Transcription

InstrumentReprocessingReprocessing ofInstruments to Retain ValueWorking GroupInstrument Reprocessing10

Reprocessing of Instruments to Retain Value10th edition 2012Surgical instrumentsMicrosurgical instrumentsDental instrumentsSurgical motor systemsMIS instruments, rigid endoscopes and HF instrumentsFlexible endoscopes and accessoriesFlexible instruments and respiration systemsPrevious German editions:1st edition, 19792nd edition, 19833rd edition, 19854th edition, 19905th edition, 19936th edition, 19977th edition, 19998th edition, 20048th revised edition, 20059th edition, 2009Previous editions in other languages:Chinese, 8th revised edition 2005Croat, 8th revised edition 2006Czech, 8th revised edition 2006Dutch, 9th edition 2009English, 9th edition 2009French, 9th edition 2009Greek, 9th edition 2009Hungarian, 8th revised edition 2005Indonesian, 8th revised edition 2005Italian, 9th edition 2009Japanese, 8th edition 2004Norwegian, 8th edition 2004Polish, 8th revised edition 2006Portuguese, 9th edition 2009Romanian, 8th revised edition 2005Russian, 9th edition 2009Spanish, 9th edition 2009Turkish, 8th revised edition 2006Website:www.a-k-i.orgThese booklets are available in pdf format to download free of charge from our website www.a-k-i.org.This page also includes our sales conditions. You can order AKI booklets direct by writing to thise-mail address: bestellung@a-k-i.org.All rights reserved by Arbeitskreis Instrumenten-Aufbereitung [Instrument Preprocessing Working Group] (c) 2012Daimlerstraße 2 D-64546 Mörfelden-WalldorfNo part of this publication may be reproduced in any form.Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org3

The working groupINSTRUMENT REPROCESSINGconsists of the following members:Authors & AddressesInstruments Product Group:Disinfectant, cleaning andcare agents product group:Disinfecting and cleaningdevices and sterilizing unitsproduct group:Wolfgang Fuchsc/o AesculapAm Aesculap-PlatzD-78532 TuttlingenTel.: 49 (0)7461-95 27 98Rudolf Glasmacherc/o EcolabReisholzer Werftstraße 38-42D-40589 DüsseldorfTel.: 49 (0)211-9893-668Hans Jörg Drouinc/o MMMDaimlerstraße 2D-64546 Mörfelden-WalldorfTel.: 49 (0)6105-9240-12Helmi Hennc/o Wolf EndoskopePostfach 1164 / 1165D-75434 KnittlingenTel.: 49 (0)7043-35-144Verona Schmidtc/o Chem. Fabrik Dr. WeigertMühlenhagen 85D-20539 HamburgTel.: 49 (0)40-78960-179Robert Eiblc/o MMMSemmelweisstraße 6D-82152 PlaneggTel.: 49 (0)89-89918-334Karl Leibingerc/o KLS Martin GroupGebrüder MartinKolbinger Straße 10D-78570 MühlheimTel.: 49 (0)7463-838-110Dr. Jürgen Staffeldtc/o Chem. Fabrik Dr. WeigertMühlenhagen 85D-20539 HamburgTel.: 49 (0)40-78960-165Dr. Winfried Michelsc/o MieleCarl-Miele-Straße 29D-33332 GüterslohTel.: 49 (0)5241-89-1491Ursel Oelrichc/o AesculapAm Aesculap-PlatzD-78532 TuttlingenTel.: 49 (0)7461-95 29 32Adviser:Dr. Holger BieringGladiolenstr. 19D-41516 GrevenbroichTel.: 49 (0)2182-3159Michael Sedlagc/o MieleCarl-Miele-Straße 29D-33332 GüterslohTel.: 49 (0)5241-89-1461Prof. Dr. Ulrich Junghannßc/o Hochschule Anhalt (FH)Bernburger Straße 55D-06366 KöthenTel.: 49 (0)3496-67 2553We should like to offer our warm thanks to all former members of AKI who are not specifically mentioned here byname for developing and constantly expanding the stock of AKI booklets.4Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

