Transcription

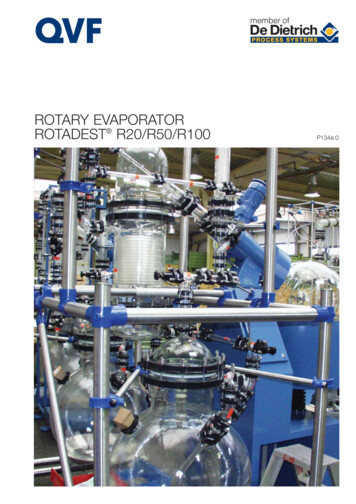

Rotary Film EvaporatorLarge-20 Liter -50 LiterP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tRotary Film EvaporatorSalient FeaturesEfficient glass condneser providesMaximum Solvent recoverySystem can be customised using differentGlass Arrangements as per solvent boilingpoints and available heightBest Vacuum sealing by Dry Mechanical SealExcelant handlingby large and easily readabledisplaywith process LED IndicationOverheat temperture control savesmaterial by cut off Power to heater in case ofin Main control action failureMicroprocesor Based Panel with large displayWith Vacuum Control and Shut down schememakes system PC Compatible .All the data canbe validated with the help of SCADA(Optional)Unique flask Handling arrrangement by whichSingle peron to remove large hot Flask like 50 literFlameproof Control panel Ensuresmaximum SafetySAMIR SHAH(CEO)Email: sr shah@udtechnologie s.comWeb si te: w w w.udtechnologie s. comC all on: 91 704 33 313 4 4TECHNOLOGIES

Rotary Film EvaporatorLarge-20 Liter -50 LiterP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tOverviewThe rotary evaporator principle is the most universal method,as it is an efficient, last and gentle way to separate liquids. The rotatingflask continuously covers a large surface area with a thin film, which is ideal for rapid heat transfer. Fortuitously, the film also ensuresuniform heat distribution without local heating.The facility to work the unit under full vacuum further facilitats evaporation at as low temperature as possible. These features rendersrotary film evaporator to be ideally suited for evaporation of heat sensitive material. It is equally successful for evaporation ofsuspension in crystallization processes drying of powder/ granule etc.SALIENT FEATURES:Movable Model, sleek, compact with minimumfootprint and available with 20 lit. ;50 lit. and 100 lit.Glass Distillation set up and Equipment can becustomised as per applications and process RequirementBest vacuum sealing with Dry Mechnical Seal .AllContact parts are of Glass or/and PTFE ,which extends its lifeand reduces down timeSpecial arrangement is provided such that singleperson can dismantle hot flask safelyOperator Friendly control panel-Higher ratedmicroprocessor based with large digital displayOverheat temperture controller saves material by cutoff Power to heater in case of Main controller failureModels available with parameter of Safety andvalidationGlass Distillation set up can be customised as perClient’s RequirementCombo models are available for Solid LiquidExtraction and Concentration

Technical data -Microprocessorbased Systems -20 literP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tTechnical data -Microprocessor based Systems -20 literThe UD large scale evaporators 20-50-100 are perfectly designed for a great deal of different distilling processes, from standardevaporation without vacuum control up to complex distillation processes with vacuum control.Aspects such as safety, convenience and cost savings have been considerably taken into account during the developmentof the large scale evaporators. This is reflected in various unique product advantages.Rota Evaporator 20 litre allows Chemist to distill 3.5 Litre/hr Water equivalent or 16 litre Acetone with 40 deg cTemperature DifferenceOur Rota evaporators are PC Compatible means its electronic control is capable to communicate with SCADA.ValidationGMP Model is availableFAT Documentation shall be providedDisplayBath temperatureVapor temperatureSet rotation speedSet bath temperatureActual vacuumSet vacuumYes (1 C steps)Yes (1 C steps)Yes (1 RPM steps)Yes (1 C steps)Yes (1 mm Hg steps)-Other units available on requestYes (1 mm Hg steps)-Other units available on requestPerformance3.5 Liter Wate condensation with 40 deg c temperature difference between Bath and boiing Point and under Vacuum 750mm Hgwith RPM 90Leakage Rate: Less than 1 mbar/minuteMaterial of ConstructionGear headCI Powder coated and SS 304 partsHeating bathStainless steel 1.4301 (AISI 304)Heating elementStainless steel 1.4301 (AISI 304)Glass Borosilicate 3.3In contact with productFDA compliant materialsCoolingConsumptionRestrictionDepends on solvent to get condnesed ;250 liter/hr to 450 liter hour at 5 deg C Temp. Differencemax. 2.7 bar abs. without pulsationOur models has four variants as shown in model selection chartSAMIR SHAH(CEO)Email: sr shah@udtechnologie s.comWeb si te: w w w.udtechnologie s. comC all on: 91 704 33 313 4 4TECHNOLOGIES

