Transcription

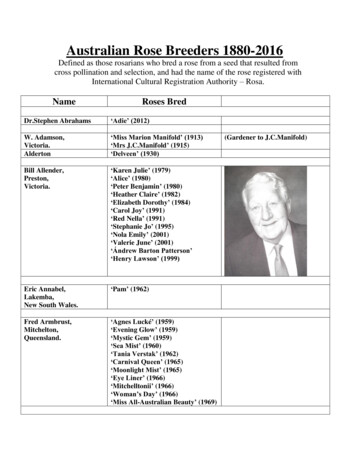

Enabling Industry 4.0productivity pioneersContinuous InkjetVideojet 1880

The Videojet 1880 harnessesthe collective intelligenceof 10,000 cloud-connectedVideojet printers to helpkeep your line running2

Avoid manufacturing downtimewith the Videojet 1880 smartContinuous Inkjet (CIJ) printer, madefor Industry 4.0 productivity pioneers.The Videojet 1880 CIJ printer builds uponcomprehensive insights gained from thefleet of cloud-connected Videojet printers,the largest in the industry, to enable yourjourney towards Industry 4.0.Not only does the 1880 enable exceptionaluptime, it is expressly designed to help yourteam improve productivity and help drivelower costs over the lifetime of the printer.Millions of hours of real-world printer datainformed the 1880 design, resulting inan advanced digitally-enabled solution.The Videojet 1880 continuously monitorsand tracks printer parameters so the usercan proactively address potential printerissues and help ensure your production lineoperates without interruption.With an industry-first ink build-upsensor and Videojet MAXIMiZE builtin diagnostics suite, the 1880 deliversperformance without surprises.3

Born digital: enable yourproductivity journeyWith a built-in vital sign monitoring system, smart alerts, on-demandremote technical support, Wi-Fi connectivity, and an advanced automatedtroubleshooting program, the 1880 anticipates potential printer issuesin time for you to avoid them and enables you to recover faster shoulddowntime still occur.Reduce your main causes of unplannedprinter downtimeVideojet MAXIMiZE advanced diagnostics suite continuously monitors printer healthparameters to help operators easily identify if a fault is likely to occur. The printerprovides on-screen notifications and the on-board videos walk auser through proactive maintenance routines.Recommendsoptions to improveperformance41Monitors thehealth of yourprinterVideojetMAXIMiZE Guides user throughmaintenance toprevent potential linestoppages432Alerts user whenhealth parametersgo out of normaloperating ranges

l-time notification ofprinter needs, warning orfault conditionsInstant visibility tovaluable printer andproductivity informationReact sooner with real-time remotevisibility to faultsVideojetConnect Remote Service* provides real-timenotification of printer issues allowing both Videojet expertsand your technicians to remotely diagnose the problem.SwapProduction resumedRecover from faults more quicklyRapid Recover * uses advanced automatedtroubleshooting to quickly determine if a printerfailure can be easily repaired or a spare printer needsto be deployed with printer settings automaticallytransferred, enabling line recovery within 20mins.* Subject to availability in your country5

Ensure the right codeat the right quality every timeReduce human errors with code management andline integration capabilities. Quickly detect and fixprint quality issues.Reduce print clippingClipped codeQuality codeCatch coding errors if they happenFor applications where print quality is critical,the 1880 supports connection to industry-leadingvision systems that verify each code.6The 1880 printhead incorporatesa unique sensor which enables theprinter to detect build up in theprinthead, alerting the user topotential print quality issues.With just a push of a button, the1880 auto rinse brings ease ofuse and consistency to printheadcleaning, significantly reducing inkbuild-up – the main cause of codeclipping.

Streamline changeovers andreduce chance of errorsRemove potential for human error with the 1880 suiteof line integration and code management capabilities.The Videojet message designand code management softwareenables faster line set-up andchangeovers, and eliminatesunnecessary operator interactions,reducing the opportunities forcoding errors.Ethernet / IP is a trademark of ODVA. PROFINET is aregistered trademark of Profibus & Profinet International (PI).OPC Foundation is a registered trademark of OPC Foundation.Guiding you every step of the wayOur SIMPLICiTY interface delivers Code Assuranceout-of-the-box with error-proofing rules that defineeditable fields, permissible data types, date rangerestrictions and more - greatly reducing printerinteractions and potential user errors.7

