Transcription

Designed for your goals.Designedforyouryourreality.goals.Built forBuilt for your reality.Continuous Ink JetVideojet 1550 & 1650

It’s not aboutbells and whistles.It’s about whatyou need to meetyour goals in thereal world.2

Your goals. Your reality.The practical world, where codes need to be right everyday, every time. A world where uptime and continuousimprovement are directly reflected in your metrics. Wherethe goal is to shrink downtime and expand true availability.And where maintenance is a predictable, preventive routine.That’s what Videojet 1550 and 1650 printers are all about.Videojet is your partner for productivity.Uptime advantageBuilt-in productivityWith customer field research showing 99.9%availability*, our 1000 Line Continuous Ink Jetprinters clearly demonstrate the efficacy of ourinnovations – like the CleanFlow printheadand Dynamic Calibration .To continuously improve uptime and OEE,you need more than availability percentages.Our interface gives you instant fault informationto get your line back and running again – fast.But it also enables you to get to the root causeof downtime events and fix them for good.Code AssuranceOur advanced software minimizes andmistake-proofs operator inputs to the codingand marking process to help reduce errors.By specifying error-proofing rules during set-up,operator inputs are limited to the choicesyou specify.*For more details on printer availability,please refer to page 4 of this brochure.Simple usabilityFrom the large, bright interface to theSmart Cartridge fluid system that significantlyreduces waste, mess, and mistakes, ourContinuous Ink Jet printers are designed forsimple and limited interaction. We makestart-up, operation and maintenance simple– so you can focus on production.3

Your goal is uptime,pure and simpleNo excuses. No ifs, ands, or buts.The more scheduled production time, and the more equipment availability during that time, themore you hit your targets. In the real world, there’s unplanned downtime. Difficult maintenanceprocedures. Shutdowns, headaches and setbacks. Standing in the way of your goals.The Videojetuptime advantageRecent customer field results show:99.9%availability** Results of 99.9% availabilityobtained from a surveyof customers representingover four hundred 1000Line printers on activeproduction lines.Over half of the surveyedcustomers experienced100% availability.Individual results may vary.Your goal is to maximize planned productiontime. Make sure unplanned downtimedoesn’t get in the way.Less frequent printheadcleanings.Uptime drives Overall Equipment Effectiveness(OEE). And OEE drives profits. Everymanufacturer’s goal is to bring productionlines as close as possible to 100 percent uptime.For variable coding processes, Videojet’s 1550and 1650 printers help you get there, withinnovations no other printers can deliver.Our patented CleanFlow printhead design providesa positive flow of filteredair to reduce ink buildupthat can cause ordinaryink jet printers to shutdown.Our exclusive CleanFlow printhead andDynamic Calibration resist ink buildup andhelp ensure print quality to keep the printerrunning reliably. Our long-lasting core providesindustry-leading runtimes – up to 14,000 hoursof continuous operation between plannedmaintenance procedures that your staffcan perform.And our 1550 and 1650 printers provideAvailability metrics that can be configuredto your measurement preferences.4So you get reliably clearand consistent codes,and run longer betweenprinthead cleanings.

TMDynamic Calibrationfor better print qualityMatch the measurementto your operationDynamic Calibration applies some of the industry’s most sophisticatedmeasurements and controls to adjust jetting parameters automatically.As ambient temperature and humidity change throughout the day andacross the seasons, you can count on the same great print quality– only from Videojet.Configure the printer to track Availability the way you want.Track against Power-On time – meaning the printer is turnedon. Or track against Jets-On time – meaning ink is cycling andthe printer is either printing or ready to print on demand.Choose the method that best represents your plannedproduction time and OEE MENTMpump speedMMCink streamvelocityCCCONTROL5

Information you can acton to improve productivityYour targets only get tougher over time.You need to be producing, not struggling.What kind of informationwould it take to discoverroot causes of downtimeand put them behind you?So you can hit yourtargets today, and makesustainable improvementsfor even greaterproductivity tomorrow?Productivity toolsOEEAvailability percentage Uptime/potential production timePlant operating timePlanned production timeFully productive timePlanned downtimeImprove OEE over timeUnplanneddowntimeThe 1550 and 1650 printers are designed to support continuousOEE improvement, providing usable information you can act upon– whether that means changing a print parameter or correcting anoperator procedure.6