Rotary Film EvaporatorLarge-20 literP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tModel rproofFlameproofReceiving Flasks1Single Flask-10 liter2Twin Flask-2 x 10 literAutomation1Regular2Microprocessor Based control;PC Compatible3PC linkedVoltage1234Single Phase 230V,50 hzThree Phase 440V,50 HzSingle Phase 200 V,50 HzOthers ,Specify-on request

Rotary Film EvaporatorLarge-50 literP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tTechnical data -Microprocessor based Systems -50 literThe UD large scale evaporators 20-50-100 are perfectly designed for a great deal of different distilling processes, from standardevaporation without vacuum control up to complex distillation processes with vacuum control.Aspects such as safety, convenience and cost savings have been considerably taken into account during the development of thelarge scale evaporators. This is reflected in various unique product advantages.Rota Evaporator 50 litre allows Chemist to distill 6 Litre/hr Water equivalent or 16 litre Acetone with 40 deg c Temperature DifferenceOur Rota evaporators are PC Compatible means its electronic control is capable to communicate with SCADA.ValidationGMP Model is availableFAT Documentation shall be providedDisplayBath temperatureVapor temperatureSet rotation speedSet bath temperatureActual vacuumSet vacuumYes (1 C steps)Yes (1 C steps)Yes (1 RPM steps)Yes (1 C steps)Yes (1 mm Hg steps)-Other units available on requestYes (1 mm Hg steps)-Other units available on requestPerformance5.5 Liter Water condensation with 40 deg c temperature difference between Bath and boiing Point and underVacuum 750mm Hg and RPM 60Leakage Rate: Less than 1 mbar/minuteMaterial of ConstructionGear headCI Powder coated and SS 304 partsHeating bathStainless steel 1.4301 (AISI 304)Heating elementStainless steel 1.4301 (AISI 304)Glass Borosilicate 3.3In contact with productFDA compliant materialsCoolingConsumptionRestrictionDepends on solvent to get condnesed ;250 liter/hr to 450 liter hour at 5 deg C Temp. Differencemax. 2.7 bar abs. without pulsationOur models has four variants as shown in model selection chartSAMIR SHAH(CEO)Email: sr shah@udtechnologie s.comWeb si te: w w w.udtechnologie s. comC all on: 91 704 33 313 4 4TECHNOLOGIES

Rotary Film EvaporatorLarge-50 literP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tModel rproofFlameproofReceiving Flasks1Single Flask-20 liter2Twin Flask-2 x 20 liter3If others,Please specifyAutomation1Regular2Microprocessor Basedcontrol; PC Compatible3PC linkedVoltage12Three Phase 440V,50 HzOthers ,Please Specify-onrequest

