Transcription

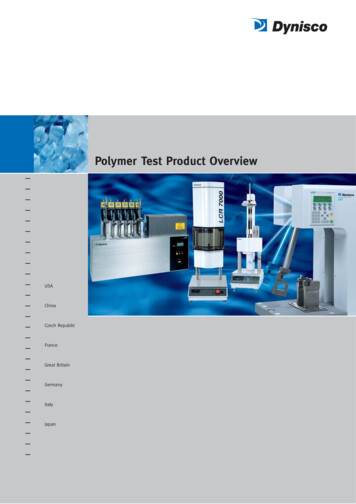

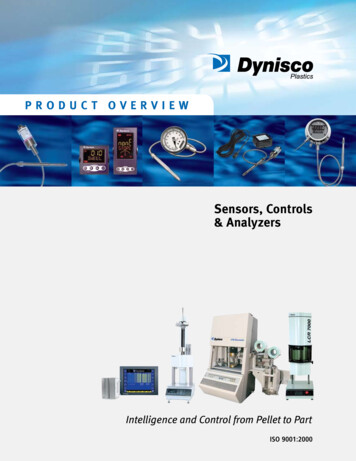

Product OverviewSensors, Controls& AnalyzersIntelligence and Control from Pellet to PartISO 9001:2000

table of contentsPAGE2i n t r od u ctio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A n al y tical i n st r u m e n tsRheological TestingLMI 4000 – Melt Flow Indexer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4LCR 7000 – Capillary Rheometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5VTM – Viscosity Transition Modulus Rheometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Online RheometersViscoSensor – Online Rheometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7CMR IV – Continuous Melt Rheometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7FCR – Flow Chart Rheometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7REX – Rheology Extrusion System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Laboratory Processing EquipmentHDV3 – HDT/VICAT System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8LOI – Limiting Oxygen Index Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8LME – Laboratory Mixing Extruder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9TUS – Take Up System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9LEC – Pelletizing Chopper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9LMM – Laboratory Mixing Molder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Impact TestingAPI – Advanced Pendulum Impact Tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10ASN – Automatic Sample Notcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10MiscellaneousMini Granulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Block-Reblock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10inDicators & Controls1/8 DIN Pressure/Process Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111/16 DIN (TCS) and 1/8 DIN (TCE) Temperature Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111/4 DIN Pressure/Process Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111/4 DIN Pressure/Process Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Opt Trol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PAGEse n so r Snk itsnaccesso r iesBurst Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Mechanical Pressure Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14DYN-X Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Melt Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15PT460E Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15PT420A Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15MRT Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15SPX Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16SPX-L Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16SPX-T Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16Digital Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16Food and Medical ProductsNaK Filled Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Oil Filled Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Push-Rod Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17AccessoriesBurst Plugs, Thermocouples and Mounting Hole Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17The Dynipak SeriesClassic Dynipaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18MRT Dynipaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Pressure/Temperature Dynipaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Differential Dynipaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18service worldwideService Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Global Service and Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Extrusion Control Systems and SolutionsFor decades, Dynisco has been a global leader providing innovative solutions for materials testing and extrusion-controlmonitoring for the plastics industry. Today, it is more vital than ever for us to offer leading-edge technology, manufacturedto ISO 9000 quality standards, so our customers can achieve maximum manufacturing efficiency and productivity.Extrusion Control SystemsFor the first time, Dynisco’s Opt Trol system providesprecision extruder pressure and temperature control. Throughadvanced auto-tuning, Opt Trol automatically monitorstemperature, pressure and controls in new installations orretrofitted applications.Opt Trol is pre-programmed prior to delivery for easy, plug-and-play installation, and aswith all Dynisco technology, it is manufacturedto meet or exceed the highest industry standards for process control systems.Melt Flow IndexerProcessors can utilizeOPT TROL or local indicatorsand discrete controllers tooptimize the extrusion process2Screwpressure