Apart from the permanent members of theWorking Group, the following personscontributed as guests:Endoscopes and MIS:Dr. Birgit Kampfc/o Pentax EuropeD- 22527 HamburgKlaus Hebestreitc/o AesculapD-78532 TuttlingenThomas Brümmerformerly Olympus DeutschlandD-20097 HamburgHorst Weissc/o Karl StorzD-78532 TuttlingenManuela von Lennepc/o Fujinon EuropeD-47877 WillichElastic instruments:Roland Maichelc/o Teleflex Medical GmbHProduktbereich Rüsch CareD-71394 KernenSurgical motor systems:Rainer Häuslerc/o AesculapD-78532 TuttlingenMarcus Schäferc/o AesculapD-78532 TuttlingenUltrasound:Stefan Bandelinc/o BandelinD-12207 BerlinWater treatment:Dr. Herbert Bendlinc/o Technisches SachverständigenbüroD-56235 Ransbach-BaumbachReprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org5

Reprocessing of Instrumentsto Retain ValueTable of Contents6Authors & Materials and DesignMaterialsDesign1414172.2.12.22.2.12.2.2Media used for instrument reprocessingWaterProcess chemicalsTypes of process chemicalsProperties and assessment of constituent substances17172223243.How to Treat Brand-New and Repaired Instruments274.Procedure Recommendation for Returned Goods285.Preparation for Cleaning and Disinfecting306.6.16.26.2.16.2.26.2.36.3Manual and Automated Cleaning and DisinfectingManual Cleaning/Disinfecting CleaningAutomated Cleaning and DisinfectingAutomated Cleaning and Thermal DisinfectionAutomated Cleaning and Chemo-thermal DisinfectionInstrument Groups Requiring Special TreatmentUltrasonic Cleaning and Disinfecting333336383941447.Final Disinfection468.Checks and Care489.Packaging54Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

10.10.110.210.3SterilizationSteam SterilizationHot Air SterilizationLow-Temperature Sterilization5556585911.11.111.2StorageStoring Non-Sterile InstrumentsStoring Sterile Instruments60606112.12.1312.1412.1512.16Surface changes, deposits, corrosion, aging,swelling and stress cracksMetal/Deposits – Organic ResiduesMetal/Deposits – Process Chemical ResiduesMetal/Deposits – Spotting Caused by LimeMetal/Deposits – SilicatesMetal/Deposits – Discoloration Due to OxidationMetal/Deposits – Discoloration/Loss of color incolored plasma layersMetal/Corrosion – PittingMetal/Corrosion – Wear Friction CorrosionMetal/Corrosion – Stress CorrosionMetal/Corrosion – Surface CorrosionMetal/Corrosion – Contact CorrosionMetal/Corrosion – Extraneous and FilmRust/Subsequent RustMetal/Corrosion – Crevice CorrosionPlastic/Rubber – AgingPlastic / Rubber – SwellingPlastic – Stress Cracks13Glossary8214.Bibliography8615.Schematic flow chart as per EN ISO .1112.12AKI sales conditions:Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org6262646565676869717273757778798081907

Preface33 years after the appearance of the first edition, this is now the10th edition of "Reprocessing of Instruments to Retain Value". This newedition is clear proof of its importance, and also of the great interestshown in this "Red booklet".Its international relevance is reflected in the fact that the previous versionhas been published in 19 languages, and other language versions areplanned.The first edition appeared in 1979 and must have seemed very advancedthen, at a time when the concept of "Central Sterilization" was still in itsinfancy. Since then reprocessing has undergone major changes.Instrument reprocessing has developed from a small appendage tothe operating room into an independent Central Sterile SupplyDepartment (CSSD)- a move away from an open area with wildly conflicting different activitiesand procedures, to a department that is strictly divided into differentzones;- a move away from mainly manual working towards automatedinstrument and device preparation;- a move away from the unrestricted and uncontrolled reusing of medicalinstruments that should be disposed of after use, to responsible reuse ofinstruments, or even a ban on such reuse;- a move away from the use of chemical and biological indicators towardsphysical validation of sterilization processes;- a move away from a quality check at the end of the sterilization processtowards permanent monitoring of each step of the decontaminationprocess; and also- a move away from untrained staff to highly qualified personnel.In other words, sterile preparation has developed from a departmentconcentrating on the sterilization process to a department with a wholistic"reprocessing" approach.However the fact that all these changes have taken place does not meanthat there is no room for further improvement. Quite the opposite.The introduction of traceability and quality systems, centralization ofthose specialist departments – including outside of the hospital –in combination with more economical and ecologically sustainablemethods, as well as the appraisal of a range of measures, poses newchallenges.8Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

