Transcription

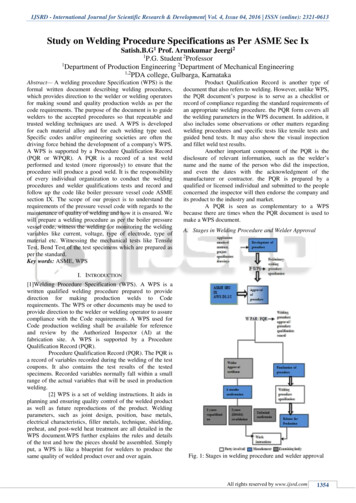

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONPage 1 of 2Form No. 101-401WPS No.:1001Date: 06.11.93Rev. No.:00Date: ---Welding Process: SMAWSupporting PQR No.: cation: Butt-welding of P1 Gr. 1 & Gr.2 tubes without preheat and without PWHT.JOINTS (QW-402)Joint Design: Groove as per drawingBacking (Yes/No): As per drg.Backing Material (type): -- do –Metal/Non fusing metal/Non metallic/OthersBASE METAL (QW-403)P. No.: 1Group No.: 1 or 2 TOP. No.: 1Group No.: 1 or 2Spec. Type & Grade: N.A.Chem. Analysis & Mech. Prop.: N.A.Thickness RangeBase Metal:Groove: 1.6 to 9.0Fillet:N.A.Weld Metal:Groove: E6013; 5.0 max. : E7018; BalanceFillet: N.A.Pipe dia.:Groove: UnlimitedFillet: N.A.Others: NilFILLER METALS (QW-404)AWS No. (Class):E6013 E7018Specn. No. (SFA):5.1Size of filler metal: See TableF. No.:2,4Flux Trade Name: N.A.A. No.: 1Consumable insert: N.A.Electrode Flux (Class): NA.POSITION (QW-405)PREHEAT (QW-406)Nil (min. 100C)Position of Groove:AllPreheat temp. (min.):Position of fillet:N.A.Inter pass temp. (max.): 300 CWeld Progression:(Up/Down)Vertical upPost heat maintenance: Nil0Others:Nil

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 2 of 2WPS No.: 1001PWHT (QW-407)GAS (QW-408)GasesMix.%Flow Rt.Temp. Range:NilShieldingN.A.------Time ---ELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): See TablePolarity: See TableAmps. (Range):Volts: -- do –-- do --Tungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):N.A.Electrode wire feed speed range:N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:Root & 2G: String; Others: String/Weave (3dia max.)Orifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back gouging:NilOscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side):Single or MultipleMultiple or single electrode:SingleElectrode ngeTravelspeedrangeOthers(hot wire,torchangle lassDia.TypeRootSMAWE60132.5OthersSMAWE7018- Do -- Do -- Do -Approved by: (V. Ravindran)Manager/WTCDate: 06-11-93Prepared by: (D.N. Ravishankar)S.W.E./WTCDate: 06-11-93

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1228Date: 15.12.06Rev. No:00Date: ------Supporting PQR No: 1258Welding Process: FCAW (CO2)Type: Semi n: Groove & fillet welding of IS2062 carbon steel structure up to 50 mm thicknesswithout PWHT. (AS PER AWS D1.1, SIP: NP: 07/01. QCP: 002/02).JOINTS (QW-402)Joint Design: Groove / Fillet as per drawing.Backing (Yes/No): As per drawing.Backing Material (type): MetalMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: --Group No: --toSpec. Type & Grade: IS 2062Chem. Analysis & Mech. Prop: --Thickness RangeP. No: --Group No: --:-Pipe dia range:Others: NilGroove: 3.0 mm – 50 mmFillet: Unlimited.Groove: ---Fillet: ---FILLER METALS (QW-404)AWS No. (Class):E 71T-1Size of filler metal: Refer tableSpecn. No. (SFA):5.20Flux Trade Names:N.AF. No.:6Consumable insert:N.AA. No.:1Electrode Flux (Class): N.A.Deposited weld metal thickness range: Groove: 3.0mm-50mmFillet:3.0mm-50mmOthers:NilPOSITION (QW-405)PREHEAT (QW-406)Position of Groove:FlatPosition of fillet:FlatWeld Progression:N.A.Preheat temp (min):Thickness,T 38:Nil38 T 63: 100OcT 63: 150oCInter pass temp. (Max.): 300OCOthers:NilPreheatOthers::NilNil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401WPS No.: 1228PWHT (QW-407)Page 2 of 2GAS (QW-408)GasesMix%Flow Rt.Temp. Range:NilTime ckingNil-------100%16-24 LPMELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): DCPolarity: EPAmps. (Range):Volts : 26-28180-220Tungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):GlobularElectrode wire feed speed range:N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:Root: String; Others: string or weaveOrifice or Gas cup size:Max. 3 times dia.