Transcription

Design of Helix-Rotary EvaporatorConcept development, Design and Material selectionRotationsförångareKonceptutveckling, konstruktion och materialvalSurafel TesemaFaculty of Health, Science and TechnologyDegree Project for Master of Science in Engineering, Mechanical Engineering30hpSupervisor: Mikael GrehkExaminer: Jens Bergström2018-07-131

AbstractTougher environmental legislations are a driving force for development of aftertreatmenttechnologies for truck and car exhaust gases. In particular, the emission requirements are highon nitrogen oxides (NOx) and particulate matter. Focus of this thesis work is to develop acomponent in the exhaust system, a NOx level reduction system. The currently used technologywith urea evaporator has problem with formation of urea crystals due to delayed ureaevaporation. Crystalline urea causes reduced exhaust flow and thus build up a pressure in thesystem that has negative impact on the performance of the engine. Feasibility study was doneto understand function, advantage and disadvantages of current design and the need for a newdesign.The main task of this project was to investigate and propose a new design of the helix-rotaryevaporator and to present it in the form of parametric model. Material selection needed for ureainjection arrangement, 3D printed model for visualization of the concept and integration of themodel to next generation aftertreatment system (NGA) are examples of sub-tasks that wasperformed to reach the main objective.Several generations of selected concept were developed in 3D design which later was 3Dprinted to visualize the ideas. The parametric 3D model was designed so that it later serves asinput model for a later phase in the development project, where computational fluid dynamicsis utilized. Parametric modelling is used to provide wide range of possibility to generatedifferent models for simulation and reduce pre-simulation works. Selected concept parametricmodel has six different parameters that can be analysed. Material selection carried out toinjection manifold thought CES Edupack and consultancy of material engineers. Threedifferent austenitic stainless steels were recommended.Keywords:Aftertreatment system, SCR, Urea evaporator, Material selection, Parametric modelling

SammanfattningHårda miljökrav har varit största drivkrafterna bakom utvecklingen avavgasefterbehandlingssystem. Främsta emissionerna som är lagkrav på är kväveoxider ochpartiklar. I detta examensarbete utreds och designas en parametrisk 3D-modell helt frångrunden i en nästa generations ljuddämpare, med utgångsinformation från en innovation. Engeometriskt gångbar konfiguration av en förångare som är lämpad för simuleradflödesberäkning samt visualisering av densamma via formfriframställning.Den nuvarande förångaren har problem att det bildas en ammonia klump på grund avofullständig förångning av urealösning. Bildad kristall skapar mottryck för flödet och därförvill man utveckla en bättre förångare för att kunna förånga urean jämnare och därmed minskaöverdoseringen. Förstudien handlade om att förstå principerna bakom den nuvarandeförångningsmodulen och nya tänket där Scania har tagit ett patent på, vill man styra in flödettangentiellt samtidigt som man en insprutningsarrangemanget placerat i inloppet.Koncept vald från patentet och utvecklad i olika generationer, vilket senare användes för attbeställa FFF-modell. En parametrisk modell av konceptet utvecklades och är förbered för CFDberäkning. Parametriska modellen består av sex olika parameter som senare kommer användasför att kunna optimera modellen. Modellens lämplighet för CFD är verifierad. Materialval förinsprutningsarrangemanget gjordes och tre olika autentiska stål rekommenderad. Slutgiltigamaterialvalet bör göras senare med diskussion med leverantörer. 3D printad plast modellentestade med tryckluft för att simulera flödesvägarna.Stora konstruktions ändringar krävs för att kunna integrera rotationsförångare med nästagenerations avgasefterbehandlingssystem. Parameter optimering och tillverkningsbarhet arbetekrävs för att kunna ta arbete till nästa fas.

AcknowledgementsFirst and foremost, thanks to the Almighty God for giving me strength and wisdom to finishthis thesis work.I am thankful to my supervisors Gustav Jonsson and Ingmar Lundin for their guidanceand discussions which always resulted in improvements of the work.Thanks to my KAU supervisor, Mikael Grehk, for his continuous follow up andshown interest.Further thanks for whole my team, NXDX and David Norrby(NXPS) for their helpand encouragement during my thesis work.Lastly, I wish to thank my family and my close friends for support and motivation toachieve my goals.Surafel Fiseha Tesema

NomenclatureCAD Computer Aided DesignComputer based tool to design and draftingDOE Design of experimentsSmart and very powerful tool to gather knowledge to develop a systemCFD Computational Fluid DynamicsA type of fluid mechanics to calculate and analyse fluid flowsDOC Diesel Oxidation CatalystCatalyst converter, hydrocarbon and carbon monoxide to carbon dioxide and waterKBE Knowledge Based EngineeringA methodology to capture the engineer’s routine knowledge to perform the design automationSCR Selective Catalytic ReducerA method used in aftertreatment system to reduce NOx emissionsNGA Next Generation Aftertreatment SystemA new aftertreatment system under developmentNEDC New European Driving CycleA driving cycle designed to analyse emission levels and fuel economy

