Transcription

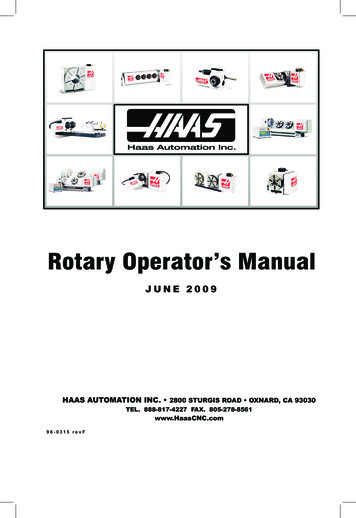

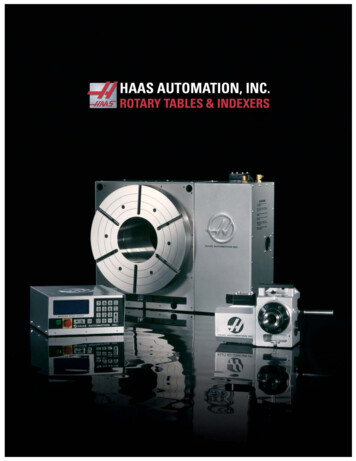

IN THE BEGINNING . . .In 1983, Haas Automation, Inc., developed the first fully programmable 5Ccollet indexer. Built with quality materials and engineered to be dependableand highly accurate, the unit was a tremendous success. By closing the gapbetween cumbersome, manually operated indexers and very expensive true4th-axis machining centers, Haas established itself as an industry leader inautomated 4th-axis parts positioning. By assisting industry in the quest toincrease productivity through automation, Haas has become America’sleading builder of machine tools and rotary tables.After more than two decades of ongoing refinement and development,Haas rotary products continue to dominate the industry with qualitycraftsmanship, dependable operation and affordable prices. Today, Haasmanufacturers more than 40 models of rotary tables and indexers thatdeliver the same high quality and extremely accurate performance that isthe Haas made-in-America trademark.The full line of Haas rotary products includes many specialized unitsdesigned for maximum productivity. From the multi-head HA5Cs to tiltingT5Cs and dual-axis trunnion models, Haas continues to lead the way tohigher productivity through automation.Haas rotary products are built from top-quality materials and undergoconstant re-engineering and refinement to offer only state-of-the-arttechnology. Constructed of heavy-duty materials, and designed fordependable day-in, day-out operation, Haas rotary products are thebenchmark by which all others are measured.Take a close look at the components that go intoour rotary tables. Haas manufactures all criticalcomponents in-house at our modern Californiamachining facility. By controlling the machiningprocess, we’re able to deliver the kind of qualityand accuracy our customers demand.One example of this is the indexing accuracy ofour rotary tables. At the core of every Haas rotarytable is a large-diameter, aluminum-bronze wormgear meshing with a ground alloy steel worm(hardened to 60 Rc) submerged in a synthetic oilbath. The secret to Haas’ indexing accuracy iscutting the worm gear while it’s attached to thespindle, rather than assembling the finishedworm gear to the spindle as other rotary tablemanufacturers do. Each assembled spindle isindividually trammed-in on a CNC gear hobber toa maximum 2-micron runout, and then the wormgear is precision cut.This process guarantees the utmost concentricitybetween the large-diameter ball bearings and theworm gear, ensuring many years of smooth,extremely accurate and bind-free operation. Thisis just one of the many quality designs that go intoevery Haas product.CONTENTSServo ControlUltra-Compact Rotary2-34HA5C6-7HRT8-9HRT SP Series10-11HRT SHS, 320FB12-13HRT Dual Platter14-15HRT A lstocks25-27QuikChange System28-29Accessories30-32