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:Air arc gouging / grinding for second side weldingOscillation:16/18Contact tube to work distance:8-15 mmMultiple or single pass (per side): MultipleMultiple or single electrode:SingleElectrode spacing:N.A.Travel speed rocessFCAWPrepared by:(Kinkar P Narzary)Welding Engineer / peE71T-11.6DCEPReviewed by:(Dr.K.P.Dhandapani)DGM / WTC & WCMCApproved by:(B.Natarajan)SDGM/ WTC & WCMC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1227Date: 17.11.06Rev. No:00Date: ------Supporting PQR No: 1332Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove & fillet welding of A588 Gr A components with PWHT.JOINTS (QW-402)Joint Design: Groove / Fillet as per production drg.Backing (Yes/No): As per production drawing.Backing Material (type): NilMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: NilGroup No: NiltoP. No: NilGroup No: NilSpec. Type & Grade: A 588 Gr A or equivalent S3 material.Chem. Analysis & Mech. Prop: Nil.Thickness Range:-Pipe dia range:Others: NilGroove: 5.00 to 32 mmFillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.FILLER METALS (QW-404)AWS No. (Class):Specn. No. (SFA):E 8018-B2Size of filler metal: Refer table5.5Flux Trade Names:N.AF. No.:4Consumable insert:NilA. No.:3Electrode Flux (Class): N.A.Deposited weld metal thickness range: Groove: 32 mm maximum (4 mm maximum per pass)Fillet: Unlimited. (4 mm maximum per pass)POSITION (QW-405)PREHEAT (QW-406)150oCPosition of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 300OCWeld Progression:(Up / Down)Vertical up.Post heatOthers:NilOther::N.ANil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401PWHT (QW-407)GAS (QW-408)oTemp. Range:Time RangePage 2 of 2WPS No.: 1227655 15 CGases2.5 min / mm(Minimum 30 minutes.)Others:NilMix%Flow gN.A.N.A.N.A.ELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): Refer tableAmps. (Range): Refer tableTungsten Electrode type and size:Mode of metal transfer for (GMAW):Electrode wire feed speed range:Polarity: Refer tableVolts : Refer tableN.A.N.A.N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:Root: String; Others: string or weave (3 dia. max)Orifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:Back grinding for second side weldingOscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side): MultipleMultiple or single electrode:SingleElectrode torchangleetc.)CurrentClassdia.TypeRootSMAWE 8018-B22.5DCEP70-100N.A.N.A.Nil1 to 2 &BacksideSMAWE 8018-B23.15DCEP100-130N.A.N.A.NilE 8018-B24.0 DCEPReviewed by:140-180N.A.N.A.Approved by:FurtherSMAWPrepared by:(Kinkar P Narzary)Welding Engineer / WTC(Dr.K.P.Dhandapani)DGM / WTC & WCMCNil(B.Natarajan)SDGM/ WTC & WCMC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1226Date: 17.11.06Rev. No:00Date: ------Supporting PQR No: 1331Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove & fillet welding of A588 Gr A components with out PWHT.JOINTS (QW-402)Joint Design: Groove / Fillet as per production drg.Backing (Yes/No): As per production drawing.Backing Material (type): NilMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: NilGroup No: NiltoP. No: NilGroup No: NilSpec. Type & Grade: A 588 Gr A or equivalent S3 material.Chem. Analysis & Mech. Prop: Nil.Thickness Range:-Pipe dia range:Others: NilGroove: 5.00 to 16 mmFillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.FILLER METALS (QW-404)AWS No. (Class):Specn. No. (SFA):E 