Transcription

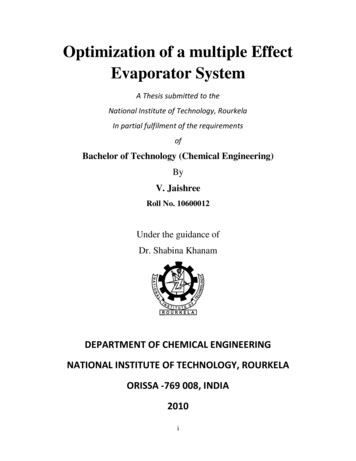

Optimization of a multiple EffectEvaporator SystemA Thesis submitted to theNational Institute of Technology, RourkelaIn partial fulfilment of the requirementsofBachelor of Technology (Chemical Engineering)ByV. JaishreeRoll No. 10600012Under the guidance ofDr. Shabina KhanamDEPARTMENT OF CHEMICAL ENGINEERINGNATIONAL INSTITUTE OF TECHNOLOGY, ROURKELAORISSA -769 008, INDIA2010i

DEPARTMENT OF CHEMICAL ENGINEERINGNATIONAL INSTITUTE OF TECHNOLOGY,ROURKELA -769 008, INDIACERTIFICATEThis is to certify that the thesis entitled “Optimization of a Multiple Effect Evaporator”,submitted by V.Jaishree for the requirements of bachelor’s degree in ChemicalEngineering Department of National Institute of Technology, Rourkela is an originalwork to the best of my knowledge, done under my supervision and guidance.Date-07/05/10Dr. Shabina KhanamDepartmentofChemicalEngineeringNational Institute of Technology,Rourkela- 769008ii

ACKNOWLEDGEMENTIn the pursuit of this academic endeavour, I feel I have been singularly fortunate. I shouldfail in my duty if I do not record my profound sense of indebtedness and heartfeltgratitude to my supervisor Dr. Shabina Khanam who inspired and guided me in thepursuance of this work.I owe a depth of gratitude to Prof. S.K. Agarwal, H.O.D. of Chemical Engineeringdepartment, National Institute of Technology, Rourkela, and all other faculties for all thefacilities provided during the course of my tenure.Date-07/05/10V.Jaishreeiii

CONTENTSPage No.Abstracti iList of figuresii iiList of tablesiiiNomenclatureivChapter 11INTRODUCTION21.1 Application of evaporators31.2 Problems associated with multiple effect evaporators31.3 Objectives4Chapter 25LITERATURE REVIEW62.1 Different types of evaporators62.1.1 Horizontal tube evaporators62.1.1.1 Horizontal spray film evaporators672.1.2 Short tube vertical evaporators2.1.2.1 Basket type evaporators72.1.2.2 Inclined tube evaporators72.1.3 Long tube vertical evaporators7iv

2.1.3.1 Rising or climbing film evaporators82.1.3.2 Falling film evaporators82.1.3.3 Rising falling film evaporators82.1.4 Forced circulation evaporators82.1.5 Plate evaporators92.1.6 Mechanically aided evaporators92.2 Black liquor102.2.1 Properties of black liquor102.2.2 Composition of black liquor in the current study112.3 Methods of modeling of multiple effect evaporator systems12Chapter 31314PROBLEM STATEMENT15Chapter 417DEVELOPMENT OF MODEL & SOLUTION TECHNIQUE184.1 Mathematical model for a particular effect204.2 Model for liquor flash tank214.3 Model for condensate flash tank214.4 Empirical relation for overall heat transfer coefficient224.5 Representation of flow sequence234.6 Generalized model of an effect304.7 Solution technique31v

4.8 Algorithm33Chapter 534RESULT & DISCUSSION35Chapter 641CONCLUSION42REFERENCE43vi

ABSTRACTA septuple effect flat falling film evaporator system for the concentration of blackliquor is studied and a generalized cascade algorithm is developed for the differentoperating strategies. The amount of live steam consumption in the system is evaluated forthe given base case parameters. Then the amount of auxiliary vapour produced due to theuse of one feed flash tank and seven condensate flash tanks was determined. It was foundthat the presence of flash tanks helps in recovering heat from the used vapour and therebyreduces the overall live steam consumption of the system and improves the overall steameconomy of the system. Thus it helps in making the system more economical.i

LIST OF FIGURESFigure no.TitlePage no.Fig 3.1Schematic diagram of the system15Fig. 4.1Block Diagram of ith effect of an evaporator17Fig 4.2Block diagram of a flash tank19Fig. 4.3Block Diagram of a Condensate Flash Tank20Fig 4.4Block diagram of an effect for cascade simulation22Fig 4.5Matrix representation of toal mass balance23of n effect evaporatorFig 5.1Block diagram representing resultsii36