A solid, robust design.Fast Alignment – All Haas rotary tables and tailstocks have 0.6245"alignment keys. These keys are parallel to and centered on the spindle. Whenused on Haas VMCs with their precision T-slots, you can bolt on a rotary productwithout the need to indicate the table in. (Not shown)Main Body – Class 30 iron is used for its superior damping qualities.Extremely rigid, it damps vibration and deflects machining forces. Machined byHaas in only two operations on FMS machinery.➋➋Turntable Platter – Haas uses only 4140 alloy steel, heat-treatedto 35-40 Rc, for our platters. Machined and rotary ground in-house, theydeliver superior strength and durability. Made by Haas.➌Bearings – Two pre-loaded, deep-groove radial bearings withstandloads up to 31,000 lb. By supporting the worm gear on both sides withthese massive bearings, Haas is able to deliver superior performance anddependable operation. Precision-made in the USA.➍Worm Gear – Haas’ large-diameter aluminum-bronze worm gearis hobbed on a CNC gear hobber and inspected on a Wenzel WGT500CNC gear analyzer. Made by Haas.➎Worm Drive Shaft – Our drive shafts are made of 8620 steelhardened to 60 Rc. They are CNC precision-ground, and then inspected toa 2-micron runout on a Wenzel WGT500 CNC gear analyzer. Made by Haas.➏Brake Disc – Our brake discs are made from 4140 chromoly steelheat treated to 30-35 Rc. The thrust-bearing surface on the brake is rotaryground to further enhance wear resistance. Specially-designed seals provideprotection from the elements, while reducing the drag commonly associatedwith compression seal designs. Made by Haas.➐➌Motor Enclosure – The motor enclosure features heavy-gaugesteel, with special closed-cell foam gaskets to maintain a watertightassembly. Powder coated in brilliant silver for protection.➍➎➐➏

The HaasServo ControlABCSCOLAGENCY STEROPEMBrushlessRotary Two-AxisControlAt the heart of all Haas rotary products is the Haas Servo Control.Refined by more than two decades of development, it offers the utmostin versatility, coupled with fast, easy, flexible programming. The Haascontrol always incorporates the latest high-speed microprocessor and drivetechnology.CYCLESTARTJOGZERORETURN7 8 94 5 61 2 -ACHaas’ exclusive software replaces failure-prone mechanical components, andincludes a self-diagnostic subroutine that maximizes uptime. A single circuitboard controls all main functions.When used with any CNC machining center, the control performs asa semi-4th axis, activated by a single M code. Easy interfacing, fast set up andlow cost make Haas the perfect alternative to cumbersome, high-priced,offshore 4th-axis machines.DIMENSIONSSCOLSCO2-AC(Inches Millimeters)ABC11.12 282.511.12 282.56.19 157.29.19 233.40.62 15.80.62 15.8Using the control’s standard features, odd-number bolt circles and unevenhole spacing are easily performed with simple programming.You can program the control to rotate the spindle in either direction, in stepsizes from 0.001 to 999.999 . There can be up to 99 different steps in memory,and each step can be repeated (or looped) up to 999 times. Thememory is non-volatile, so programs are fully retained, even when the power isturned off. You may store up to 10 separate programs.You can easily achieve three times the performance of a manual device witha Haas control operating the rotary table of your choice. Add to this built-in-theUSA Haas quality and reliability, and your decision becomes very simple. Haashas the solutions you need.2 Fast, easy, flexible programmingSimple CNC interfacing via M codeVariable feedratesLinear, arc & spiral millingFast setupsHigh accuracy & repeatabilityAbsolute or incremental programmingAutomatic circle divisionNon-volatile program storageRS-232 interfaceOperates on 110 to 120 VAC power12-month limited warrantyMade in the USA

