Transcription

ROTARY EVAPORATORROTADEST R20/R50/R100P134e.0

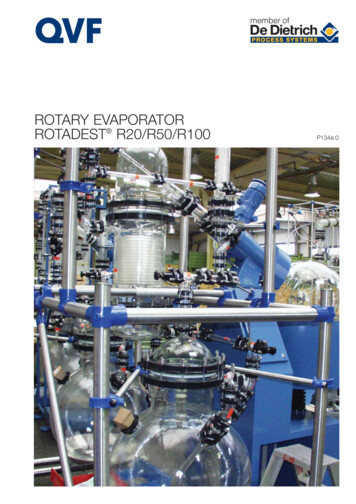

GENERALRotary evaporators belonging to the R product range, whichare preferred in production and are used in engineering, aresuitable for continuous and discontinuous distillation undernormal pressure or in a vacuum. They have the advantage ofproviding careful thermal treatment of temperature-sensitivemediums. Application limits for the rotary evaporator ariseamong other things as a result of the relatively long dwell timeand the attainable viscosity of the final product. Above reliableor attainable limit values, therefore, we recommend the use ofour thin-film evaporator which permits a maximum viscosity ofthe residue of approx. 5000 cP.Exclusive use of borosilicate 3.3 glass and PTFE for allproduct-based parts offers the following benefits:)Proper observability of all process in the areas of)Total chemical resistance against nearly all mediumsevaporation and condensation.Additional special features of this rotary evaporator are:)The robust driving of the rotary sphere by a PTFElined steel sleeve shaft and their sealing of the condenser part using a proven PTFE axial face seal(suitable for permanent and maximum load).)The possibility of choosing between different housingor bath models, types of heating, condenser partsand different varieties of display and control parts(modular system, see order number key).)Simple operationRotary evaporators are suitable for evaporating suspensions,initiating crystallisation processes and drying powders andgranulates. It is also possible to carry out various chemicalreactions.ORDER NUMBER KEY1)Module AHousing with heating bath, rotarysphere and driveR100EAHModule BModule CCondenserDisplay and control part2SpezialSpecial orstandardCondenser part (mod. 1 to 3)Hydraulic or stroke settingLowerable heating bath (not with R20)Bath heating (E electrical, D steam (Dampf)Content of rotary sphere (20, 50, 100 I)ROTADEST1)2housing with wheels are also availableExEx model

PRINCIPLE OF OPERATIONEVAPORATION RATESEvaporation takes place in the externally heated rotary sphere.In this way the rotational movement of the piston ensures agood intermixing of the medium, thus providing regulartemperature distribution.The rotary sphere is indirectlyheated by a water or oil bathto which the necessary energyis fed in a regulated way bysteam or an electrical heatingunit. The steam abandons thesphere at the point where it isflanged to the drive motor. Itflows through a sleeve shaftfeeding through the drive andreaches the condenser part.There it is condensed in thecondenser and cooled in anafter cooler. Then thecondensate reaches therecipient container(s).R100Evaporation rates for carbontetrachloride (CC14) at 1013 mbarThe liquid to be processed in the rotary evaporator is feddirectly into the rotary sphere by a feed pipe conductedthrough the condenser part. When operating under normalpressure, i.e. with open air release valve, this happens bymeans of a pump or through gravitational force, depending onthe arrangement of the supply vessel.8R5064R20200102030405060Flask rotation speed (min-1)Fig. above: The variation of evaporation rates of carbon tetrachloride with theflask rotation speed.Areversiblealternatingrecipient enables condensateto be withdrawn duringoperationundernormalpressure and in a vacuum. The simple recipient makes thispossible only with distillation under atmospheric pressure.SICMTIA PICA vacuumTICA TZ KW3