It is obvious that the CSSD endeavors to provide a highly professionalservice in the hospital environment, as is expected. Quite rightly, oldprocedures and working methods are being reassessed. The traditionalrules of thumb are no longer acceptable; all our activities should beunderpinned by science.The Instrument Reprocessing Working Group has without doubt madean important contribution to this development of the CSSD into anexemplary department such as we see today.The aim of this development and the core activity of the CSSD is, andcontinues to be, to supply medical products of the best possible qualityfor the healthcare settings and for the patients. This should take place in areproducible manner.Although the title of this booklet appears to indicate otherwise, in factit deals appropriately with every aspect of the reprocessing of surgicalinstruments. The main benefit is that it concentrates on the importantinformation. Basic facts are discussed and explained clearly, plainly and inpractical terms.As a consequence it takes special account of what actually happens indaily practice.All this has contributed to the fact that this booklet has become astandard work, frequently consulted within sterilization departments,regardless of the stage of development they might have reached.The booklet has contributed to solving a wide variety of reprocessingproblems, and continues to do so today. Quite rightly, it concentrateson "cleaning" - one of the most important steps in the decontaminationprocess.Every contribution, however small, that helps to improve the qualityof the end product is a step in the right direction. However, in practiceinstrument reprocessing is a way-marker, pointing the way towards astandardization of processes in sterilization departments throughout theworld.Wim RendersPresident, World Forum for Hospital Sterile Supply (WFHSS)Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org9

ForewordInstruments are a major asset and represent a significant share of the totalcapital investment of a hospital. The practical experience recorded in thisbooklet, together with a description of fundamental interrelationships, isintended to help users to keep their reusable medical products in goodworking order and preserve their value for many years, by ensuring properreprocessing. It should be emphasized that the recommended measuresmust always be carried out in accordance with the manufacturer'sinstructions, pertinent hygiene requirements and official safety-at-workguidelines.Instrument reprocessing is increasingly subject to medical productslegislation, and is harmonized in many countries.In addition, there are direct legal requirements that need to be observed,such as the German "Betreiberverordnung" (Operator Regulations), whichimplement the Medical Devices Directive (MDD). They provide detailedinstructions in the form of validation measures that should be carried outby the Central Sterile Supply Department (CSSD).Compliance with such requirements can best be assured and documentedwithin the context of a quality management system.This "Red Booklet" is structured according to the procedures applied inreprocessing, and incorporating the provisions of EN ISO 17664. It cantherefore be integrated into a process-oriented system.This 10th edition extensively updates text and photographic content.In particular, its chapter 2, "Media for Instrument Reprocessing", has beencompletely revised. The new chapter 13 includes a glossary explaining thekey terms used in the booklet.A cross-check has also been conducted comparing reprocessingprocedures focused on retaining the value of instruments againstUS AAMI* standards. This has resulted in a number of additions the"Red Booklet" at various points.* Association for the Advancement of Medical Instrumentation10Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

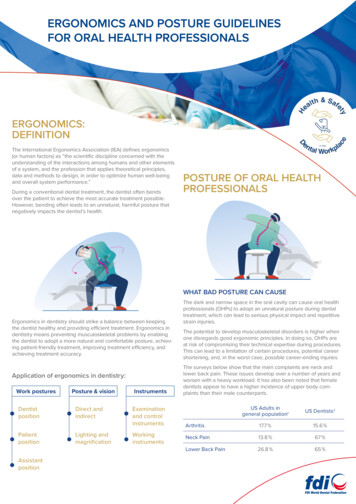

IntroductionEach chapter starts with handling instructions for surgical instruments,and subsequently general instructions for the product groups below aredescribed. Special instructions for these product groups are given underthe following symbols.* For detailed information relating to preprocessing of dental instruments, please refer tothe yellow AKI booklet "Proper Reprocessingof Dental Instrument".Surgical instrumentsFlexible endoscopesand accessoriesMicrosurgicalinstrumentsFlexible instruments andrespiration systemsDental instruments*Surgical motor systemsMinimal invasive surgery instruments,rigid endoscopes and instruments ofhigh-frequency surgery (HF)However, one should keep in mind that these product-specific instructionsmust always be seen in the context of the general instructions given for allinstruments in a particular section.Contrary to the widely held view that stainless steel is indestructible andpermanently resilient, it must be stated that it is in fact susceptible to awide range of potential mechanical, thermal or chemical attacks.Nonetheless, as long as you understand the material and its characteristicsand know how to handle these products, you will be able to extend thetrouble-free life of your stainless steel instruments.Microsurgical instruments require particularly careful reprocessing.Due to the requirements of the applications, these instruments are verydelicate and incorporate very delicate and fine filigree parts.Dental instruments also need special care due to their great variety and theparticular materials used in each case.The same applies to individual components of surgical motor systems,especially those that may be used only under sterile conditionsand therefore need to be cleaned and resterilized after use, such asaccumulator and compressed-air driven devices or handpieces.Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org11