The Rotary Interfaceaas rotary products can be interfaced to virtuallybeen successfully interfaced to a very wide variety ofany type of machine. There are three distinctmachines over the years. Haas Automation’s Servicemethods of interfacing listed below, each with differentDepartment can provide expert advice on the bestcapabilities. Thousands of Haas rotary products haveinterface for any application.HTrue 4th-Axis* Direct Control Via Host MachineNotes:This method does not use the Haas Servo Control unit; instead,an amplifier built into the host machine provides power and truemulti-axis simultaneous motion control. All Haas machiningcenters can be fitted with additional amplifiers that work with offthe-shelf Haas rotary products. With this method, the rotary axis isprogrammed and controlled directly by the host control – just likethe X, Y and Z axes. For direct control on machines other than Haas,some Haas rotary products can be refitted with compatibleservomotors (Fanuc , Yasnac , Allen Bradley, etc.).The Haas Servo Control can also be interfaced to PLCunits and computers for general-purpose use. Please contactHaas Automation for details.*The term “4th axis” is used as a general description. Unitmay operate as any axis depending on host machine.4th-Axis Control Via RS-232 PortThis method requires use of a Haas ServoControl unit and a host machine capable ofsending data via an RS-232 line. All Haas CNCmachine tools can send such data to control upto three daisy-chained Servo Controls. On HaasCNC machines, the rotary axis is programmeddirectly on the CNC control – just like the X, Yand Z axes – and no M codes are required. Allother CNC machines require macro functioncapability, an external M-code controlled relay,and an M-FIN connection. Programming is stilldone at the CNC control.Semi 4th-Axis Control ViaCNC Interface CableThis method requires use of a Haas ServoControl unit and a host machine capable ofclosing a relay (or switch). Most CNC machinetools are equipped with spare M codes, whichcan be used to close a relay. Indexingcommands are stored only in the ServoControl’s program memory. Each pulse of thehost machine’s relay triggers the Servo Controlto index to its next programmed position. Afterfinishing the index, the Servo Control signalsthat it has finished and is ready for the nextpulse. Fully-synchronized multi-axis motionscannot be performed with this method. Thismethod can be used with machine tools thathave no controls.Diagram of Control Indexer InterfaceSERVO CONTROLYOUR MACHINECNCINTERFACECABLEM FUNCTIONRELAYYOUR CNC MILLCYCLESTART680 OHM43 24 VOLTSM FINSIGNALINDEXER / ROTARY TABLEINDEXERCONTROL CABLE4 PIN DIN CONNECTORREAR OF CONTROLLER12 12 VOLTSCYCLEFINISHRELAYHAAS HA5C INTERNAL4th-axis ordering informationWhen ordering a Haas rotary table or indexer for use on a Haas machiningcenter with a built-in 4th- and/or 5th-axis drive, it is not necessary to purchasethe Haas Servo Control unit. However, we suggest you purchase the ServoControl so you can use your rotary table on other machines. Before placing yourorder, please discuss with your Haas distributor the make and model of CNCmachine on which you intend to use your new rotary table.3

New Ultra-compact 110 SeriesThe TR110 dual-axis trunnion table provides accuratepositioning and full 5-axis motion for machining small parts. Itssmall size and light weight make the TR110 the perfect 5-axissolution for even the smallest machining centers. Indexingspeeds up to 300 /sec ensure fast cycle times.The HRT110 is a single-axis rotary table driven by an80:1 harmonic drive system coupled to a powerfulbrushless servomotor to provide indexing speeds upto 300 /sec, and spindle torque of 65 ft-lb. Smallerthan a 7" cube and weighing just 29 lb, the HRT110rotary table provides accurate positioning andsimultaneous 4-axis motion for machining small parts.TR110SPINDLE65 ft-lb 88 NmRunout Max0.001" 0.03 mmBacklash30 arc-secSpeeds0.001 to 300 /secTooling3 Bolt Patterns x 6Brake Torque40 ft-lb @ 40 psi 54 Nm @ 2.8 barCenter Height3.000" 0.001 76.20 mm 0.03 45 arc-secRepeatability10 arc-secResolution0.001 Max Rotation/Step999.999 Operating Temp. (max ambient)100 F 38 CPower Required (VAC)115 5% @ 15 AMax Air Pressure60 psi 4.1 barPlatter Diameter30 arc-sec30 arc-secSpeeds0.001 to 300 /sec0.001 to 300 /secBrake Torque (ft-lb @ 40 psi) (Nm @ 2.8 bar)40405454Accuracy 45 arc-sec 45 arc-secRepeatability10 arc-sec10 arc-secResolution0.001 0.001 Max Rotation/Step999.999 120 80:1 Harmonic Drive80:1 Harmonic DriveDuty Cycle full/low speedOperating Temp. (max ambient)50% / 100%100 F 38 CPower Required (VAC) 1-axis control115 5% @ 15 APower Required (VAC) 2-axis control235 10% @ 20 AMax Air Pressure60 psi 4.1 barPLATTERPart Swing (max)7.35" 186.7 mmCapacity20 lb 9.1 kgPlatter Diameter4.3" 110 mmWEIGHTPLATTERCapacityN/ABacklashOPERATING SPECIFICATIONS80:1 Harmonic Drive50%/100%65 ft-lb 88 Nm0.001" 0.03 mmMOTOROPERATING SPECIFICATIONSDuty Cycle full/low speed65 ft-lb 88 NmRunout MaxGear RatioMOTORGear RatioTorqueINDEXING1INDEXING1AccuracyTilt A axisSPINDLEHRT110TorqueRotary B axis20 lb 9.1 kgTable4.3" 110 mmBrushless ControlWEIGHTTable29 lb 13.2 kgBrushless Control14.2 lb 6.4 kg485 lb 39 kg23.1 lb (2-axis) 14.2 lb (1-axis)10.5 kg (2-axis) 6.4 kg (1-axis)