The 1550 and 1650 CLARiTY interfacepresents fault information in a logicalway that allows you to identify andfocus on the biggest issues and drilldown to discover the root causes ofunplanned downtime.Result: You can take action toeliminate the root cause andachieve sustainable improvements.To continuously improve uptimeand OEE, you need more thanavailability percentagesWithout understanding the context of this information, you can’t solve theproblem. You need the ability to focus on the biggest issues and drill down todiscover the root causes of unplanned downtime.More than the status of technical functions, the 1550 and 1650 printersdisplay details about both Printer Availability and Operational Availability.Drill down into Printer Availability data to discover technical and operationalcauses of unplanned downtime. Everything is presented in a logical way tosupport efficient and effective problem-solving. The CLARiTY interfacedisplays the information you need to quickly learn not just what happened,but what’s really going on. So you can confidently identify the root cause ofdowntime and fix it to achieve sustainable process improvements.See the biggest drivers of downtimeReview frequency and durationRecover faster from a faultOur CLARiTY interface gives you instant fault informationthat you can use to troubleshoot problems and get your lineback up and running ASAP.Diagnose root cause,make process improvements7

Foolproofing code entryThis is how your goal looks:This is how reality looks:Never, ever a wrong code,a wrong date, a wrong lotidentification. Ever.Codes that are one digit off, dates that don’texist, codes on wrong products, typing errors,wrong offset dates. Coding errors that are likelyto be operator errors 50% – 70% of the time.Welcome to Code AssuranceVideojet’s comprehensive approach to printing the right codes onthe right products.Our advanced software minimizes and mistake-proofs operatorinputs to the coding and marking process to help eliminate errors.Bad codes canmean waste, rework,regulatory fines andpotential damage toyour brand. Let thathappen to the otherguys. We can helpyou keep your lineproductive, and yourbrand strong.8Easily create error-proofing rules during setup – for example, whether or notfields can be edited, permissible data types and date range restrictions.The operator is limited to the choices you specified, with field prompts,drop-down menus, calendar displays and predefined formats that helpensure correct entries. A preview of the print layout must then beconfirmed before starting the job.Want even more Code Assurance?Add CLARiSOFT to get rules-based code creation on your office PC andprevent unauthorized users from editing rules or codes. Add CLARiNET and you can push codes to one or more printers automatically over yourexisting network and pull data from a database to populate your codes,further reducing the opportunity for mistakes.

Foolproof set-up wizardry. Easily create error-proofing rulesduring job setup – such as whether or not fields can be edited,permissible data types, date range restrictions and more.Visual job selection. Job files can be saved and searched using meaningfulnames, such as the product that is being coded. A preview of the messageprovides additional confidence that the right job is loaded.Step-by-step guided data entry. Based on the rules youdefined during job setup, only permissible fields can be edited.The print job can be loaded only after the operator hasconfirmed each entry.Multiple choices for minimal errors. Data-entry screens limit operatorsto the choices defined during job setup. Entering a date? Choose itfrom a calendar showing permissible expiration dates. A country code?Choose it from a drop-down list. A lot code? Load it into a predefinedformat automatically.9

Designed for limited and simpleinteraction so you can focuson productionThis starts with a large, bright interface. The Smart Cartridge fluid system significantly reduces waste, mess and mistakes.And when it’s time for planned maintenance, the modular coresystem gets you right back to production.10Interactive touchscreenModular coreModular printhead designOur bright 264mm (10.4”)touchscreen makes it easy tomonitor job status at a distance.And our fast, intuitive interfacestreamlines daily interaction,clearly displaying real-time fluidlevels, maintenance alerts, printjobs and other operationalinformation.The advanced core design enables1550 and 1650 printers to performup to 14,000 hours betweenplanned maintenance. The core iscustomer-replaceable, and includesall ink system filters and commonwear parts.Automatic setup, calibration andadjustment helps ensure consistentperformance with minimaloperator intervention. Theprinthead is easy to clean andprovides long runs betweencleanings, with fast, easy startupeven after extended shutdown.