8018-B2Size of filler metal: Refer table5.5Flux Trade Names:N.AF. No.:4Consumable insert:NilA. No.:3Electrode Flux (Class): N.A.Deposited weld metal thickness range: Groove: 16mm maximum (4 mm maximum per pass)Fillet: 13mm maximum (4 mm maximum per pass)POSITION (QW-405)PREHEAT (QW-406)150oCPosition of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 300OCWeld Progression:(Up / Down)Vertical up.Post heatOthers:NilOther::N.ANil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 2 of 2WPS No.: 1226PWHT (QW-407)GAS (QW-408)Temp. Range:NilTime .N.A.N.A.BackingN.A.N.A.N.A.GasesELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): Refer tableAmps. (Range): Refer tableTungsten Electrode type and size:Mode of metal transfer for (GMAW):Electrode wire feed speed range:Polarity: Refer tableVolts : Refer tableN.A.N.A.N.A.Pulsing current (GTAW):N.A.Mix%Flow Rt.TECHNIQUES (QW-410)String or Weave Bead:Root: String; Others: string or weave (3 dia. max)Orifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:Back grinding for second side weldingOscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side): MultipleMultiple or single electrode:SingleElectrode torchangleetc.)CurrentClassdia.TypeRootSMAWE 8018-B22.5DCEP70-100N.A.N.A.Nil1 to 2 &BacksideSMAWE 8018-B23.15DCEP100-130N.A.N.A.NilFurtherSMAWE 8018-B24.0DCEP140-180N.A.N.A.NilPrepared by:(Kinkar P Narzary)Welding Engineer / WTCReviewed by:(Dr.K.P.Dhandapani)DGM / WTC & WCMCApproved by:(B.Natarajan)SDGM/ WTC & WCMC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1225Date: 04.05.06Rev. No:00Date: ------Supporting PQR No: 292Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove & fillet welding of IS 2062 attachments to SS attachments withoutPreheat and PWHT.JOINTS (QW-402)Joint Design: Groove / Fillet as per drg.Backing (Yes/No): As per drg.Backing Material (type): MetalMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: ---Group No: --toP. No: 8Group No: 1Spec. Type & Grade: IS 2062 Stainless Steel (18Cr –8Ni)Chem. Analysis & Mech. Prop: N.A.Thickness Range:-Pipe dia range:Others: NilGroove: 4.5 to 20.0 mmFillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.FILLER METALS (QW-404)AWS No. (Class):E 309Size of filler metal: See tableSpecn. No. (SFA):5.4Flux Trade Names:N.AF. No.:5Consumable insert:N.A.A. No.:8Electrode Flux (Class): N.A.Deposited weld metal thickness range: Groove: 20.00 max (Maximum 8 mm per pass)Fillet: Unlimited (Maximum 8 mm per pass)PREHEAT (QW-406)POSITION (QW-405)Position of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 350OCWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOthers:NilOther:NilNil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401WPS No.: 1225PWHT (QW-407)Page 2 of 2GAS (QW-408)GasesMix%Flow Rt.Temp. Range:NilTime RangeNilShieldingNot required --------Others:NilTrailingNot required-------BackingNot required---------ELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): See tableAmps. (Range): See tableTungsten Electrode type and size:Mode of metal transfer for (GMAW):Electrode wire feed speed range:Polarity: See tableVolts : See tableN.A.N.A.N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:Orifice or Gas cup size:Initial and inter pass cleaning:Method of back Gouging:Oscillation:Contact tube to work distance:Multiple or single pass (per side):Multiple or single electrode:Electrode ngGrinding for second side weldingN.A.N.A.Single or angeOthers(hotwire,torchangleetc.)AllSMAWE 3092.5DCEP70-100N.A.N.A.NilAllSMAWE 3093.15DCEP90-130N.A.N.A.NilAllSMAWApproved by:E 3094.0DCEP120-160N.A.Prepared