High-Speed 5C Collet IndexerOur Super-High-Speed5C Collet IndexerThe Haas HA5CSB collet indexer reducescycle times and positions parts at725 /secHA5C SBSPINDLETorque20 ft-lb 27 NmRunout Max0.0004" 0.010 mmBacklash40 arc-secSpeeds0.001 to 725 /secColletsstd 5C (1/64" -11/16") std 5C (0.4 to 27 mm)Nose Thread2 3/16" -10Center Height4.000" 0.001 101.60 mm 0.03INDEXING1Accuracy 30 arc-sec High-torque brushless servoRepeatability10 arc-sec 725 /second feedratesResolution0.001 Max Rotation/Step999.999 Simple bolt-on mountingWorm Gear Diameter2.8" 71 mm Reduces cycle timesMOTOR Speeds drill & tap operationsOPERATING SPECIFICATIONS High-speed engravingDuty Cycle*75% @ full speedOperating Temp. (max ambient)100 F 38 C 20 ft-lb spindle torquePower Required (VAC)115 5% @ 10 AMax Air Pressure (air collets)120 psi 8.3 barGear Ratio (worm & gear)33:1WEIGHTHA5C SeriesPart #HA5CSBDescriptionSuper-High-Speed Servo Indexerw/Manual Handle Collet CloserRotary Head48 lb 21.8 kgBrushless Control14.2 lb 6.4 kg*Without tailstock. 1See page 36.Due to continual development, all machine specifications are subject to change.Dimensions are the same as the HA5C (see page 6).See next page for standard 5C-series indexers5

StandardHA5C SeriesThe Haas HA5C series is the ideal choice for holdingsmaller parts. Clamp your parts using standard 5Ccollets, or chuck them by threading a 3-jaw chuck to the2 3/16 "-10 spindle nose. Collets can be closed with yourchoice of a manual handle or an optional air collet closer.The HA5C series is easy to program, interface and setup. Haas’ own precision in-house manufacturing andmachining processes ensure high quality and years ofdependable operation. With more than two decades ofrefinement, the Haas HA5C is the industry benchmarkfor quality, accuracy and dependability.HA5C SeriesHigh-ProductivityMulti-Spindle IndexersBy spacing the heads as close together as possible,Haas is able to obtain the

You can easily achieve three times the performance of a manual device with a Haas control operating the rotary table of your choice. Add to this built-in-the-USA Haas quality and reliability, and your decision becomes very simple. Haas has the solutions you need. † Fast, easy, flexible programming † Simple CNC interfacing via M code † Variable feedrates † Linear, arc & spiral milling .