Transcription

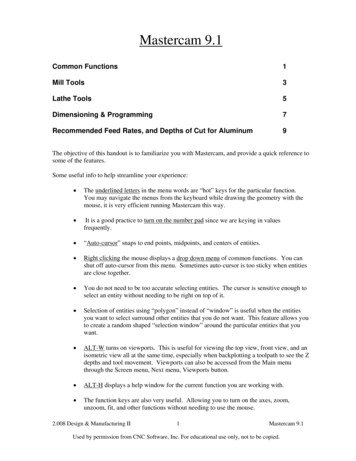

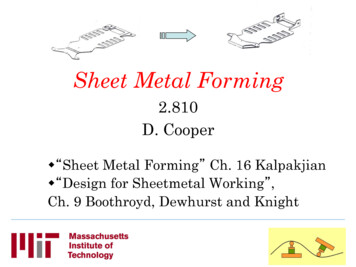

Sheet Metal Forming2.810D. Cooperw “Sheet Metal Forming” Ch. 16 Kalpakjianw “Design for Sheetmetal Working”,Ch. 9 Boothroyd, Dewhurst and Knight

Examples-sheet metal formed

Sheet metal stamping/drawing – car industry 90million cars andcommercial vehiclesproduced worldwide in 2014Female dieMetal sheetBlank holder(ring) oncushionCompressiblecushionMale die (punch/post)

Stamping Auto body panels 3 to 5 dies each Prototype dies 50,000 Production dies 0.75-1 Forming dies Trimming station Flanging station

ObjectivesBy the end of today you should be able to describe different forming processes, when they mightbe used, and compare their production rates, costsand environmental impacts calculate forming forces, predict part defects(tearing, wrinkling, dimensional inaccuracy), and proposesolutions explain current developments: opportunities andchallenges

LMP ShopBrake pressFinger brake

Technology – a brief reviewMaterial drawn into shape Conventional drawing/stampingtooling, no net thinning, quick Hydro-formingFormingSpeed– expensive20-1000pts/hr– cheap tooling, no net thinning, slow, highformability7-13cycles/hrMaterial stretched into shape Stretch forming – very cheap tooling, net thinning, slow,low formability3-8pts/hr Super-plastic forming – cheap tooling, net thinning,expensive sheet metal, slow, very high formability0.3-4pts/hr

Drawing – expensive tooling, no net thinning, quickDeep-drawingShallow-drawing (stamping)

Deep-drawingBlank holder helps prevent wrinkling and reduces springbackBlank holder not necessary if blank diameter / blank thickness is less than25-40. Smaller values for deeper forming.

ring-fabricating/wrinkling-during-deep-drawing

Depth of drawBlank holder force: forming windowWrinklingTearingWindowforformingBlankholder force

Deep Drawingof drinks cansHosford and Duncan(can making): http://www.chymist.com/Aluminum%20can.pdf

Hydro-forming – cheap tooling, no netthinning, slow(ish), high formabilityLow volume batches

Hydro-forming – cheap tooling, no netthinning, slow(ish), high formabilityLow volume batches

Hydro-forming – cheap tooling, no netthinning, slow, high formabilitySmall flexforming tool made by additive manufacturing

Stretch forming – very cheap tooling, net thinning, slow, lowformability, sheet metal up to 15mx9mLoadingWrapping* source: http://www.cyrilbath.com/sheet process.htmlLow volume batchesPre-stretchingRelease

Stretch forming: Example partsHigher aspect ratio, deeper parts

Super-plastic forming – cheap tooling, net thinning,slow, expensive sheet metal, very high formabilityLow volume batches, 0.5-0.75 melting temp

Forming forces and partgeometry

Tensile test – the Stress-strain diagramUTSσy Y

Nominal strain

True stress & strainεtr ln(1 ε en )σ tr σ en (1 ε en )True stress can be expressedusing a power law (Hollomonequation):nσ tr Kε trσy Y

Power-Law Expression (Hollomon equation)nσ tr Kε trCan be re-written:log(σ tr ) n log(ε tr ) log Klog(σ tr ) -3-2-10log(ε tr )

Power-Law Expression (Hollomon equation)nσ tr Kε trCan be re-written:log(σ tr ) n log(ε tr ) log Klog(σ tr ) kn -3-2-10log(ε tr )

Tensile instability - necking

Useful assumptionsσOnly interested in plastic effects:Perfectly plastic materialAt Y, material defoms (‘flows’)in compression and fails intensionY orUTSεσY orInterested in elastic and plastic effects: UTSElastic-perfectly plastic materialEε

3D ProblemsIn 1-D,In 3-D,nσ Kε assuming perfectly plastic, yielding at: σ Yσ eff Kε effn assuming perfectly plastic, yielding at:σ eff Y

3D Yield CriteriaTresca: Yielding occurs at a maximum shear Von Mises: Yielding at maximumstressdistortion strain energyEffective stress (in principal directions):Effective stress (in principal directions):σ eff [σ i σ j ]max,σ effi jYield criterion:Yield criterion:σ eff Yσ eff Yτ maxY k 2 Y 3kEffective strain:Effective strain:ε eff (ε i ) max%(σ σ )2 (σ σ )2 (1 ' 2331* 2 '& (σ σ )2*)12 ε eff#2& % ( ε12 ε 22 ε 32 3'()