MODULE AROTARY SPHEREHOUSING WITH HEATING BATH, ROTARYSPHERE AND DRIVEIn all rotary evaporators this consists of nearly totallycorrosion-resistant borosilicate 3.3 glass. Attachment to thedrive makes detachment easier using hasp screws. Use ofspecial palettes when assembling and disassembing thespheres also simplifies this job. Such palettes are, however,only usable in housing versions with lowerable heating bathsand can be delivered as an accessory.Only housing models with integrated heating bath are availablefor size R20 rotary evaporators. The possibility of lowering thebath heating is not necessary here because the overall heightand the content of the sphere are low. To make assembly anddisassembly easier the sphere can be equipped with anadditional support ring.Housings for the R50 and R100 rotary evaporators can bedelivered with permanently installed or lowerable heating bath.With the model just mentioned the bath heating is raised andlowered using a hydraulic cylinder. The standard versionactivates it with a hand pump or a pressure outlet valve. Thespecial model on the other hand is delivered with an electricaloil pump and an on/off buttonon the operator panel. In theevent of power failure ornetwork shutdown, in bothvariants the heating bath isforcibly lowered with amagnetic valve. The entirehydraulic installation includingthe oil supply container isplaced in the housing. Allheating baths can be heatedeither electrically or with steam. Either water or other heatexchangers, e.g. oil, can be used as a bath liquid. A splashguard keeps back the entrained bath liquid with the rotation ofthe sphere and serves at the same time as protection againstaccidental contact.The nominal capacity of the spheres is 20, 50 or 100 litres. Forthe purpose of intensive intermixing as well as for powderedsubstances the rotary spheres can also be delivered withindentations (internally raised) distributed above the surface.DRIVEIn all models a robust andproven drive motor serves asa power plant for the rotarysphere. Its driving motorspeed can be continuouslyadjusted by hand. Speedmeasurement with digitaldisplay on the operator panelcan be provided.An electric motor withfrequency converter, setpointadjuster and digital displaycan be provided as analternative to the drive motor,likewise at extra cost.The rotary evaporator's housings are delivered ready forconnection i.e. including internal pipework and wiring. Theaccesses and outlets for the cooling water to and fromcondenser parts are in the housing wall. The associatedmanually actuated valve is placed on the operator side. A ductis planned for the electrical connection.A PTFE-lined steel sleeveshaft serving as a vapourpipe, to which the rotarysphereispermanentlyattached, is directly driven atthe same time. This sleeve shaft is sealed against thecondenser part by a PTFE axial face seal. The connection ofdrive and condenser part is made by a PTFE bellows.All rotating parts, including the connection flange of the rotarysphere are sealed with a protective cap.TECHNICAL DATATypERotating flaskCapacityRotation speedDriveElectrically heatedSteam heatedBath activity1)2)4R50.R100.l2050100min-10 - 1080 - 820 - 82Type1)PowerBath heatingR20.kW2)Drive motor with continuous speed regulation0,250,370,37kW4,5912bar666Hand hydraulicsHydraulic cylinder, hand pump, pressure outlet valve,automatic lowering during power failure or networkshutdown by magnetic valveMotor hydraulicsHydraulic cylinder, electrical oil pump, on/off button(forced gearing as in standard)Alternative motor with electrical speed regulation by frequency converter at extra costSurface temperature is limited to 160 C, for equipment in Ex-zones to 120 C.