SensorsDynisco has developed some of the most innovative measurementsolutions for plastics extrusion, molding, and process control applicationsthanks to hundreds of models of transducers and transmitters and thelatest sensing technologies. We’re recognized for high-accuracy pressuremeasurement at high temperatures with transducers that withstand themost corrosive production environments.Analytical InstrumentsDynisco instruments are recognized and used around theworld for testing the physical, mechanical, thermal and flammabilityproperties of polymers. Our bench-scale processing instrumentsare used to prepare test specimens or evaluate the processabilityof materials. And all Dynisco instruments conform to the strictestindustry, national and international standard test methods.Melttemperatureby zoneOutlet pump pressureScrewpressureInlet pumppressureOnline viscosityDie pressure3

Analytical InstrumentsRheological TestingMelt Flow IndexerThe most precise instrument for the measurement of Melt Flow Rate (MFR) or melt volume rate (MVR) inquality control and research applications. The LMI 4000 is the first melt flow indexer to utilize a powerful32-bit microprocessor to provide test parameter control, self-diagnostics and digital calibration. The onboard computer controls and displays temperature to 0.1 C using a unique PID control algorithm. Fourmelt indexer models are offered in the advanced Dynisco LMI 4000 series, each with features designed tomeet specific application requirements. ModelLMI 4000Features & Benefits 4Advanced microprocessor designASTM D1238 and ISO 1133-2005 standardsSelf-diagnostics capabilityComprehensive statistical capabilitySimple push-button RTD calibrationSmart keys for easy programmingBright, 4-line by 20-character vacuumfluorescent displayWindows software for test database and analysis

Capillary RheometerDesigned to meet the demands of a 24-hour-a-day shop floor operation while maintaining the highest possible level of accuracy, repeatability and sensitivity. The LCRseries rheometers are versatile and easy to use yet they offer the most sophisticatedmaterials characterization, data analysis and reporting capabilities. The LCR 7001can be used with a standard load cell or a barrel-mounted pressure transducer. Manyyears of service ensured through the use of tungsten carbide dies and a hardenedand honed tool steel barrel. LAB KARS advanced rheology software provides programming, control, analysis and data storage capability. ModelLCR 7000Features & Benefits Advanced microprocessor designASTM D3835 and ISO 11433 standardsSelf-diagnostics capabilityComprehensive statistical capabilitySimple push-button RTD calibrationSmart keys for easy programmingBright, 4-line by 20-character vacuumfluorescent displayWindows software for test database and analysis5

Analytical Instruments (cont’d)Rheological Testing (cont’d)Viscosity-Transition-Modulus RheometerThe VTM Rheometer is a more robust and versatile alternative to the traditional Dynamic Mechanical Analyzer (DMA).Measurements of melt-to-solid dynamic properties are provided as well as a wide range of the most meaningfulparameters for plastics, including Tangent , melt viscosity ( *), shear modulus (G’ & G”) and Modulus cross-overpoint (Gc and c). The VTM can also replace or eliminate traditional test methods such as melt flow index and gelpermeation chromatography.The VTM will increase analysis throughput with the optional fully automated sampler. Up to 100 samples may betested with no need for operator interaction once testing is commenced. The VTM’s automation system allows foroperation outside normal laboratory hours, as well as the elimination of time-consuming clean-up between samples.This system also helps with eliminating operator influence on data. ModelFeatures & BenefitsVTM Rapid analysis of samples with typical test times at 10 to 12 minutes Employs an industry-unique closed cavity technology for analysis Minimal clean-up between tests minimizes operator interaction Easy-to-use software suite for quick data analysis Automated sampler increaseslab throughput Capable of measuring LongChain Branching of polymers6

OnlineRheometersn Dynisco’s series of on-line Rheometers can be used to measure continuous, real-time ASTM D1238 Melt FlowRate (MFR), high/low load MFR and Apparent Viscosity.ViscoSensor – Online RheometerThe world’s smallest in-line polymer melt rheology instrument, measuring only 25 inches inlength by 10 inches in width. The ViscoSensor is extremely easy to install, calibrate and operatemaking it the most cost-effective in-line sensor on the market. The ViscoSensor’s zero dis

Dynisco instruments are recognized and used around the world for testing the physical, mechanical, thermal and flammability properties of polymers. Our bench-scale processing instruments are used to prepare test specimens or evaluate the processability of materials. And all Dynisco instruments conform to