ShearingSheetPunchDTDiePart or slugF 0.7 T L (UTS)T Sheet ThicknessL Total length ShearedUTS Ultimate Tensile Strengthof materialShear press - LMP Shop

Side Note: For a general state ofstress use “effective stress”Yielding occurs when σeffective YMaterial taken from Metal Forming, by Hosford and Caddell

Origin of effective strainσ KεnMaterial taken from Metal Forming, by Hosford and Caddell

3D Yield Effective stressσ1 σ2σ3 0 Tresca predicts‘flow’ for lowerstresses thanvon Mises

Forming Limit Diagrams

ε1 n neckingTensile testε1 -2ε2

Pure Shearε1 -ε2

Stretch forming: Forming forceF (YS UTS)/2 * AF stretch forming force (lbs)YS material yield strength (psi)UTS ultimate tensile strength of the material (psi)A Cross-sectional area of the workpiece (in2)

Forces needed to bend sheet metal

Bending

Stress distribution through thethickness of the partYsElasticsYyY-YElastic-plasticsh-YFully plasticFully Plastic Moment, M Y (b h/2) h/2 Ybh2/4

Balance external and internal momentsFσhL-YFully plasticYbh2/4 FL/4 MmaxF bh2Y/LF/2F/2σσYEεyε

Bending Force RequirementLT 2F (UTS )WForcePunchWorkpieceDieTT Sheet ThicknessW Width of Die OpeningL Total length of bend(into the page)UTS Ultimate TensileStrength of materialWNote: the notation used in the text (L, W) differsfrom that used in the previous development (b, L).

LMP ShopBrake pressFinger brake

What shape have we created?

Steel versus aluminum Strength (σy) versus Stiffness (E)Mild steel (30E6psi)Mild steel (33,000psi) &Al. 5052H32 (33,000psi)Al. 5052H32(10.6E6psi)

Steel versus aluminum Strength (σy) versus Stiffness (E)Mild steel (30E6psi)Low spring backMild steel (33,000psi) &Al. 5052H32 (33,000psi)Al. 5052H32(10.6E6psi)High spring back

Steel versus aluminum Strength (σy) versus Stiffness (E)Al. 2024T3 (50,000psi)Mild steel (30E6psi)Low spring backMild steel (33,000psi) &Al. 5052H32 (33,000psi)Al. 2024T3 & 5052H32(10.6E6psi)High spring back

Steel versus aluminum Strength (σy) versus Stiffness (E)Al. 2024T3 (50,000psi)High spring backMild steel (30E6psi)Low spring backMild steel (33,000psi) &Al. 5052H32 (33,000psi)Low spring backAl. 2024T3 & 5052H32(10.6E6psi)High spring back

σTiMild steelAl ECε

σTiMild steelAl ECεεˆ

σTiMild steelAl ECεεˆ

σTiMild steelAl ECεεˆ

Springback note R in the figure below ismislabeled, should go to the centerline of the sheet

Elastic Springback AnalysisyxhLbr 1/KMMy1.Assume plane sections remain plane:ey - y/r2.Assume elastic-plastic behavior for material(1)ssYEeyeσ E ee e ψσ σ Ye e

Bending Moment – CurvatureMLoadingMYEIEI1/rY1/R1Unloading1/R01/r

3. We want to construct the followingBending Moment “M” vs. curvature “1/ρ” curveMLoadingMYM (1 ρ )YMYEIEI1/ρY1/R1Springback is measured asPermanent set is&1 1 # !% ρ R1 "Unloading1/R01/R0 – 1/R11/R11/ρ(2)

4. Stress distribution through the thickness of the beamYσElasticσYyY-YElastic-plasticσh-YFully plastic

dσ5. M A σ y dAdAybdyhElastic regionM σydA E y2EIdA ρρ(3)At the onset of plastic behaviorσ - y/ρ E - h/2ρ E -Y(4)This occurs at1/ρ 2Y / hE 1/ρY(5)YσSubstitution into eqn (3) gives us the moment at on-set ofyield, MYMY - EI/ρY EI 2Y / hE 2IY/h(6)After this point, the M vs 1/r curve starts to “bend over.”Note from M 0 to M MY the curve is linear.