Other instrument groups for which this booklet provides specialreprocessing guidance are MIS instruments, rigid endoscopes,HF instruments, flexible endoscopes and elastic instruments.Needless to say, users of medical products expect well-knownmanufacturers to exercise the greatest of care in both selecting the rightmaterials and manufacturing the product. Because of this, the user cancount on medical products that are optimally adapted to the intendedpurpose and provide excellent functionality. However, to retain the valueof the instruments in the long run, users must make a significantcontribution, i.e. by ensuring correct reprocessing and care. To explainhow this is done is the purpose of this booklet.Disposal instrumentsDisposal instruments are intended for single use, because their conformityassessment covers such use only. This is why this booklet contains noinstructions on how to reprocess disposal instruments.General notes andinstructionsBasically, the reprocessing of medical products comprises: Preparation (pretreatment, collecting, precleaning and, whereapplicable, taking the instruments apart). Cleaning, disinfecting, rinsing, drying (if required). Visual inspection of cleanliness and acceptable condition of material. Care and repair where required. Functional test. Marking. Where applicable, packaging and sterilization, approval for reuse andstorage.National regulations, such as the German Operator Regulations relatingto medical products and the recommendations of the Robert KochInstitute (RKI) entitled:"Anforderungen an die Hygiene bei der Aufbereitung vonMedizinprodukten" [Hygiene requirements to be observed whenreprocessing medical products], demand quality control and assurancein these processes. It is the owner's/operator's responsibility to evaluatethe risks, to classify the various risk areas, to provide written standardwork instructions that clearly define each step in the reprocessing processand to ensure adequate documentation. Validated cleaning, disinfectingand sterilization processes, supplemented by defined configurations forloading the washers/disinfectors (W/D) and sterilizers are an indispensableprerequisite for quality assurance.12Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

It is particularly important to follow the manufacturer's instructionsin the instruction manual, not only because ignoring them mightlead to expensive replacements or repairs, but also because incorrectreprocessing or medical product failure might endanger the patient orthird parties. We urge you to consult the manufacturer if you have anydoubts.Automated reprocessing with thermal disinfection and steam sterilizationshould be preferred to other methods in the case of thermostable medicalproducts.Instruments and components which are exclusively provided for singleonly use must be disposed of after use.Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org13

1. Materials and Design1.1 MaterialsWhen producing medical products, the manufacturer must design themto be fit for their intended use not only in design, manufacture andsurface finish, but also by selecting adequate materials.For surgical instruments generally only stainless steel (hardened, nonrusting) can meet the tough requirements in terms of elasticity, tenacity,rigidity, blade characteristics, resistance to wear and maximum corrosionresistance.Corrosion resistance/Passive layerhigh gloss/e-polishedmatt/brushedmatt/pearl mattThe corrosion resistance of stainless steel primarily depends on thequality and thickness of the passive layer. This is a protective layer ofiron/chromium oxide that results from the chemical reaction between thechromium in the steel alloy (at least 12%) and oxygen in the ambient air.This layer is not affected by the specific surface finish of the product(matt or high-gloss). In fact, its formation and growth are influenced bythe following factors: Composition of the material/alloy, Microstructure of the material, which is influenced by heat treatmentSurface finishes on instruments(e.g. forging, tempering, annealing, welding, soldering), Surface condition, e.g. roughness or cleanliness, Handling and reprocessing conditions, The service life and number of reprocessing cycles.Chlorides are dangerousPassive layers are extremely resistant to many chemical substances.Depending on the factors mentioned above, on every passive layer thereare areas with a specific crystallographic structure where the passivelayer is very susceptible to corrosive attack, particularly when in a dampor aqueous environment. Among the few substances that can attackand destroy this layer are halogenides (halides), the most common anddangerous of them being chlorides. Chlorides tend to react with thepassive layer in a process leading to the well-known, chloride-induceddamage called "pitting". Depending on the concentration of chlorides, thedamage caused ranges from a few sparse points of attack (visible as smallblack dots) to a completely damaged instrument surface covered withlarge deep holes. Chlorides also cause "stress corrosion cracking".Scanning electron microscope image,chloride-induced pitting14Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