Contents1.Introduction . 2Scania . 2Background . 2Purpose and Objective . 4Deliveries . 42.Thesis methodology. 5Thesis delimitations. 5Pre-phase . 5Patent study . 5Visualization of concept . 5Concept integration . 6Parametric modelling . 6Material selection . 63.Theoretical Framework. 7Diesel Engine . 73.1.1What Is the Diesel Engine? . 73.1.2Types of Diesel Engines . 83.1.3Characteristics of Diesel Engines . 83.1.4Emissions . 9Silencer . 113.2.1Purification . 113.2.2NOx reduction systems . 123.2.3SCR . 123.2.4Evaporations unit . 133.2.5Urea evaporation . 14Catia V5. 154.3.3.1Direct modelling . 153.3.2Parametric modelling . 153.3.3Knowledge-based Engineering . 16Results . 181st generation of helix-rotary evaporator . 182nd generation of helix-rotary evaporator . 19

3rd generation of rotational evaporator . 19Design of Experiment result . 20Parameter selection . 22Material selection . 244.6.1Injector . 24Material selection . 28Applied experiments, preliminary CFD simulation and proposal for a new design . 295.Discussions . 336.Conclusions . 347.Future work and challenges . 358.Reference . 369.Appendix . 39

AppendicesAppendix A:Design space . 39Appendix B:Generated geometric designs . 40Appendix C:Valid model results from DOE . 41Appendix D:Mechanical properties of EN 1.4990. 45Appendix E:Mechanical and physical properties of EN 1.4305 . 46Appendix F:Mechanical and physical properties of EN 1.4404 . 46Appendix G:Mechanical and physical properties of AISI 310 . 47Appendix H:Mechanical and physical properties of EN 1.4948 . 47Appendix I:Creep and physical properties of EN 1.4878. 47Appendix J:Mechanical and physical properties of EN 1.4828 . 47Appendix K:Mechanical and physical properties of EN 1.4550 . 48Appendix L:Development of models . 48Appendix M:Chemical composition, mechanical and physical properties thema xx . 55

1. IntroductionThis section describes company, backgrounds, purposes, delimitations and the method forwhich the thesis work is intended to be performed. The section is intended to give a clearview of the content of the thesis.ScaniaScania CV AB is one of the world's leading manufacturers of heavy duty vehicles and enginesfor industrial and marine use. Scania is the market leader in heavy duty exhaust after-treatmentsystems that is seen as a strategic technology area where Scania will continue to develop thetechnology on its own and in cooperation with the other heavy vehicles of the VW VehicleGroup. Scania has 45,000 employees and operates in 100 countries. The R&D (Research andDevelopment) activities are mainly located in Södertälje, Sweden, with some 3,500 employees.Scania also has some Research and Development operations in Brazil and India [1].NXDX is a group at Scania CV AB, Södertälje, which develops silencer and exhaust aftertreatment technology for trucks and buses. After-treatment system includes exhaust gaspurification, such as reducing diesel particle and nitrogen oxide emissions. In order to be ableto keep up with the development and environmental legislation, Scania must constantly developnew technologies. This thesis project is part of such a development project.BackgroundEnvironmental considerations for vehicle have developed over time and hence environmentallegislation has become tougher. In particular, the emission requirements are higher on nitrogenoxides (NOx) and particulate matter. When comparing the legal requirement as entry 17 yearswith Euro 3 to the current Euro 6, one can see a large

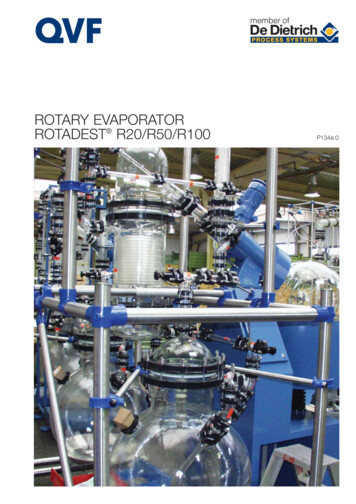

Patent only incorporates the principle of the helix-rotary evaporator therefore Scania is interested in implementing this thinking. Figure 1 Tangential injection arrangement. [3] 17 Inlet 26 Manifolder Alternative solution. 4 Purpose and Objective This project is performed by request of Scania CV AB, as a thesis work for the Degree of Master of Science at Karlstad University, Department of .