Minimize operatorinterruptionsOur most advanced printer, the 1880 is designedto reduce and simplify cleaning intervals andcartridge changeovers, keeping your operatorsfocused on production.Up to2x*replacementintervalIndustry-leading make-upconsumption as low as 3.5ml/hrChoose between 0.75L and 1L cartridges.Correct cartridge sizing can reduce ink wastageor increase make-up changeover interval by 2x.* Compared to other Videojet modelsRemote access withVideojetConnect Remote Service†Receive instant access to the world’s largest networkof CIJ experts at the touch of a button, and bring thetechnician directly to your line to aid troubleshootingand remote printer recovery. No other technologydelivers help faster to ensure you make the rightdecisions when needed.†8Subject to availability in your country

Extended interval betweenprinthead cleaningsAdvanced printhead design with intelligentstop-start sequence minimizes the needfor printhead cleaning by notifying theoperator only when needed.Simple preventative maintenancetakes 5 minutes per yearEasily accommodate operator-performed annualpreventative maintenance within your productionschedule.Videojet Technical Support remotely helpsa customer set up a new coding message,avoiding delays in implementation.Videojet Remote Service ProactiveMonitoring helps a customeravoid downtime.When a leading food producer began using a new typeof box and coding layout, the operators realized theydid not have the knowledge to adjust printer settingscorrectly for the new application and contacted Videojetfor assistance. The Field Service Engineer from Videojetconnected with remote access immediately andset up the machine remotely.Videojet Technical Support team detected a'Check Speed' warning from a printer and proactivelycontacted the customer to avoid downtime. The teamaccessed the printer’s configuration through customergranted remote access. Technical support correctedout-of-range shaft encoder parameters, allowing theprinter to resume operation in just a few minutes.9

Natural fit in your lineAdvanced features to meet the most exactingstandards and the flexibility to expand capabilities.350 45 degreerotatingprinthead10Agile printhead works for yourline, not against itDurable over-molded umbilicalfor traversingUnique printhead options deliver better line integrationwith more mounting options and closer proximity tothe product.The over-molded umbilical is built to last, featuringa slim, durable design that is engineered to withstandthe toughest traversing environments.Optimized for washdownInk choices to match your applicationOptional IP66 rating eliminates the need to remove theprinter from the line during washdown and 316 gradestainless steel provides superior rust protection.With over 30 inks to choose from, Videojet can matchthe ideal ink to meet your requirements.

Your pathway to productivityLeverage our integrated suite of advanced analytics,remote connectivity, and the largest service footprintin the industry.ImproveMaintainthe capabilityand utilization of yourprinter over timethe optimalperformance ofyour printer Predictive analytics andcloud-based reporting MAXIMiZE diagnostics suite On-site preventativemaintenance Advanced performancemonitoring to guidecontinuous improvement Remote alerts to monitorprinter status One-on-one consultationservices for optimization On-demand remoteand on-site trainingRecoverfrom faults rapidly and maintain your productivity Rapid Recover automated troubleshooting Largest service footprint with unmatched response time Remote Videojet CIJ experts available on-demand11

Peace of mind comes as standardVideojet Technologies is a world-leader in the product identificationmarket, providing in-line printing, coding, and marking products,application specific fluids, and product LifeCycle AdvantageTM.Our goal is to partner with our customers in the consumerpackaged goods, pharmaceutical, and industrial goodsindustries to improve their productivity, to protect andgrow their brands, and to stay ahead of industry trendsand regulations. With our customer application experts andtechnology leadership in Continuous Inkjet (CIJ), ThermalInkjet (TIJ), Laser Marking, Thermal Transfer Overprinting(TTO), case coding and labeling, and wide array printing,Videojet has more than 400,000 printers installed worldwide.Our customers rely on Videojet products to print on overten billion products daily. Customer sales, application, serviceand training support is provided by direct operations withover 4,000 team members in 26 countries worldwide.In addition, Videojet’s distribution network includes morethan 400 distributors and OEMs, serving 135 countries.Global HeadquartersVideojet Sales & Service OfficesManufacturing & ProductDevelopmentCountries with VideojetSales & ServiceCountries with VideojetPartner Sales & Service 2020 Videojet Technologies Inc. — All rights reserved.New printer quote 866-871-3226Order supplies shop.videojet.comCall 800-843-3610Email info@videojet.comor visit www.videojet.comVideojet Technologies Inc.1500 Mittel Blvd. Wood Dale IL 60191 / USAVideojet Technologies Inc.’s policy is one of continued product improvement.We reserve the right to alter design and/or specifications without notice.Part No. SL000688br-1880-us-1120Printed in U.S.A

troubleshooting program, the 1880 anticipates potential printer issues in time for you to avoid them and enables you to recover faster should downtime still occur. Reduce your main causes of unplanned printer downtime Videojet MAXIMiZE advanced diagnostics suite continuously monito rs printer health parameters to help operators easily identify if a fault is likely to occur. The pr inter .