As a result of chemical passivation by the manufacturers, for examplesupported by dip processing in a citric acid mixture, and as the servicelife progresses, the passive layer increases in size. From experience, thiscauses a decrease in corrosive attack because the probability of chloridespenetrating all the way down to the unprotected base material is reduced.Reactivation salt containing chloride causedmassive pitting on the surface of the instrument.Leaking ion-exchanger connection in the W/D.Chloride sources in the instrument usage and processing cycle: Fresh-water chloride content (depending on the source area of thesupply). Insufficient demineralization of the water used for the final rinse andsteam sterilization. Reactivation salt carry-over, leakage or spillage from ion exchangersused for water softening. Use of agents not permitted for or incorrectly used during reprocessing. Isotonic solutions (such as physiological salt solutions), etchants anddrug residues. Organic residues (body fluids such as blood, chloride content3,200-3,550 mg/ltr, saliva, sweat) dried on the surfaces. Laundry, textiles, packaging materials.Pitting and stress corrosion cracking are seldom or never observed in achloride-free or low-chloride environment irrespective of the degree ofgloss and the given passive layer of the instrument surface.If corrosion only occurs on new, high-quality instruments processedin the same cycle with older instruments, the reason can probably befound in the instrument reprocessing conditions. In all cases investigatedso far, treatment had taken place under conditions that individually orcollectively approached or exceeded the limits of process security.As well as heat-treatable chromium steels, standardized non-hardenablechromium steels with modified chromium contents and rust/acid-resistantchromium-nickel steels are also used to make instruments in accordancewith EN ISO 7153-1 and EN ISO 16061. Their mechanical properties arelimited however, so that the use of these steels is restricted to certaintypes of instruments.Color etching - austenitic microstructure onrust and acid-resistant instrument steel(magnified 500 times)For instruments used in endoscopy and minimally invasive surgery, a greatvariety of materials is employed, depending on the given applicationtechnique and the particular instrument design. The most important ofthese are:Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org15

Rust/Acid-proof chromium-nickel steels (also as welding filler). Pure titanium or titanium alloy. Cobalt-chromium alloys. Carbide metals, such as sintered metal, tungsten carbide with nickelbinding phase, cobalt-chromium base alloy. Non-ferrous heavy metal alloy with surface finishing (e.g. chromium-/ Special processes maybe required depending onthe material combinationused.nickel-plated brass).Coatings (e.g. titanium aluminum nitride, titanium aluminumcarbonitride, zirconium nitride and titanium nitride)Light metals (e.g. anodized aluminum).Non-corrosion-resistant steels (e.g. for coated assemblies andcomponents).Glass (for optical systems).Ceramics.Cements and other adhesives.Solder.Plastics and rubber.The combination of these very different materials in a particular instrumentplaces restrictions on reprocessing. In other words, these items mayrequire special reprocessing treatment apart from standardized instrumentreprocessing. These are described in the manufacturer's instructions.The design and application requirements of flexible instrumentsand respiration systems also make it necessary to combine a varietyof materials (which are more or less identical with those used forendoscopes). Here, the most frequently used materials are rubber andlatex (based on natural rubber) and various synthetic materials, especiallysilicone elastomers (or silicone rubber).For surgical motor systems, the full range of materials described in thisguide is used, because of the design and manufacturing requirementsinvolved. Stainless, heat-treatable chromium steels, for example, areused for drill bits, cutters, burrs, saw blades and gear components, whilesterilizable plastic materials are usually used for handles, switches, gearcomponents or cables and flexible tubes.Special reprocessing treatment methods may be necessary for varnishedhousings made of unalloyed sheet steel, handpieces with coloredgraduations (indicating gear ratios) or anodized aluminum housings(as used for handpieces). For appropriate treatment recommendations,please refer to the manufacturer's instructions. In addition to specialreprocessing treatments, lubrication is also essential for heavy-duty shaftsas well as for bearing and gear components made of stainless steel (and insome cases, also for those made of non-stainless quenched and temperedsteels or bronze materials).16Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