MODULE BCONDENSER OPTION 2CONDENSER PARTThis version has the same principal as option 1 but utilises astandard condenser. This system is fitted with two sphericalreceivers, therefore allowing one to be exchanged, enablingcontinuous operation under vacuum as well as atmosphericpressure. The vacuum connection in this system is fitted withthe bellows unit.This module is the complete condenser part in which thecondensate is condensed and collected. It essentially consistsof a condenser with or without an after cooler, one or tworecipients, the connecting pipes, including the necessary fixingas well as a vacuum connection. The condenser part issupported by a console attached to the housing.Condenser parts have already been designed and delivered ina variety of different models to cater to the special desires ofthe user. However, experience has shown that a wide field ofapplication is covered by the varieties described below. Theyall have product feeding, concentrate and distillationextraction, connections to cooling water and vacuum as wellas a ventilation and pressure measurement acuumventventventdraindrainCONDENSER OPTION 1Option 2:This condenser arrangement with integral spherical receiverhas single vacuum, venting and drain connections fitted withvalves. The vacuum connections is equipped with a bellowsvia tee-piece for connection to both vacuum pump andpressure gauge. There is also a facility for filling and suctionemptying the rotating flask. This arrangement is supported bymeans of a bracket fixed to the cabinet.CONDENSER OPTION 3This system incorporating a combined condense and productcooler was developed for particularly high performancecooling and continuous operation under vacuum. A risingcondenser and a flooded secondary product cooler ensureoptimum cooling of the condensate. The exchangeablereceivers also provided, permit continuous operation undervacuum as well as atmospheric pressure. The flooding of thelower cooler is achieved by means of a overflow.Rotary film evaporators incorporating this type of condenserarrangement are suitable for continuous operation atatmospheric pressure or batch operation under rcooling inOption 1:Condenser partCoolerOption 1Option 2m2m21,01,01,51,51,5 0,7m2l2,52,52,5 0.R100.CapacitydrainOption 3:Option 35

MODULE CThis module includes all component parts of the rotaryevaporator for monitoring and controlling the distillationprocess parameters. The operating panel with analogue and/or digitally display devices and buttons, positioned for theconvenience of the operator, is placed in the upper housingpart. The main switch is directly below the operator panel.All housings with their switch and control gear are, as with theterminal boxes, placed in the lower housing part of the rotaryevaporator and easily accessible from outside by a removablecover. Explosion-protected models have compression-proofenclosed housings.In all other cases they aredesigned splash-proof (IP 54type of protection). The operatorpanels have analogue or digitaldisplays depending on themodel (see technical data):- the head temperature in thecondenser- the bath temperature- the vacuum- the speed of the rotary sphere(special request)Fig. above: glass parts with dissipative coating.One power supply 230/400 V, 3 Ph, N, PE.TECHNICAL DATADesignStandardStandard ExFunctionHead temperatureBath temperature electricallyheatablesteam heatedVacuumRPM1)2)3)6SpecialSpecial ExMeasurementThermometer withexpansion sensor 1)Resistance thermometer withelectric display 1)DisplayAnaloguedigitalMeasurementThermometer with expansion sensoras two-position controller incl. limitvalue signal max.Resistance thermometer with electr.two-position controller incl. limitvalue signal ition controllerTwo-position controllerThermometer with expansion sensorincl. max. limit value signalResistance thermometer with electr.two-position controller incl. limitvalue signal maxDisplayAnaloguedigitalControldirect-acting thermostat with set value area 50 150 CMeasurementManometer with measurement range-1 to 0 bar 2)Absolute pressure transmitter withelectric indicator 2) 3)DisplayAnaloguedigitalFinal controlelementDisplayHandwheel with vernier scaleHandwheel with vernier scale atextra cost (with digital display)With limit value signalling Max at extra costWith limit value signalling min at extra costAlternative electrical two-position controller at extra cost.

DIMENSIONSR20.R50./R100.,Spherical receiver integralSpherical receiverR50. .A/R100. A,Spherical receiver mm660740840mm-3203801)control panel can be installed on the other side2)inclusive level control (in case of Ex-proof version)2)2)CONDENSER PARTOption 1Option 2CondenserTypeOption 3Option 1Option 2Option 33757

Postfach 33 69D-55023 MainzHattenbergstraße 36D-55122 MainzTel.: ( 49) 0 61 31/ 97 04-0Fax: ( 49) 0 61 31/ 97 04-500E-mail: mail@qvf.deInternet: www.qvf.com05.05, Engi34e.0, Änderungen vorbehaltenQVF ENGINEERING GMBH

PRINCIPLE OF OPERATION EVAPORATION RATES The liquid to be processed in the rotary evaporator is fed directly into the rotary sphere by a feed pipe conducted through the condenser part. When operating under normal pressure, i.e. with open air release valve, this happens by means of a pump or through gravitational force, depending on the arrangement of the supply vessel. Evaporation