widths of 25 mm to 250 mm and lengths up to 600 mm. . Metal plate connected trusses are used to create arches of all types. 4.