1.2 DesignThe capacity for reprocessing medical products is of extreme importancefor patient and user safety. During the design and development stageof a medical product it is necessary to consider its capacity for goodreprocessing after use. However, the focus must also be on correctfunctioning and the capacity for reprocessing. Often the mechanismrequired is accommodated in the tiniest of spaces in order to avoid patientdiscomfort.Optimum cleaning results can be achieved if the medical product canbe dismantled as much as possible. But there are limits here too. It ispossible to dismantle many medical products only with great difficulty for example jointed instruments used in minimally invasive surgery withdiameters of less than 3 mm, because users are unable to dismantle andreassemble these filigree-thin components. Another important point isthe choice of materials and joining techniques. Since at 134 C steamsterilization represents the most important sterilization method, thematerials used must be temperature-resistant. A further requirement ofthe materials selected is the alkaline resistance at the places in specialapplications where prior contamination is possible.To achieve optimum reprocessing results, close cooperation is essentialbetween all the parties involved: from the medical product manufacturer,the manufacturers of washers/disinfectors and sterilizers, to themanufacturers of process chemicals. When purchasing medical products itis recommended that those responsible for reprocessing instruments areincluded in the process at an early stage.2. Media used for instrumentreprocessing2.1 WaterThe quality of water used for instrument reprocessing has a considerableinfluence on value retention.Water fulfills a variety of functions in the treatment process, including: Dissolving cleaners and other process chemicals. Transferring mechanical forces and heat to the instrument surface. Dissolving soluble dirt and impurities. Flushing process chemicals. Thermal disinfection for automated reprocessing. Medium for steam sterilization.Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org17

Use correct water quality!Unfavorable water composition can have an adverse effect both on thereprocessing treatment and on the appearance and materials of theinstruments. This is why water quality in sufficient quantity is alreadyimportant when planning on-site plumbing installations.Water constituents and their influence in reprocessingWhile any natural water contains dissolved salts, their types andconcentrations in drinking water vary depending on the source area of thewater and how it is collected.The water constituents may cause the following problems:Minerals causing water hardness(calcium and magnesium salts)Scaling, lime deposits due tocalcium and magnesium saltsHeavy and nonferrous metals, e.g.iron, manganese, copperBrownish red scalingSilicates, silicon dioxideGlaze-like colored appearance, thinscalingChloridesPittingEvaporation residueSpotting and scalingApart from its natural constituents, drinking water sometimes contains rust,generally flushed from corroded pipework. During the reprocessing cyclethis rust tends to adhere to instruments, causing rust spots (extraneousrust) and subsequent corrosion.Aluminum might beattacked by softenedwater.Minerals causing water hardnessDepending on water hardness and temperature, minerals causing waterhardness can lead to the formation of a hard layer (lime deposits, scale)that is difficult to dissolve. It is even possible for corrosion to occurunderneath such deposits.Heavy and nonferrous metalsHeavy and nonferrous metals and their compounds in the water can leadto colored scaling even at low concentrations.Image page right: Corrosion of black anodizedinstrument surfaces by softened water.SilicatesSilicon dioxide and silicates may cause yellowish brown or bluish purplediscolorations even at low concentrations.ChloridesChlorides dissolved in the water are particularly critical substances, asthey tend to cause pitting even on stainless steel instruments if present inhigher concentrations.18Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org

Chlorides are dangerousThe danger of chloride-induced pitting generally rises with: An increase in the chloride content, An increase in temperature, Decreasing pH value, Increasing exposure time, Insufficient drying, Increasing concentration by evaporation of chloride resulting fromadherence of dry residues to instrument surfaces after evaporation.Pitting induced by chlorides on instrument.While the causal relationships between the chloride content of thewater and pitting are not always predictable, experience shows that theprobability of pitting is low as long as the chloride content does notexceed a level of approx. 120 mg/l (equivalent to 200 mg/l NaCl ) at roomtemperature. However, with increasing chloride concentrations the risk ofpitting also increases rapidly.Evaporation residueWhen water evaporates, some substances contained in it remain as visiblemineral evaporation residue. These may result in spotting and/or corrosion.Owing to the substances in the water, the natural drinking water cannotbe recommended for all reprocessing steps. The drinking water should besoftened or demineralized depending on the application. The followingmethods are applied:Water treatment methodsWater softeningIn the water so

Reprocessing of Instruments to Retain Value, 10th edition 2012, www.a-k-i.org 3 Reprocessing of Instruments to Retain Value 10th edition 2012 Surgical instruments Microsurgical instruments Dental instruments Surgical motor systems MIS instruments, rigid endoscopes and HF