LIST OF TABLESTable noTitlePage no.Table 2.1Organic constituents of black liquor10Table 2.2Inorganic constituents of black liquor10Table 3.1Base case operating parameters13Table 3.2.Geometrical parameters of the evaporator14Table 4.1Values of the constants for equation number 1221Table- 4.2Matrix representation of set of linear algebraic28equations given by equation 36 and 37Table 5.1Initial pressure difference values of each effect33Table 5.2Specific enthalpy of vapour of each effect33Table 5.3Specific enthalpy of liquor from each effect34Table 5.4Liquor flow rate, concentration and vapour35flow rate from each effectTable 5.5Vapour generated from flash tanks37Table 5.6Modified values of vapour from each effect37Table 5.7Values of parameters to obtain set of38linear equations in table 4.2Table 5.8Modified pressure values after first iteration39Table 5.9Amount of vapour required by each effect39before flashing and after flashingiii

NOMENCLATUREThe following nomenclature is used for the development of modeling equationsSymbol usedParameterLLiquor flow rate (kg/s)COCondensate flow rate (kg/s)VRate of vapour produced in evaporator (kg/s)xiMass fraction of solid in liquor in ith effectxfMass fraction of solid in feedhSpecific enthalpy of liquid phase (J/kg)HSpecific enthalpy of vapour phase(J/kg)hlSpecific enthalpy of liquor (J/kg)UOverall heat transfer coefficient (W/m2 K)AHeat transfer area of an effect (m2)TVapour body temperature in an effect (K)TLLiquor temperature in an effect (K)τBoiling point risenTotal number of effectsnsNumber of effects supplied with live steamC1 – C5Constants in mathematical modelPPressure of steam in vapour bodies (N/m2)iv

kIteration numberPIPerformance indexa1 – a4Coefficients of cubic polynomialCPPSpecific heat capacity of black liquorv

Chapter 1Introduction1

Chapter 1INTRODUCTIONEvaporators are kind of heat transfer equipments where the transfer mechanism iscontrolled by natural convection or forced convection. A solution containing a desiredproduct is fed into the evaporator and it is heated by a heat source like steam. Because ofthe applied heat, the water in the solution is converted into vapour and is condensed whilethe concentrated solution is either removed or fed into a second evaporator for furtherconcentration. If a single evaporator is used for the concentration of any solution, it iscalled a single effect evaporator system and if more than one evaporator is used for theconcentration of any solution, it is called a multiple effect evaporator system. In amultiple effect evaporator the vapour from one evaporator is fed into the steam chest ofthe other evaporator. In such a system, the heat from the original steam fed into thesystem is reused in the successive effects.1.1 Application of evaporatorsEvaporators are integral part of a number of process industries namely Pulp and Paper,Chlor-alkali, Sugar, pharmaceuticals, Desalination, Dairy and Food processing, etc(Bhargava et al., 2010). Evaporators find one of their most important applications in thefood and drink industry. In these industries, evaporators are used to convert food likecoffee to a certain consistency in order to make them last for considerable period of time.Evaporation is also used in laboratories as a drying process where preservation of longtime activity is required. It is also used for the recovery of expensive solvents andprevents their wastage like hexane. Another important application of evaporation iscutting down the waste handling cost. If most of the wastes can be vapourized, theindustry can greatly reduce the money spent on waste handling (Bhargava et al., 2010).The multiple effect evaporator system considered in the present work is used for theconcentration of weak black liquor. It consists of seven effects. The feed flow sequenceconsidered is backward and the system is supplied with live steam in the first two effects.2