Rotary Film EvaporatorLarge-100 literP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tTechnical specificationsModelGMP FlameproofElectrical connection req.440V, 50 Hz, (3 Phase neutral)Total Power consumption9 HPRotation drive1.0 HP , Three Phase, Flameproof TEFC MotorBath lift1.0 HP, , Three Phase , Flame Proof, TEFC motorSpeed Control20 – 90 RPM with Electronic control and digital display-Frequency ConverterHeater8 KW, FlameproofBath heating controlElectronic, On Off with PT-100 & Digital displayBath MovementMotorizedVapor temperaturePT-100 with Digital displayBath temperatureUp to 180oCProcess Timing IndicationDigitalVacuum IndicationDigitalElectric Control PanelWith push buttons ,switches and electrical safety protection, FlameproofBathDouble walled Stainless steel (SS 304) with insulationGlass Assembly100 lit Evaporating Flask, 3.2 m2 upward condenser, product cooler, 20lt receiver X 2with drain valveHousing and trolleySS 304 Mirror Finished , Castor Wheels Movable and LockableSupporting StructureSS 304Flanges and GasketSS 304 Flanges and Gasket- 100% PTFEEvaporation Performance5.4 Liter Water evaporation with Vacuum 740 MM Hg and 40 deg C temperature Differencebetween Bath and Vapor Temperature, Coolant –Chilled Water (For Different Solvents quantitiesmay vary. Generally Organic Solvents have lower Latent Heat of vaporization ,so More Outputcan be achievedSafety FeaturesAll the electric parts are flameproof suitable for Gas Groups I, IIA,IIB.Electrical Safety-Overall Protection of Flameproof control panel with MCBMechanical Safety :Limit switches are provided to restrict Up and Down MovementOverall dimensionsLength: 1100 mm, Breadth: 800 mm, Height: 2500 mmSAMIR SHAH(CEO)Email: sr shah@udtechnologie s.comWeb si te: w w w.udtechnologie s. comC all on: 91 704 33 313 4 4TECHNOLOGIES

Rotary Film Evaporator5 literP i l o t P l a n t s - P r o c e s s E n g i n e e r i n g S y s t e m s -Te c h n i c a l Te a c h i n g E q u i p m e n tSalient FeatureEspecially designed for Reserch and Development LaboratoryIt is designed such a way that 1 litre-2 litre-3 litre flask can be fixed easilyfor smaller volume of Feed.This rotary film evaporator is considered for Scale up where allparameters like geometry of Evaporating Flask ,Instrumentation and GlassAssembly is similat to their large peers say 20 litre-50 litre-100 litre.To make it it truly multipurpose ,Digital vacuum controller (optional 0can be coupled with Rota Evaporator to boil andy solvents with ExistingUtilities.Glass Distillation set up with vertical condenser shall supply as standardset up.Ascending and decending evaporation set up or any othercustomised glass set up can be supplied on request .WE developed Combo Models such as Rota Extractor which includesEvaporator and Soxhelete Extractor.ModelRE –05-SW -02Electrical connection req.230V, 50 Hz, (1 Phase neutral)Total Power consumption2 KWRotation drive0.18 HP , Three Phase, Weatherproof TEFC MotorBath lift0.12 HP, , Three Phase , Weatherproof, TEFC motorSpeed Control20 – 200 RPM with Electronic control and digital display-Frequency ConverterHeater2 KW, WeatherproofBath heating controlElectronic, On Off with PT-100 & Digital displayBath MovementMotorizedVapor temperaturePT-100 with Digital displaySealing of Vapor ShaftBorosilicate -Glass and PTFE with Mechanical SealBath temperatureUp to 180oCProcess Timing IndicationDigitalElectric Control PanelWith push buttons ,switches and electrical safety protection, WeatherproofBathDouble walled Stainless steel with insulationGlass Evaporation Set up5liter-3liter-2liter-1liter Evaporating Flask, 0.2 m2 upward condenser, 2 lt receiver with drainvalve,Soxhelte ExtractorHousing and trolleyMS Powder coated , Castor Wheels Movable and Lockable-German MakeSupporting StructureMS powder coatedFlanges and GasketMS powder coated Flanges and Gasket- 100% PTFE

The rotary evaporator principle is the most universal method,as it is an efficient, last and gentle way to separate liquids. The rotating The rotating flask continuously covers a large surface area with a thin film, which is ideal for rapid heat transfer.