YIn the elastic – plastic regionσM σybdy 2 h/2yY2 h/2 2Yby2yYbydy 2 Ybydyy0 Y3 yY 2yYyYY ybyY 30h22 22 Yb( yY ) yY Yb432&bh1 , yY ) #M Y 1 *' !4 % 3 h / 2 ( !"2(7)Note at yY h/2, you get on-set at yield, M MYAnd at yY 0, you get fully plastic moment, M 3/2 MYyY

To write this in terms of M vs 1/ρ rather than M vs yY, notethat the yield curvature (1/ρ)Y can be written as (see eqn (1))1εY ρY h / 2(8)Where εY is the strain at yield. Also since the strain at yYis -εY, we can write1 εY ρ yY(9)Combining (8) and (9) givesyY(1 ρ )Y h/21ρ(10)

Substitution into (7) gives the result we seek:& 1 , (1 ρ )3YM M Y 1 **2 % 3 1 ic unloading curveUnloading1/R01/ρMYM (1 ρ )Y&1 1 # !% ρ R1 "(12)

Now, eqn’s (11) and (12) intersect at 1/ρ 1/R0Hence,& 1 , (1 ρ )MY & 11# 3Y* M1 Y !*(1 ρ )Y % R0 R1 " 2 % 3 1 R0)''(2#!!"Rewriting and using (1/ρ)Y 2Y / hE (from a few slides back),we get-11*Y2& Y # 4 R0 ! ( 3hE% hE ", R0 R1 )3(13)

R0 R1

Methods to reduce springback Smaller Y/E Larger thickness Over-bending Stretch forming “coining” or bottoming the punch

Pure BendingtensionYσhcompression-YFully plasticYσhBending & StretchingYFully plastic

Stretch forming: can weachieve a strain of 0.035 at A?R 8m, θ 0.25ASheet thickness 1mm,µ 0.1Material:σ 520ε0.18MPaR’ 0.1m, , θ 1.25BPunchCGrips

Can we achieve a strain of0.035 at A?Sheet thickness 1mm,µ 0.1Material: σ 520ε0.18MPaFA 0.001*520*(0.035)0.18 284kN/mR 8m, θ 0.25AR’ 0.1m, , θ 1.25BPunchFB FA*exp(0.1*0.25) 292kN/mCFC FB*exp(0.1*1.05) 323kN/mGripsMax allowable force 0.001*520*(0.18)0.18 381kN/mCapstan equation

Friction and the capstan equationTypical stamping lubricants: Oil-based lubricants Aqueous lubricants Soaps and greases Solid filmsTload Thold exp(µθ )

Researchopportunities and challenges:reducing cost and environmentalimpacts

Energy & cost: Stamping alum car hoods Final part 5.4kgs Total number of parts made 400 Die material: cast and machined zinc .4kgO/P.((400pts)(Cost.&136USD/pt&18#590%Sheet (MJ/pt)Sheet (USD/pt)Elec (MJ/pt)16%Elec (USD/pt)Die (MJ/pt)1743%Sheet metalscrapped infactory 44%Source: Unpublished work: Cooper, Rossie, Gutowski (2015)0#Die (USD/pt)118#Excludes equipmentdepreciation and laborduring forming

60 Ton Discrete Die Press(LMP - Hardt)6 feet

The Shape Control Conceptdesiredshape shapeerror-SHAPECONTROLLERDISCRETE DIESURFACEfinishedpartWORKPIECESHAPEMEASUREMENTDie ShapeChangeNewPartShapeDISCRETE DIEFORMING PRESSTRACING CMMCONTROLLERPart Error

Stretch Forming withReconfigurable Tool @ NorthropGrumman

Flexible Forming at Ford

Conventional l-forming

Flexible SpinningMusic, O., & Allwood, J. M.(2011). Flexible asymmetricspinning. CIRP Annals Manufacturing Technology, 60(1),319–322. doi:10.1016/j.cirp.2011.03.136

Greater accuracy requiredToo slow?Polyblank, J. a., Allwood, J. M., & Duncan,S. R. (2014). Closed-loop control of productproperties in metal forming: A review andprospectus. Journal of MaterialsProcessing Technology, 214(11), 2333–2348. doi:10.1016/j.jmatprotec.2014.04.014

Thank youSheet metal forming in a lowcarbon future?See the wonderful http://www.withbotheyesopen.comAllwood, J., Cullen, J., Carruth, M.,Cooper, D., McBrien, M., Milford, R., Patel, A. (2012). Sustainable Materialswith Both Eyes Open. Cambridge: UIT.

Extra slides – just for fun

Surface finish defects Orange peel effect Lüders bands

Material embodied energy: Aluminum primary production350"Milford et al. (2011): Whole supply rfect"yield"50"0"al)making" Ingot"cas4ng"Sawing"Scalping"Prehea4ng" Hot"rolling" Cold"rolling" Annealing"Process%step%Sli@ng"Blanking"

Material embodied energy: Aluminum primary production350"Milford et al. (2011): Whole supply t"yield"100"Real"yield"50"0"al)making" Ingot"cas4ng"Sawing"Scalping"Prehea4ng" Hot"rolling" Cold"rolling" Annealing"Process%step%Sli@ng"Blanking"

Material embodied energy: Aluminum primary production350"4kg cardoorMilford et al. (2011): Whole supply " Ingot"cas4ng"Sawing"Scalping"Prehea4ng" Hot"rolling" Cold"rolling" Annealing"Process%step%Sli@ng"Blanking"

expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr 0.3-4pts/hr . Drawing – expensive tooling, no net thinning, quick Deep-drawing Shallow-drawing (stamping) Deep-drawing Blank holder helps prevent wrinkling and reduces springback Blank holder not necessary if blank diameter / blank thickness is less than 25-40 .