M/MinUltra high speed coding600500Speed, Content and Qualitywithout Compromise400300200100Glass, plastics and metal. Oily, waxyor damp substrates. High-speedand high-temperature processes.Resistance to fading, solvents,abrasion and transfer. Whateveryour requirements, there’s likely aVideojet Smart Cartridge ink thatwill handle it. And we have theexpertise to help you choose theright one.From installation and trainingtailored to your operational needs –to preventive maintenance andrapid response – to collaborationfor continuous improvement. Ourglobal service organization isn’t justthe world’s largest and mostresponsive. It’s a team of expertsdedicated to your completesuccess, from day one throughevery day’s productivityrequirements.We don’t just want to be yoursupplier. We want to be part of yourteam, whether it’s solving today’sproblems or helping you achievemore tomorrow than you thoughtpossible.10000Dual line 7 high200Tri-line 7 highM/MinVideojet’s Smart Cartridge fluidsystem makes it easy to changeinks on a predictable schedule, withno waste, no mess and no chanceof loading the wrong ink or anincompatible make-up fluid bymistake. We fill these self-containedcartridges with the industry’shighest-quality inks and fluids,formulated to meet nearly anyapplication requirement.Quality, productivity, uptime.We’ll help you reach your goalsM/MinThe perfect ink for every job.Service/support20015015010010050500041% fasterM/MinSuperior inktechnologyM/MinM/MinIn your production environment the need for increased speed never0relents, and when it comes to product codingit can go beyond justrunning your line faster. The Videojet 1650 Ultra High Speed600200(UHS) printer is the ultimate in speed with dual and tri-line codes upto 40% 500faster than the previous industry 150benchmark, the Videojet400 all without compromising print quality. The 1650 UHSExcel UHS,allows youspace, shrink an100300 to print more content in the sameexisting200code to preserve precious packaging real estate50or make it bigger or bolder to be easily readable.2001650 UHS43% fasterExcel UHS150The 1650100 UHS printer’s Videojet Precision Ink Drop Systemdelivers superior code quality. The 1650 UHS generates up to100,00050individual drops per second. Generating the drops is theeasy part rendering them into a high quality code is what sets the01650 UHS apart. With Precision Ink Drop technology, Videojettakes a system-based approach to print quality, combining uniqueink chemistry, advanced high frequency printhead design, andsophisticated software algorithms that modify the flight path ofindividual ink drops for optimal code quality.11

Peace of mind comes as standardVideojet Technologies is a world-leader in the product identificationmarket, providing in-line printing, coding, and marking products,application specific fluids, and product life cycle services. ur goal is to partner with our customers in the consumerOpackaged goods, pharmaceutical, and industrial goodsindustries to improve their productivity, to protect andgrow their brands, and to stay ahead of industry trendsand regulations. With our customer application experts andtechnology leadership in Continuous Ink Jet (CIJ), Thermal InkJet (TIJ), Laser Marking, Thermal Transfer Overprinting (TTO),case coding and labeling, and wide array printing, Videojet hasmore than 325,000 printers installed worldwide.Our customers rely on Videojet products to print on over tenbillion products daily. Customer sales, application, service andtraining support is provided by direct operations with over3,000 team members in 26 countries worldwide.In addition, Videojet’s distribution network includes morethan 400 distributors and OEMs, serving 135 countries.Global HeadquartersVideojet Sales & Service OfficesManufacturing & ProductDevelopmentCountries with VideojetSales & ServiceCountries with VideojetPartner Sales & ServiceCall 800-843-3610Email info@videojet.comor visit www.videojet.comVideojet Technologies Inc.1500 Mittel Blvd. Wood Dale IL 60191 / USA 2014 Videojet Technologies Inc.

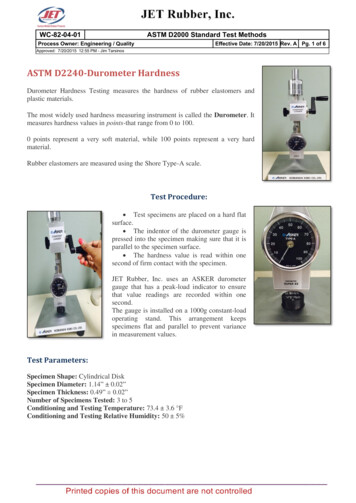

Modular core The advanced core design enables 1550 and 1650 printers to perform up to 14,000 hours between planned maintenance. The core is customer-replaceable, and includes all ink system filters and common wear parts. Modular printhead design Automatic setup, calibration and adjustment helps ensure consistent performance with minimal