by:N.A.Nil(S.Ramesh)SDGM/WTC & WCMC(Dr.K.P.Dhandapani)DGM/ WTC & WCMC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1224Date: 27.04.06Rev. No:00Date: ------Supporting PQR No: 814, 819Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Welding butt joints of Galvanized Iron Pipes.JOINTS (QW-402)Joint Design: Groove as per Drg.Backing (Yes/No): As per drg.Backing Material (type): MetalMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: NilGroup No: NiltoP. No: NilGroup No: NilSpec. Type & Grade: IS 3586 and equivalent Carbon content 0.25%Chem. Analysis & Mech. Prop: Galvanized pipesThickness Range:-Pipe dia range:Others: NilGroove: 5.0 to 12 mmFillet: N.A.Groove: Unlimited.Fillet: N.A.FILLER METALS (QW-404)AWS No. (Class):E 7018Size of filler metal: See tableSpecn. No. (SFA):5.1Flux Trade Names:N.AF. No.:4Consumable insert:N.A.A. No.:1Electrode Flux (Class): N.A.Deposited weld metal thickness range: Groove: 12 mm (6 mm per pass max.)Fillet: 12 mm (6 mm per pas max.)POSITION (QW-405)PREHEAT (QW-406)Position of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 300OCWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOthers:NilOther:NilNil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 2 of 2WPS No.: 1224PWHT (QW-407)GAS (QW-408)Temp. Range:NilTime RangeNilOthers:NilELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): See tableAmps. (Range): See tableTungsten Electrode type and size:Mode of metal transfer for (GMAW):Electrode wire feed speed ckingN.A.Flow Rt.Polarity: See tableVolts : See tableN.A.N.A.N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:Orifice or Gas cup size:Initial and inter pass cleaning:String or weave (3 dia. max)N.A.initial grinding of Galvanic coating at the joint / Chipping &Brushing of slags.Method of back Gouging:N.A.Oscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side): Single or MultipleMultiple or single electrode:SingleElectrode rangeOthers(hotwire,torchangleetc.)AllSMAWE 70183.15DCEP100-140N.A.N.A.N.A.AllSMAWE 70184.0DCEP140-190N.A.N.A.N.A.AllSMAWE 7018Approved by:5.0DCEP160-210N.A.Prepared M / WTC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1223Date: 25.10.2004Rev. No:00Date: ------Supporting PQR No: 1121Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove welding of IS8500 Fe 540 Structural components like Ceiling girders /Columns / Built up Beams etc.JOINTS (QW-402)Joint Design: As per production Drg.Backing (Yes/No): As per production Drg.Backing Material (type): MetalMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: NilGroup No: NiltoP. No: NilSpec. Type & Grade: IS 8500 Fe 540 or equivalentChem. Analysis & Mech. Prop: Nil.Thickness RangeGroup No: Nil:-Pipe dia range:Others: NilGroove: 10 to 200 mmFillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.FILLER METALS (QW-404)AWS No. (Class):Specn. No. (SFA):E 8018-B2Size of filler metal: Refer table5.5Flux Trade Names:N.AF. No.:4Consumable insert:N.A.A. No.:3Electrode Flux (Class): N.A.Deposited weld metal thickness range: Groove: 200mm maximum (maximum 5 mm per pass)Fillet: Unlimited (maximum 5 mm per pass)POSITION (QW-405)PREHEAT (QW-406)150oCPosition of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 300OCWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOthers:NilOther:Nil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401WPS No.: 1223PWHT (QW-407)Page 2 of 2GAS (QW-408)OTemp. Range:600 –650 cTime Range2.5minutes/mm(minimum 120 ngN.A.