In the system, feed and condensate flashing is incorporated to generate auxiliary vapourto be used in vapour bodies in order to improve the overall steam economy of the system.1.2 Problems associated with multiple effect evaporatorsThe problems associated with a multiple effect evaporator system are that it is an energyintensive system and therefore any measure to reduce the energy consumption byreducing the steam consumption will help in improving the profitability of the plant. Inorder to cater to this problem, efforts to propose new operating strategies have been madeby many researchers to minimize the consumption of live steam in a multiple effectevaporator system in order to improve the steam economy of the system. Some of theseoperating strategies are feed-, product- and condensate- flashing, feed- and steamsplitting and using an optimum feed flow sequence.One of the earliest works on optimizing a multiple effect evaporator by modifying thefeed flow sequence was by Harper and Tsao in 1972. They developed a model foroptimizing a multiple effect evaporator system by considering forward and backwardfeed flow sequence. This work was extended by Nishitani and Kunugita (1979) in whichthey considered all possible feed flow sequences to optimize a multiple effect evaporatorsystem for generating a non inferior feed flow sequence. All these mathematical modelsare generally based on a set of linear or non- linear equations and when the operatingstrategy was changed, a whole new set of model equations were required for the newoperating strategy. This problem was addressed by Stewart and Beveridge (1977) andAyangbile, Okeke and Beveridge (1984). The developed a generalized cascade algorithmwhich could be solved again and again for the different operating strategies of a multipleeffect evaporator system.In the present work, in extension to the modeling technique proposed by Ayangbile etal,(1984) feed and condensate flashing has also been included and it also considers thevariations in the boiling point elevation and overall heat transfer coefficient.3

1.3 ObjectivesTo study the seven effect evaporator system for the concentration of black liquor.To developed a generalized algorithm which can be used for different operatingstrategies.To incorporate the effect of feed and condensate flashing to enhance the steameconomy of the system.To compare the results with the published models.4

Chapter 2Literature Review5

Chapter 2LITERATURE REVIEWEvaporation is a process of removing water or other liquids from a solution and therebyconcentrating it. The time required for concentrating a solution can be shortened by exposingthe solution to a greater surface area which in turn would result in a longer residence time or byheating the solution to a higher temperature. But exposing the solution to higher temperaturesand increasing the residence time results in the thermal degradation of many solutions, so inorder to minimize this, the temperature as well as the residence time has to be minimized. Thisneed has resulted in the development of many different types of evaporators.2.1 Different types of evaporatorsEvaporators are broadly classified to four different categories:1. Evaporators in which heating medium is separated from the evaporating liquid bytubular heating surfaces.2. Evaporators in which heating medium is confined by coils, jackets, double walls etc.3. Evaporators in which heating medium is brought into direct contact with theevaporating fluid.4. Evaporators in which heating is done with solar radiation.Out of these evaporator designs, evaporators with tubular heating surfaces are the mostcommon of the different evaporator designs. In these evaporators, the circulation of liquid pastthe heating surfaces is induced either by natural circulation (boiling) or by forced circulation(mechanical methods).Evaporators may be operated as either once through units or the solution which has to beconcentrated may be recirculated through the heating element again and again. In an oncethrough evaporator, the feed passes through the heating element only once, it is heated, whichresults in vapour formation and then it leaves the evaporator as thick liquor. This results in alimited ratio of evaporation to feed. Such evaporators are especially useful for heat sensitivematerials.6

In circulation evaporators, a pool of liquid is held inside the evaporator. The feed that is fed tothe evaporator mixes with this already held pool of liquid and then it is made to pass throughthe heating tubes.The different types of evaporators are2.1.1 Horizontal tube evaporatorsThese were the first kind of evaporators that were developed and that cameinto application. They have the simplest design of all evaporators. It has a shelland a horizontal tube such that the tube has the heating fluid and the shell hasthe solution that has to be evaporated. It has a very low initial investment and issuitable for fluids which have low viscosity and which do not cause scaling. Theuse of this kind of evaporator in the present day is very less and limited to onlypreparation of boiler feedwater.2.1.1.1 Horizontal spray film evaporatorsThis evaporator is a modification of horizontal tube evaporator. It is a kind ofhorizontal falling film evaporator and in thos evaporator, the liquid is distributedby a spray system. This sprayed liquid falls from one tube to another tube bygravity. In such evaporators, the distribution of fluid is easily accomplished andthe precise leveling of fluid is not required.2.1.2 Short tube vertical evaporatorsThese evaporators were developed after the horizontal tube evaporators andthey were the first evaporators that came to be widely used. These evaporatorsconsist of tubes which are 4 to 10 feet long and which are 2 to 3 inches indiameter. These tubes are enclosed inside a cylindrical shell. In the centre adowncomer is present. The liquid is circulated in the evaporator by boiling.Downcomers are required to permit the flow of liquid from the top tubesheet tothe bottom tubesheet.2.1.2.1 Basket type evaporators7

These evaporators have construction similar to short

2.1.3.1 Rising or climbing film evaporators 8 2.1.3.2 Falling film evaporators 8 2.1.3.3 Rising falling film evaporators 8 . A septuple effect flat falling film evaporator system for the concentration of black liquor is studied and a generalized cascade algorithm is developed for the different operating strategies. The amount of live steam consumption in the system is evaluated for the given .