----BackingN.A.Flow Rt.ELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): Refer tablePolarity: Refer tableAmps. (Range):Volts : Refer tableRefer tableTungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):N.A.Electrode wire feed speed range:N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:String or weave (3 dia. max)Orifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:Air arc gouging / grinding for second side weldingOscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side):MultipleMultiple or single electrode:SingleElectrode EP140-180N.A.N.A.N.A.OthersSMAWE8018B2Approved by:5.0DCEP170-220N.A.Prepared yanan)DM/ WTC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONPage 1 of 2Form No. 101-401WPS No.:1220Date: 19.07.01Rev. No:00Date: ------Supporting PQR No: 1191Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Fillet welding of AISI 430 components with Preheat & without PWHT.JOINTS (QW-402)Joint Design: As per drawing.Backing (Yes/No): As per drawing.Backing Material (type): MetalMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: 7Group No: 2toP. No: 7Spec. Type & Grade: AISI 430 or equivalent.Chem. Analysis & Mech. Prop: N.A.Group No: 2Thickness RangePipe Dia. range:Groove: N.A.Fillet: 6.0 mm maximumGroove: N.A.Fillet: 100 mm maximumOthers: NilFILLER METALS (QW-404)AWS No. (Class):E 309Size of filler metal: See tableSpecn. No. (SFA):5.4Flux Trade Names:N.AF. No.:5Consumable insert:NilA. No.:8Electrode Flux (Class): N.A.Deposited weld metal thickness rangeGroove: N.A.Fillet: 6mm maximum (maximum 3 mm per pass)POSITION (QW-405)PREHEAT (QW-406)200oCPosition of Groove:N.A.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 300OCWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOther:Nil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401WPS No.: 1220PWHT (QW-407)Page 2 of 2GAS (QW-408)Temp. Range:NilGasesTime RangeNilShielding N.A.Others:NilTrailingN.ABackingN.A.Mix%Flow Rt.ELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): See tablePolarity: See tableAmps. (Range):Volts : N.A.See tableTungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):N.A.Electrode wire feed speed range:N.A.Pulsing current (GTAW):Nil.TECHNIQUES (QW-410)String or Weave Bead:StringOrifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:N.A.Oscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side):Single or MultipleMultiple or single electrode:SingleElectrode ocessClassTravelspeedrangeOthers(hot eAllSMAWE 3092.5DCEP70-90N.A.N.A.NilAllSMAWE 3103.15DCEP80-120N.A.N.A.NilApproved by:Prepared by:(V.Ravindran)(R.Rajanarayanan)DGM / WTCSr.Welding Engineer / WTC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1219Date: 19.07.01Rev. No:00Date: ------Supporting PQR No: 1043Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove & fillet welding of SA 240 Type 310S components without Preheat &without PWHT.JOINTS (QW-402)Joint Design: As per drawing.Backing (Yes/No): As per drawing.Backing Material (type): Metal.Metal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: 8Group No: 2toP. No: 8Group No: 2Spec. Type & Grade: SA 240 Type 310S or equivalentChem. Analysis & Mech. Prop: N.A.Thickness RangePipe Dia range:Groove: 4.8 mm to 20.0 mmFillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.Others: NilFILLER METALS (QW-404)AWS No. (Class):E 310Size of filler metal: See tableSpecn. No. (SFA):5.4Flux Trade Names:N.AF. No.:5Consumable insert:Nil.A. No.:8Electrode Flux (Class): N.A.Deposited weld metal thickness rangeGroove: 20.0 mm max. (Max. 4 mm per pass)Fillet: Unlimited (Max.4 mm per pass)POSITION (QW-405)PREHEAT (QW-406)Nil (10Oc Min)Position of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 250OCWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOther:Nil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 2 of 2WPS No.: 1219PWHT (QW-407)GAS (QW-408)Temp. Range:NilTime RangeNilShielding N.AOthers:NilTrailingN.A.BackingN.A.GasesMix%Flow Rt.ELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): See tablePolarity: See tableAmps. (Range):Volts : N.A.See tableTungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):N.A.Electrode wire feed speed range:N.A.Pulsing current (GTAW):Nil.TECHNIQUES (QW-410)String or Weave Bead:StringOrifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:NilOscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side):Single or MultipleMultiple or single electrode:SingleElectrode eedrangeOthers(hot wire,torchangleetc.)AllSMAWE 3102.5DCEP70-90N.A.N.A.NilAllSMAWE 3103.15DCEP90-120N.A.N.A.NilApproved by:Prepared by:(V.Ravindran)(R.Rajanarayanan)DGM / WTCSr. Welding Engineer / WTC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 1 of 2WPS No.:1218Date: 18.07.01Rev. No:00Date: ------Supporting PQR No: 636Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove & fillet welding of A 588 Gr A components.JOINTS (QW-402)Joint Design: Groove / Fillet as per production drg.Backing (Yes/No): As per production drg.Backing Material (type): NilMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: NilGroup No: NiltoP. No: NilSpec. Type & Grade: A 588 Gr A or equivalentChem. Analysis & Mech. Prop: Nil.Group No: NilThickness RangePipe Dia. range:Others: NilGroove: 1.6 to 6Fillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.FILLER METALS (QW-404)AWS No. (Class):Specn. No. (SFA):E 8018-B2Size of filler metal: See table5.5Flux Trade Names:N.AF. No.:4Consumable insert:N.A.A. No.:3Electrode Flux (Class): N.A.Deposited weld metal thickness rangeGroove: 6mm maximum (maximum 3 mm per pass)Fillet: 6mm maximum (maximum 3 mm per pass)POSITION (QW-405)PREHEAT (QW-406)Nil (10Oc Min)Position of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 300OCWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOther:Nil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 2 of 2WPS No.: 1218PWHT (QW-407)GAS (QW-408)Temp. Range:NilTime RangeNilOthers:NilGasesMix%Flow Rt.Shielding ICAL CHARACTERISTICS (QW-409)Current (AC/DC): See tablePolarity: See tableAmps. (Range):Volts : -do--do-Tungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):N.A.Electrode wire feed speed range:N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:Root: String; Others: string or weave (3 Dia. max)Orifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:Back grinding for second side weldingOscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side):Single or MultipleMultiple or single electrode:SingleElectrode rocessAllSMAW-Do--Do-CurrentOthers(hot speedrangeE N.A.N.A.NilClassApproved by:Prepared by:(V.Ravindran)(R.Rajanarayanan)DGM / WTCSr.Welding Engineer / WTC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONPage 1 of 2Form No. 101-401WPS No.:1217Date: 14.07.01Rev. No:00Date: ------Supporting PQR No: 984Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove & fillet welding of SA 240 Type 304 Stainless Steel componentswithout Preheat & without PWHT.JOINTS (QW-402)Joint Design: As per drawingBacking (Yes/No): As per drawing.Backing Material (type): MetalMetal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: 8Group No: 1toP. No: 8Spec. Type & Grade: SA 240 Type 304 or equivalent.Chem. Analysis & Mech. Prop: N.A.Group No: 1Thickness RangePipe Dia. range:Others: NilGroove: 3.0 mm to 12.0 mmFillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.FILLER METALS (QW-404)AWS No. (Class):E 308Size of filler metal: See tableSpecn. No. (SFA):5.4Flux Trade Names:N.AF. No.:5Consumable insert:N.A.A. No.:8Electrode Flux (Class): N.A.Deposited weld metal thicknessGroove: 12.0 mm max (Max. 5mm per pass)Fillet: Unlimited (Max.5mm per pass)POSITION (QW-405)PREHEAT (QW-406)Nil (10Oc min)Position of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 250OCWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOther:Nil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 2 of 2WPS No.: 1217PWHT (QW-407)GAS (QW-408)Temp. Range:NilTime RangeNilShielding N.AOthers:NilTrailingN.A.BackingN.A.GasesMix%Flow Rt.ELECTRICAL CHARACTERISTICS (QW-409)Current (AC/DC): See tablePolarity: See tableAmps. (Range):Volts: N.A.See tableTungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):N.A.Electrode wire feed speed range:N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:StringOrifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:NilOscillation:N.A.Contact tube to work distance:N.A.Multiple or single pass (per side):Single or MultipleMultiple or single electrode:SingleElectrode llProcessClassSMAWE 3.15DCEP90-120N.A.N.A.Others(hot wire,torchangleetc.)NilApproved by:Prepared by:(V.Ravindran)(R.Rajanarayanan)DGM / WTCSr. Welding Engineer / WTC

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONPage 1 of 2Form No. 101-401WPS No.:1216Date: 29.03.00Rev. No:00Date: ------Supporting PQR No: 529Welding Process: SMAWType: Manual(Auto,Semi-Auto,Manual,Machine)Application: Groove & fillet welding of 1Cr .5Mo/ 1.25Cr 0.5Mo Steel attachment to 2.25Cr1Mo Steel attachment.JOINTS (QW-402)Joint Design: Groove / Fillet as per production drg.Backing (Yes/No): As per production drg.Backing Material (type): As per production drg.Metal/Non fusing metal/:Non metallic/OthersBASE METAL (QW-403)P. No: 4Group No: 1toSpec. Type & Grade: N.A.Chem. Analysis & Mech. Prop: N.A.P. No: 5AGroup No: 1Thickness RangePipe Dia. range:Groove: 9.00 mmFillet: Unlimited.Groove: Unlimited.Fillet: Unlimited.Others: NilFILLER METALS (QW-404)AWS No. (Class):Specn. No. (SFA):E 8018-B2Size of filler metal: See table5.5Flux Trade Names:N.AF. No.:4Consumable insert:N.A.A. No.:3Electrode Flux (Class): N.A.Deposited weld metal thickness rangeGroove: 10.0 mm (Maximum 8 mm per pass)Fillet: 10.0 mm (Maximum 6.0 mm per pass)POSITION (QW-405)PREHEAT (QW-406)150oCPosition of Groove:All.Preheat temp (min). :Position of fillet:AllInter pass temp. (Max.): 300 CWeld Progression:(Up / Down)Vertical up.Pre heat maintenance: NilOOther:Nil.

BHARAT HEAVY ELECTRICALS LIMITEDWELDING TECHNOLOGY CENTRETiruchirappalli-620014WELDING PROCEDURE SPECIFICATIONForm No. 101-401Page 2 of 2WPS No.: 1216PWHT (QW-407)GAS (QW-408)Temp. Range:NilTime RangeNilOthers:NilGasesMix%Flow Rt.Shielding CAL CHARACTERISTICS (QW-409)Current (AC/DC): See tablePolarity: See tableAmps. (Range):Volts: N.A.See tableTungsten Electrode type and size:N.A.Mode of metal transfer for (GMAW):N.A.Electrode wire feed speed range:N.A.Pulsing current (GTAW):N.A.TECHNIQUES (QW-410)String or Weave Bead:Root: String; Others: string or weave (3 Dia. max)Orifice or Gas cup size:N.A.Initial and inter pass cleaning:Brushing/Chipping/GrindingMethod of back Gouging:A

WELDING TECHNOLOGY CENTRE Tiruchirappalli-620014 WELDING PROCEDURE SPECIFICATION Form No. 101-401 Page 1 of 2 WPS No.: 1226 Date: 17.11.06 Supporting PQR No: 1331 Rev. No :00 Date: ----- Welding Process: SMAW Type: Manual (Auto,Semi-Auto,Manual,Machine) Application: Groove & fillet